Dental cast guide plate preparing method, end-cutting and glaze-removing guide plate, acid etching guide plate and positioning guide plate

A production method and guide plate technology, applied in the field of medical devices, can solve the problems of consuming doctors' energy and time, poor patient experience, etc., and achieve the effects of reducing the number of repeated confirmations, improving treatment experience, and improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

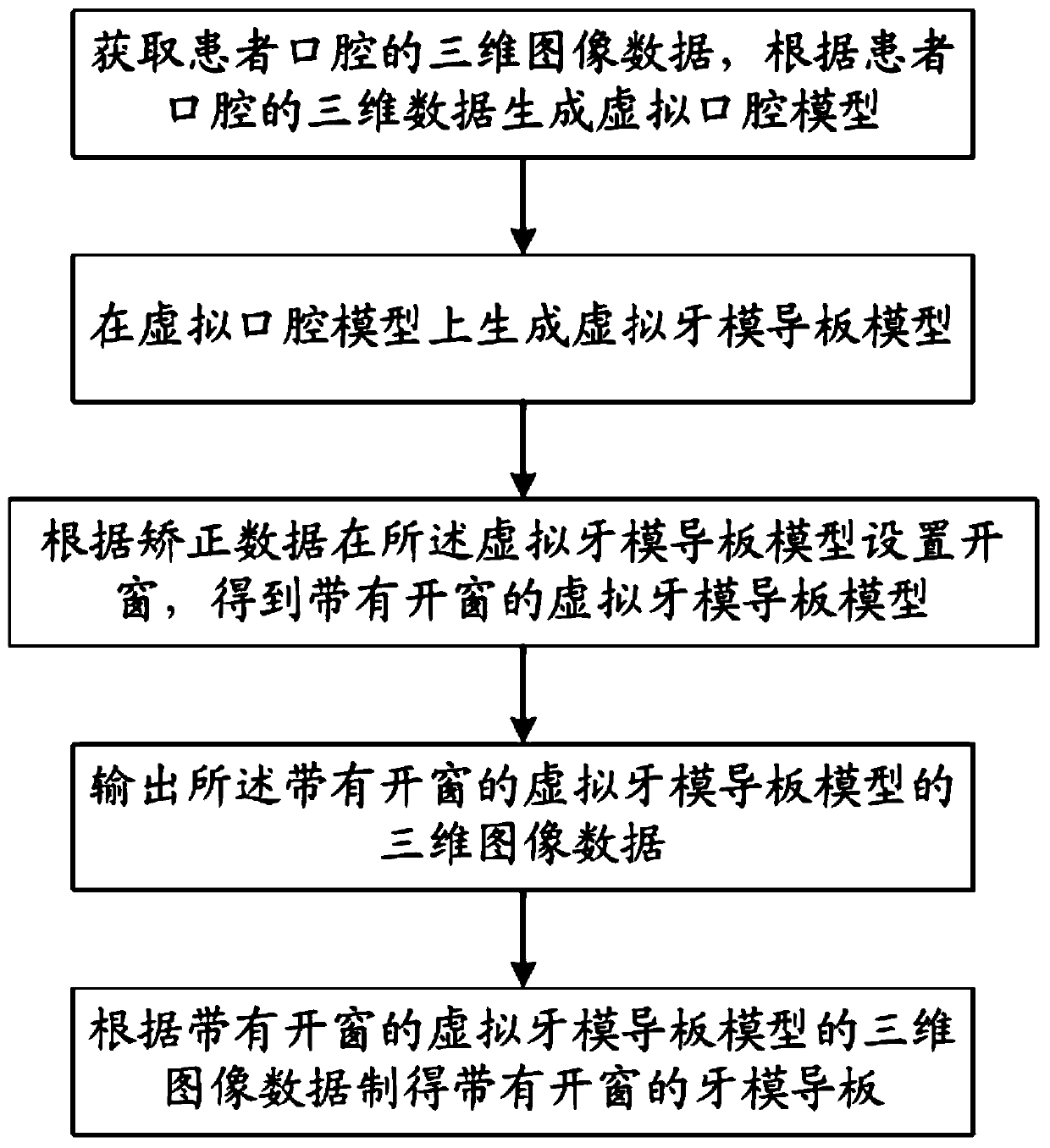

Method used

Image

Examples

Embodiment 1

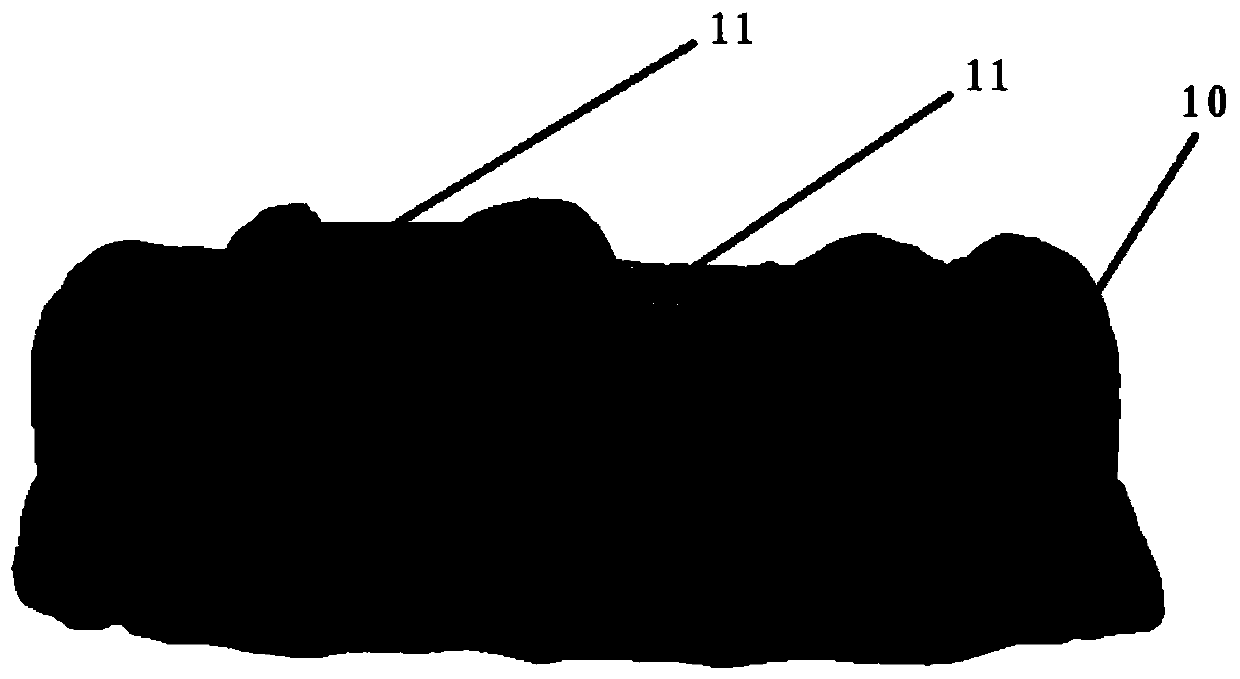

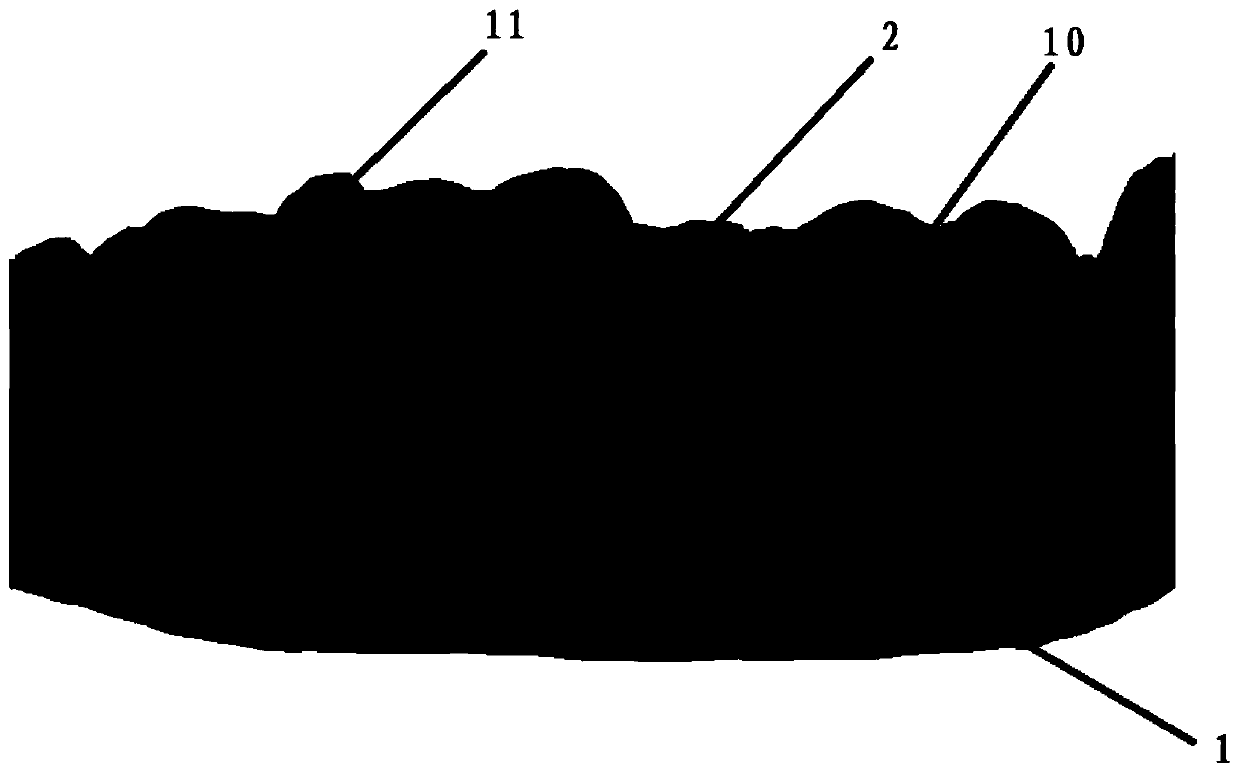

[0059] see figure 2 and image 3 , the present invention also relates to an incisal end deglazing guide plate, which is manufactured by the above-mentioned dental mold guide plate manufacturing method. The incisal deglazing guide includes an incisal deglazing guide body 10, the lower end of the incisal end deglazing guide body 10 is provided with an incisal deglazing guide depression, and the incisal deglazing guide depression is used to surround the patient's dentition and gums 1. At least one incisal deglazing opening 11 is provided on the top of the incisal end deglazing guide plate body.

[0060] The traditional incisal deglazing needs to judge how much enamel to remove based on the doctor's experience, and removing more or less will cause adverse effects.

[0061] In this example, due to the wear and tear of each tooth of the patient, the shape of the incisal end and the maxillofacial surface are also different. After the correction, the dentition will show unevenness,...

Embodiment 2

[0064] see Figure 4 and Figure 5 , the present invention also relates to an acid-etching guide plate, characterized in that: the acid-etching guide plate is made by the above-mentioned production method of the dental mold guide plate. The acid-etched guide plate includes an acid-etched guide plate body 20, the lower end of the acid-etched guide plate body 20 is provided with an acid-etched guide plate concave portion, and the acid-etched guide plate concave portion is used to surround the patient's teeth 2, and the acid-etched guide plate body The side of the 20 is provided with an acid-etched window 21, and the acid-etched window 21 is used to locate the position and range of the acid-etched teeth.

[0065] In the traditional method of etching the tooth surface, the doctor needs to estimate the general position of the bracket placement based on experience, and it is not easy to control the amount of etching agent and the area of application when applying the etching agen...

Embodiment 3

[0069] see Figure 6 and Figure 7 , the present invention also relates to a positioning guide plate, the positioning guide plate is made by the above-mentioned manufacturing method of the dental model guide plate. The positioning guide plate includes a positioning guide plate body 30, the lower end of the positioning guide plate body 30 is provided with a positioning guide plate concave portion, and the positioning guide plate concave portion is used to wrap the patient’s teeth, and the side of the positioning guide plate body is provided with a positioning window 31 The positioning window 31 is used to locate the installation angle and installation position of the bracket 3, and the positioning guide body 30 is also provided with an observation window 32, and the observation window 32 is used to check the adhesion between the positioning guide body 30 and the tooth surface. In the closed state, the positioning guide plate body 30 is also provided with a clamping portion 33,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com