Construction waste crushing device

A crushing device and construction waste technology, applied in construction waste recycling, recycling technology, grain processing, etc., can solve problems affecting air quality, reducing crushing efficiency, harmful to human health, etc., to improve crushing efficiency, accelerate crushing, The effect of convenient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

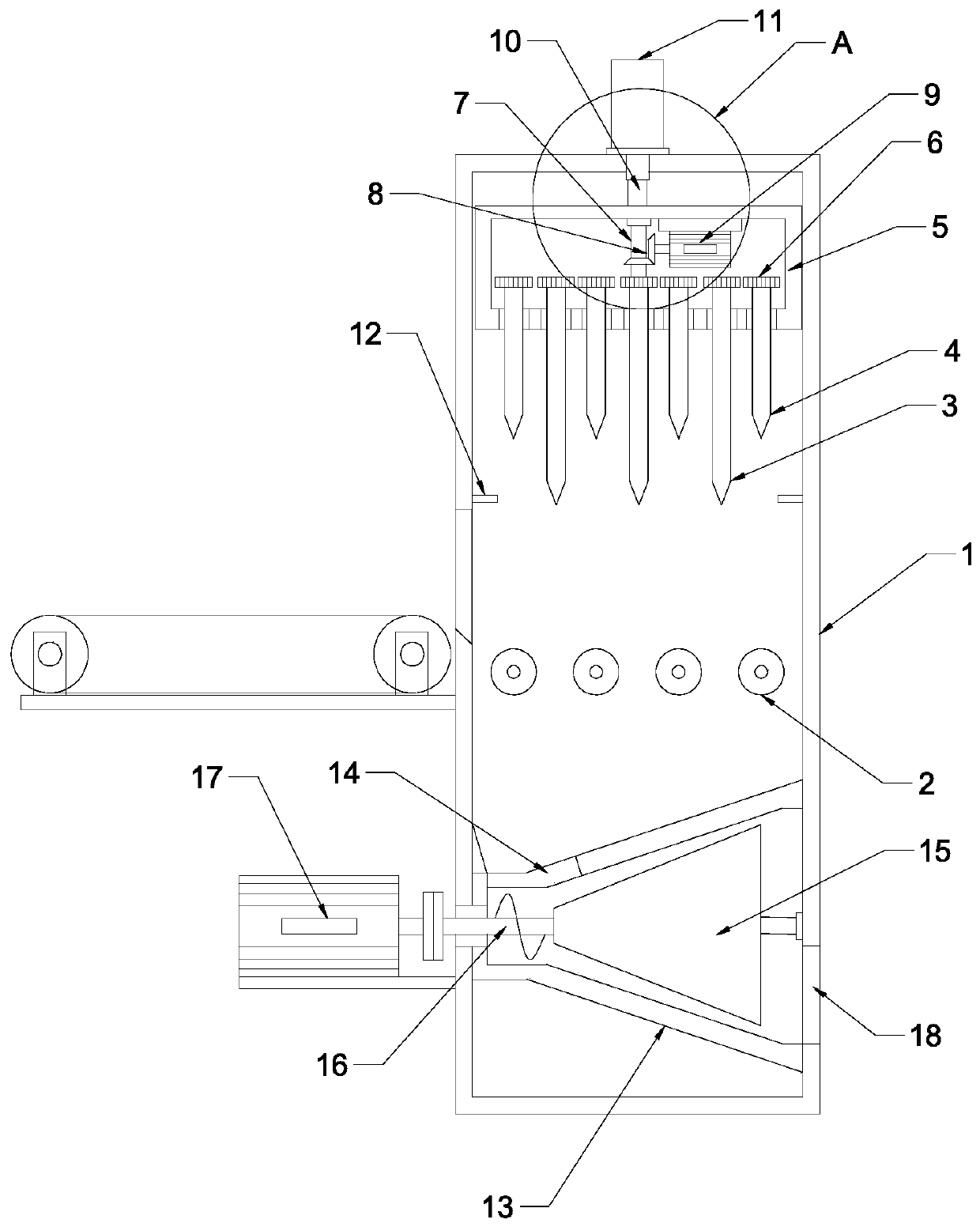

[0020] see Figure 1-3 , in an embodiment of the present invention, a construction waste crushing device includes a crushing box 1; multiple groups of crushing rollers 2 arranged longitudinally and equidistantly are arranged in the crushing box 1, and the crushing rollers 2 are connected with a driving device, and the crushing rollers are 2 pairs Concrete blocks are squeezed and crushed.

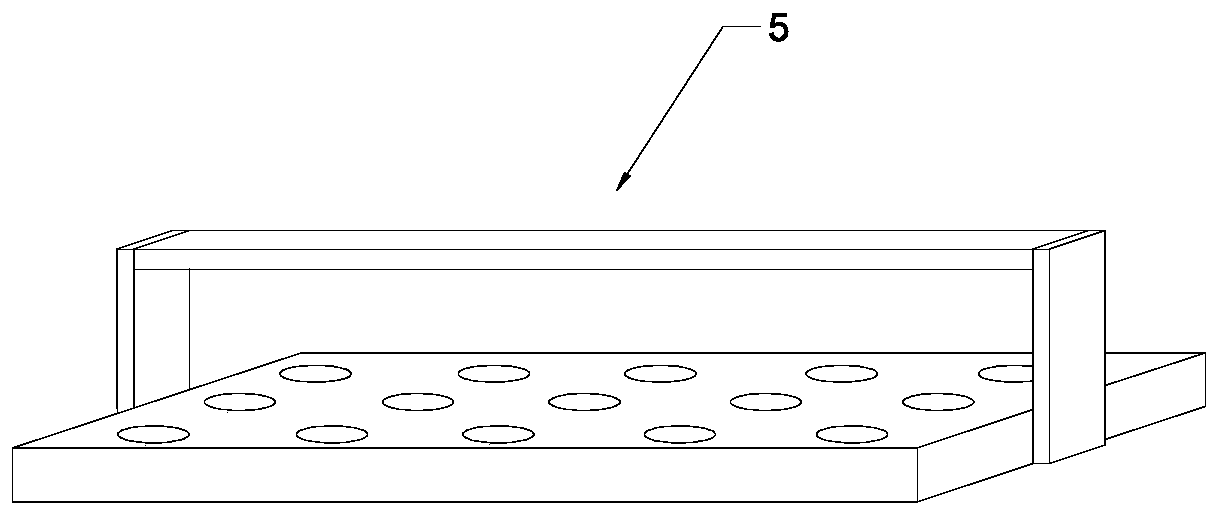

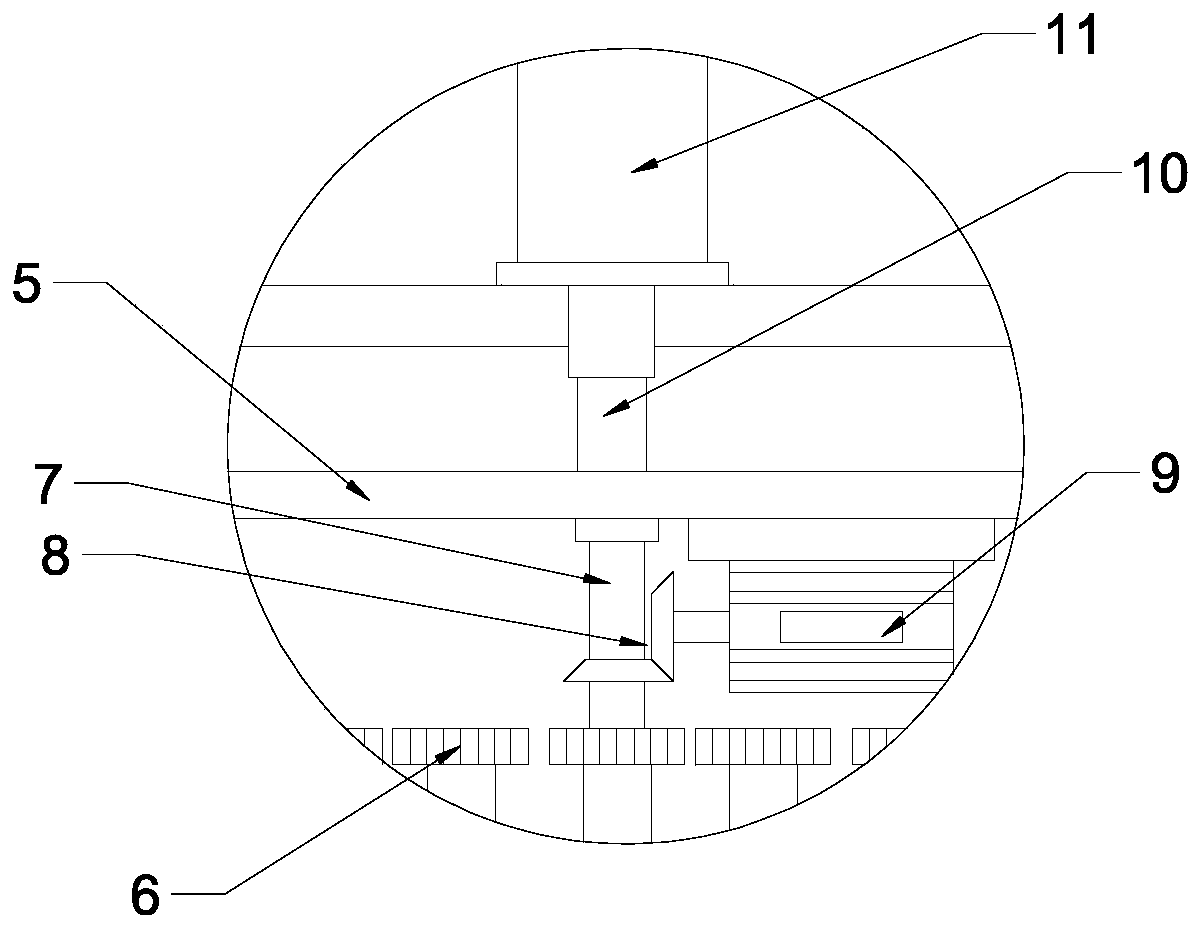

[0021] The top of the crushing roller 2 is provided with evenly distributed short drill rods 4 and long drill rods 3, and the short drill rods 4 and long drill rods 3 are distributed at intervals; , the sliding frame 5 is nested in the crushing box 1 and is slidingly connected with the inner wall of the crushing box 1; the upper ends of the short drill rod 4 and the long drill rod 3 are respectively fixedly connected with transmission teeth 6, and the upper ends of the long drill rod 3 located in the center are fixedly connected There is a connecting shaft 7, which is rotationally connected...

Embodiment 2

[0025] The difference between this embodiment and Embodiment 1 is that: a grinding cylinder 13 is provided below the crushing roller 2, and a feeding port 14 is provided at the upper end of the grinding cylinder 13; a grinding cone 15 is nested in the grinding cylinder 13, and the grinding cone 15 It is conical, and the grinding cone 15 is connected with a grinding motor 17 through a drive shaft 16, and the grinding motor 17 is fixedly connected with the crushing box 1; the bottom of the grinding cylinder 13 is provided with a discharge port 18 for unloading, and the concrete is crushed by the grinding cone 15. The particles are further ground to further granulate the concrete block, which is convenient for subsequent recycling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com