A kind of electroslag remelting slag capable of retaining sulfur and a method for electroslag remelting

A technology of electroslag remelting and electric current, applied in the field of electroslag remelting, can solve the problem of high desulfurization rate, achieve the effect of reducing slag basicity, strong versatility and applicability, and avoid excessive desulfurization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

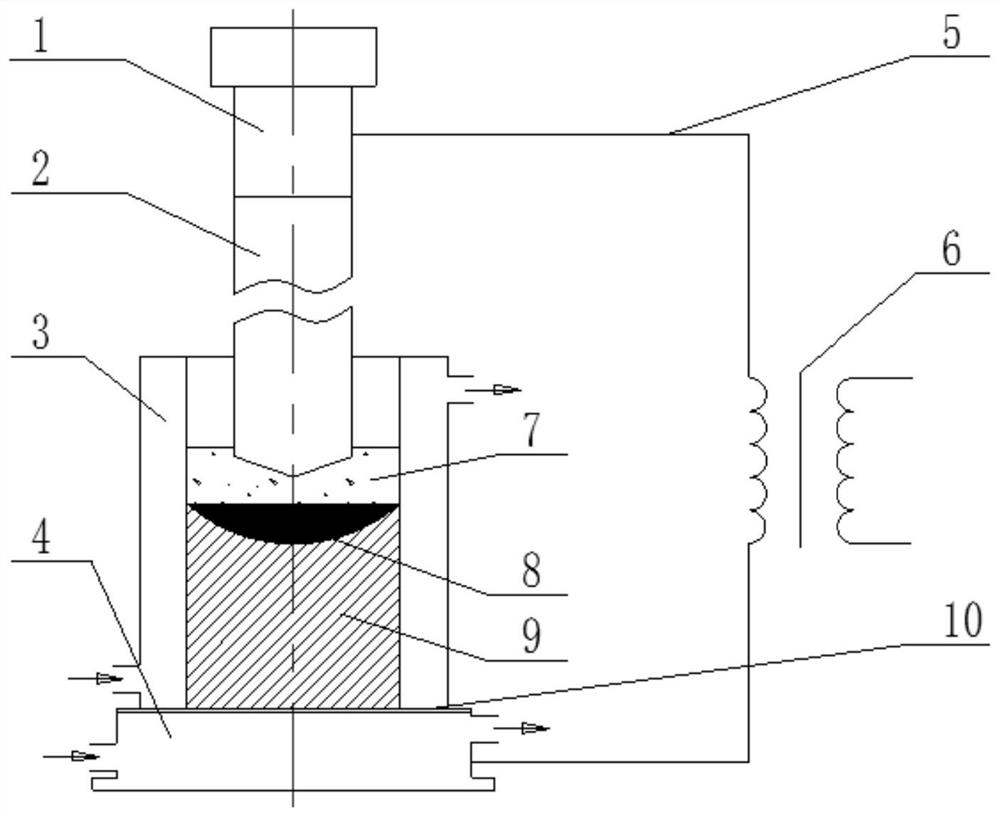

[0027] Example 1: Combining figure 1 Illustrate present embodiment, present embodiment electroslag remelting slag is by the Al of 5 parts by the CaO of 5 parts, 30 parts by weight 2 o 3 , 65 parts of CaF 2 and 3 parts of SiO 2 Prepared.

[0028] Utilize above-mentioned electroslag remelting slag to complete a kind of electroslag remelting method that can keep sulfur, carry out according to the following steps:

[0029] Step 1. Raw material selection:

[0030] Parts by weight: CaO: 5 parts, Al 2 o 3 : 30 parts, CaF 2 : 65 parts and SiO 2 : 3 parts weigh metallurgical lime block, white corundum powder, fluorite powder and quartz powder as raw materials; wherein metallurgical lime block provides CaO, white corundum powder provides Al 2 o 3 , fluorite powder provides CaF 2 , quartz powder provides SiO 2 ;

[0031] Step two, raw material drying:

[0032] Place the raw material weighed in step 1 in a furnace at 900°C for 3 hours;

[0033] Step three, slag making:

[...

Embodiment 2

[0044] The difference between this embodiment and embodiment 1 is that the consumable electrode in this embodiment is 309L austenitic stainless steel with a sulfur content of 0.01-0.015%; Table 2 is the composition comparison of 309L before and after remelting in Example 2.

[0045] As can be seen from Table 1 and Table 2, the rate of recovery of sulfur is relatively stable, being respectively 65.4% and 66.7%, and other elements change little; the deoxidation effect is good, and the deoxidation rate is respectively 47.6% and 57.6%, illustrating that the method of this embodiment has relatively Good inclusion removal effect.

[0046] Table 1

[0047] C Si mn S P Cr Ni Mo O Before remelting 0.010 0.47 1.74 0.013 0.007 19.90 10.51 0.02 0.021 After remelting 0.009 0.38 1.64 0.0085 0.007 19.86 10.50 0.02 0.011 Recovery rate 65.4% 52.4%

[0048] Table 2

[0049] C Si mn S P Cr Ni Mo ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com