A chamfer processing device for metal sheet metal parts

A processing device and a technology for sheet metal parts, applied in the field of sheet metal processing, can solve problems such as affecting the construction progress, large volume of the bending machine, and troublesome operation, and achieve the effect of ensuring construction quality, small volume and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

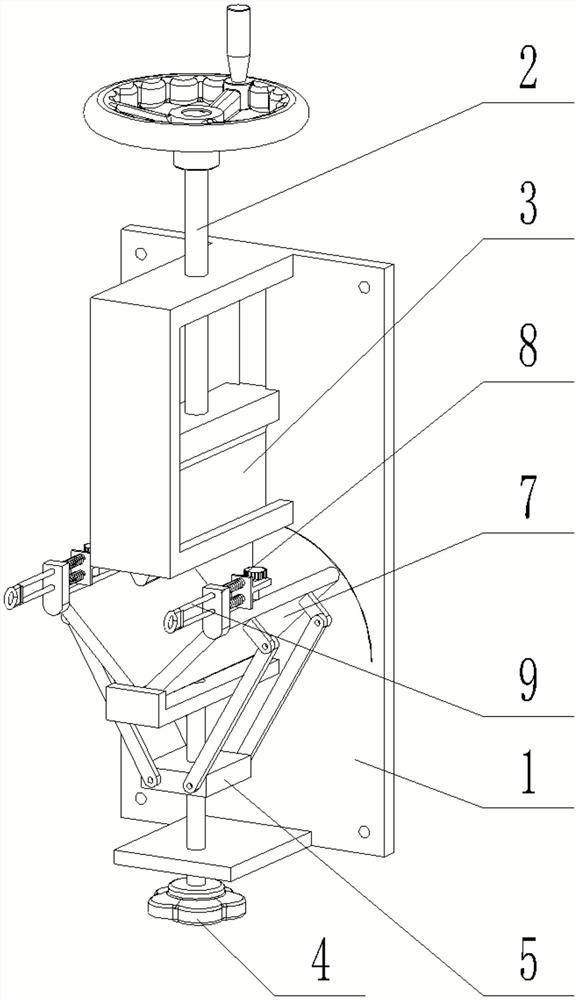

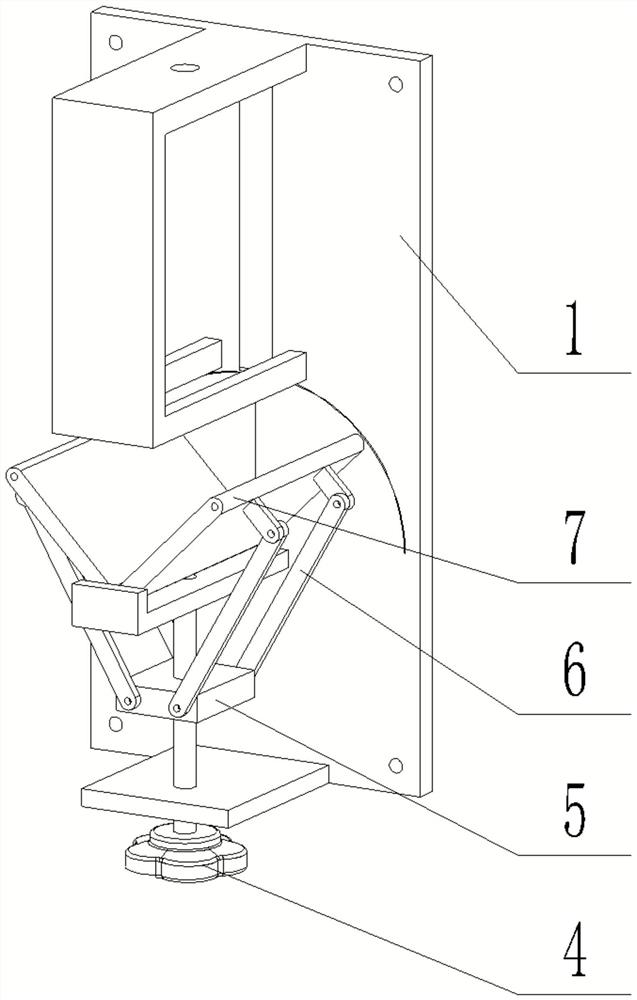

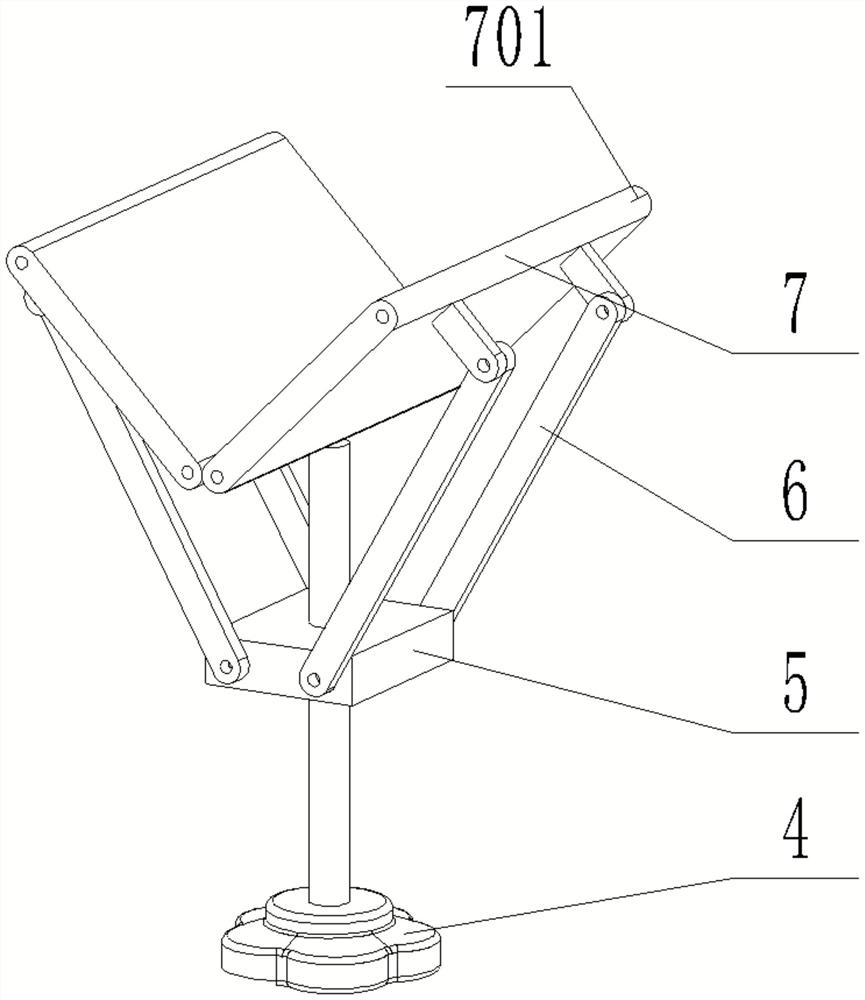

[0031] as attached figure 1 to attach Figure 8 Shown:

[0032] The invention provides a knuckle treatment device for metal sheet metal parts, which includes: a base 1, a dovetail groove 101, an angle scale 102, a central marking line 103, a knuckle handle 2, a knuckle die head 3, a sliding block 301, and an angle adjustment handle 4. Adjust the driving block 5, the support link 6, the fixed bottom mold 7, the angle reference line 701, the swing block 8, the positioning block 9, the sliding circular rail 901 and the positioning screw 902; the top threaded connection of the front end of the base 1 There is a set of knuckle handles 2; a set of knuckle dies 3 is slidably connected to the front end surface of the base 1; the knuckle dies 3 are axially connected to the knuckle handles 2; There is a group of angle adjustment handles 4 connected to each other; the angle adjustment handle 4 is threadedly connected with a group of adjustment drive blocks 5; The connecting rod 6; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com