Dust removal function carving machine and method

An engraving machine and functional technology, applied in engraving, decorative arts, processing models, etc., can solve the problems of low engraving accuracy and high processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

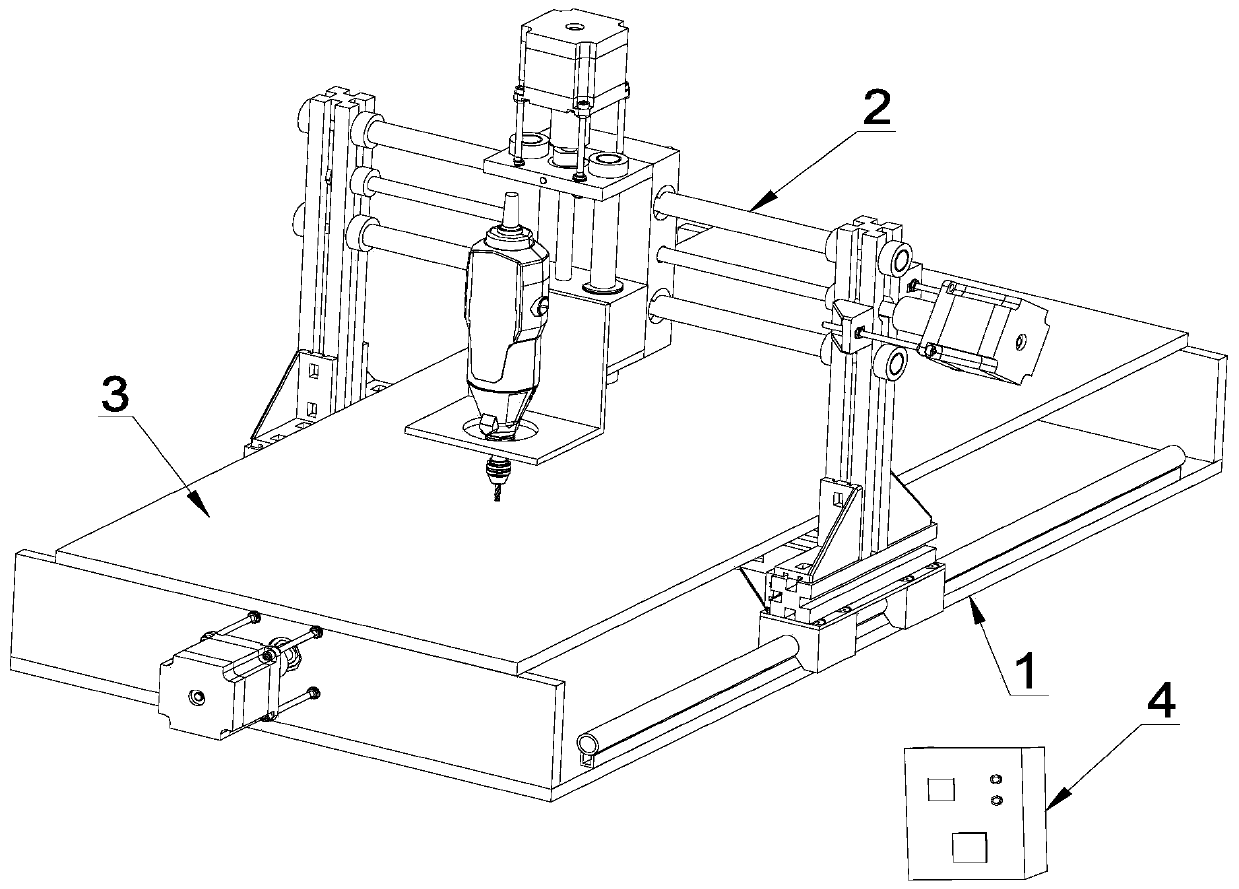

[0059] figure 1 Shown is a kind of engraving machine with dust removal function and method diagram among the present invention. It includes: a bottom transmission assembly device 1, an engraving core device 2, a workpiece 3, and a DSP control system 4; an engraving core device 2 is provided on the upper surface of the bottom transmission assembly device 1, and the engraving core device 2 and the bottom transmission assembly The devices 1 are fixedly connected by screws, the workpiece 3 is located between the bottom transmission assembly device 1 and the engraving core device 2, and the DSP control system 4 is located on the side of the bottom transmission assembly device 1; the bottom transmission assembly device 1. The total stroke of longitudinal transmission is between 0.2 m and 5 m; the total stroke of vertical transmission of the engraving core device 2 is between 0.1 m and 2 m, and the total stroke of horizontal transmission is between 0.15 m and 2.5 m.

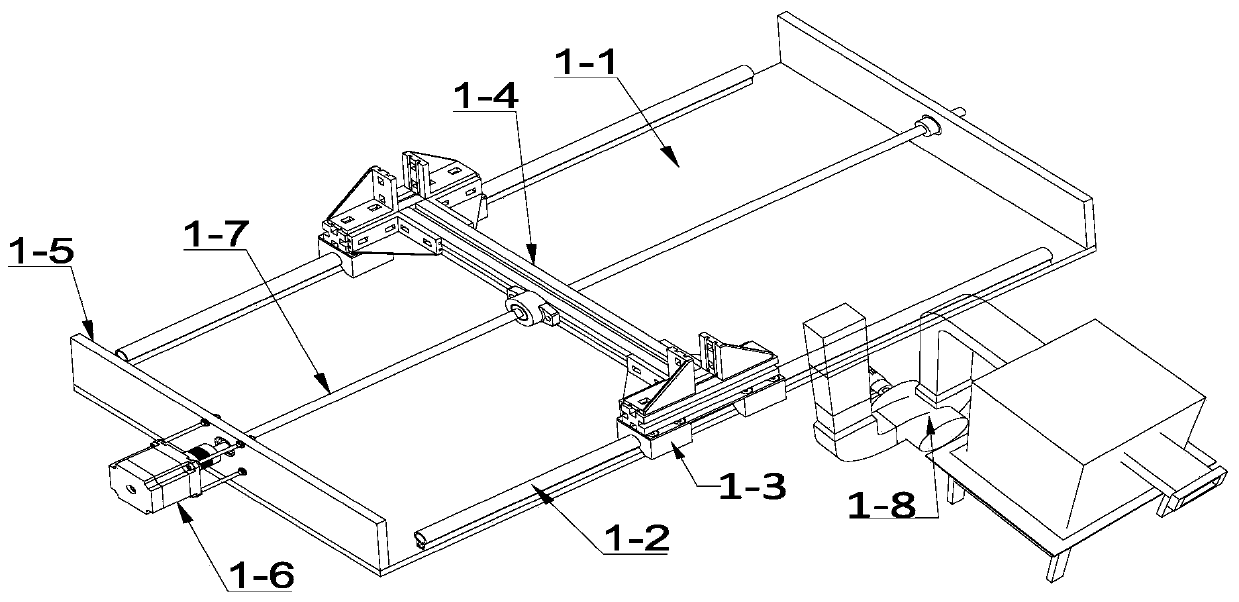

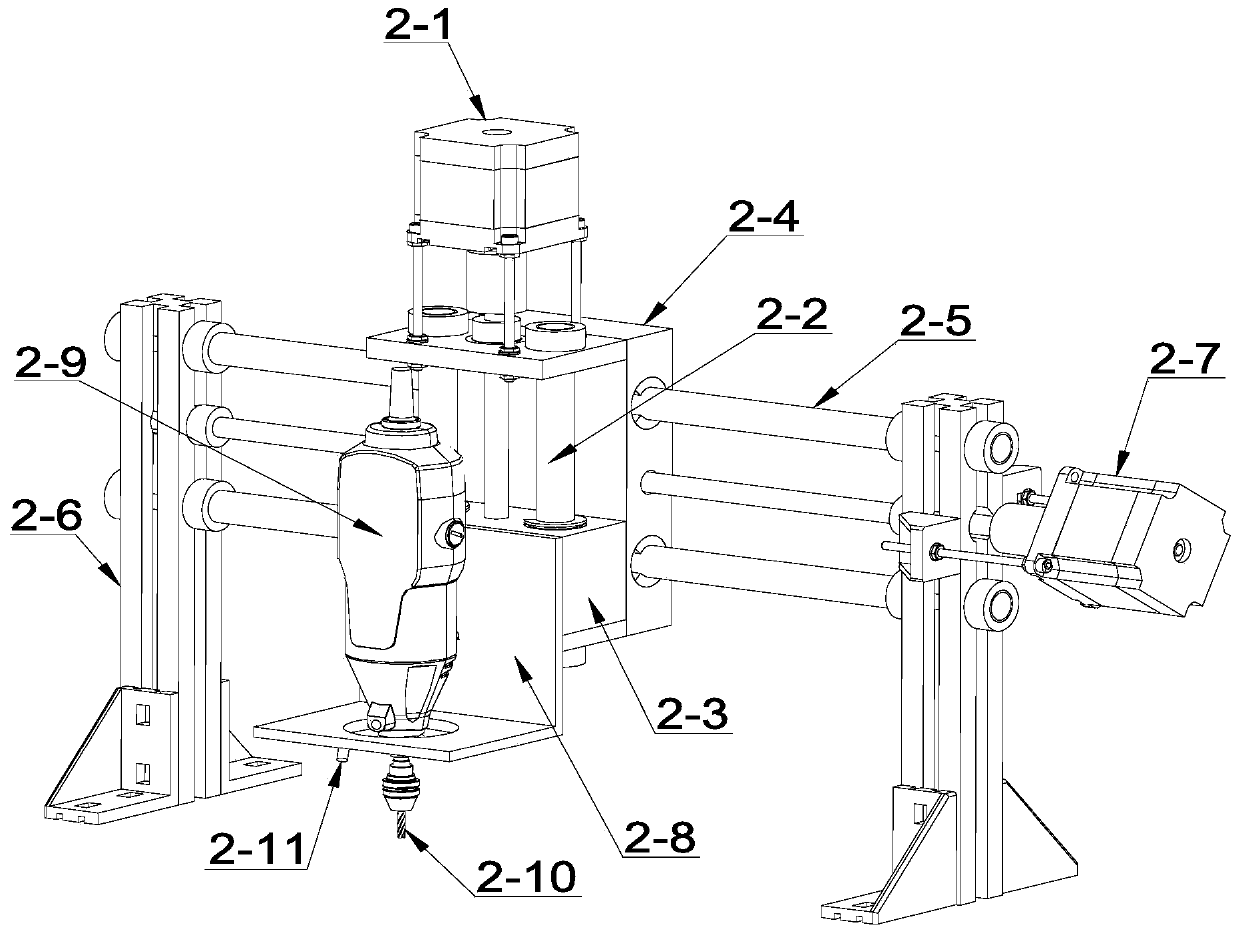

[0060] figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com