Strip longitudinal and horizontal paving device for thermoplastic continuous fiber wide-width one-way strip and application thereof

A continuous fiber, unidirectional tape technology is applied in the field of vertical and horizontal tape laying equipment for thermoplastic continuous fiber wide unidirectional tapes, to achieve the effects of improving strength and appearance, increasing precision, and improving equipment production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

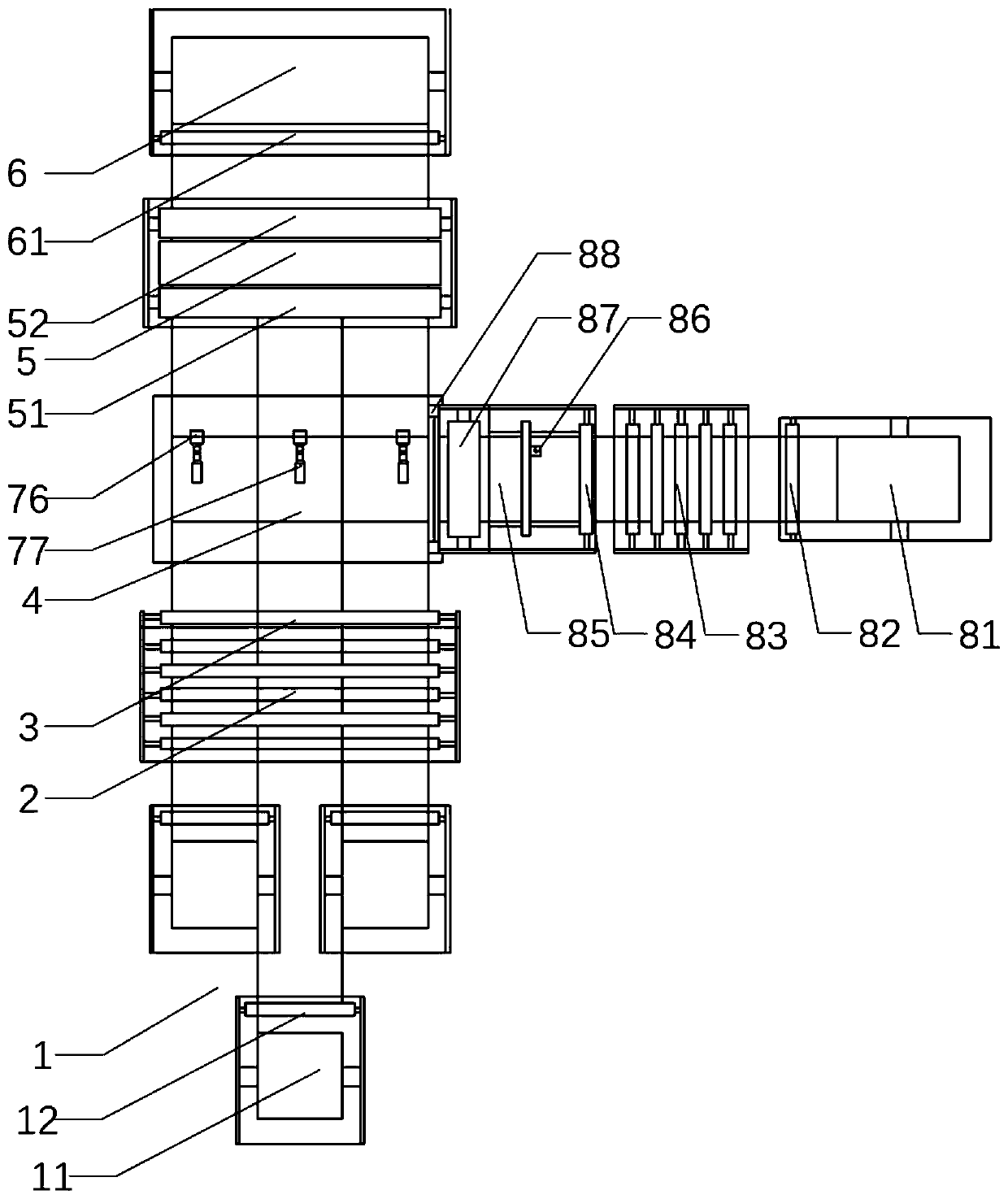

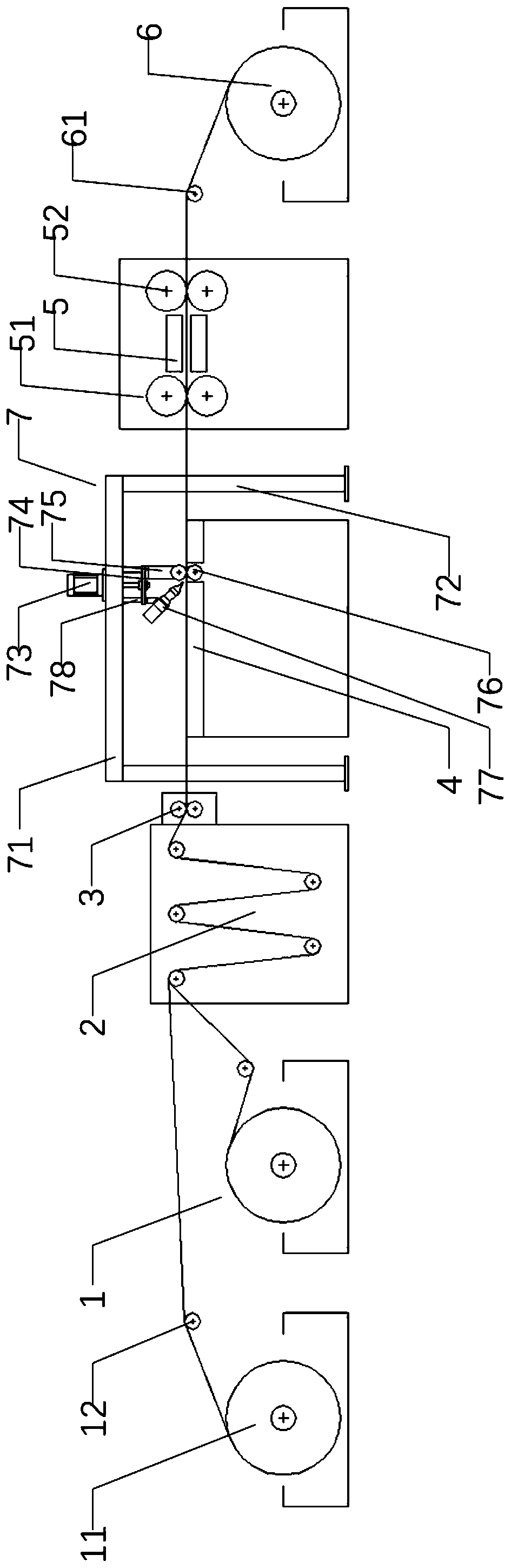

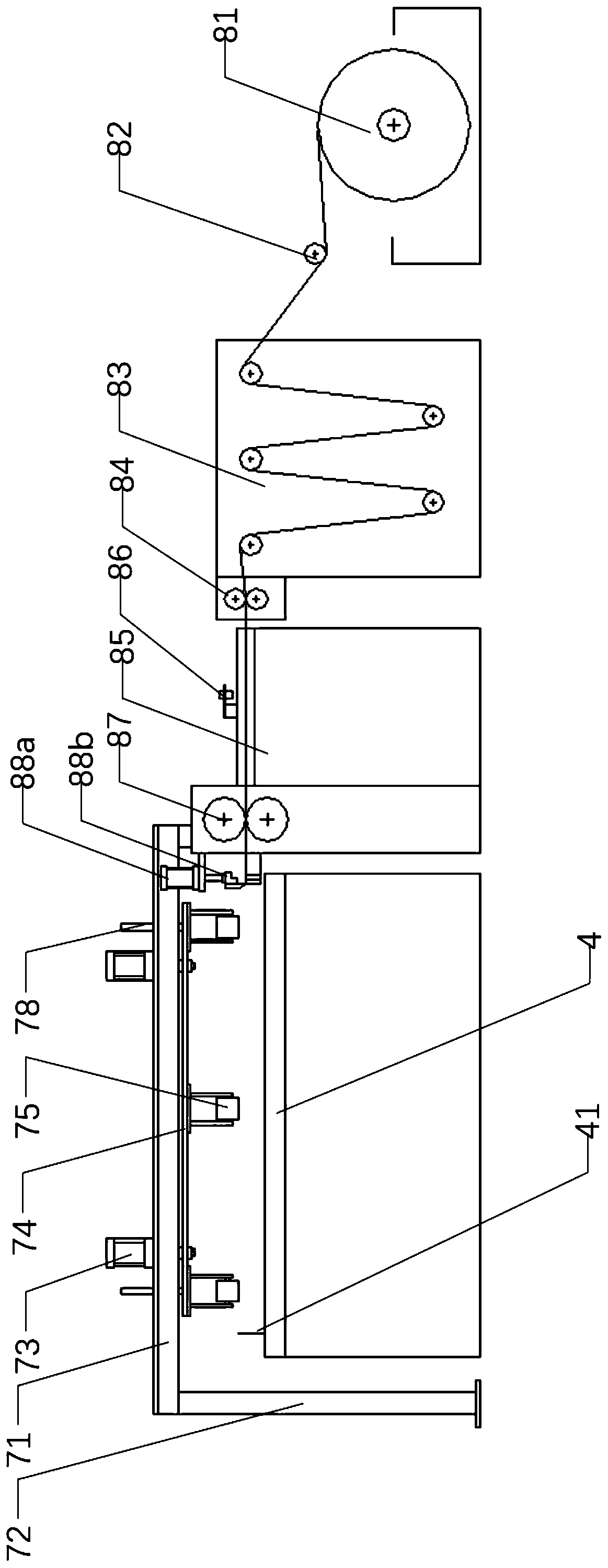

[0042] The present invention will be further described below in conjunction with the accompanying drawings.

[0043] see Figure 1 to Figure 3 , the present invention is a kind of longitudinal and horizontal tape laying equipment for thermoplastic continuous fiber wide unidirectional tape, comprising:

[0044] A longitudinal unwinding unit 1 consisting of three longitudinal unwinders 11 and first guide rollers 12 corresponding to each longitudinal unwinder 11; and a longitudinal sheet unwound along the longitudinal unwinder 1 The direction of travel is distributed sequentially:

[0045] A vertical storage rack 2 composed of five storage rollers in a W-shaped distribution;

[0046] A pair of longitudinal storage traction rollers 3 arranged up and down facing each other and installed on the longitudinal storage rack 2;

[0047] A stacking platform 4, the left side of its surface is provided with a positioning device 41;

[0048] A pair of infrared heating devices 5 arranged ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com