Design and manufacturing method of novel energy absorption structure vehicle door

An energy-absorbing structure and door technology, which is applied to vehicle components, vehicle safety arrangements, bumpers, etc., can solve the problems of short duration, small impact force, and low protection buffer volume, so as to improve the degree of safety protection and impact buffer The effect of the ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

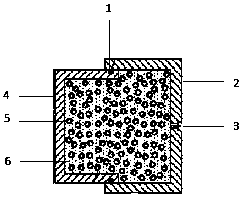

Image

Examples

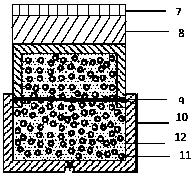

Embodiment 2

[0031] 4. The integrated structural design of the door inner bracket and the new micro-nano composite liquid energy-absorbing buffer box, such as Figure 5 shown. The outer layer of the bracket is designed as an integrated micro-nano composite liquid energy-absorbing buffer box 18, and the inner layer of the bracket is a bracket 19 made of carbon fiber composite material. Among them, the nano-porous structure inside the micro-nano composite liquid energy-absorbing buffer box uses polyurethane porous nano-foam, and the liquid uses deionized water. The rubber sealing ring is used, the piston is made of carbon fiber polyetheretherketone composite material, and the piston structure is made of carbon fiber polyetheretherketone material. The specific buffer box parameters are 300mm in length, 20mm in width, and 30mm in height, and the length of the bracket is 300mm, 20mm in width, and 20mm in height.

[0032] 5. The manufacturing method of the buffer car door composed of the unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com