Composite silencer for wall surface exhaust fan

A technology of muffler and exhaust fan, applied in the direction of machine/engine, non-variable-capacity pump, pump element, etc., can solve the problems of large pressure loss and emission impact, and achieve small flow resistance, large effective ventilation, and noise reduction frequency. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

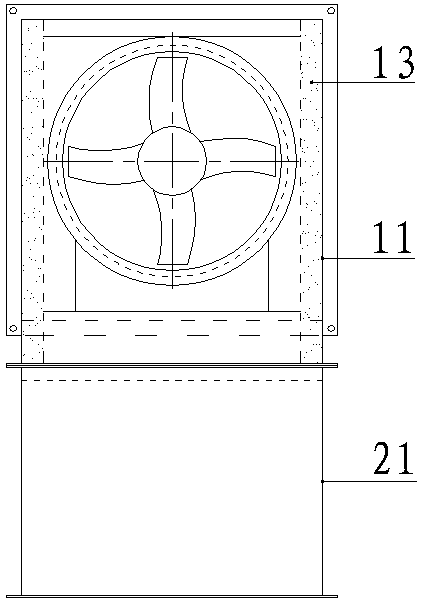

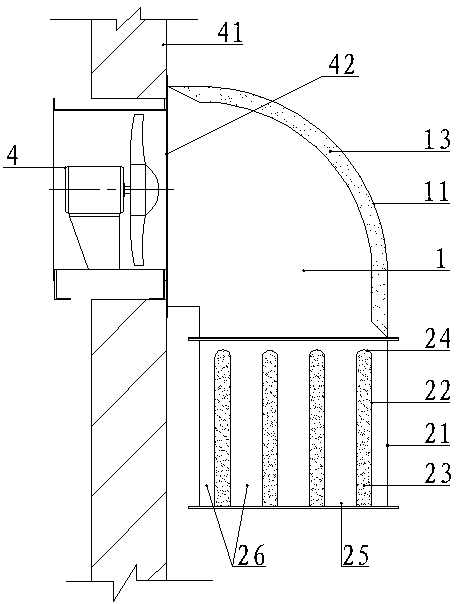

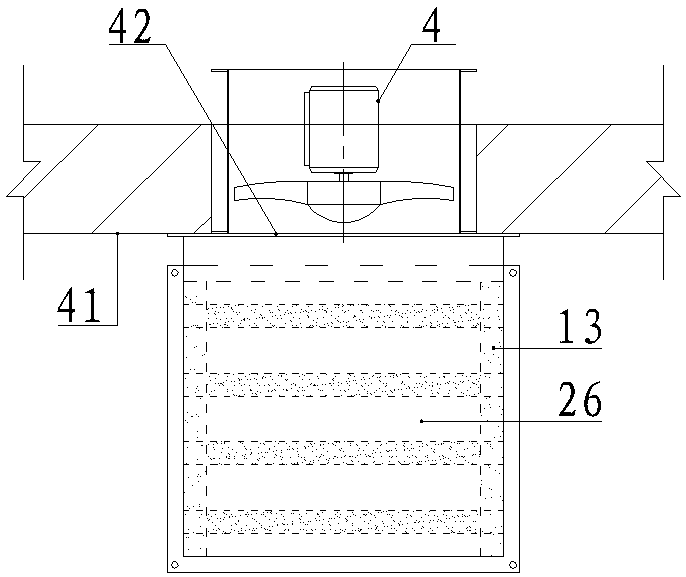

[0029] exist figure 1 , 2 . In the embodiment shown in 3, a wall exhaust fan composite muffler includes a muffler elbow 1, a low-frequency chip muffler 2, an installation bearing frame 3, and a protective net 31. The muffler elbow 1 is installed on the wall in 41 rows Outside the tuyere 42, the low-frequency chip muffler 2 is vertically installed under the muffler elbow 1. The low-frequency chip muffler 2 includes a common-plate flange straight pipe 21 and a muffler insert 22. The muffler insert 22 is made of an ultra-fine glass wool board 23 with a volume density of 60-100kg / m³, and is covered with a weather-resistant film with a thickness of 0.02mm. The panel is a metal perforated plate with a hole diameter of 6 mm and a perforation rate of 20%. The top of the disappearing insert is provided with a circular arc 24. The thickness of the sound-absorbing insert 22 is 50-70mm. The distance 25 between the sound-absorbing inserts 22 is the sound-absorbing insert Twice the thickn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com