An unpacking device for a complete set of switch test equipment with primary and secondary fusion

A switch testing and packaging device technology, applied in packaging, transportation and packaging, unsealing of objects, etc., can solve the problems of time-consuming and labor-intensive, difficult to popularize and use, and achieve the effect of compact structure, easy popularization and use, and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

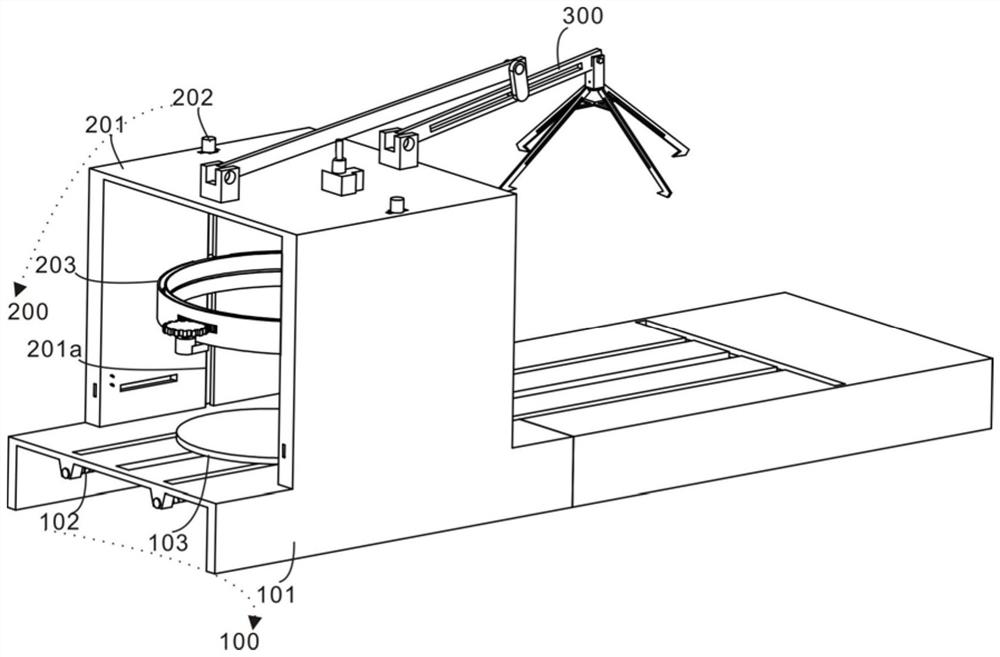

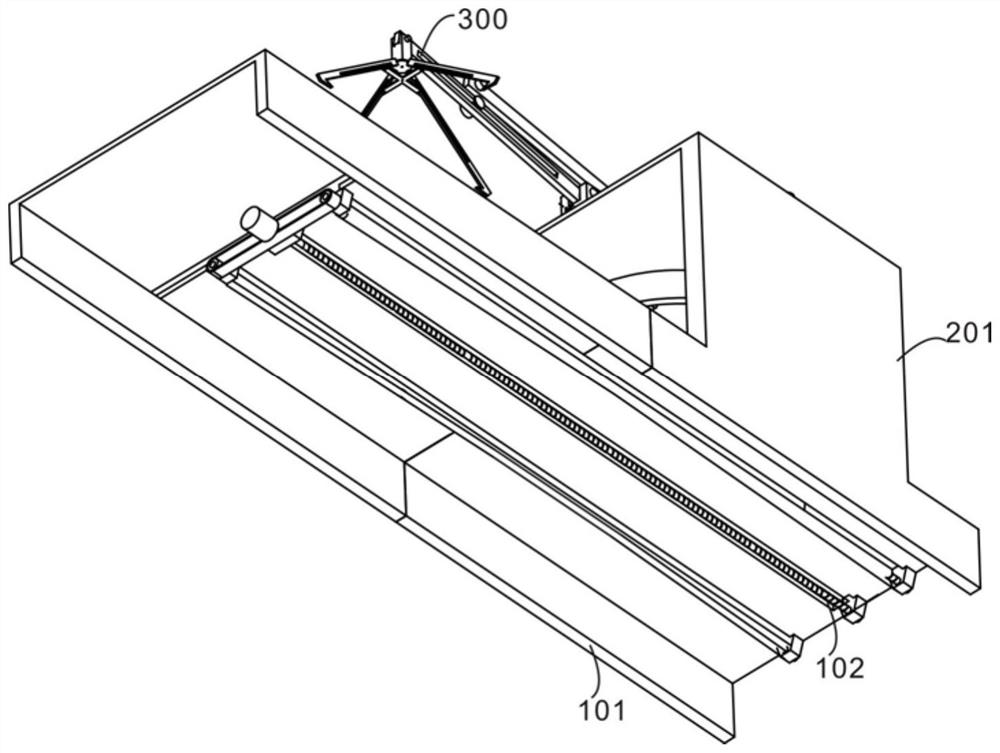

[0038] refer to figure 1 , provides a schematic diagram of the overall structure of an unpacking device for a complete set of switch test equipment for primary and secondary fusion, as shown in figure 1 , an unpacking device for a complete set of primary and secondary fusion switch test equipment includes a conveying unit 100, including a base plate 101, a first drive assembly 102, and a transport tray 103; a segmentation unit 200, arranged on the base plate 101; and, a grabbing unit 300 , connected with the supporting platform 201 of the dividing unit 200 and disposed above the bottom plate 101 .

[0039] Specifically, the main structure of the present invention includes a delivery unit 100, a segmentation unit 200, and a grabbing unit 300. Through the mutual cooperation between the delivery unit 100, the segmentation unit 200, and the grabbing unit 300, the wooden box of the packaging test device can be Carry out mechanized disassembly and opening without manual disassembly...

Embodiment 2

[0043] refer to Figure 1~3 , This embodiment is different from the first embodiment in that: the dividing unit 200 also includes a second driving assembly 202 and a cutting assembly 203, through the mutual cooperation between the set support table 201, the second driving assembly 202 and the cutting assembly 203 , by cutting the wooden box around the way so that the wooden box and the pallet are disassembled. Specifically, the dividing unit 200 also includes a second driving assembly 202 and a cutting assembly 203, the second driving assembly 202 is a driving mechanism for the cutting assembly 203 to move, and its second driving assembly 202 is embedded in the support table 201, and the cutting assembly 203 and The second drive assembly 202 is connected. It should be noted that the support table 201 and the bottom plate 101 form a cutting space. When cutting, the wooden box packaging the testing equipment needs to be transported into the cutting space.

[0044] Further, such...

Embodiment 3

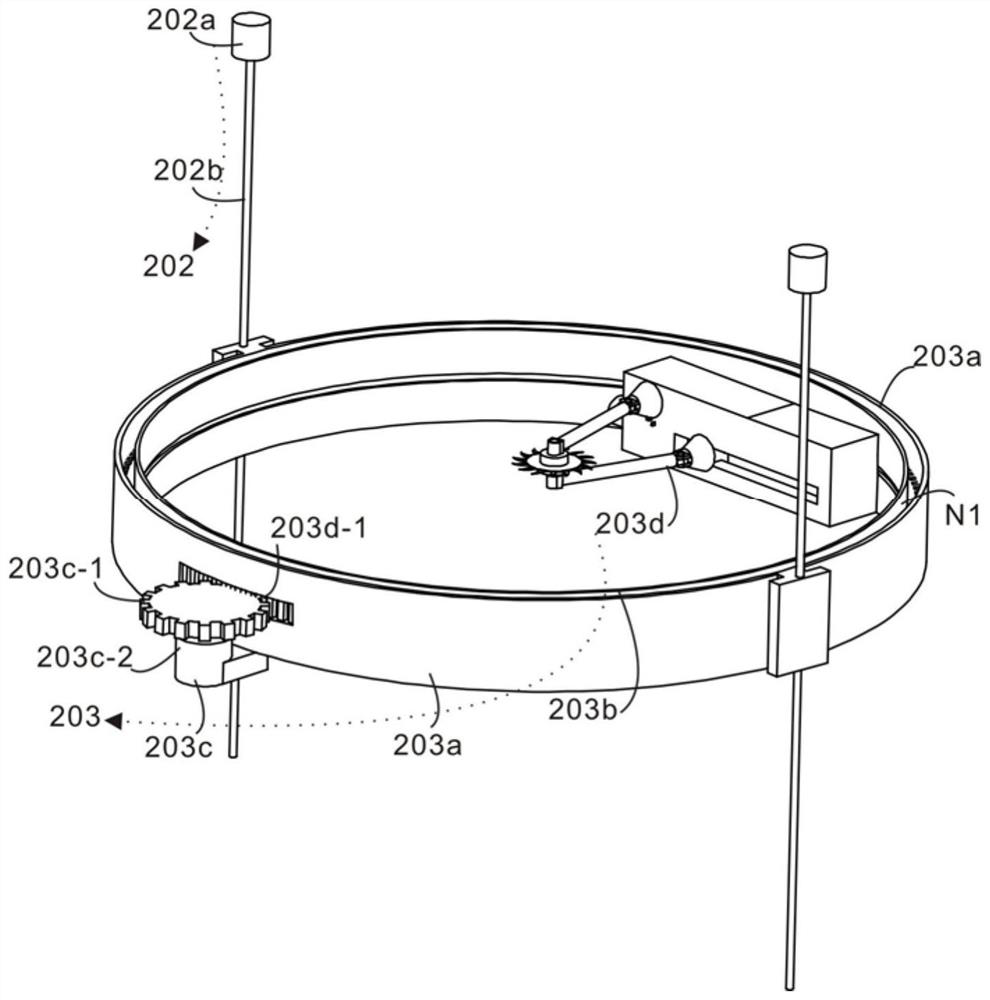

[0048] refer to image 3 and Figure 4 , This embodiment is different from the previous embodiment in that: the cutting assembly 203 also includes a limiting inner ring 203b, a cutting drive member 203c and a cutting part 203d, through the setting of the limiting outer ring 203a, the limiting inner ring 203b, the cutting The mutual cooperation between the driving part 203c and the cutting part 203d can realize the cutting of the wooden box by cutting around. Specifically, the cutting assembly 203 also includes a limiting inner ring 203b, a cutting drive part 203c and a cutting part 203d. The inner side of the position outer ring 203a, the cutting part 203d passes through the limit space N1 formed by the limit inner ring 203b and the limit outer ring 203a to establish a connection with the cutting drive 203c; wherein, the transmission gear 203c-1 of the cut drive 203c The through hole passing through the limiter outer ring 203a is engaged with the one-way toothed plate 203d-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com