Method for debitterizing zanthoxylum oil resin

A technology for debittering and debittering of prickly ash oleoresin, which is applied in the directions of edible oil/fat, food science, application, etc., can solve the problem that there is no debittering method of prickly ash oleoresin, and can not solve the problems of reducing or removing the bitterness of prickly ash oleoresin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1: a kind of method for debittering of pepper oleoresin, the steps are as follows:

[0061] (1) Zanthoxylum bungeanum is subjected to conventional supercritical CO 2 Extraction method extracts and prepares pepper oleoresin;

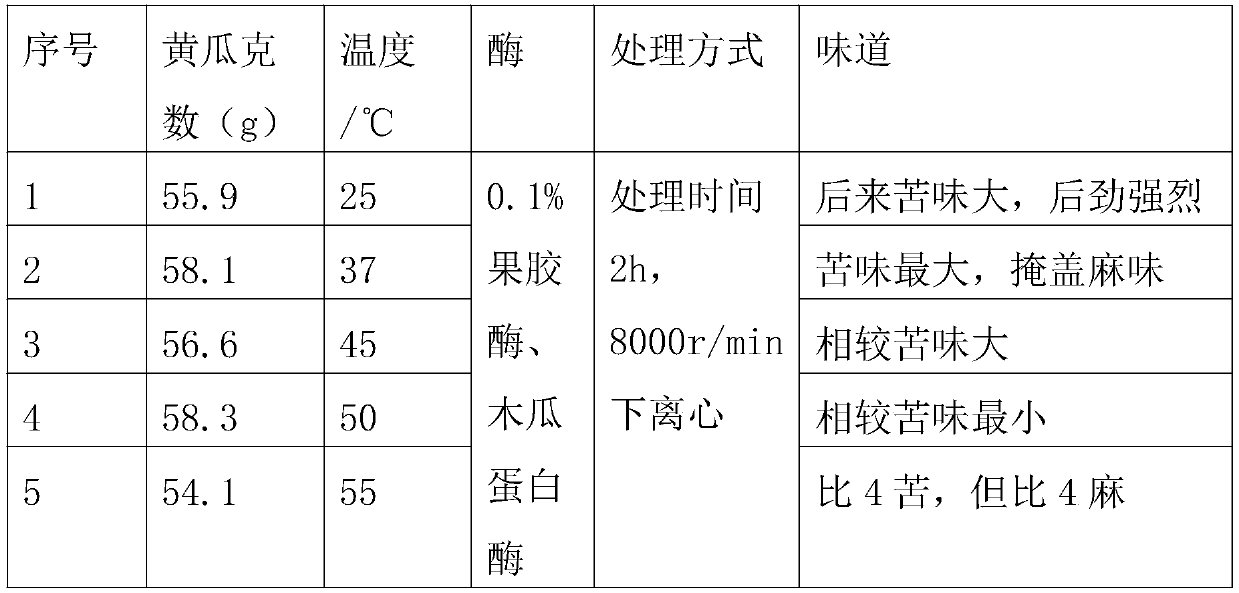

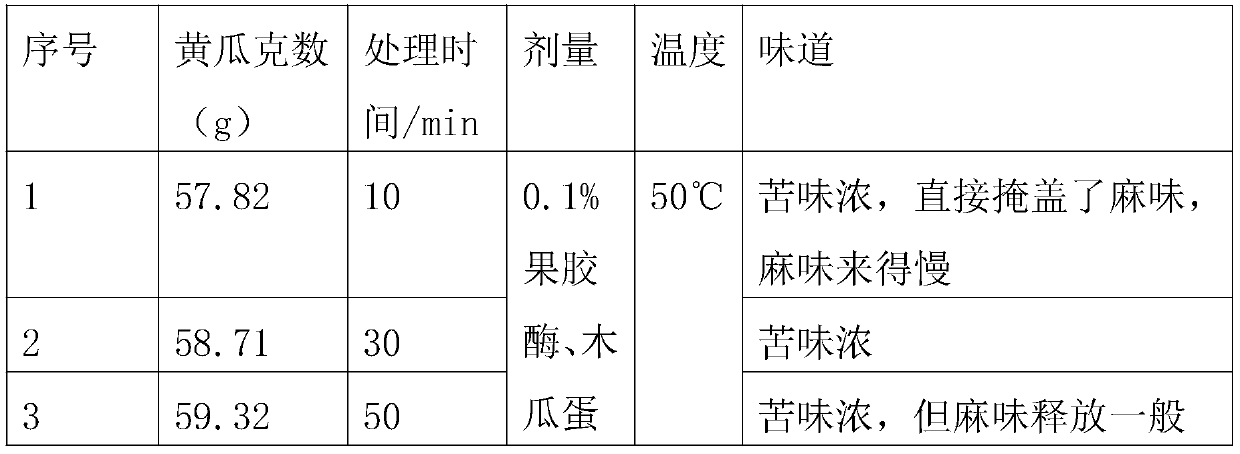

[0062](2) Add 0.1% pectinase, papain and hesperidinase to the Zanthoxylum bungeanum oleoresin prepared in step (1), and react at 50° C. for 120 minutes;

[0063] (3) Add 0.05% 5' disodium adenosine phosphate to the reactant of step (2), react for 30min;

[0064] (4) The reaction product of step (3) was centrifuged at a speed of 8000 r / s for 15 min at a low temperature of 3° C., and the supernatant was taken to obtain Zanthoxylum bungeanum oleoresin.

Embodiment 2

[0065] Embodiment 2: a kind of method of Zanthoxylum bungeanum oleoresin debitterness, the steps are as follows:

[0066] (1) Zanthoxylum bungeanum is subjected to conventional supercritical CO 2 Extraction method extracts and prepares pepper oleoresin;

[0067] (2) Add 0.05% pectinase, papain and hesperidinase to the Zanthoxylum bungeanum oleoresin prepared in step (1), and react at 45° C. for 150 min;

[0068] (3) Add 0.03% 5' disodium adenosine phosphate to the reactant of step (2), react for 20min;

[0069] (4) The reaction product of step (3) was centrifuged at a speed of 7000 r / s for 20 min at a low temperature of 2° C., and the supernatant was taken to obtain Zanthoxylum bungeanum oleoresin.

Embodiment 3

[0070] Embodiment 3: a kind of method for debittering of pepper oleoresin, the steps are as follows:

[0071] (1) Zanthoxylum bungeanum is extracted by conventional subcritical extraction method to prepare Zanthoxylum bungeanum oleoresin;

[0072] (2) Add 0.15% pectinase, papain and hesperidinase to the Zanthoxylum bungeanum oleoresin prepared in step (1), and react at 55° C. for 100 min;

[0073] (3) Add 0.07% 5' disodium adenosine phosphate to the reactant of step (2), react for 40min;

[0074] (4) The reaction product of step (3) was centrifuged at a speed of 9000 r / s for 10 min at a low temperature of 4° C., and the supernatant was taken to obtain Zanthoxylum bungeanum oleoresin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com