Double-layer threaded steel pipe pile for coral sand foundation and construction method

A threaded steel pipe and coral sand technology, applied in infrastructure engineering, sheet pile walls, construction, etc., can solve the problems of waste of pile foundation engineering materials, settlement of pile foundation or insufficient bearing capacity of pile body, so as to reduce waste and avoid piles. Overweight, waste of resources and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

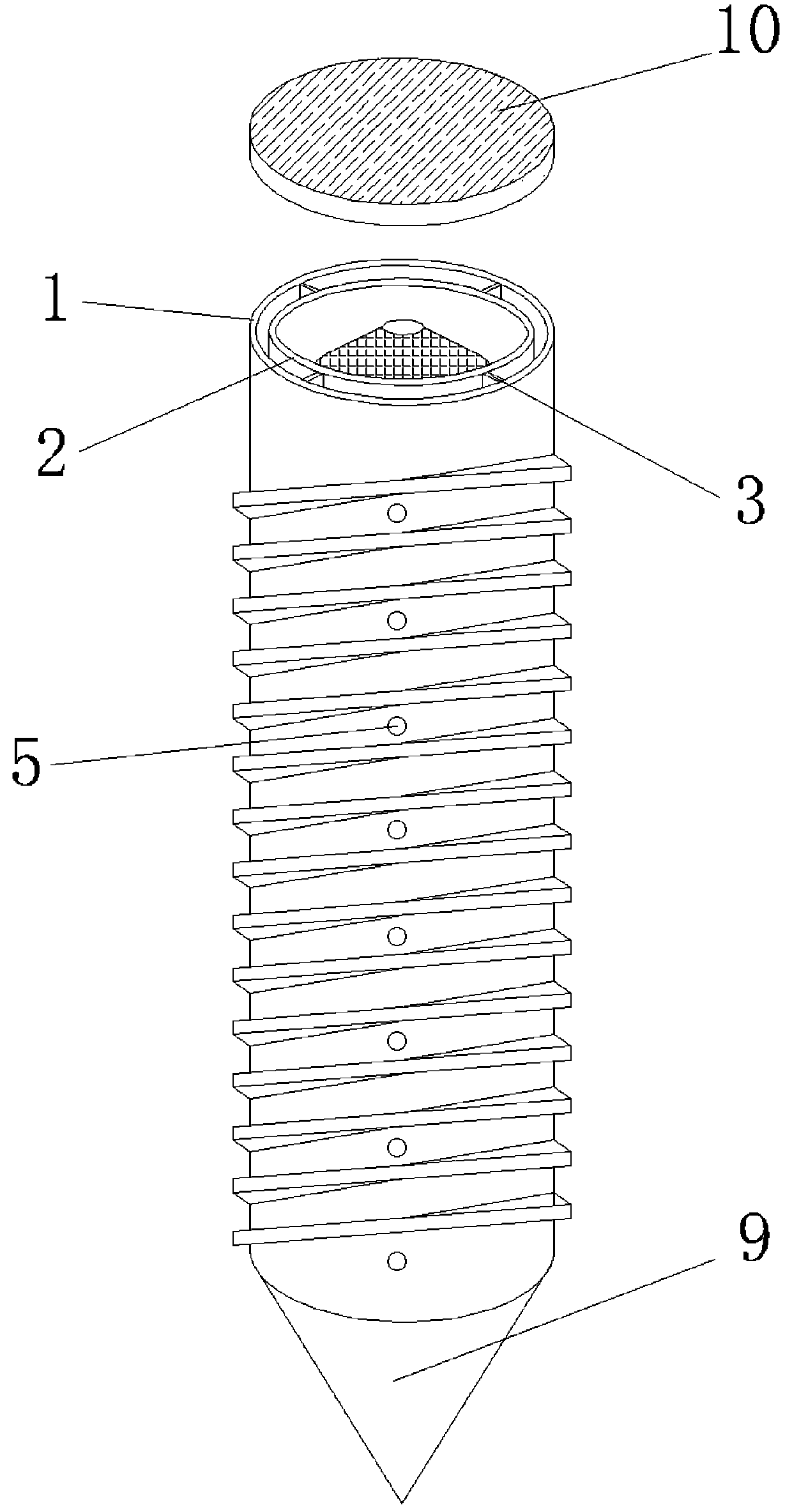

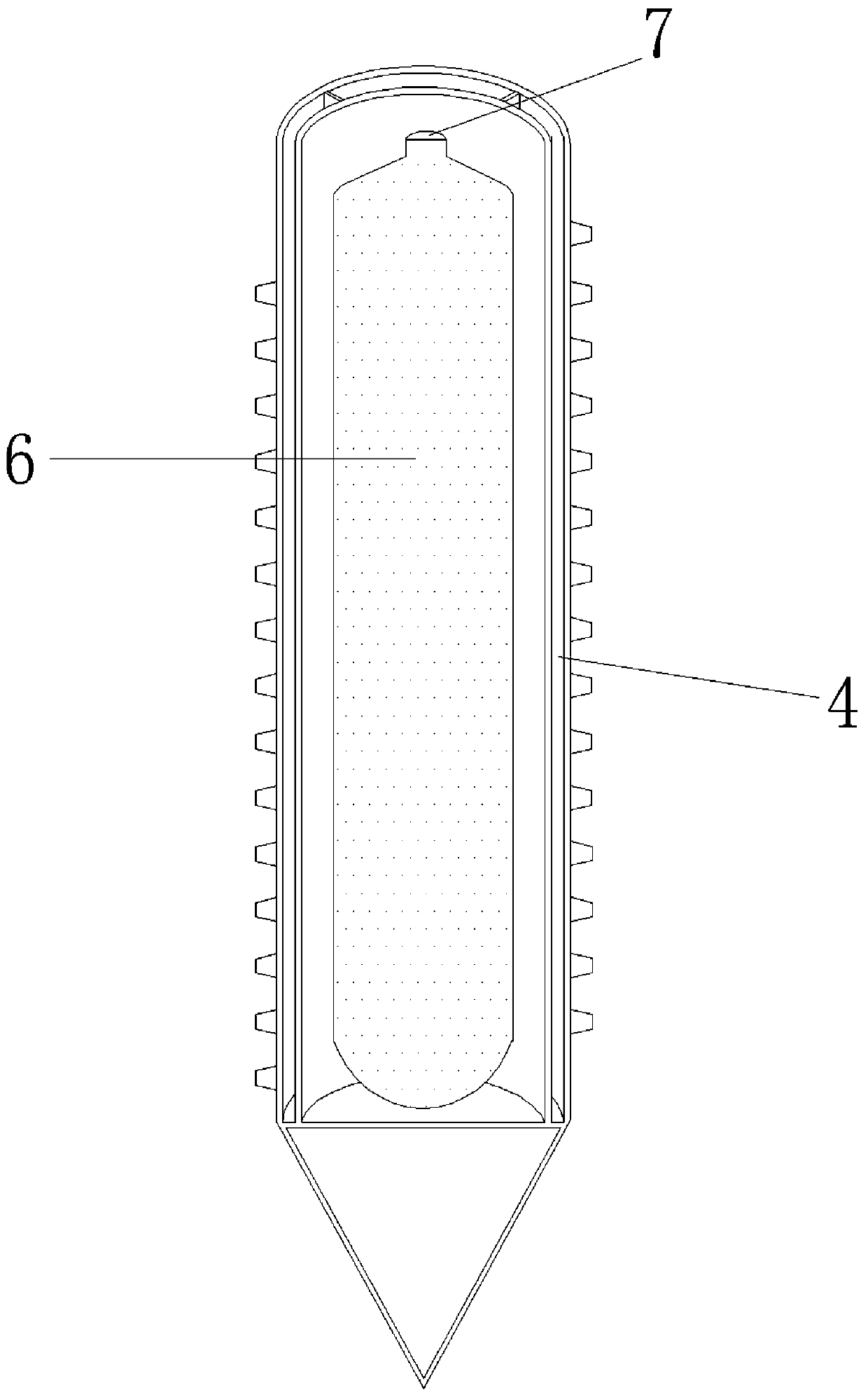

[0068] see Figure 1-2 , a double-layer threaded steel pipe pile for coral sand foundation, which includes a first outer layer of threaded steel pipe 1, and a plurality of first rectangular steel sheets 3 uniformly distributed on the inner wall of the first outer layer of threaded steel pipe 1 The first inner layer of smooth steel pipe 2 is installed, and the first rectangular steel sheet 3 divides the annular cavity between the first outer layer of threaded steel pipe 1 and the first inner layer of smooth steel pipe 2 into a plurality of fan-shaped columnar first grouting areas 4. The first grouting area 4 is close to the wall of the first outer threaded steel pipe 1 to open a plurality of first grouting holes 5 along its height direction; the bottom end of the first outer threaded steel pipe 1 is provided with the first A pile of heads 9. Compared with single-layer steel pipe piles, the double-layer steel pipe piles have better safety and stability, and the annular area bet...

Embodiment 2

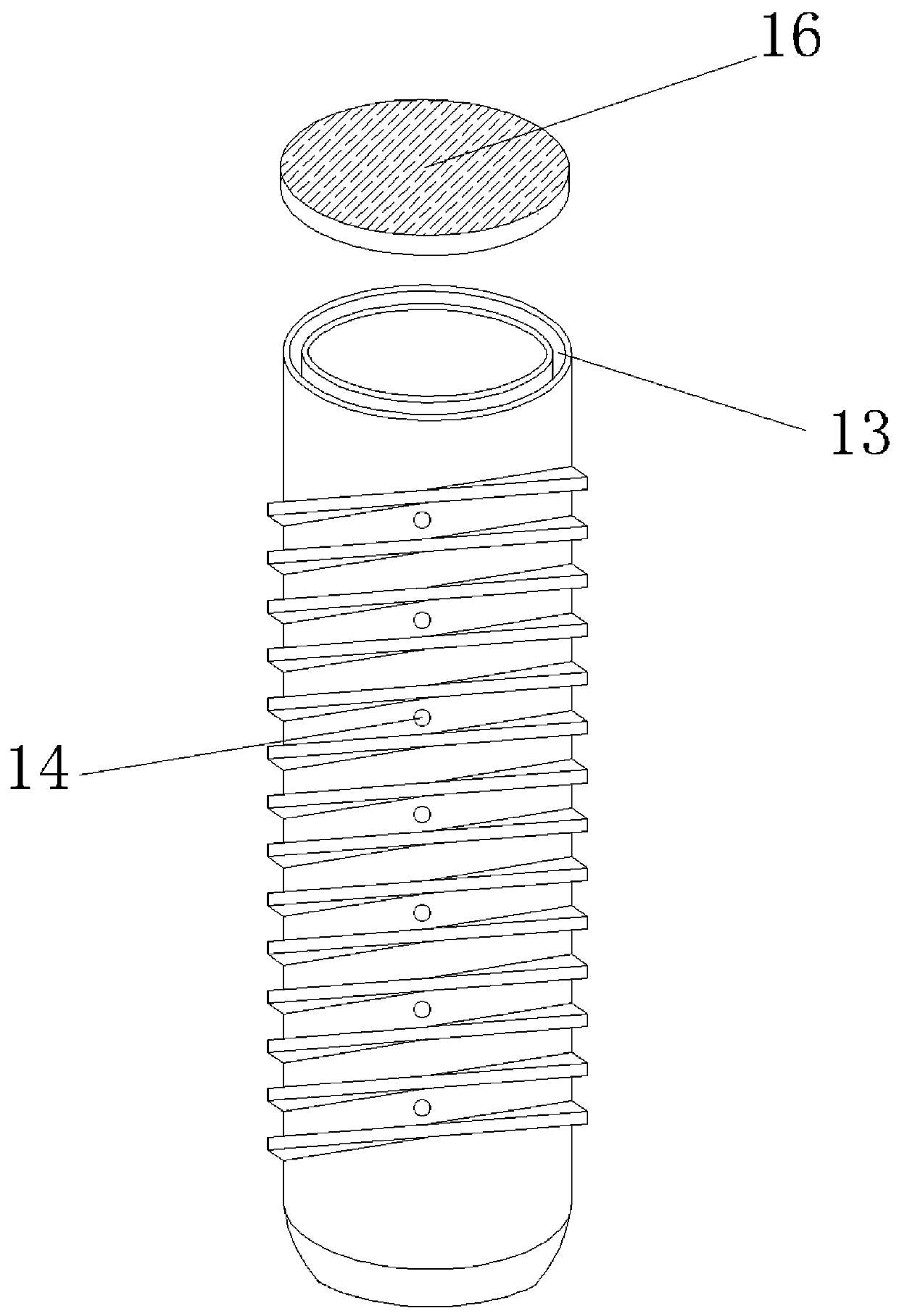

[0083] Such as Figure 3-4 , a double-layer threaded steel pipe pile for coral sand foundation, it includes a second outer layer of threaded steel pipe 11, the outer surface of the second outer layer of threaded steel pipe 11 is provided with threads, and the inner surface is smooth; the second outer layer The inside of the threaded steel pipe 11 is provided with an inner threaded steel pipe 12, the inner surface of the inner threaded steel pipe 12 is provided with threads, and the outer surface is smooth; an annular area is formed between the second outer threaded steel pipe 11 and the inner threaded steel pipe 12 And constitute the second grouting area 13; on the pipe walls of the second outer layer threaded steel pipe 11 and the inner layer threaded steel pipe 12, several second grouting holes 14 are opened, and the second grouting holes 14 are located between the thread lines. The inner and outer steel pipes are all threaded steel pipes. This type of steel pipe pile is a n...

Embodiment 3

[0095] A double-layer threaded steel pipe pile for coral sand foundations, which includes an outer threaded steel pipe 17, the thread on the outer threaded steel pipe 17 is segmented, and several wedges are arranged on the annular area between the two threads Mouth 23, the shape of wedge mouth 23 is consistent with pile inner wedge 21; The inside of outer layer threaded steel pipe 17 is equipped with inner layer smooth steel pipe 18 through second rectangular steel sheet 19, and the corresponding wedge on the inner layer smooth steel pipe 18 inner wall 21 high-strength spring steel sheets 20 are installed; each wedge opening 23 is correspondingly inserted with a wedge block 21, and the wedge block 21 is connected with the high-strength spring steel sheet 20 by a rivet 22. Groove, available for rivet 22 to slide on it; The end of the steel pipe pile is provided with the second pile head 24;

[0096] Further, after the steel pipe pile enters the foundation, a gear rod 25 is inse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com