A kind of anti-tempering automatic slag discharge boiler

An automatic slagging and anti-backfire technology, applied in lighting and heating equipment, etc., can solve problems such as incomplete combustion, poor safety performance of boilers, pollution, etc., and achieve accelerated heating efficiency, improved fuel utilization, and uniform contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

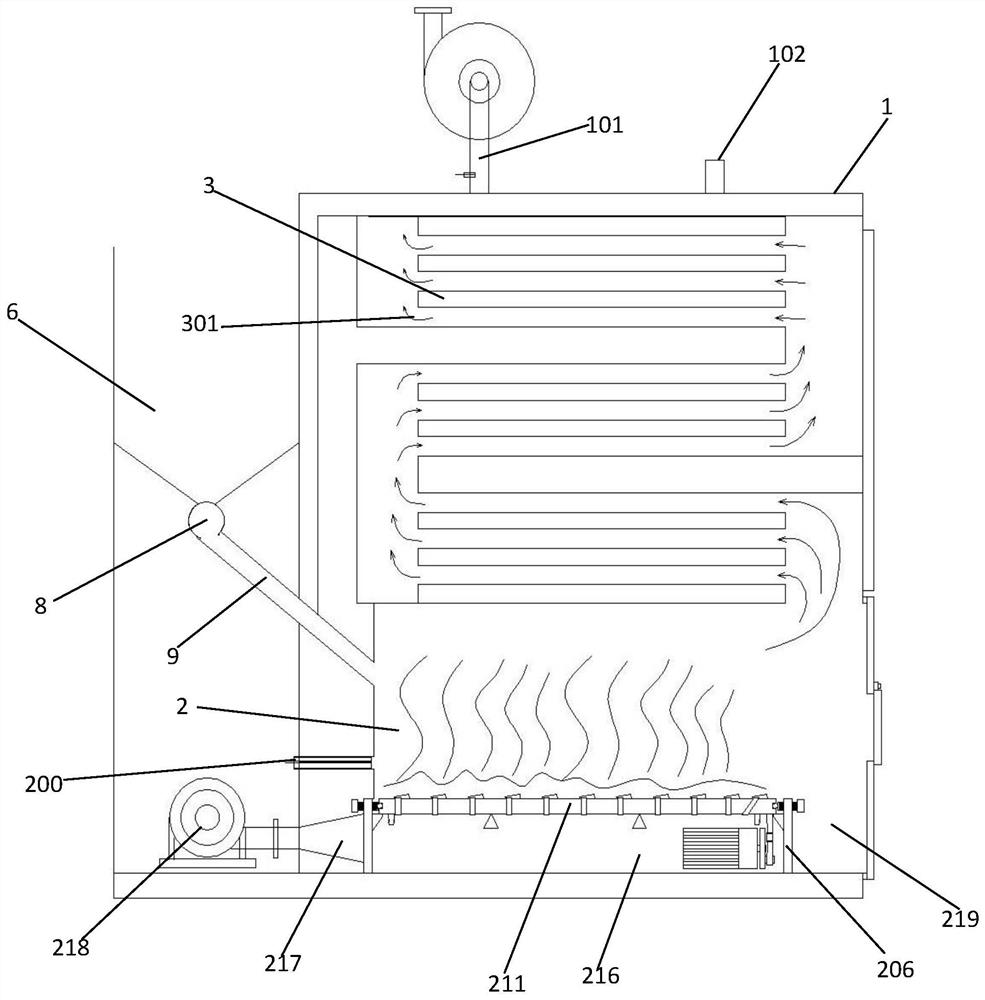

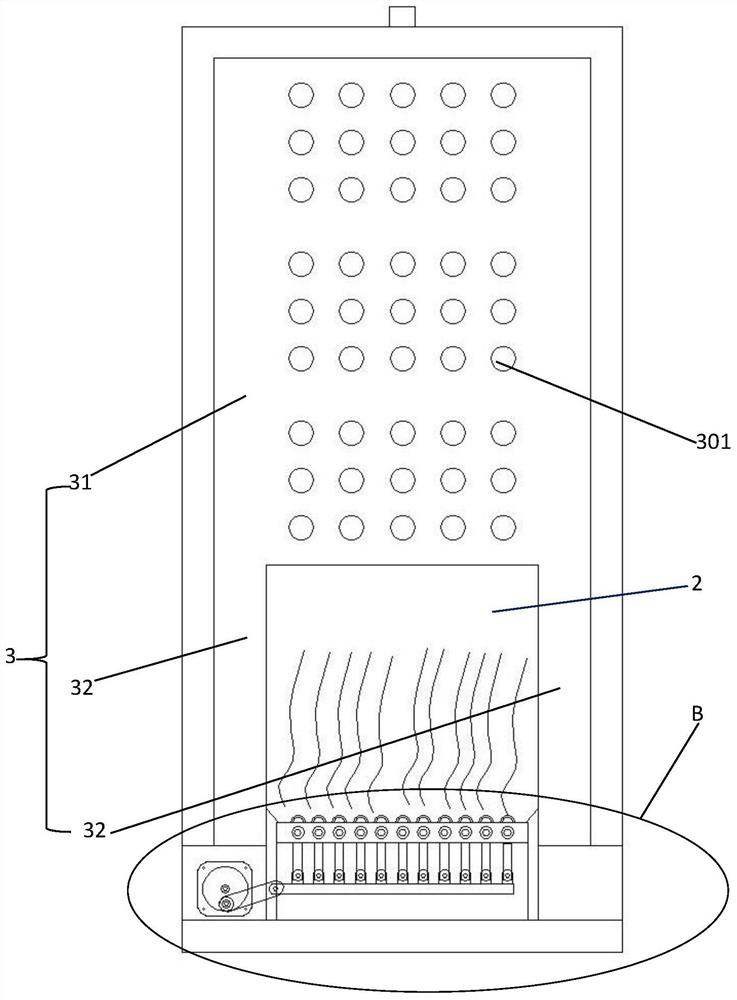

[0121] The present invention drives the inner casing 5 to rotate in the outer casing 4 through the feeding motor 7, and in the process of rotation, the fuel switching port 501 is switched correspondingly to the feed port and the discharge port 43 respectively, that is, when the fuel switching port 501 is connected to the When the feed port corresponds to receive the fuel in the fuel tank, and as the inner sleeve 5 rotates in the outer sleeve 4, when the fuel conversion port 501 corresponds to the discharge port 43, the fuel entering the inner sleeve 5 passes through the outlet The port 43 enters the feed pipe 102, the feed pipe 102 delivers the fuel to the grate assembly 211 in the combustion chamber 2, and ignites the fuel through the igniter 200;

[0122] During the combustion process of the fuel on the grate assembly 211, the air chamber 216 stores wind through the vent and then introduces the wind to the grate assembly 211 through the air guide hole 201, thereby acceleratin...

Embodiment 2

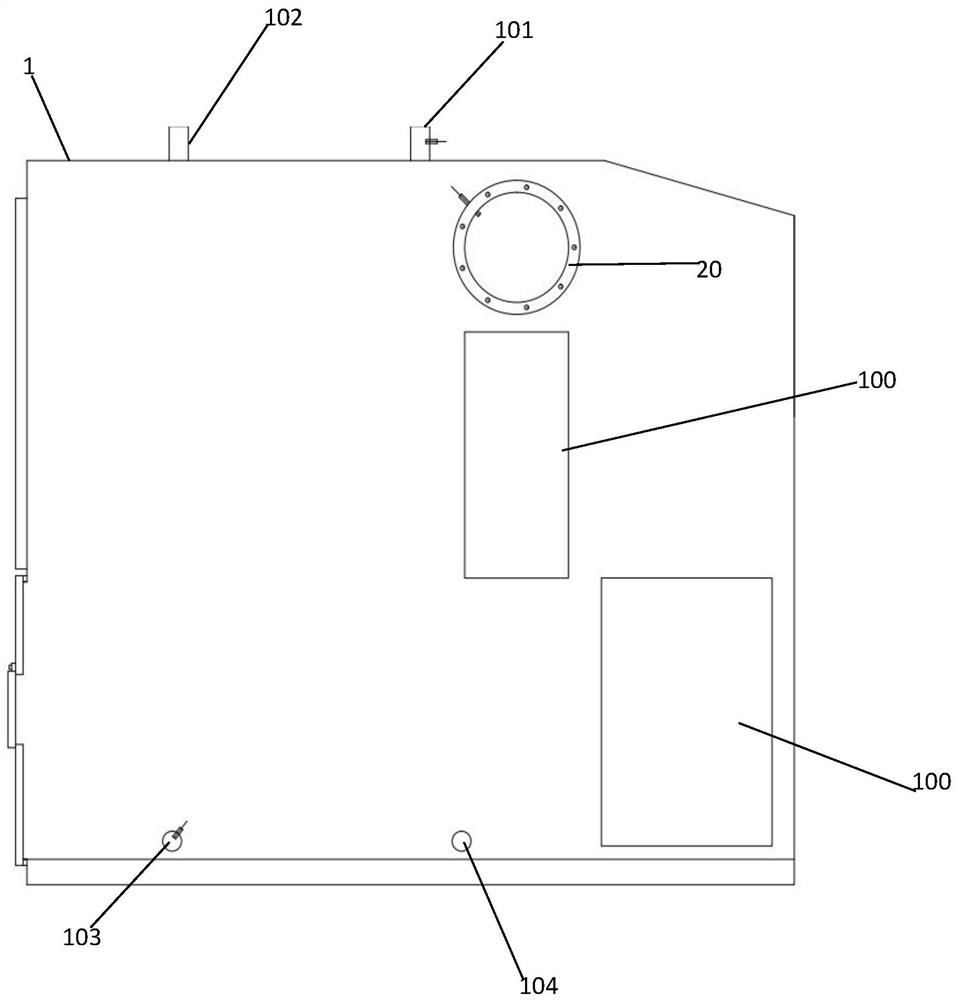

[0129] On the basis of Embodiment 1, a water outlet temperature sensor is provided on the outlet 101, a flue gas temperature sensor is provided on the connecting flange 20 of the smoke exhaust machine, a water inlet temperature sensor is provided on the water inlet 103, and the water temperature sensor, smoke The gas temperature sensor, the water inlet temperature sensor, the igniter 200 and the grate drive reduction motor 212 are all connected to PLC, so that the PLC controls the speed of the fire grate drive reduction motor 212 and the speed of the feed motor 7 according to various temperature information received. The rotation speed and the working state of the igniter 200 are controlled, so as to control the wind speed and air volume in the air chamber 216 and to control the feeding amount of the fuel, thereby controlling the combustion of the fuel.

[0130] Each embodiment in this specification is described in a progressive manner, each embodiment focuses on the difference...

Embodiment 3

[0132] On the basis of Embodiment 1 and Embodiment 2, the two ends of the fire grate air pipe 204 are closed, and the two ends of the pipe wall of the fire grate air pipe 204 are respectively connected with a cold water inlet pipe 294 and a hot water outlet pipe 284. Import cold water into the grate air duct 204 through the cold water introduction pipe 294 to realize the cooling effect on the fire grate air duct 204, avoid the problem that the fire grate air duct 204 is easily damaged under long-term high temperature conditions, and pass the hot water outlet pipe 284 to The hot water formed after the heat exchange between the cold water and the grate air duct 204 is exported through the hot water outlet pipe 284 to realize the circulation of the cold water in the fire grate air duct 204 and realize the continuous cooling effect on the fire grate air duct 204 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com