High level filling mining method of fully mechanized caving in thick coal seam under railway in coal mine

A thick coal seam and strip technology, applied in the direction of filling, ground mining, mining equipment, etc., to achieve the effect of increasing economic benefits, improving resource recovery rate, and speeding up mining progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

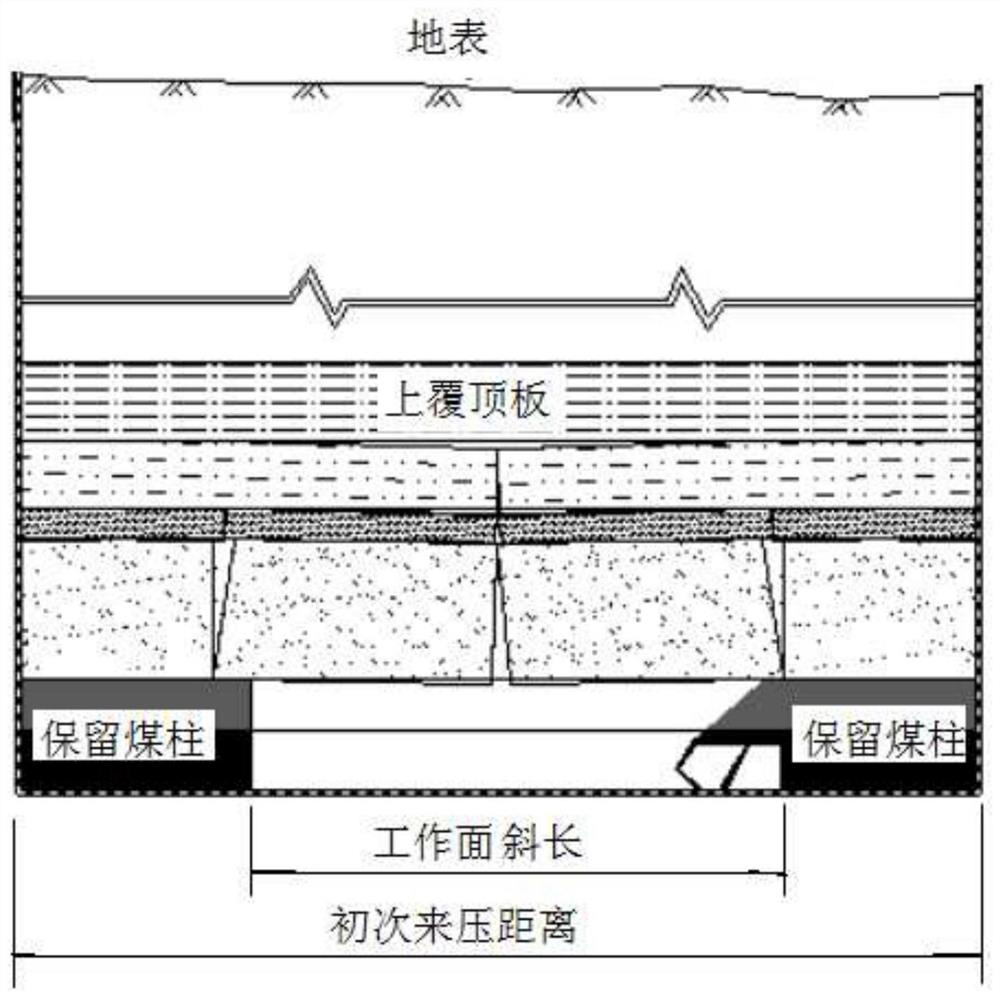

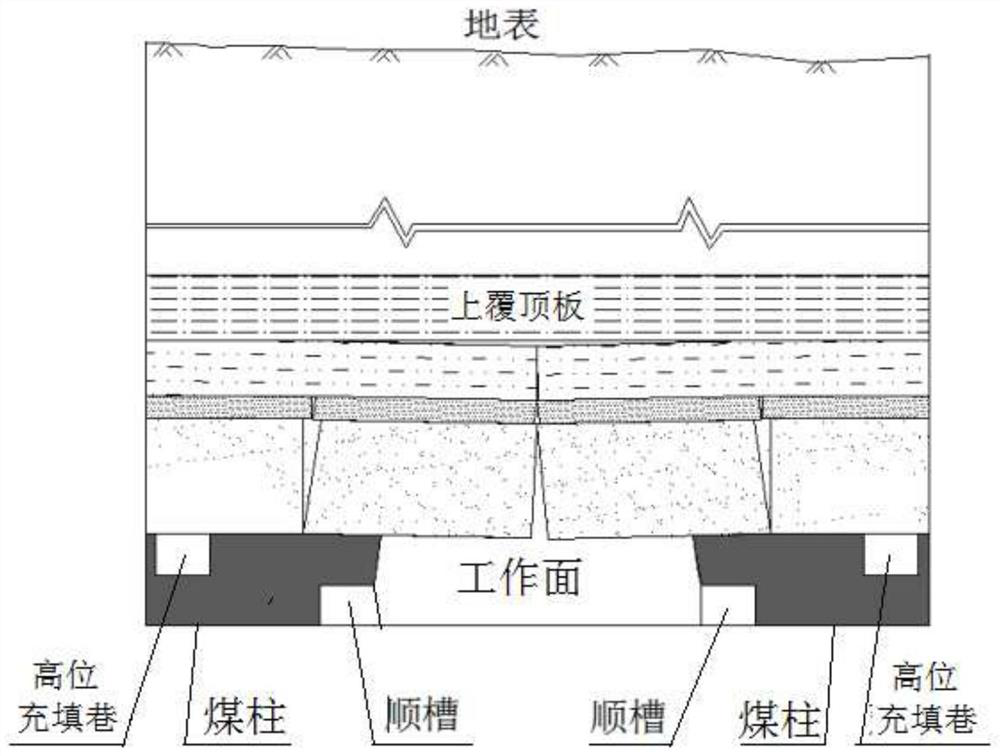

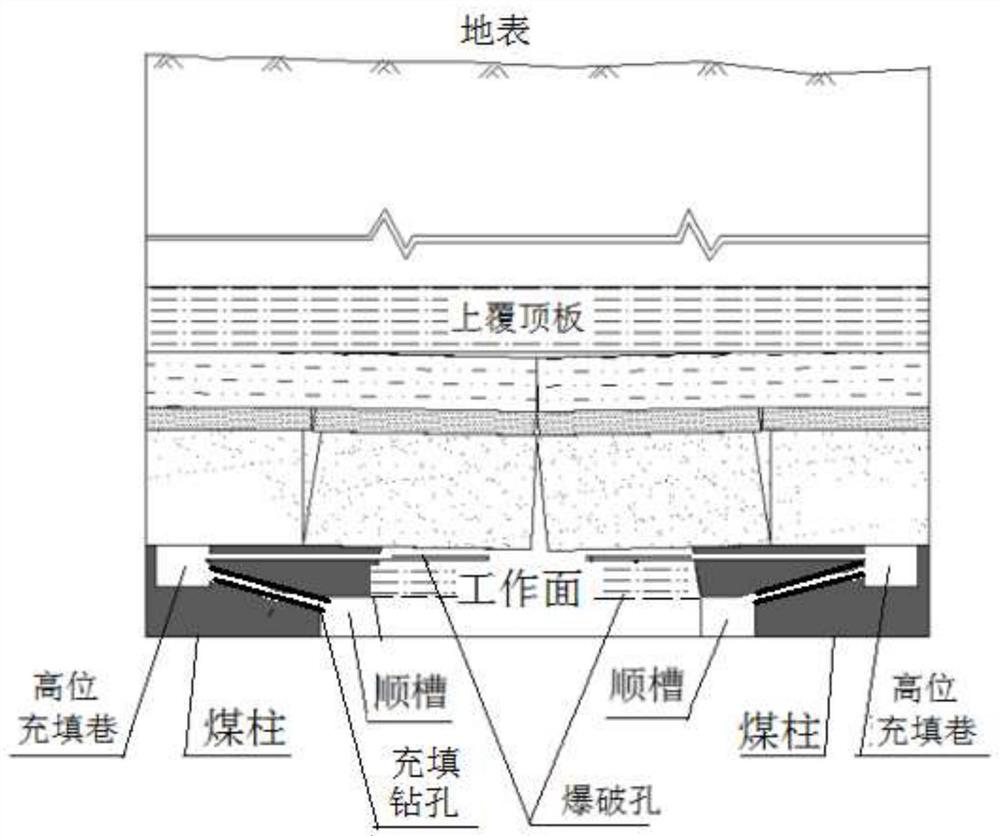

[0019] Such as Figure 1-4 As shown, a coal mine railway under the thick coal seam strip fully mechanized caving high-level filling mining method adopts the strip-type working face mining method, and adopts the comprehensive mechanized top-coal caving process for mining, and also includes the following process steps;

[0020] 1. Before arranging strip work, collect the initial pressing distance of the fully mechanized caving working face near the stope, and use half of the smallest initial pressing distance collected as the inclination length of the strip working face to ensure that the working face will go up after mining The roof covering can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com