A method for one-time production of colored TPU foamed particles using twin-screw equipment

A foaming particle and twin-screw technology, which is applied in the field of foaming material preparation, can solve the problems of high cost, complicated foaming process, and changes in the physical properties of TPU resin, and achieve the effects of reducing changes in physical properties, simplifying the foaming process, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

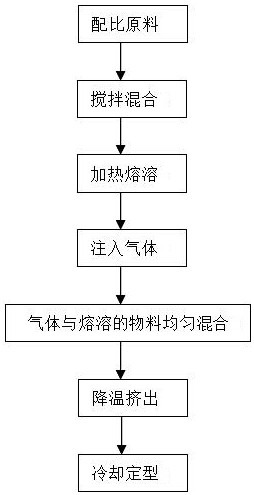

[0018] The invention discloses a method for making colored TPU foamed particles at one time by using twin-screw equipment, which includes the following steps:

[0019] (1) Proportioning raw materials: Take 100 parts by weight of TPU resin, 2-5 parts by weight of POE-g-MAH and 1-3 parts by weight of organic pigment; in this embodiment, the organic pigment is a fluorescent pigment, which can be Various colors are not limited.

[0020] (2) Stirring and mixing: Put the above-mentioned raw materials into a blender and stir and mix evenly.

[0021] (3) Heating and melting: Put the mixed material into the twin-screw hopper and adjust the temperature of the first to fifth zones of the twin-screw to be the melting section, so that the material passes through the first to fifth zones to complete the melting process.

[0022] (4) Injecting gas: Set reverse-rotating threads in the sixth zone of the twin-screw, and inject nitrogen or carbon dioxide gas here.

[0023] (5) Uniform mixing o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com