Device for arranging a light-emitting diodes (LED) light product in an array and production line of LED light product

A technology of LED lamps and products, applied in welding equipment, metal processing equipment, lighting and heating equipment, etc., can solve problems such as low efficiency and instability, achieve high production efficiency, stable production efficiency, and overcome the shortcomings of production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

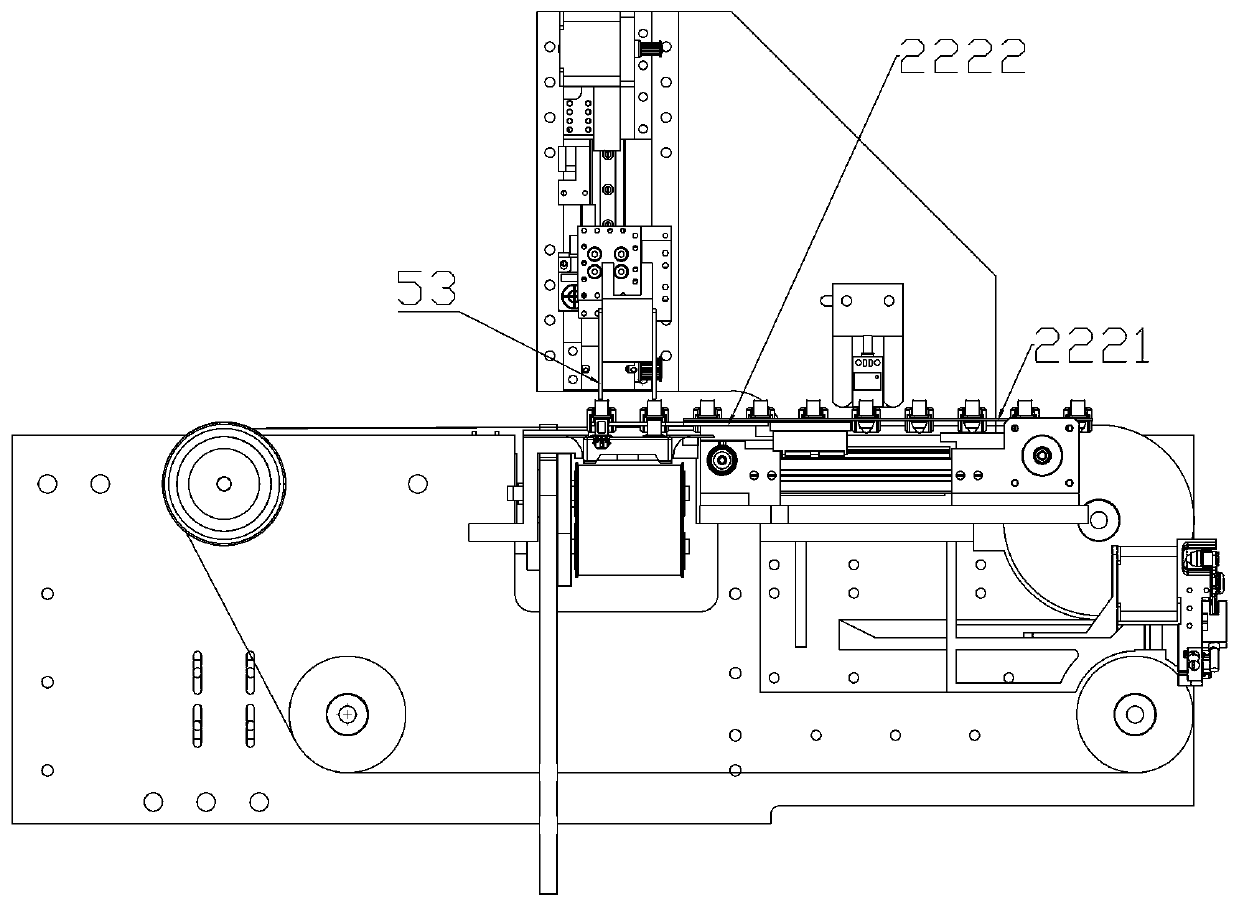

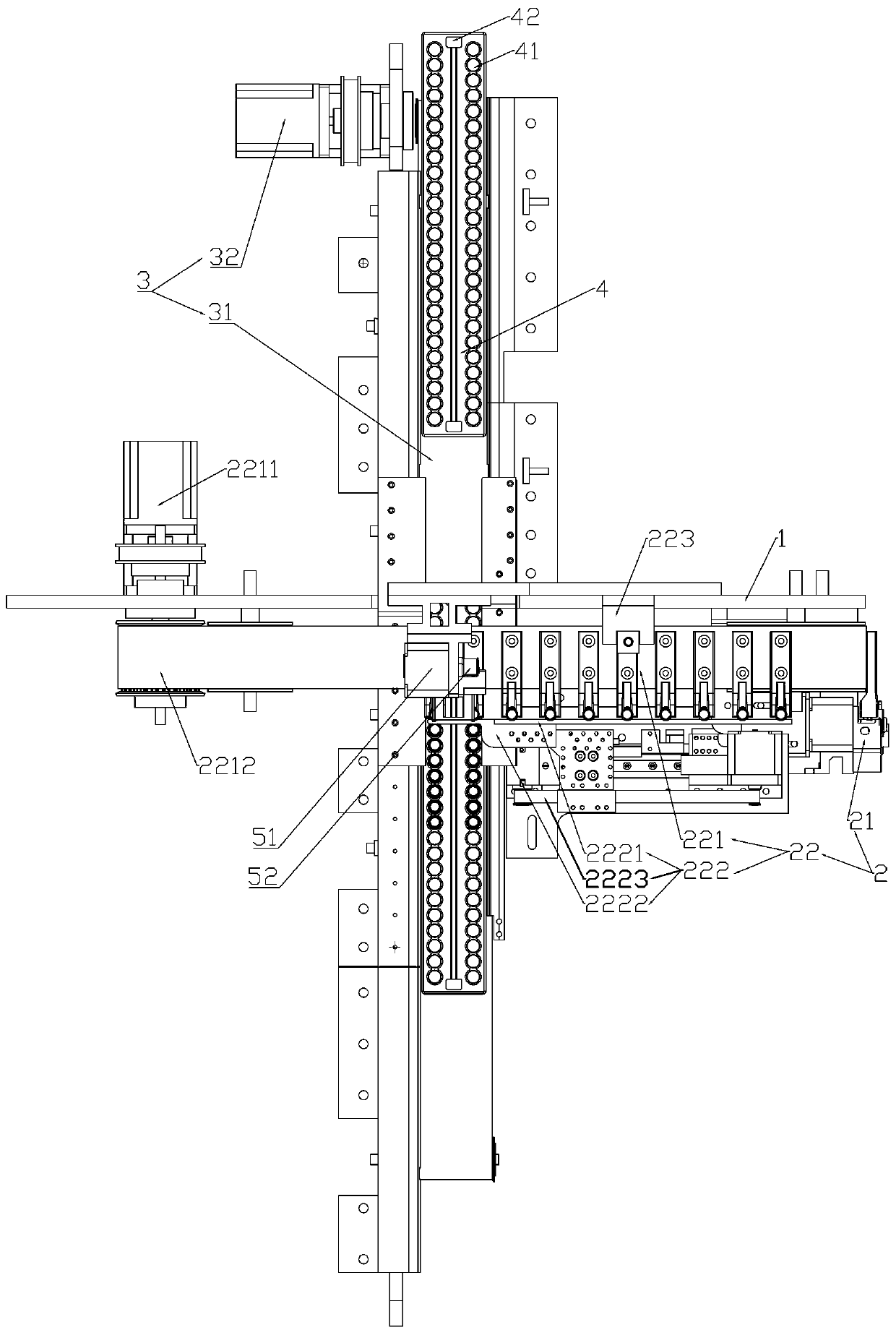

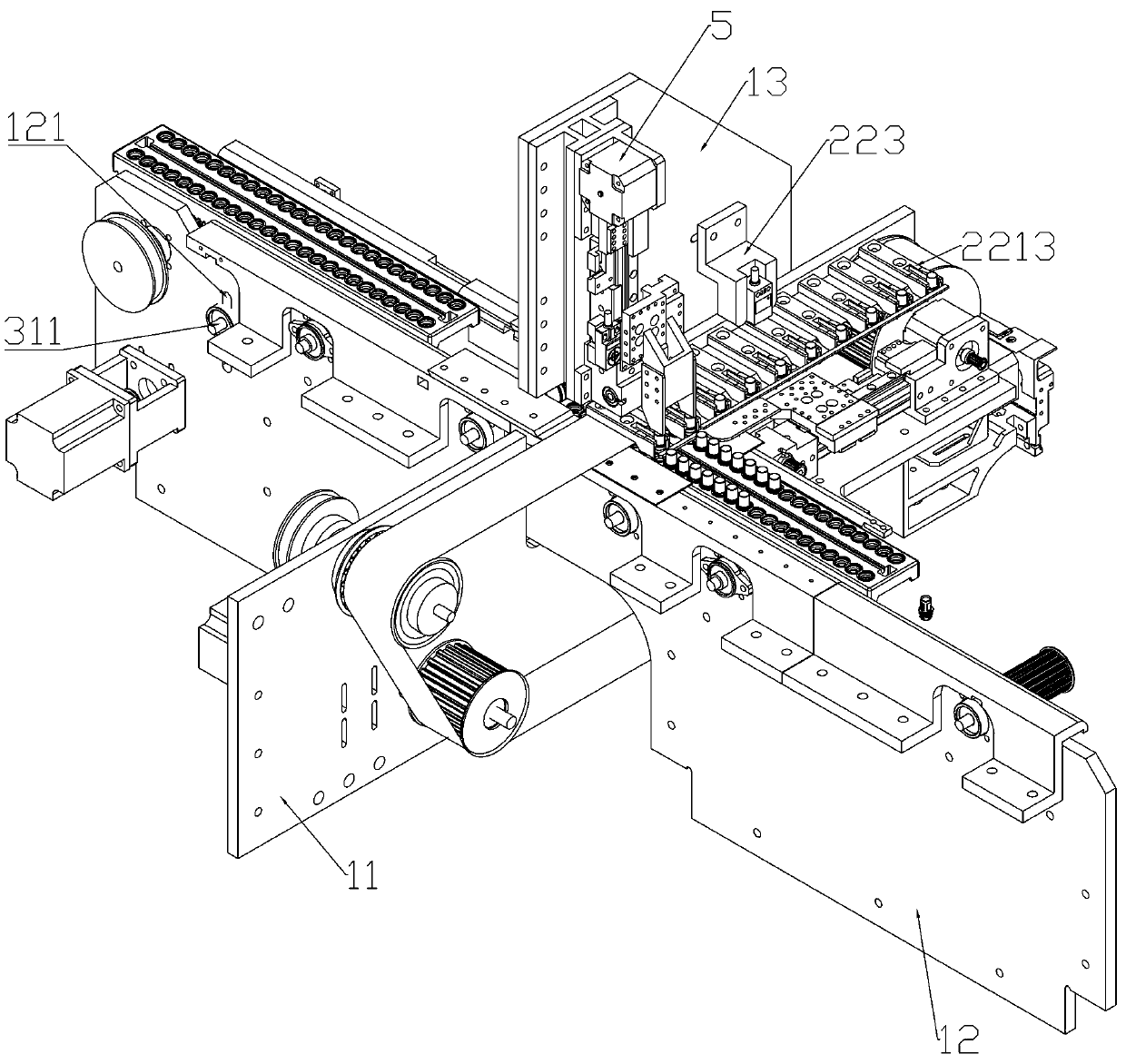

[0034] Embodiment 1: A device for arraying LED lamp products, see Figure 1-4 , including LED lamp product arrangement conveying device 2, jig conveying device 3 and LED lamp inserting device 5; when in use, these devices generally need to be fixed on the fixing frame 1 to form a definite relative positional relationship. corresponds to Figure 1-4 , the fixed frame 1 includes a fixed plate 11 of the LED lamp product arrangement conveying device, a fixed plate 12 of the jig conveying device, and a fixed plate 13 of the LED lamp insertion device arranged in relative positioning, but the shape of the fixed frame 1 is not limited to Figure 1-4 in the form. The LED lamp product array conveying device 2 is installed on the fixed plate 11 of the LED lamp product array conveying device, the fixture conveying device 3 is installed on the fixture conveying device fixed plate 12, and the LED lamp inserting device 5 is installed on the LED lamp inserting device for fixing plate 13.

...

Embodiment 2

[0037] Embodiment 2: A device for arraying LED lamp products, as an improvement to Embodiment 1, see Figure 1-6 , including LED lamp product arrangement conveying device 2, fixture conveying device 3, LED lamp inserting device 4 and fixture transfer mechanism; fixture transfer mechanism includes fixed frame 14, manipulator 7 and displacement mechanism 6 installed on fixed frame 14 , the fixed frame 1 can be installed on the fixed frame 14, at this moment, the fixed frame 1 and the fixed frame 14 have just formed an integral structure. The manipulator 7 is relatively common, and there is a manipulator 7 in the pneumatic actuator products, for example, the pneumatic finger series produced by Dawei Automation Company.

[0038] The displacement mechanism 6 can drive the manipulator 7 to move in the X-axis, Y-axis and Z-axis relative to the fixed frame. The displacement mechanism with this structure is also relatively common, see Figure 5-6 One way is to install the X-axis screw...

Embodiment 3

[0039] Embodiment 3: A device for arraying LED lamp products, see Figure 1-4 , including LED lamp product arrangement conveying device 2, jig conveying device 3 and LED lamp inserting device 4; as a preference for embodiment 1 or embodiment 2, the following optional technical features are added in this embodiment.

[0040] Optionally, the conveying track surface of the LED lamp product arrangement conveying device 2 is perpendicular to the conveying track surface of the jig conveying device 3 . Specifically, see Figure 1-4 , LED lamp product arrangement conveying device fixing plate 11 and jig conveying device fixing plate 12 are vertically fixed together. Such a relative position is convenient for equipment coordination and cooperation, and can reduce the difficulty of mechanical cooperation. In other embodiments, the conveying track surface of the LED lamp product arrangement conveying device 2 and the conveying track surface of the jig conveying device 3 can be arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com