Concrete conveying device having heating function

A transportation device and function technology, applied in the field of concrete transportation devices with heating function, can solve the problems of the transportation device lacking heating function and difficult to solve the problem of heat preservation, and achieve the effects of lowering temperature, reducing heat loss and reducing residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

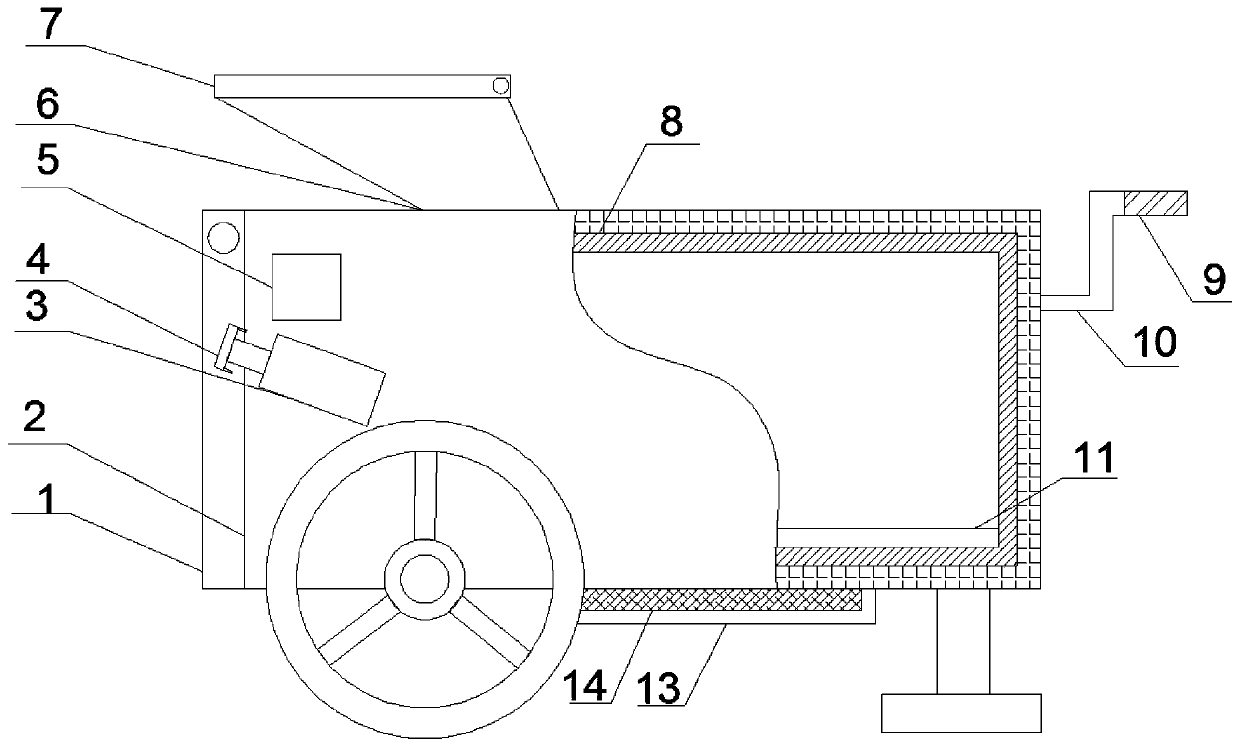

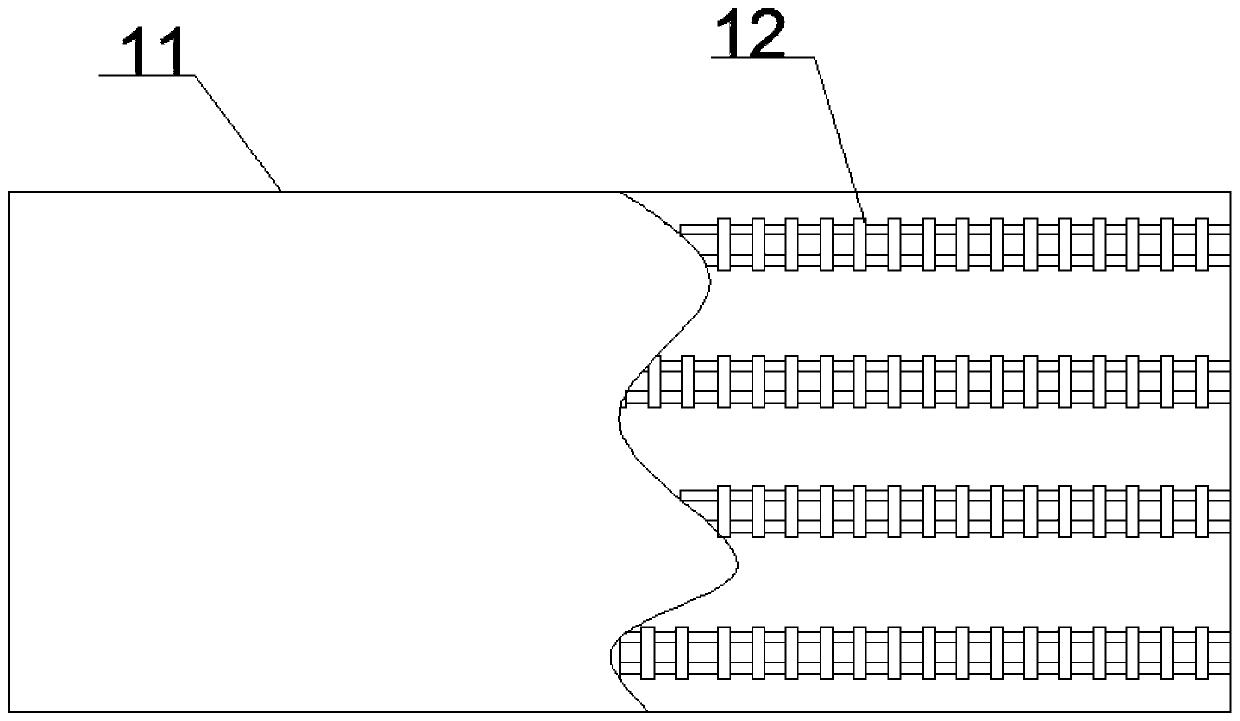

[0029] A concrete transportation device with a heating function, comprising a box body 2, a discharge cover plate 1 is arranged on one side of the box body 2, a storage battery 14 is arranged on the lower part of the box body 2, and an inlet is arranged on the upper part of the box body 2 A feed port 6, the feed port 6 is provided with a feed cover 7, the box 2 is provided with an insulating layer 8, the bottom wall of the box 2 is provided with a metal plate 11, and the metal plate 11 A radiation heating tube 12 is arranged inside, and the radiation heating tube 12 is electrically connected with a storage battery 14 .

[0030] working principle:

[0031] First, the feed cover 7 is opened, and concrete is loaded into the box body 2 through the feed port 6, and when the filling is completed, the feed cover 7 is closed. By setting the feeding cover plate 7, the feeding port 6 can be closed to prevent the hot air in the box body 2 from flowing out and lower the temperature of th...

Embodiment 2

[0033] On the basis of Example 1, a limit block 4 is arranged on the discharge cover 1, an automatic push rod 3 is arranged on the box body 2, and one side of the automatic push rod 3 moves with the limit block 4 connect. During use, the automatic push rod 3 is extended to push the limit block 4, and the limit block 4 rises to drive the discharge cover to rise to realize the opening of the discharge cover. In order to ensure the heating efficiency, the discharge cover 1 is relatively thick, and by setting the limit block 4 and the automatic push rod 3, the opening and closing of the discharge cover can be mechanized, reducing the use of manpower.

Embodiment 3

[0035] On the basis of Embodiment 1, the box body 2 is provided with a double-glazed observation window 5 . By setting the double-layer glass observation window 5, the situation in the box body 2 can be observed in time, the amount of concrete in the box body 2 can be known, and the practicability of the device can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com