Full-automatic rubber pipe ring sleeving machine

A ferrule machine, fully automatic technology, applied in metal processing, metal processing equipment, manufacturing tools and other directions, can solve the problems of low ferrule accuracy and quality, complex structure of automatic ferrule machine, etc., to improve accuracy and quality, Ingenious structural design and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

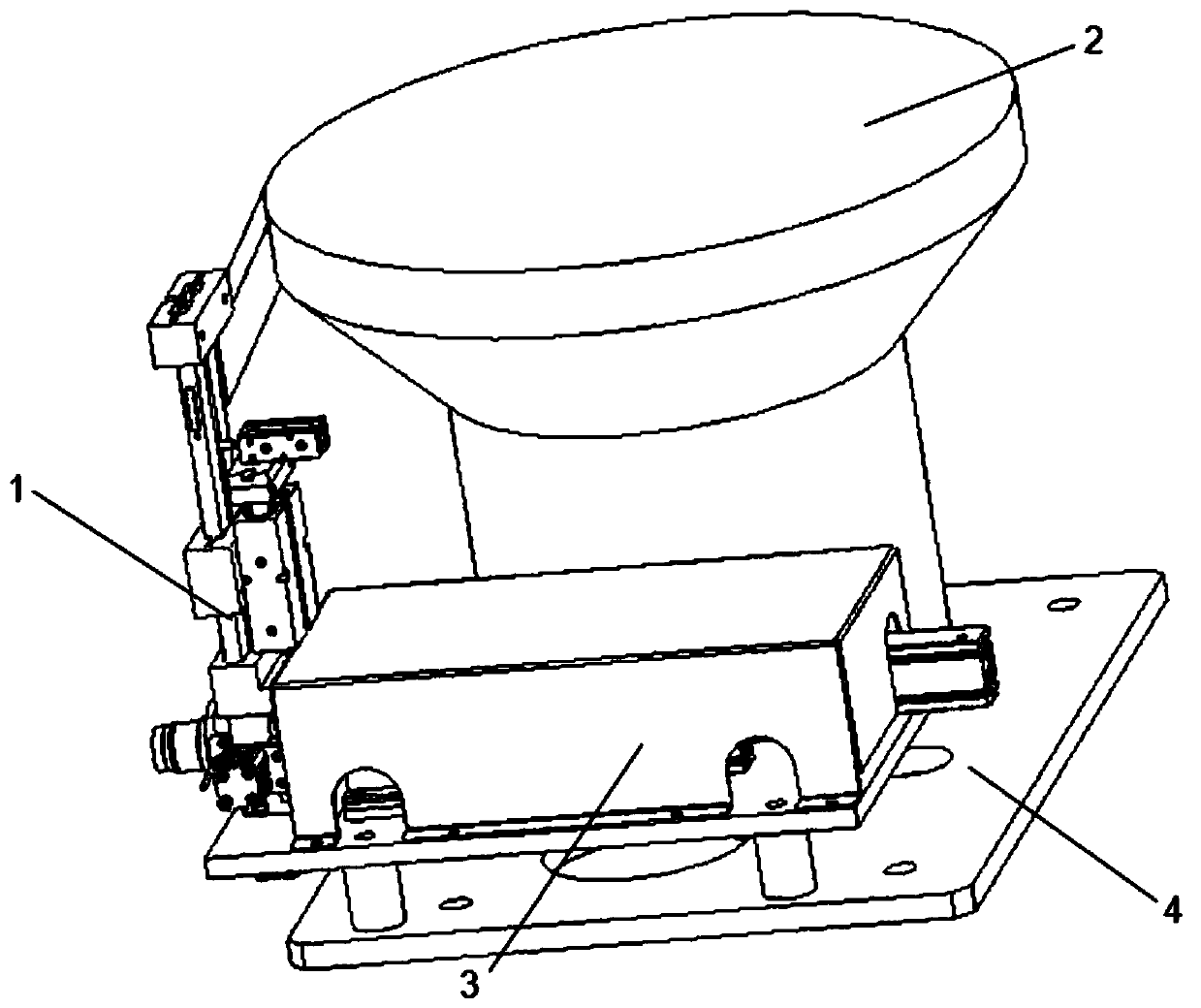

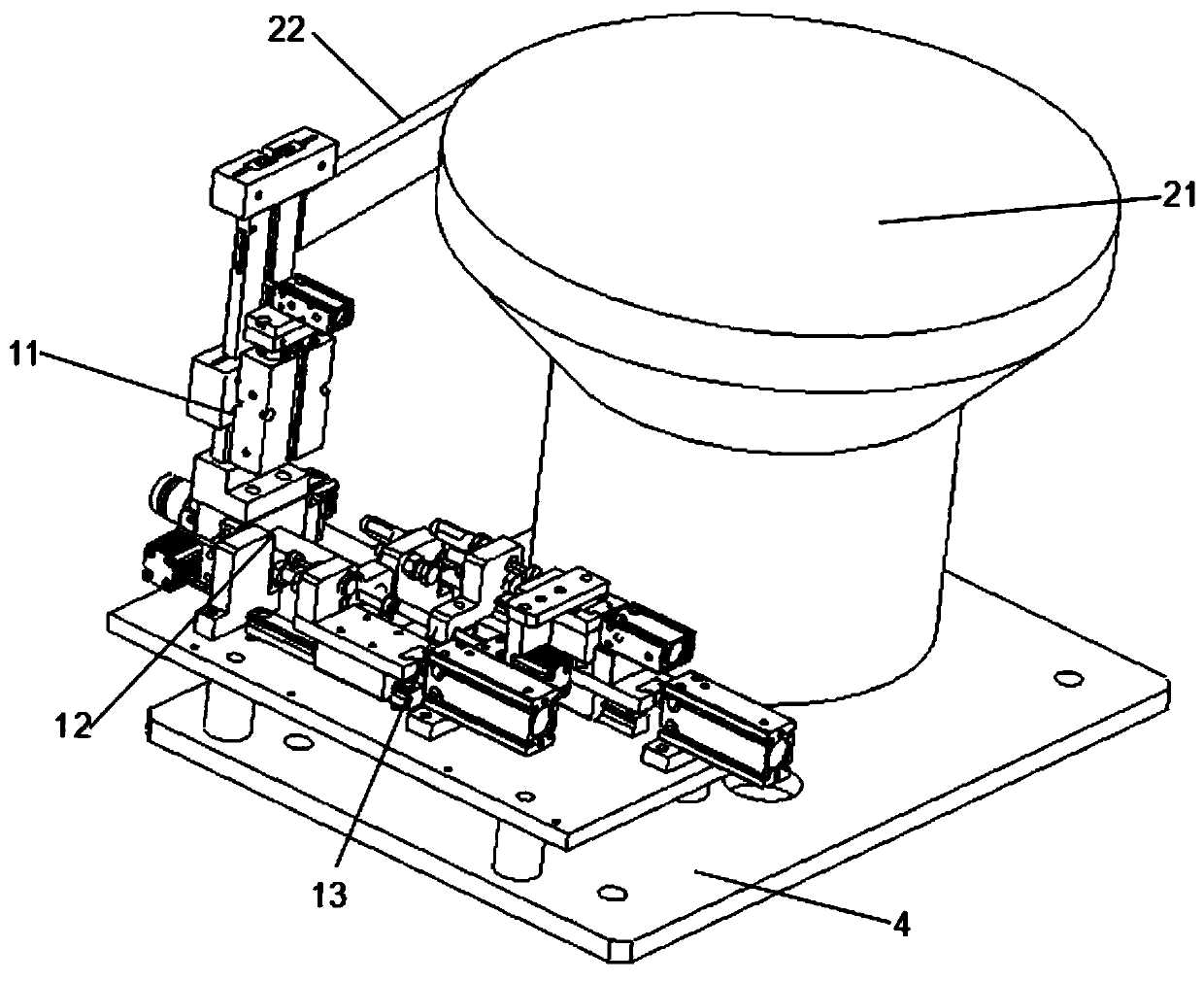

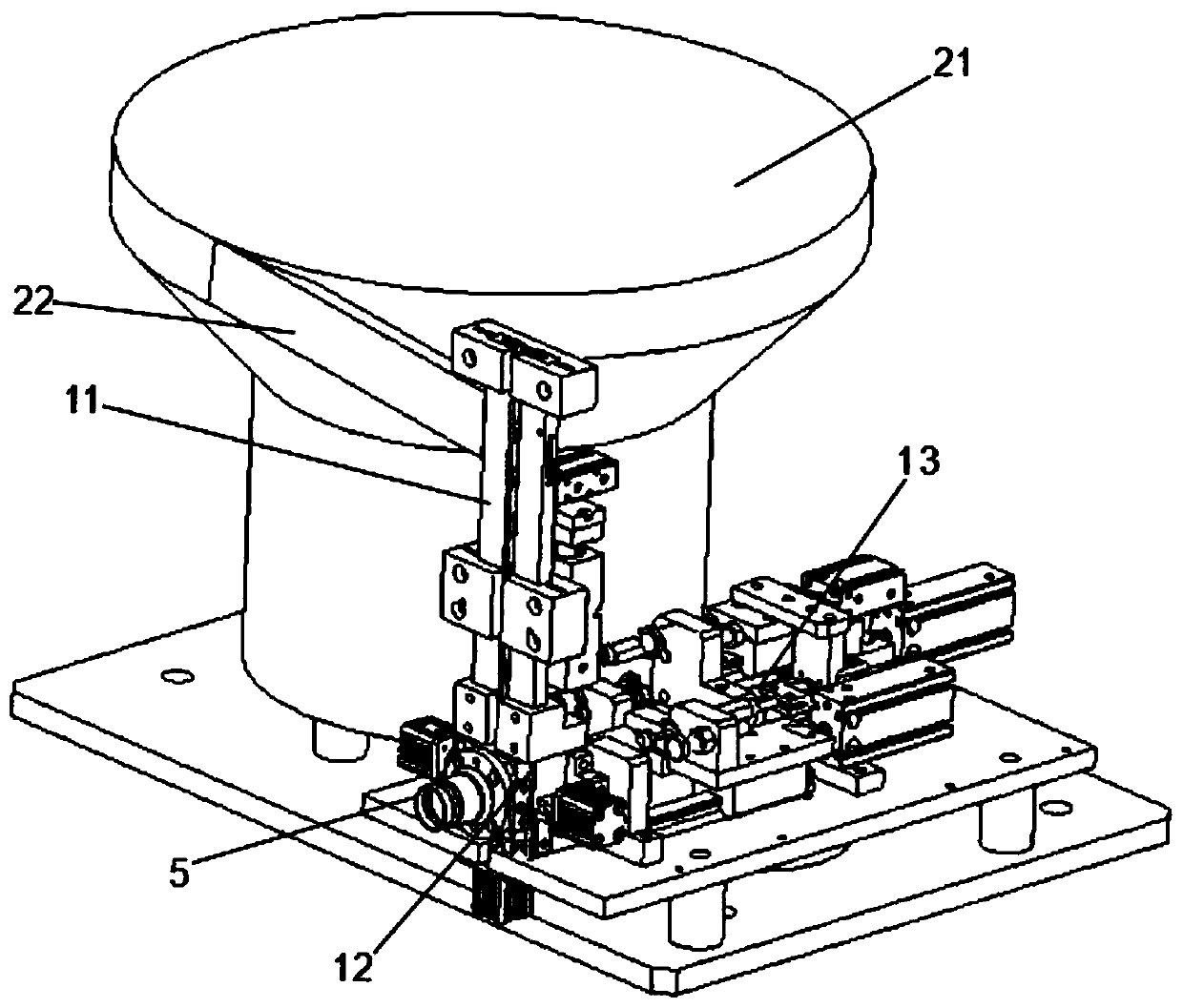

[0023] Embodiment: a kind of fully automatic rubber hose ferrule machine.

[0024] refer to Figure 1 to Figure 7 As shown, a fully automatic rubber hose ferrule machine, including:

[0025] The feeding device 2 installed on the base 4, the feeding device 2 is a vibrating plate 21, and the discharge port of the vibrating plate 21 is connected to the top side end of the feeding channel pipe 111 through the feeding pipe 22. The apron feeding port 112 realizes the feeding of the aprons 7 one by one through the vibration of the vibrating plate 21, and then enters the feeding channel pipe 111 through the feeding pipe 22;

[0026] The casing device 1 installed on one side of the feeding device 2, the casing device 1 includes a feeding mechanism 11, a positioning mechanism 12 and a fine blanking mechanism 13, wherein the positioning mechanism 12 includes a positioning seat 121, and the positioning seat 121 The left and right positioning cylinders 122 and the right positioning cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com