Steel-concrete combined structure conical cast iron bolt connecting piece

A technology of concrete and connectors, which is applied to bridge parts, bridge materials, bridges, etc., can solve the problems of performance impact of bolt shear parts, large wet operation, and low initial stiffness of bolt connectors, so as to reduce time and cost, reduce Quantity, effect of increasing bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

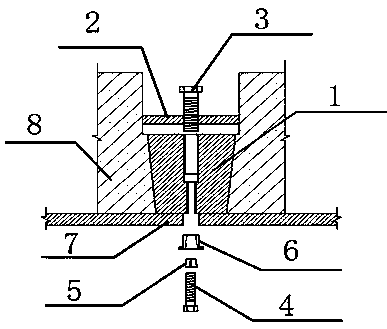

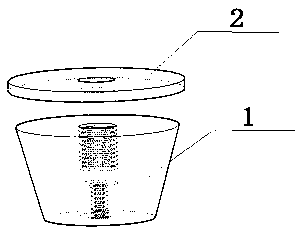

[0025] In order to explore the mechanical properties of TIBC, referring to the European EC-4 specification, a set of push-out test pieces was made, and the overall size of the test pieces was rolled out. The nominal diameter of the lower high-strength bolts of the test piece is 12 mm, and they are 8.8-grade high-strength bolts. The steel beams for the test pieces are all made of Q235 hot-rolled H-shaped steel with a specification of HM 250×250×9×14. The flanges of the steel beams need to have holes matching the size of the lower high-strength bolts. The concrete used for the specimens is the same batch of concrete, the concrete strength is C45, and the concrete is equipped with two-way HPB235 grade stirrups.

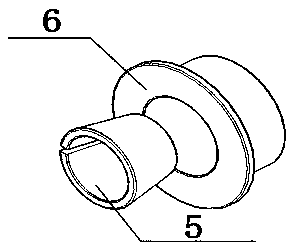

[0026] The inner and outer taper sleeves fixed by bolts are all made of 45# steel, and their dimensions must correspond to those of the lower high-strength bolts. The conical cast iron block is a conical cast iron block with a certain taper on the outside. The cast iron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com