A stamping device for pipe fitting mold production

A stamping device and mold technology, which is applied in the field of stamping devices for the production of pipe fitting molds, can solve the problems of cumbersome operation, low precision, and reduced quality of pipe fitting mold processing and molding, so as to improve connection strength, efficiency, connection strength and stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

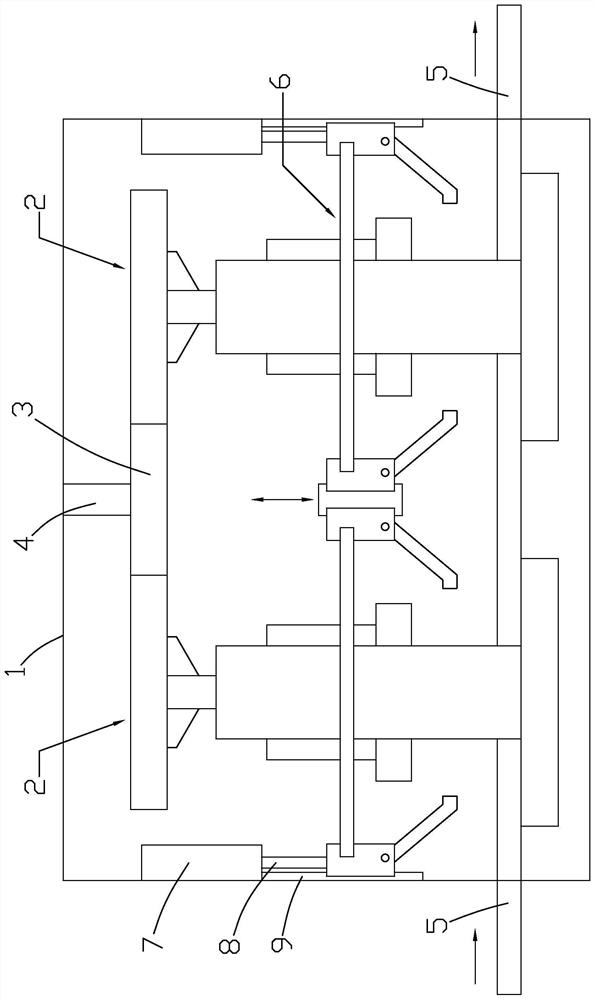

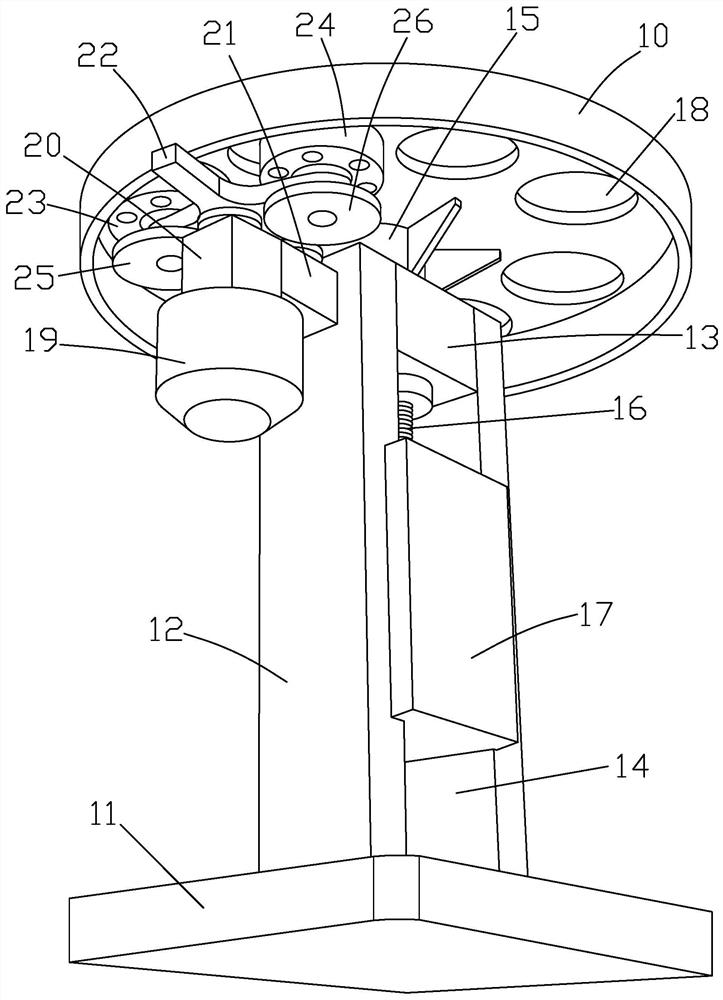

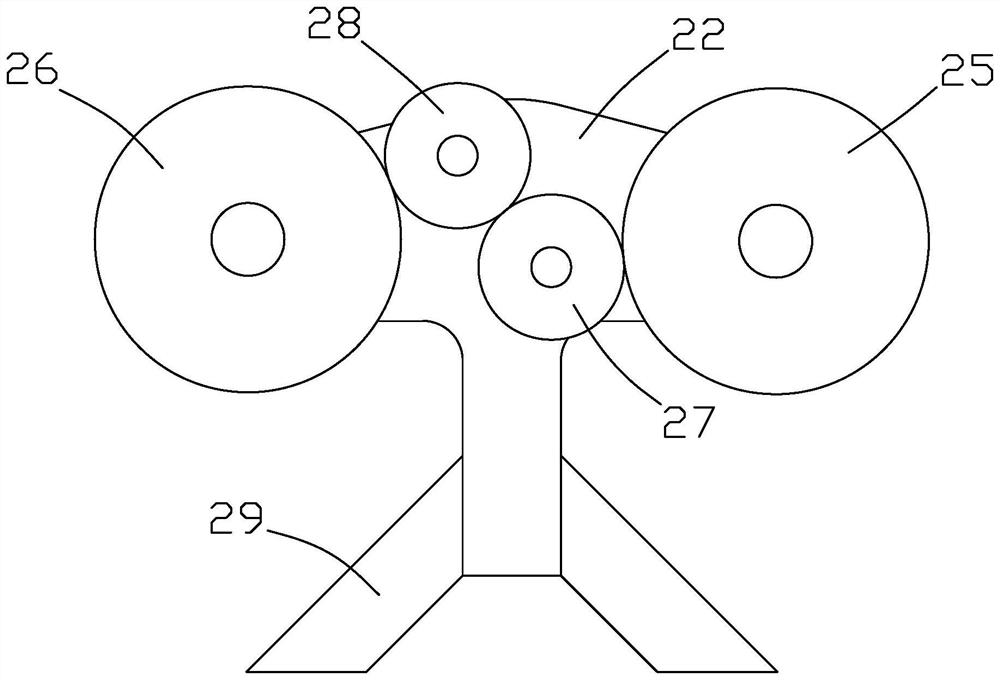

[0030] Such as Figure 1 to Figure 5As shown, it is a stamping device for pipe fitting mold production according to the present invention, which includes a box body 1, a stamping mechanism 2 and a mold positioning mechanism 6 are arranged in the box body 1, two stamping mechanisms 2 are arranged horizontally, and the two stamping mechanisms 2 The connecting gear 3 is connected to the top of the box body 1 through the column 4, and the conveyor belt 5 is horizontally arranged in the box body 1, and the conveyor belt 5 runs through the punching mechanism 2 horizontally, and the punching mechanism 2 includes a turntable 10 and a motor 19. , the base 11 and the transmission mechanism, the base 11 is fixedly connected to the bottom surface of the box body 1, two support plates 12 are arranged in parallel on the top surface of the base 11, and a crossbeam 13 is arranged between the top inner surfaces of the two support plates 12, A lifting groove 14 is formed between the crossbeam 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com