Method of manufacturing hollow octet truss structure through 3D printing

A truss structure and 3D printing technology, applied in the field of truss structure, can solve the problems of low deformation ability and low porosity, and achieve the effect of material saving, high porosity and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

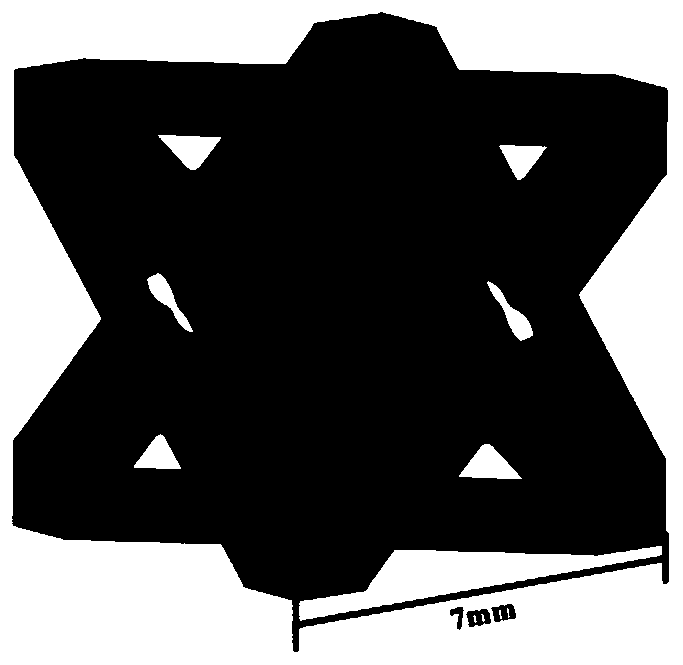

[0032] The hollow octave truss cubic structure models of different sizes made by the invention. figure 1 The process of making the hollow octave truss structure model is as follows: first use the drawing software to draw a solid cube with a design size of 7mm, and then remove and convert the cube to obtain a solid rod octave truss structure with the design size. The rods of the eight-couple truss structure model are treated as solid conversion shells, and the wall thickness is set to 0.15mm. In the above operations, not all solid rods are converted into shells, and the rods on the cube surface remain solid, which can ensure that the model can bear more loads and achieve further weight reduction.

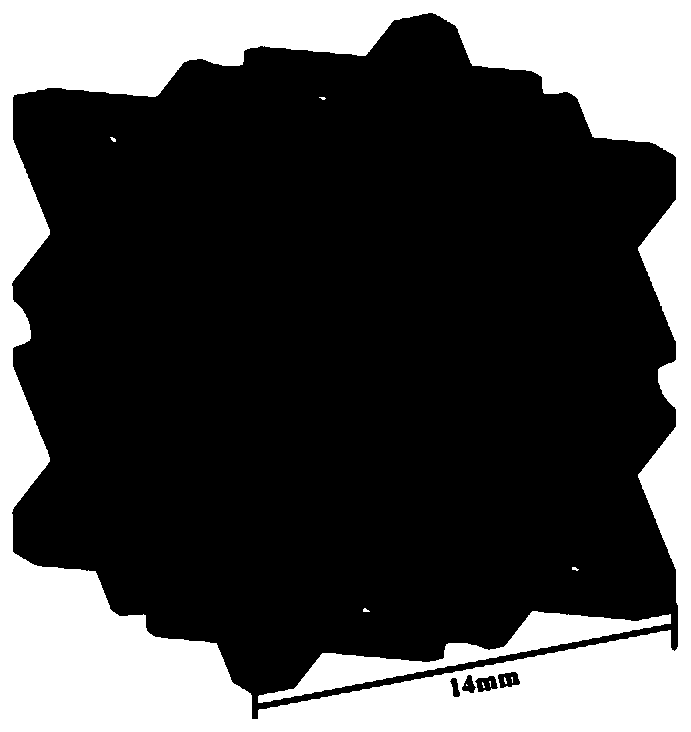

[0033] Similarly, figure 2 As shown in the hollow octagon truss structure, first use the drawing software to draw a solid cube with a design size of 7 mm, and then remove and convert the cube to obtain a solid rod octagon truss structure with a design size. For the solid rod eight ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com