Lens structure made of materials with different refractive indexes

A refractive index and lens technology, applied in lenses, instruments, optics, etc., can solve problems such as cumbersome steps, reduce imaging dark areas, increase the scope of lighting, and solve astigmatism and aberrations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Relevant detailed description and technical contents of the present invention are as follows with regard to coordinating accompanying drawings now:

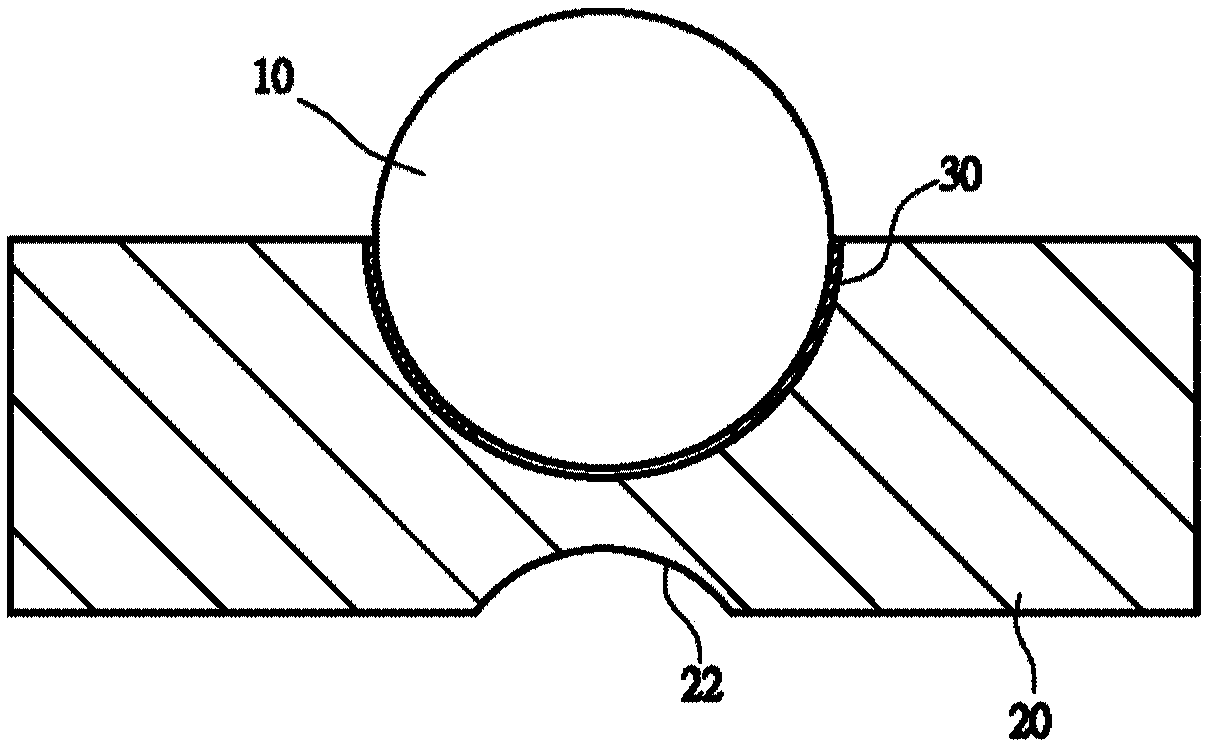

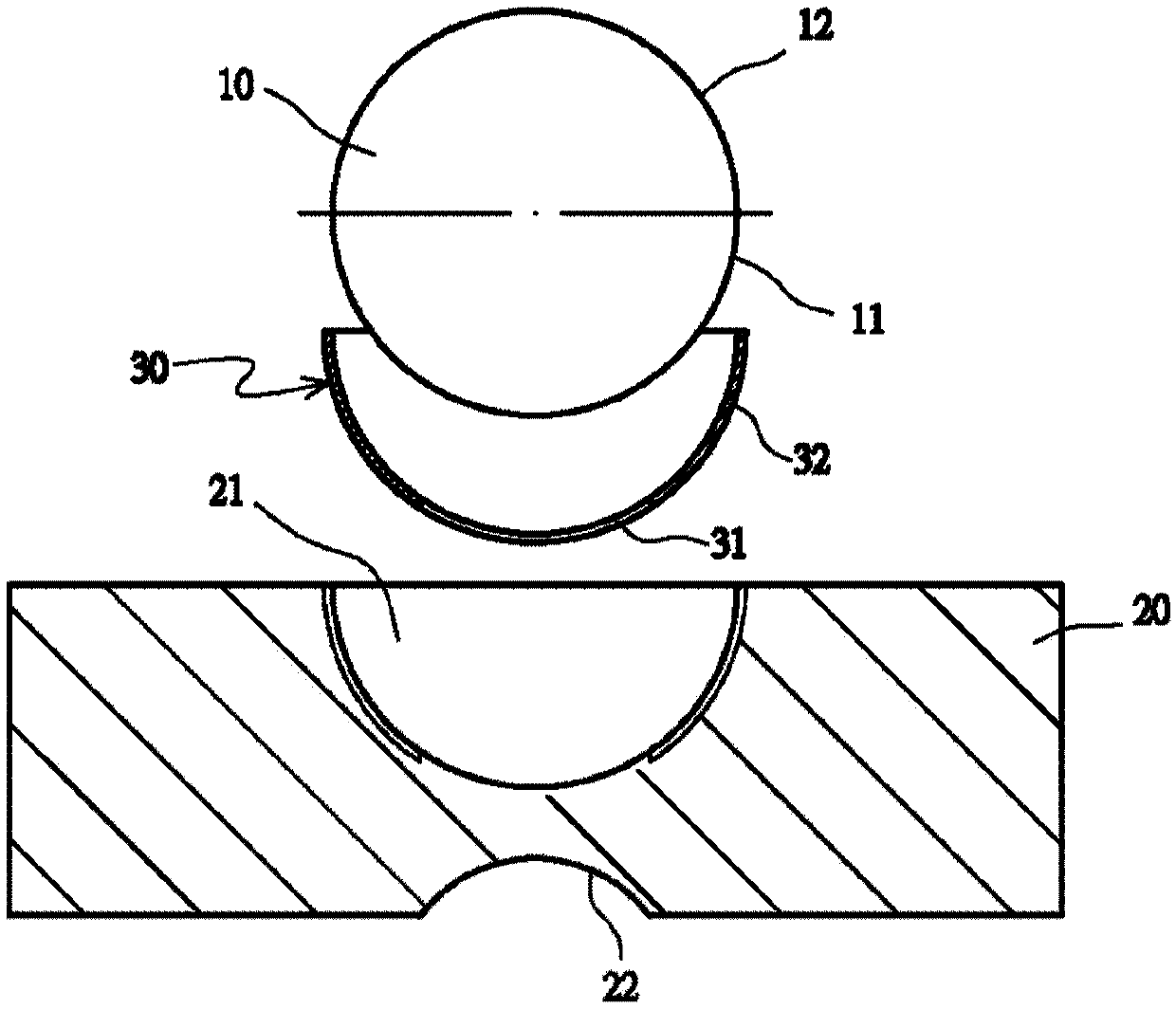

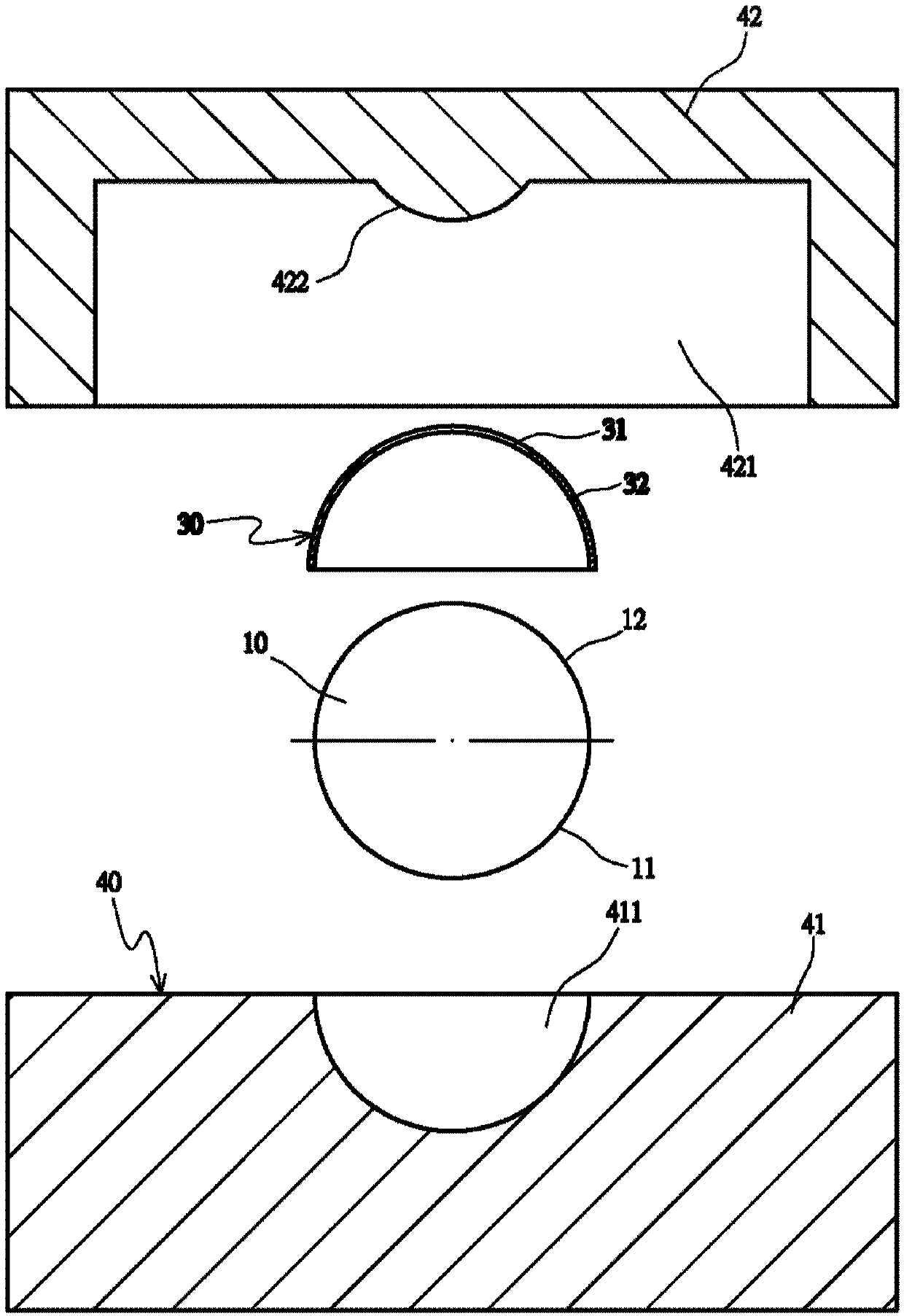

[0066] like figure 1 and figure 2 Shown is the first embodiment of the present invention. The present invention is a lens structure made of materials with different refractive indices. The lens structure includes a sphere 10 , a first lens 20 and a spacer layer 30 .

[0067] Specifically, the sphere 10 has a first part 11 and a second part 12 integrally connected with the first part 11, the first part 11 and the second part 12 form a spherical shape and have light transmission, And the sphere 10 has a first refractive index. The first lens 20 is formed on one side of the sphere 10, and the first lens 20 is adjacent to the first part 11 of the sphere to form a first fitting groove 21 for the first part 11 to be embedded. , make the first part 11 embedded in the first fitting groove 21, make the second part 12 of the sph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com