Recycling glycol stirring and mixing tank

A technology of stirring and mixing, ethylene glycol, applied in the direction of chemical instruments and methods, chemical/physical processes, feeding devices, etc., can solve problems such as mutual interference, easy blockage of pipes and flowmeters, uneven distribution, etc., to prevent inhalation Exhaust system, reduce the loss of ethylene glycol, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

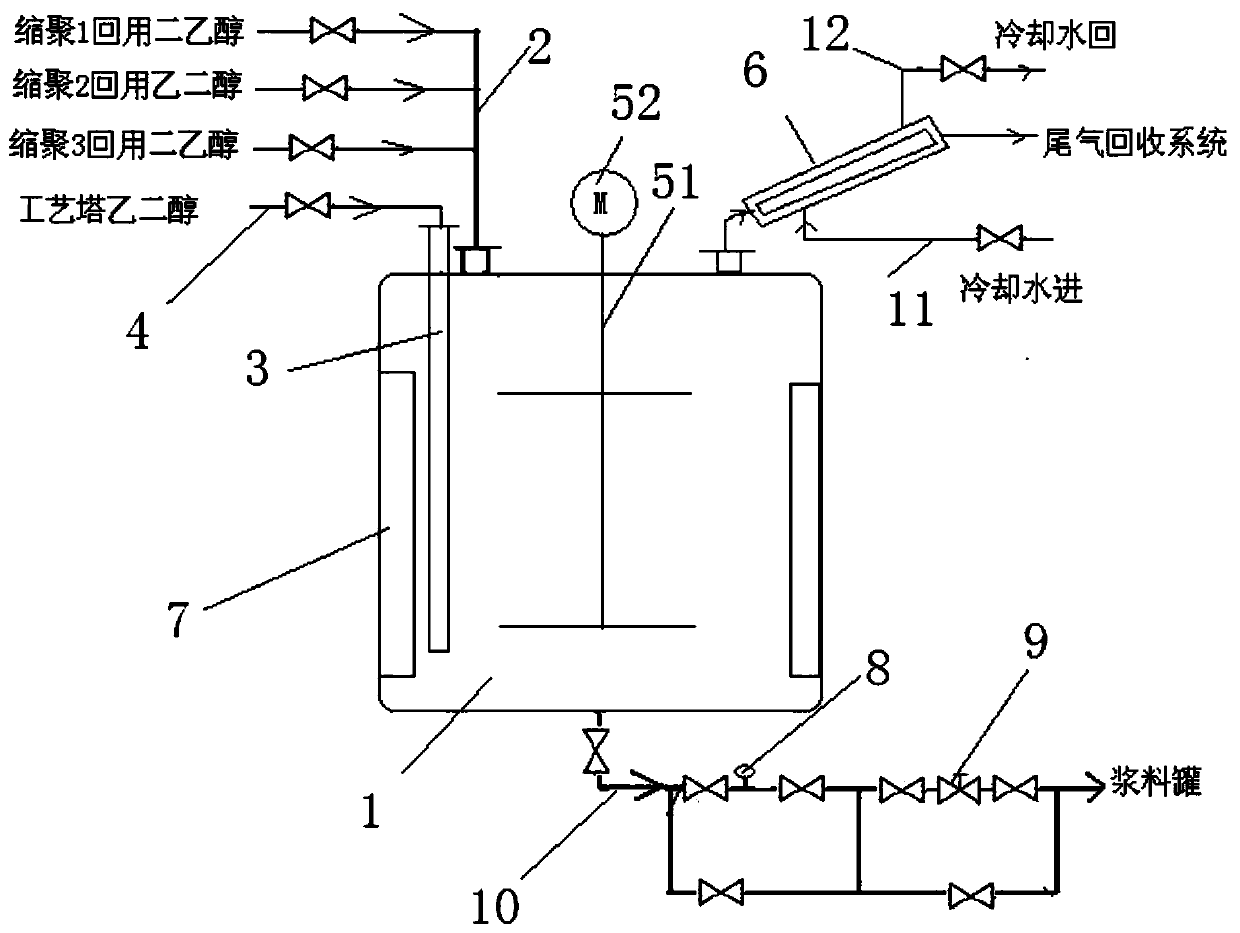

[0016] Such as figure 1 As shown, a mixing tank for recycling ethylene glycol includes a mixing tank body 1, a liquid inlet is provided on the top of the tank body 1, and the liquid inlet is connected to the polycondensation recycling ethylene glycol pipeline 2, and also includes a submerged intubation tube 3. The top of the sinking intubation 3 is connected to the high-temperature ethylene glycol pipeline 4 coming out of the process tower. The lower end of the sinking intubation 3 penetrates the tank body and extends below the diethanol liquid level, and seals the penetration. Preferably, the sinking Cannula 3 is vertically arranged, and its lower end is 40cm away from the bottom of the tank. The tank body 1 is also provided with a stirring device and a jacket condenser 6. The stirring device includes a stirring shaft 51 extending into the tank an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com