Large-scale production method of semi-micron cobalt powder

A production method and technology of cobalt powder, applied in the field of large-scale production of half-micron cobalt powder, can solve the problems of single furnace output, production efficiency to be improved, difficulty in batch production, and need to consume oxalic acid, so as to achieve no need for oxalic acid consumption, reduce The effect of ball milling mixing time and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

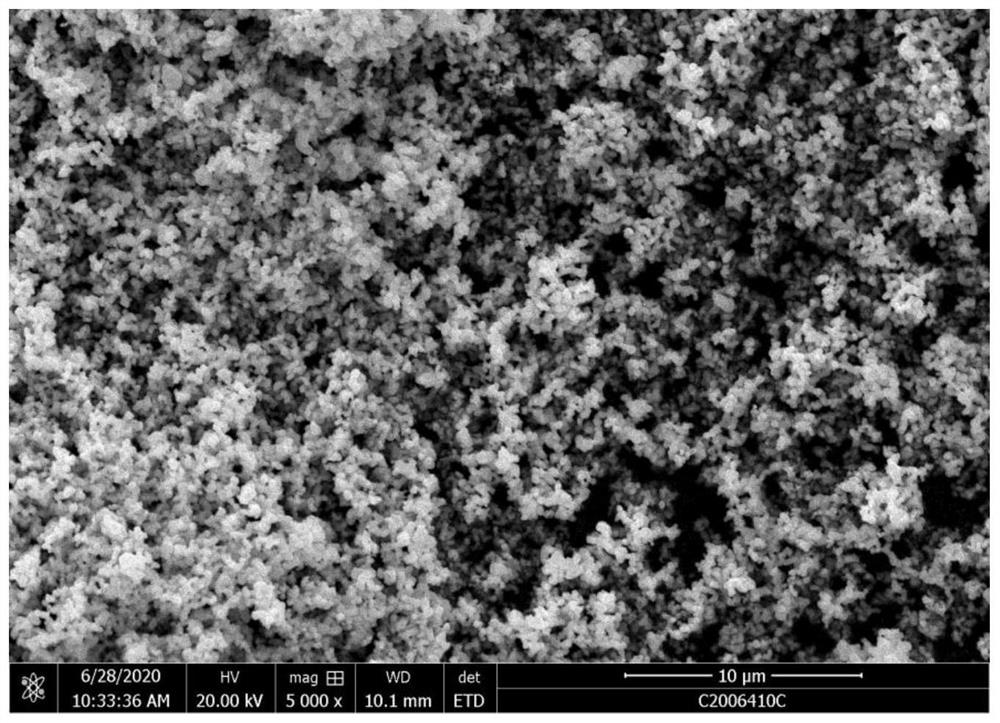

Image

Examples

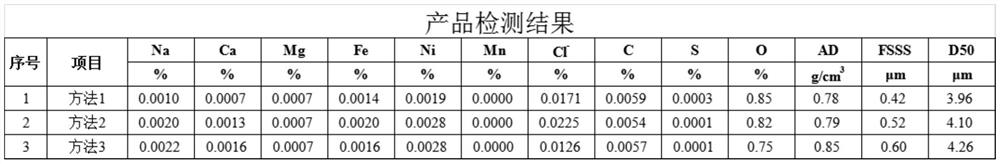

Embodiment 1

[0025] Put cobalt carbonate in a rotary kiln for calcination to obtain tricobalt tetroxide; during calcination, the feed rate of cobalt carbonate is 60kg / h, and the rotation frequency of the main engine of the rotary kiln is 12Hz; The wind frequency is 12Hz, and the calcination time is 3h. The index of cobalt carbonate is: the AD of cobalt carbonate is 0.35g / cm 3 , The particle size D50 is 0.8 μm, and the Fischer particle size is 0.28 μm.

[0026] The tricobalt tetroxide is transported to the distribution bin of the 15-tube reduction furnace through the airflow, the tricobalt tetroxide is put into a bowl and pushed into the furnace tube, and the hydrogen gas is introduced to carry out the reduction reaction to obtain high-temperature cobalt powder. The process conditions for passing cobalt tetroxide into hydrogen for reduction reaction are: hydrogen flow rate is 50m 3 / h, the reduction temperature is 280°C, and the reduction reaction time is 3.5h.

[0027] Cool the high-tem...

Embodiment 2

[0031] Put cobalt carbonate in a rotary kiln for calcination to obtain tricobalt tetroxide; during calcination, the feed rate of cobalt carbonate is 70kg / h, and the rotation frequency of the main engine of the rotary kiln is 10Hz; The air frequency is 15Hz, and the calcination time is 2.8h. The index of cobalt carbonate is: the AD of cobalt carbonate is 0.36g / cm 3 , The particle size D50 is 1.0 μm, and the Fischer particle size is 0.30 μm.

[0032] The tricobalt tetroxide is transported to the distribution bin of the 15-tube reduction furnace through the airflow, the tricobalt tetroxide is put into a bowl and pushed into the furnace tube, and the hydrogen gas is introduced to carry out the reduction reaction to obtain high-temperature cobalt powder. The process conditions for passing cobalt tetroxide into hydrogen for reduction reaction are: the flow rate of hydrogen is 45m 3 / h, the reduction temperature is 200°C, and the reduction reaction time is 3.2h.

[0033] Cool the ...

Embodiment 3

[0037] Put cobalt carbonate in a rotary kiln for calcination to obtain tricobalt tetroxide; during calcination, the feed rate of cobalt carbonate is 80kg / h, and the rotation frequency of the main engine of the rotary kiln is 8Hz; The air frequency is 18Hz, and the calcination time is 2.5h. The index of cobalt carbonate is: the AD of cobalt carbonate is 0.38g / cm 3 , The particle size D50 is 1.2 μm, and the Fischer particle size is 0.35 μm.

[0038] The tricobalt tetroxide is transported to the distribution bin of the 15-tube reduction furnace through the airflow, the tricobalt tetroxide is put into a bowl and pushed into the furnace tube, and the hydrogen gas is introduced to carry out the reduction reaction to obtain high-temperature cobalt powder. The process conditions for passing cobalt tetroxide into hydrogen for reduction reaction are: the hydrogen flow rate is 40m 3 / h, the reduction temperature is 320°C, and the reduction reaction time is 3.0h.

[0039] Cool the high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com