Full-life attenuation simulation experiment device for traction motor bearing of high-speed train

A technology for high-speed EMUs and traction motors, which is applied in the direction of mechanical bearing testing, measuring devices, and testing of mechanical components, and can solve problems such as the decline in the life of traction motor bearings and the lack of simulation test devices for high-speed EMUs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

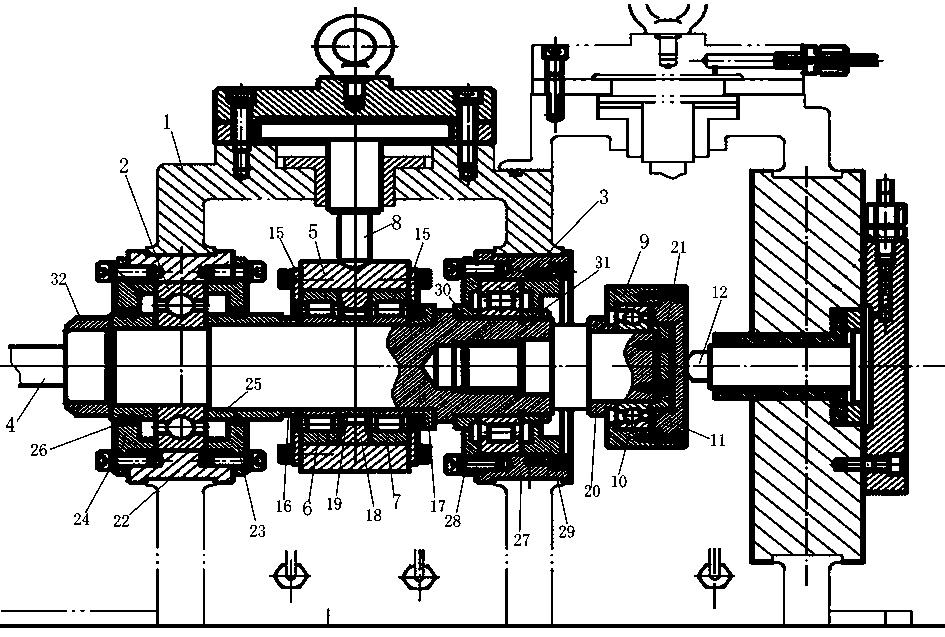

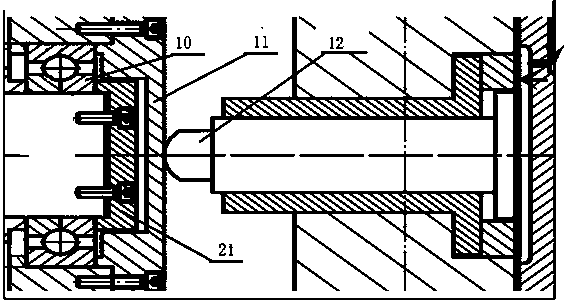

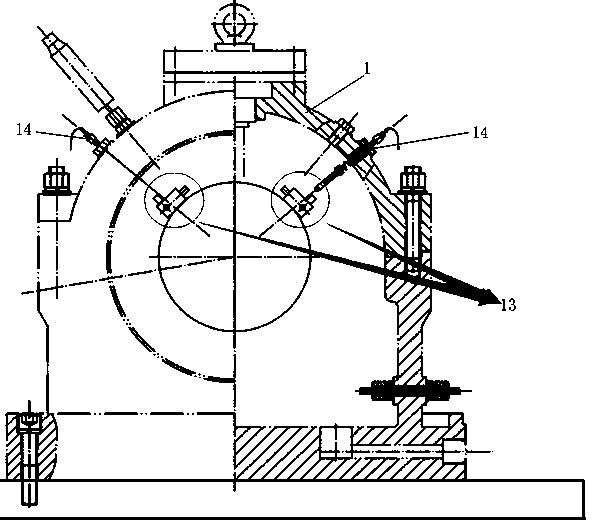

[0016] The high-speed EMU traction motor bearing full-life decline simulation test device includes a cylinder body 1. The test ball bearing support seat is installed at the left end of the cylinder body 1. The test ball bearing 2 is located in the test ball bearing support seat and is lubricated with grease. The right end of the cylinder body 1 is installed. There is a test roller bearing support seat. The test roller bearing 3 is located in the test roller bearing support seat and is lubricated with grease. The two ends of the test shaft 4 are respectively supported on the test ball bearing 2 and the test roller bearing 3. The test ball bearing 2 The distance between the test roller bearing and the test roller bearing 3 is consistent with the distance between the bearings at both ends of the shaft of the traction motor (one end is a ball bearing and the other end is a roller bearing), thereby ensuring that the test ball bearing and the test roller bearing are subjected to The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com