Pipe fitting joint ferrule packaging production line

A packaging production line and joint sleeve technology, applied in packaging, packaging machines, wrapping paper, etc., can solve the problems of inability to realize the automatic ferrule of pipe joint rubber rings, poor adaptability, and low level of flexibility, and achieve ingenious and continuous structural design. High performance and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] Embodiment: A production line for packing ferrules of pipe fittings.

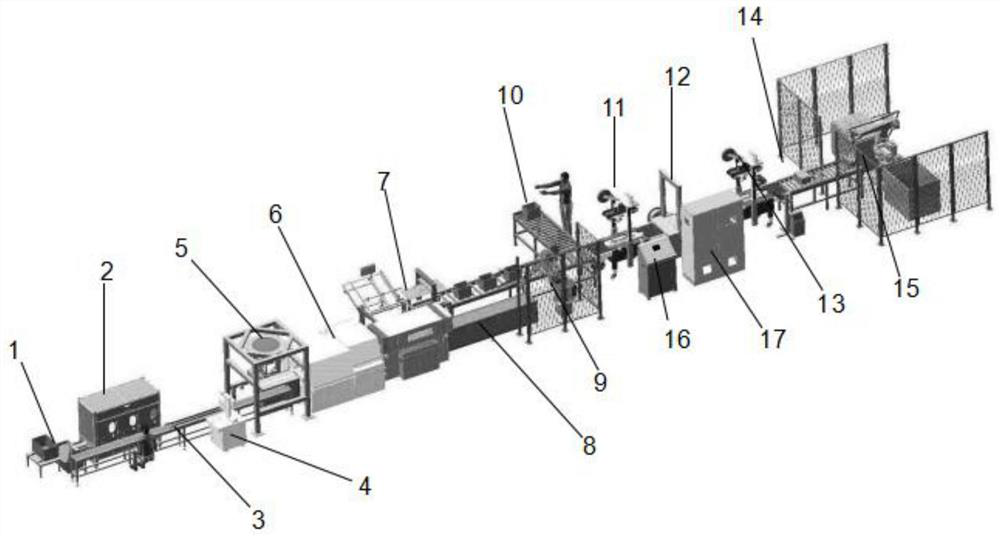

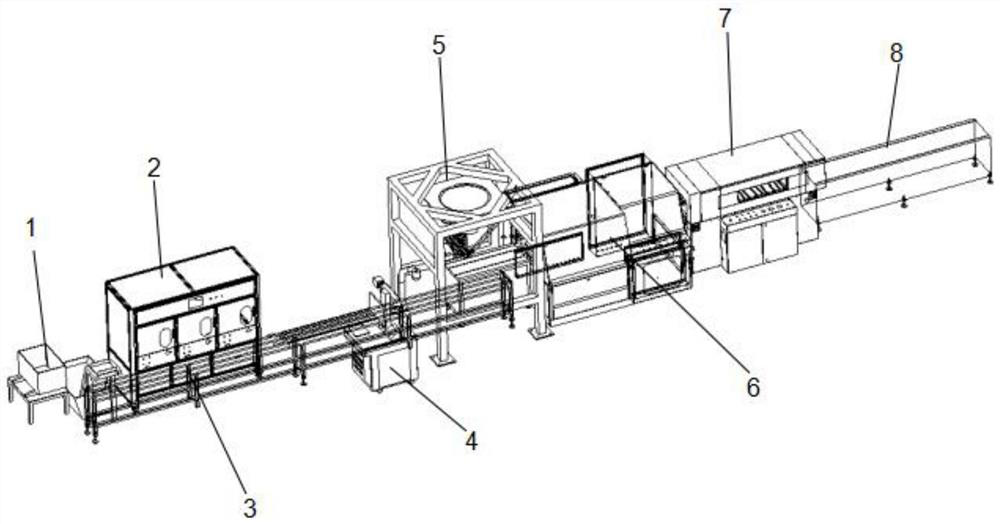

[0029] refer to Figure 1 to Figure 8 As shown, a pipe fitting ferrule packaging production line, including:

[0030] A belt conveyor 3 is arranged longitudinally along the production line, and the belt conveyor 3 is used for the transmission of pipe joints and cartons;

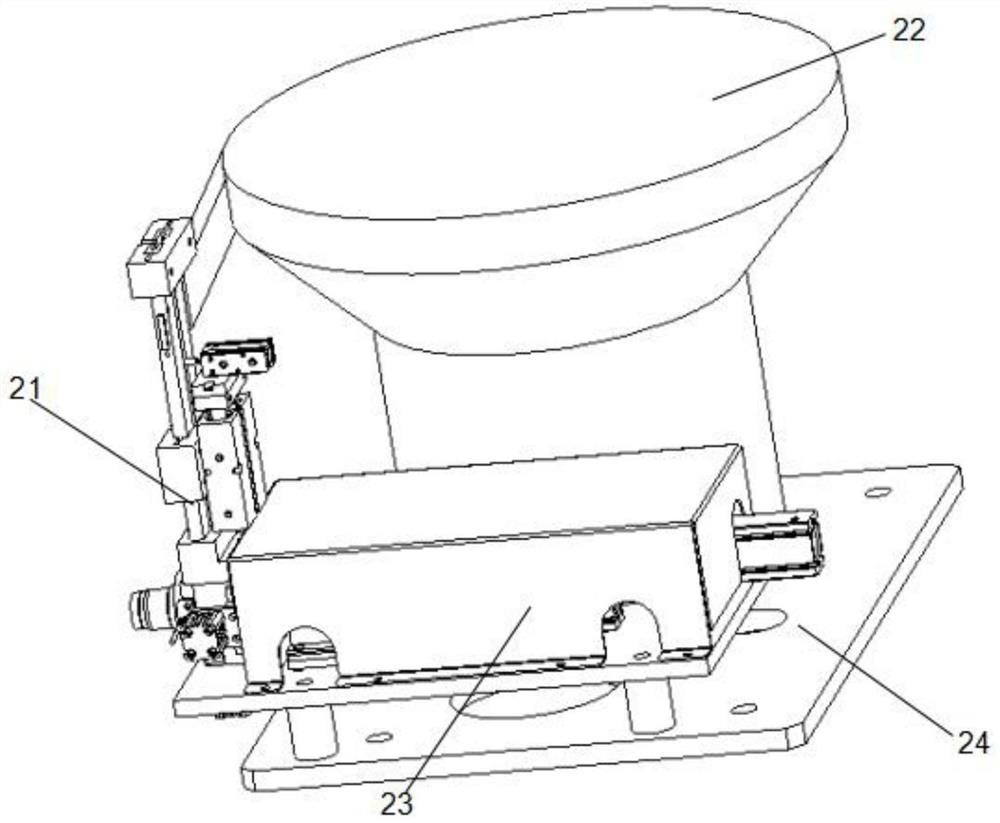

[0031] The storage box 1 installed at the front end of the belt conveyor 3, the pipe joints are placed in the storage box 1, during the actual operation, the pipe joints placed in the storage box 1 can be transported to the ferrule by manual or external feeding device In the feeding device 22 of machine 2;

[0032] The ring machine 2 installed behind the material storage box 1 and on the side of the belt conveyor 3, the ring machine 2 is used to press the rubber ring 27 into the pipe joint;

[0033] The laser coding machine 4 installed on the side of the belt conveyor 3 and behind the ring machine 2, the laser coding machine 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com