Graphene production and processing tank

A technology of graphene and processing towers, which is applied in the direction of dissolution, mixers, chemical instruments and methods, etc., can solve the problems of raw material waste, time-consuming, and decreased material utilization, and achieve the effect of improving the liquid separation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

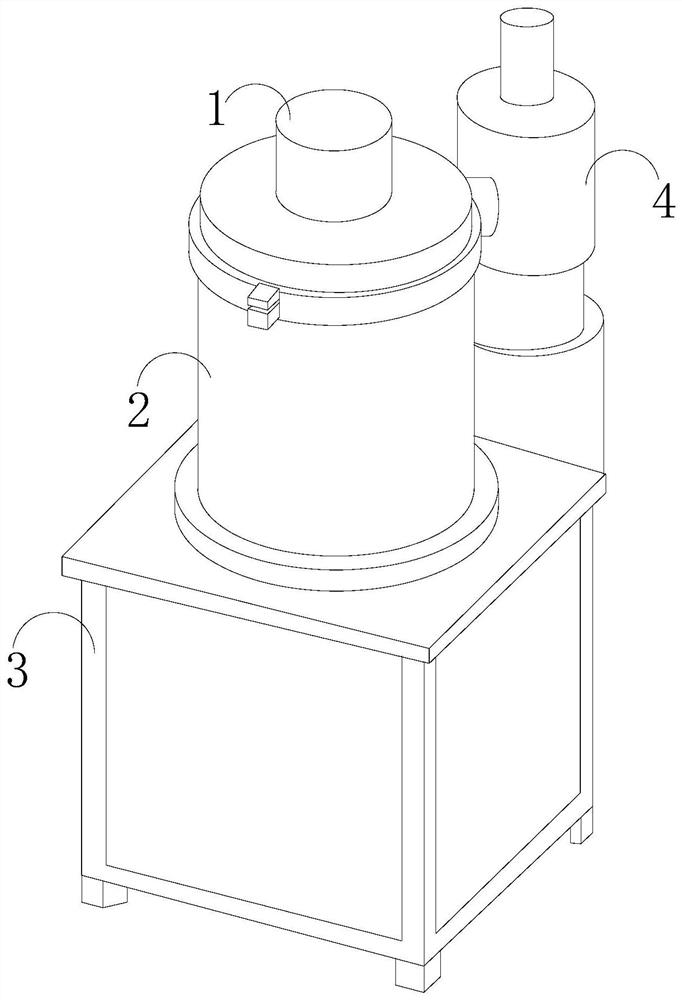

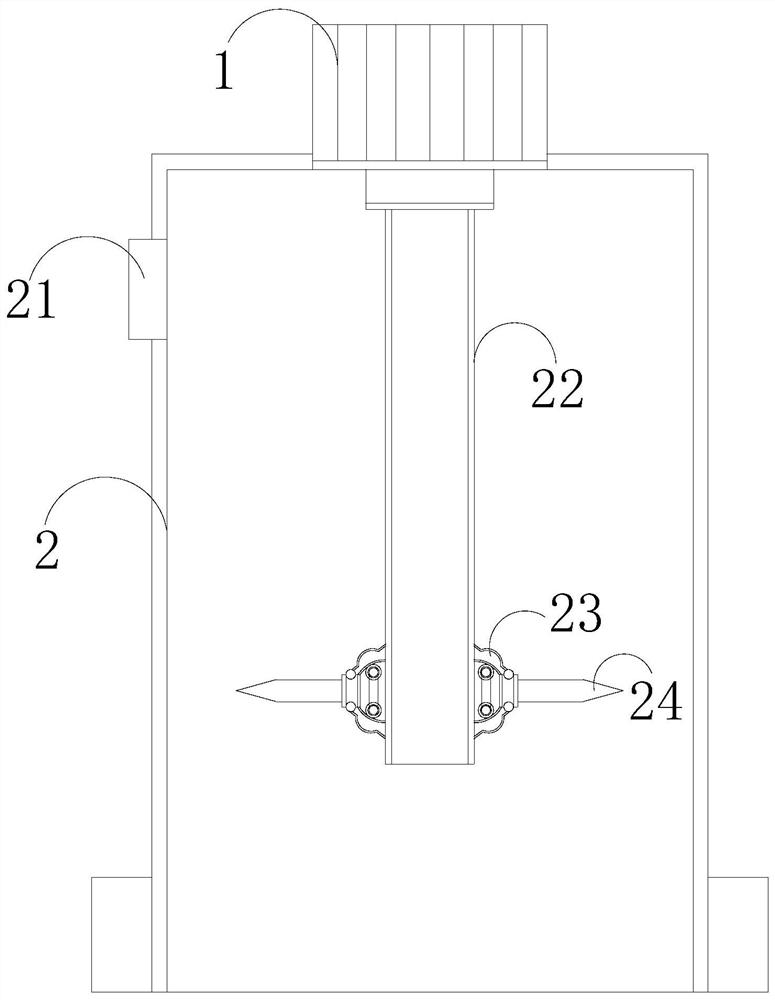

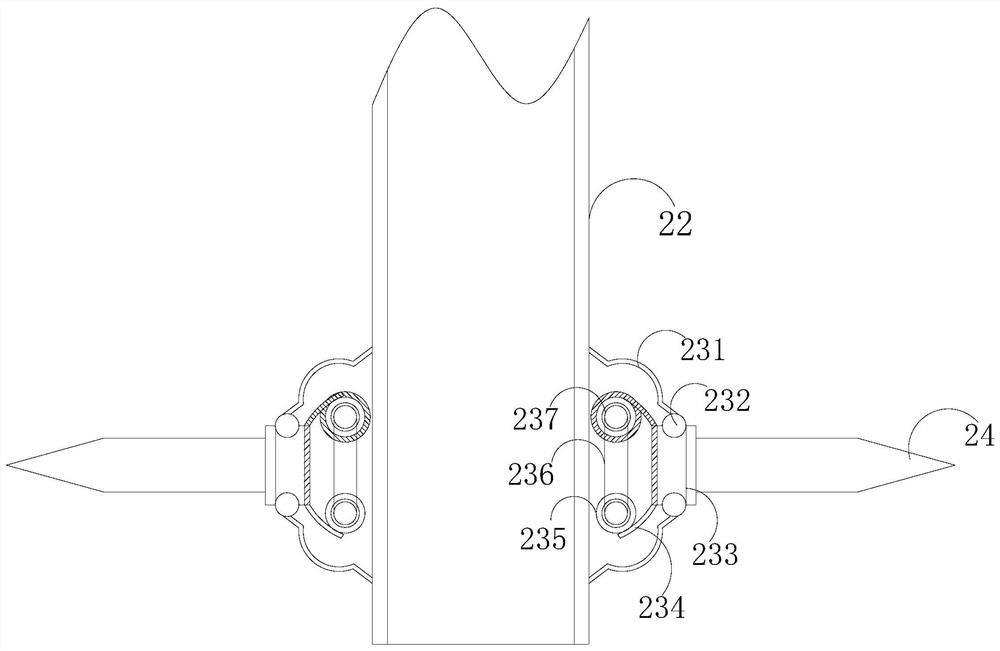

[0026] Such as Figure 1-Figure 6 As shown, the present invention provides a kind of graphene production processing tank, and its structure comprises motor 1, mixing tank body 2, cabinet 3, processing tower 4, described mixing tank body 2 is equipped with motor 1, and described mixing tank body 2 Welded on the cabinet 3, the processing tower 4 communicates with the mixing tank body 2, and the inside of the mixing tank body 2 is provided with an addition port 21, a stirring shaft 22, a blade holder 23, and a stirring blade 24, and the stirring shaft 22 Mechanically connected with the motor 1, the stirring blade 24 is connected on the stirring shaft 22 through the blade holder 23, and the blade holder 23 is composed of a connecting shield 231, a fixed port 232, a mounting seat 233, a transmission chain 234, a first transmission The gear 235, the connecting rod 236, and the second transmission gear 237 are composed of the mounting seat 233 and the stirring blade 24 welded togethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com