Quick blocking grouting nozzle and grouting method for large-depth water leakage of dam

A technology of water leakage and large depth, which is applied in water conservancy projects, sea area projects, buildings, etc., to achieve the effects of excellent waterproof performance, good toughness and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

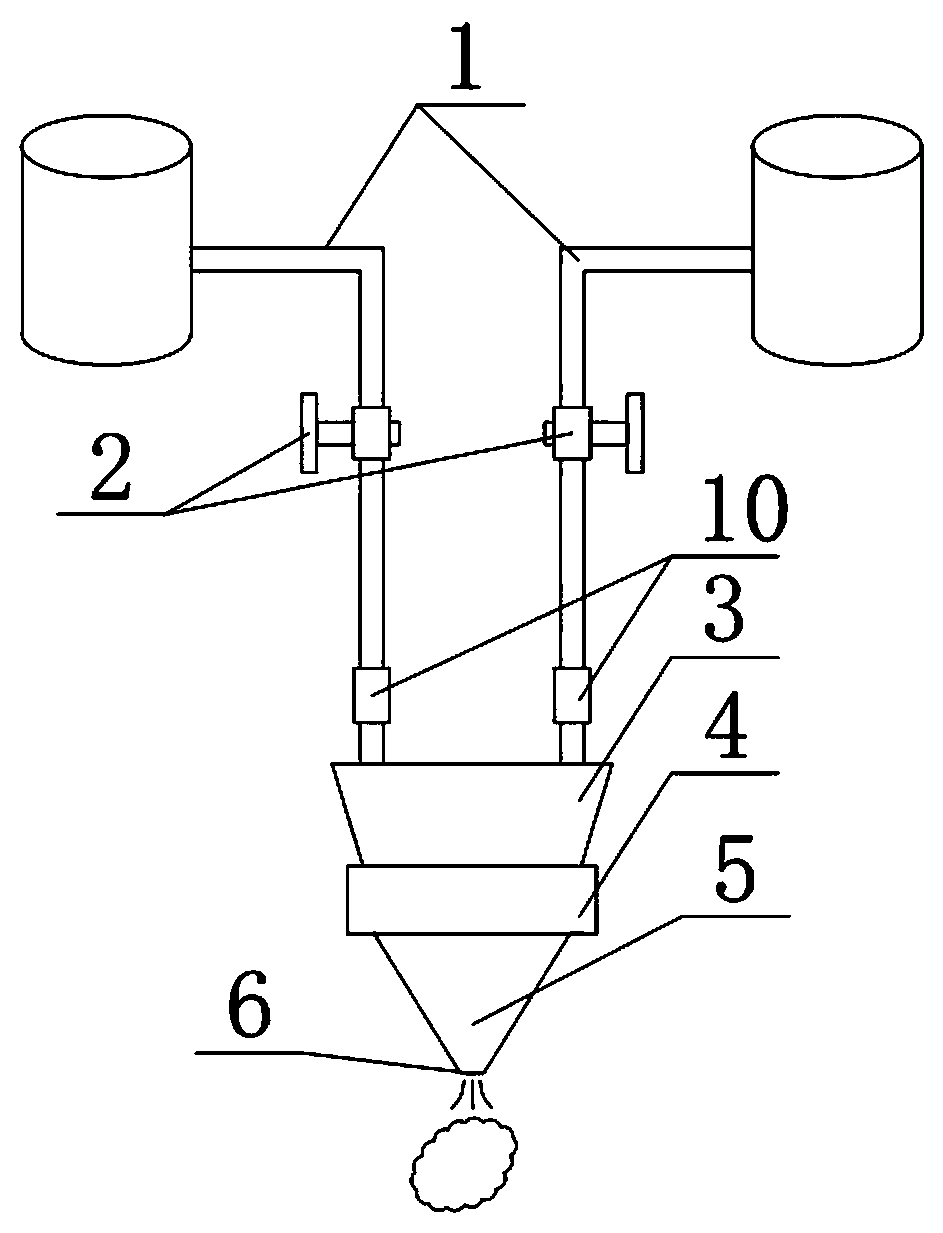

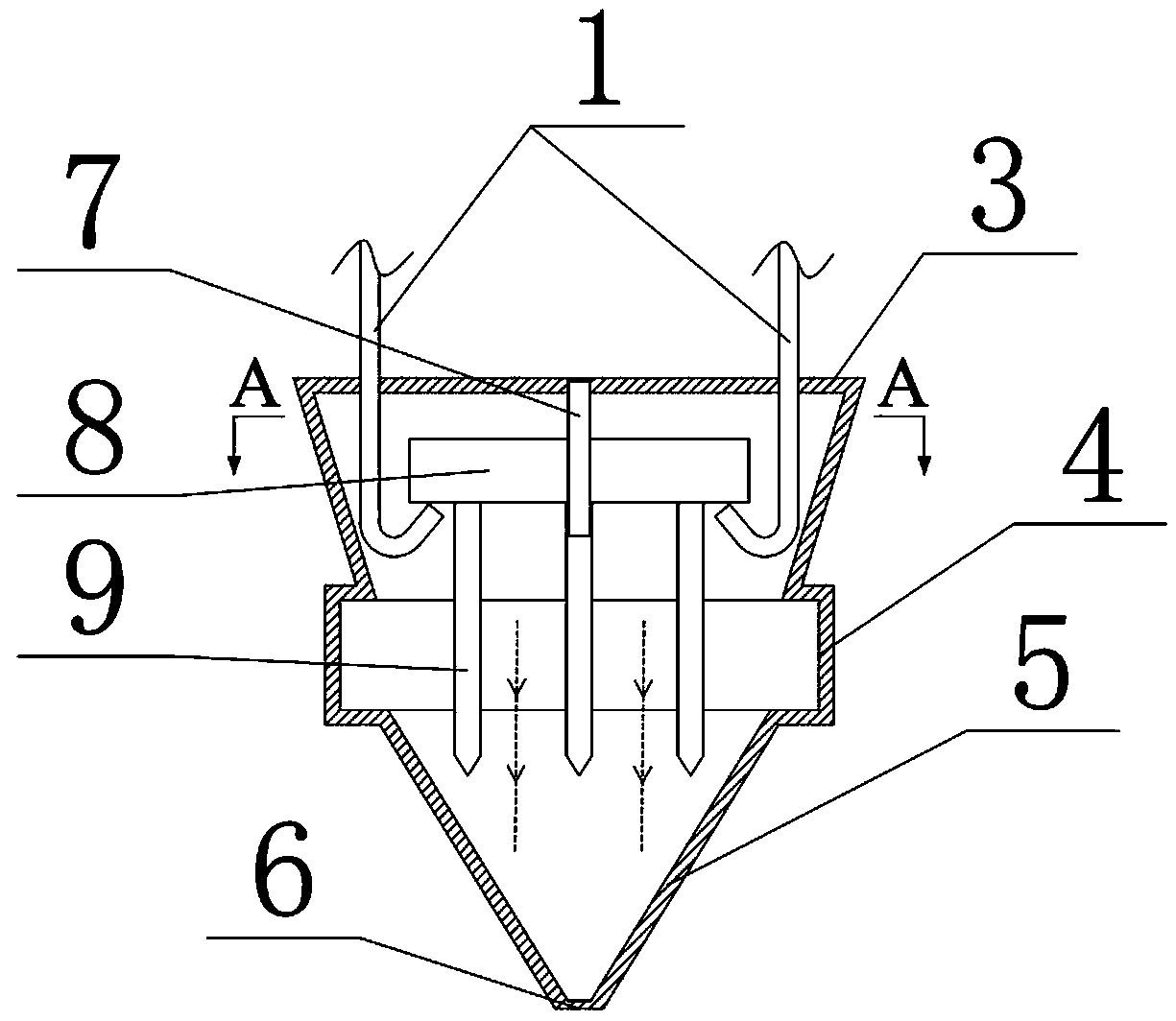

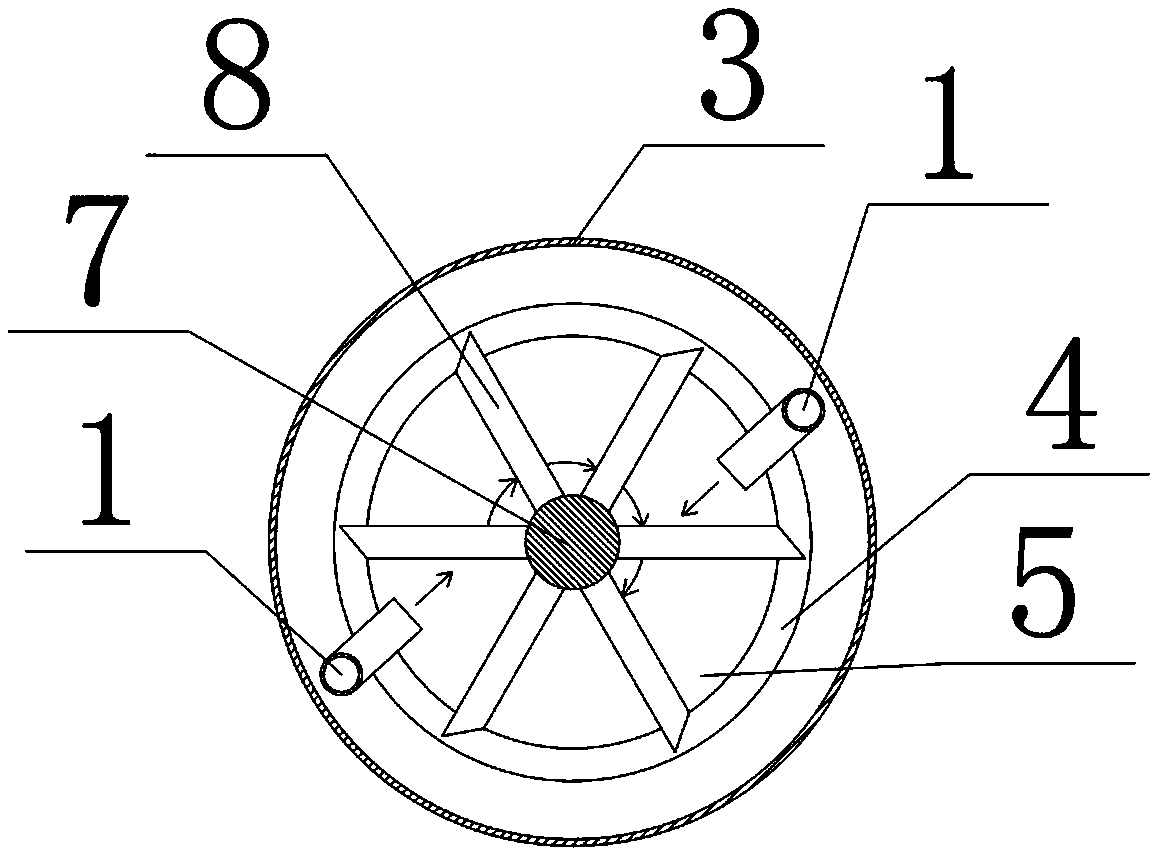

[0031] Embodiment 1: as Figure 1~Figure 3 As shown in the figure, a fast plugging grouting nozzle for large-depth seepage water in a dam includes two grouting pipes 1 and a nozzle body connected to the lower part of the grouting pipe 1;

[0032] The upper part of each of the grouting pipes 1 is respectively provided with a switch 2, and the lower part is respectively provided with a one-way valve 10; the one-way valve 10 prevents leakage water from flowing back during the repair process;

[0033] The nozzle body includes a mixing chamber 3 and a pulping chamber 5, and the inside of the mixing chamber 3 is provided with a stirring member; the bottom of the mixing chamber 3 is connected with a pulping chamber 5 through a threaded pipe 4, and the pulping chamber 5 is conical. Shaped structure, the lower part of the slurry outlet chamber 5 is provided with a slurry discharge hole 6; the mixing chamber 3, the threaded pipe 4 and the inside of the slurry outlet chamber 5 are all co...

Embodiment 2

[0040] Embodiment 2: as Figure 4 Shown, a kind of embankment large-depth seepage water rapid plugging grouting method based on a kind of embankment large-depth seepage water rapid plugging grouting nozzle, comprises the following steps:

[0041] Step 1: Drill the grouting hole, and the drilling depth reaches the leakage position of the embankment;

[0042]Step 2: Connect one end of the two grouting pipes 1 to the nozzle body, and the other end to the grouting equipment;

[0043] Step 3: Deepen the sprinkler body to the leaking position of the embankment;

[0044] Step 4: The grouting equipment transports the two components in the high polymer used for repairing leakage to the nozzle body through two grouting pipes 1;

[0045] It should be noted that before this step, the high polymer used for repairing leakage is divided into grouting liquid containing two components in advance, and the above two components are injected into the two grouting pipes 1 through two grouting equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com