A kind of suction muffler and compressor capable of improving muffler volume

A technology of muffler and volume, applied in the direction of machine/engine, mechanical equipment, liquid variable capacity machinery, etc., can solve the problems of complicated and time-consuming assembly, poor coordination, large oil absorption of the oil drain hole, etc., to avoid the position deviation of the two ports. Remove, improve oil discharge effect, improve the effect of noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Attached below Figure 1-6 The present invention is described in detail, specifically, the structure is as follows:

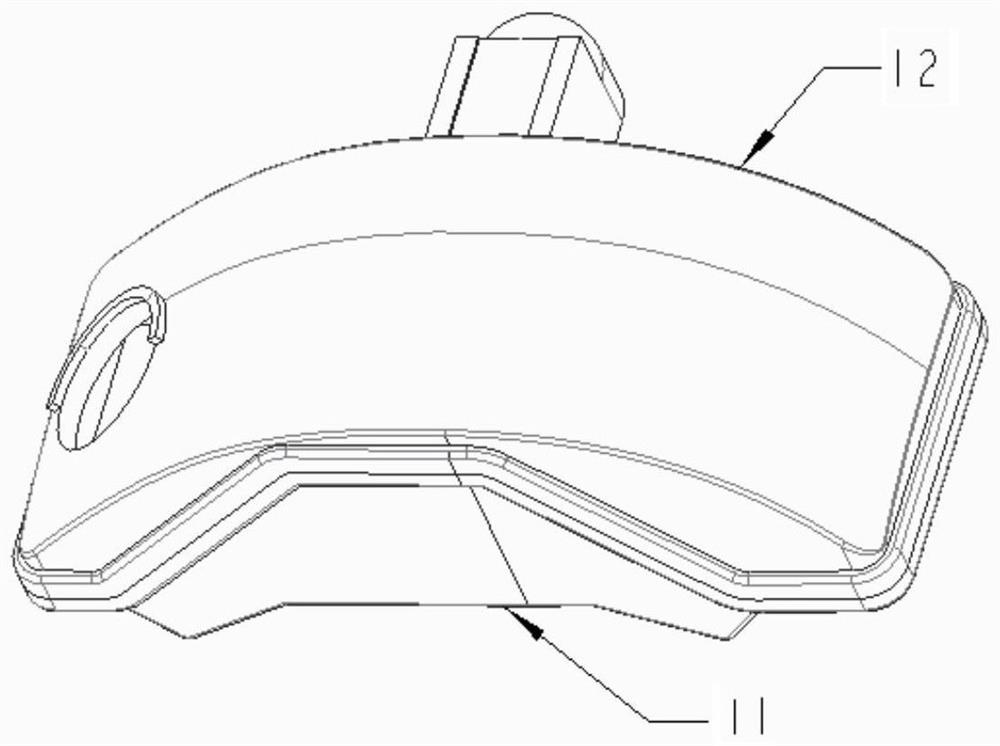

[0036] This embodiment provides a suction muffler capable of improving the muffler volume, which includes a first housing 11 and a second housing 12 that are inserted together to form a closed structure. Good, high structural strength. The first housing 11 has a W-shaped structure for matching with the motor stator, which can enlarge the volume of the muffler, improve the noise reduction performance, and prevent the refrigerating machine oil from entering the oil drain hole.

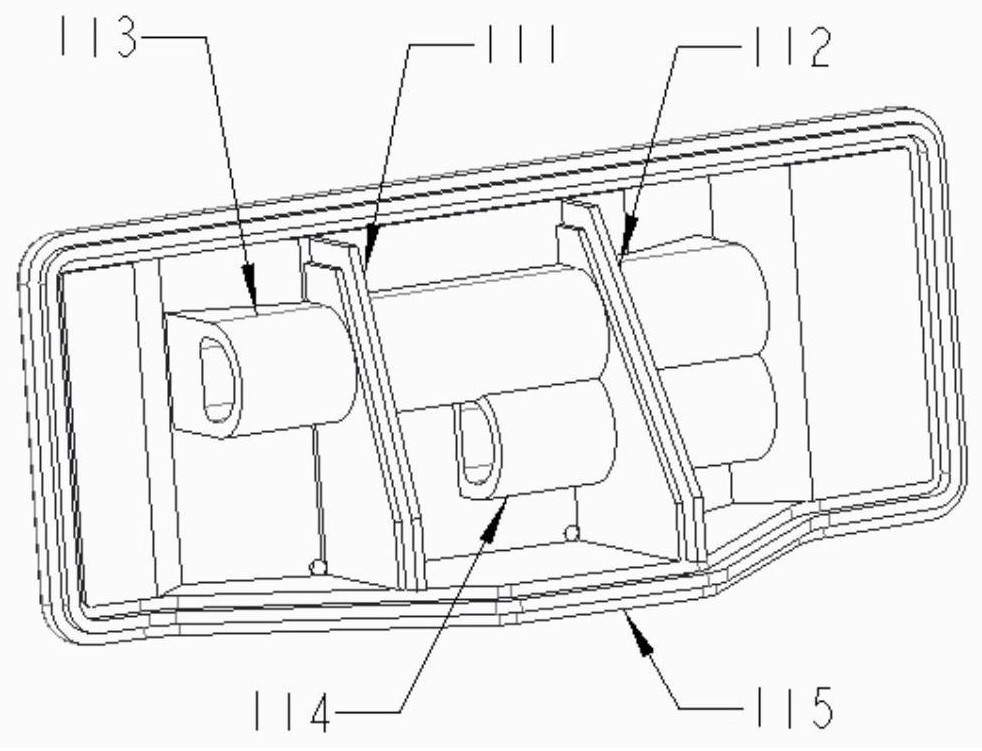

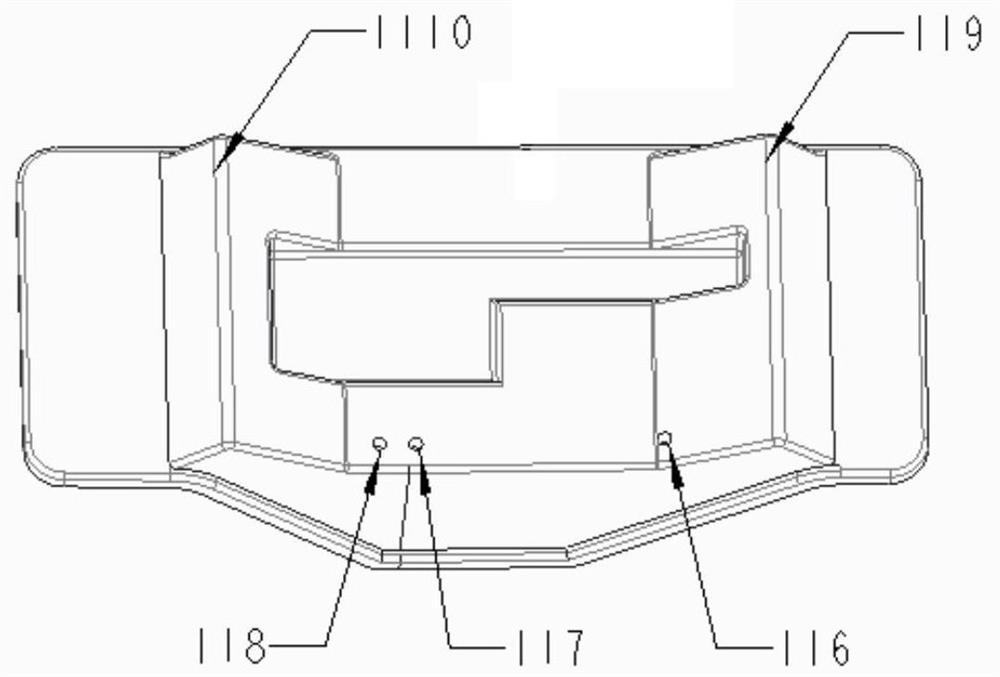

[0037] The first casing 11 is divided into three chambers by the first partition 111 and the second partition 112, and the second casing 12 is divided into three chambers by the third partition 121 and the fourth partition 122. The partition 111 and the second partition 112 are arranged along the width direction of the first casing 11 , and the third partition 121 and the fourth ...

Embodiment 2

[0049] This embodiment provides a compressor, such as figure 2 As shown, it includes the suction muffler 1, motor and other components, wherein the W-shaped structure of the suction muffler 1 is installed in conjunction with the motor stator 2, which can expand the volume of the muffler, improve the noise reduction performance, and prevent the refrigerating machine oil from entering the oil drain hole. , Reduce compressor oil discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com