Mixed-flow pump

A mixed-flow pump and volute technology, which is applied in the direction of pumps, pump components, and parts of pumping devices for elastic fluids, etc., can solve the impact loss of the gap flow field in the rear pump chamber to the mainstream flow field, and the rear cover plate The large gap at the wheel rim affects the overall efficiency of the unit, etc., so as to reduce the secondary flow vortex and hydraulic loss, reduce the impact loss, and reduce the impact loss of the wheel rim.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

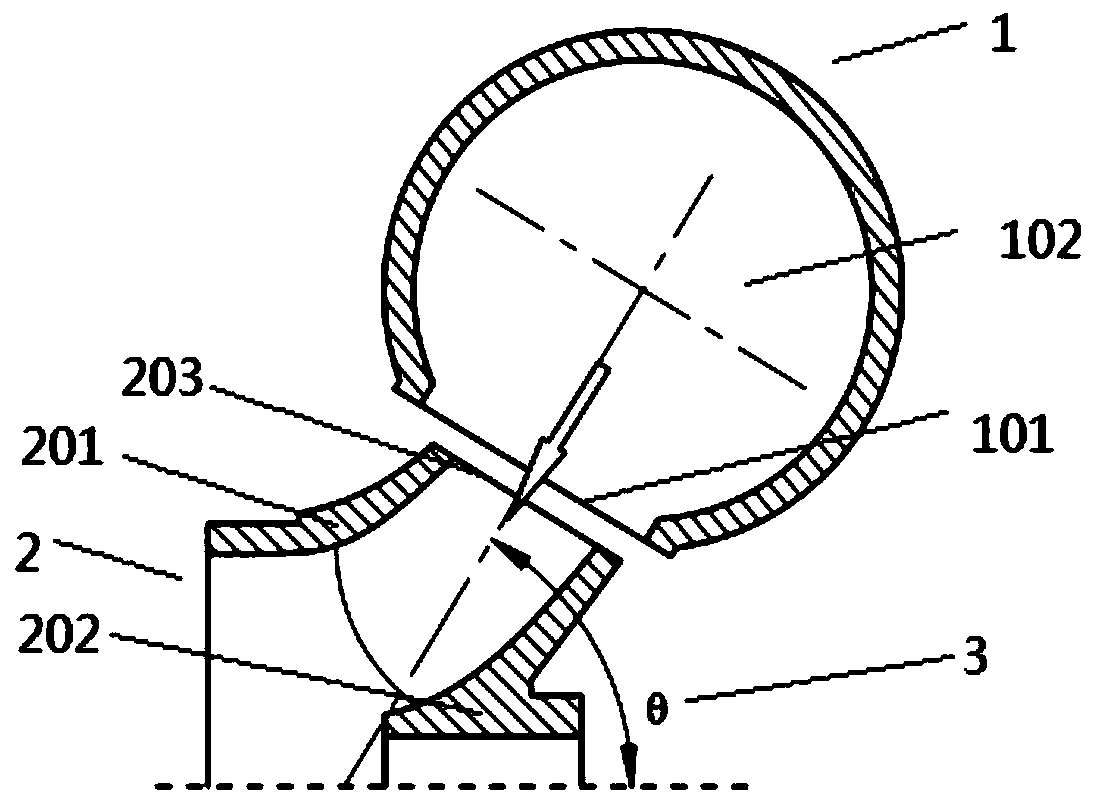

[0028] Such as figure 1 As shown, the embodiment of the present invention provides a mixed flow pump, which includes a volute 1 and an impeller 2; the outlet 101 of the volute communicates with the inlet 203 of the impeller;

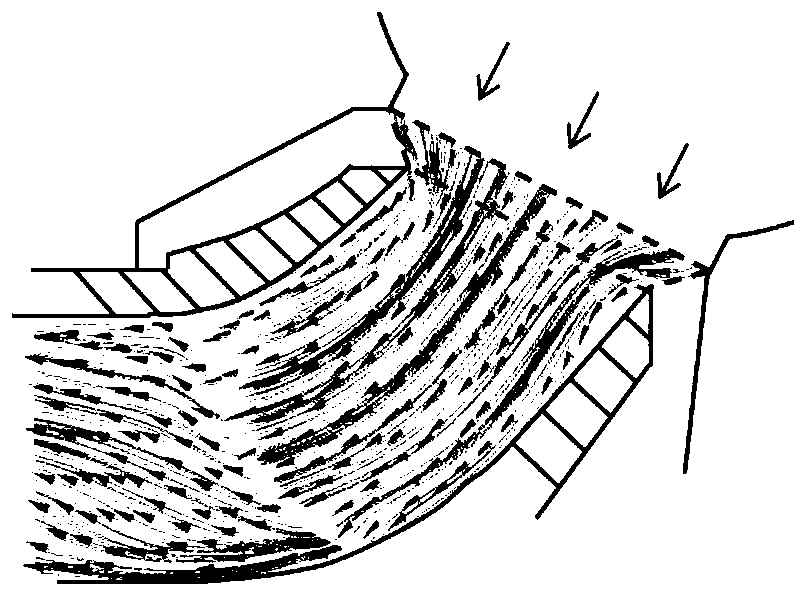

[0029] The volute 1 is placed obliquely relative to the centerline of the impeller 2 , so that the centerline of the volute outlet 101 has a flow cone angle θ3 relative to the centerline of the impeller 2 .

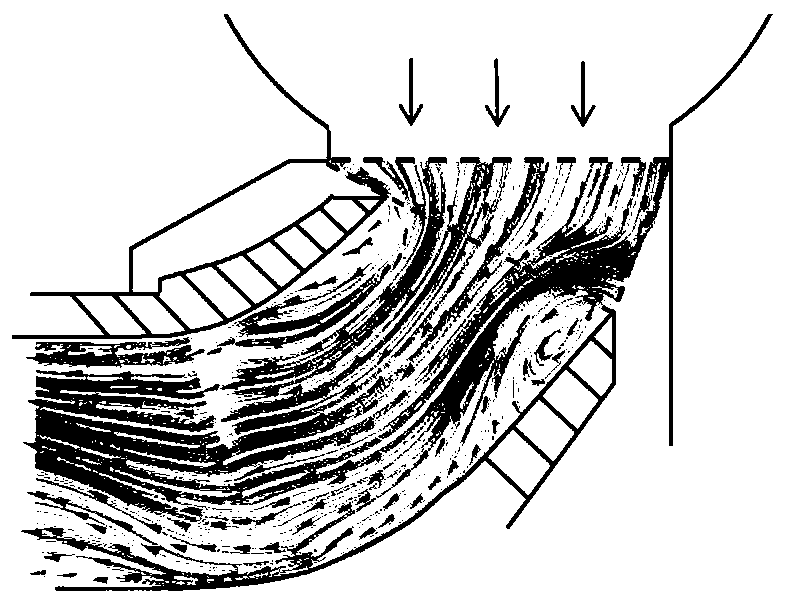

[0030] It can be understood that in the volute matched with the turbine impeller of the mixed-flow pump in the prior art, the outlet design is mostly based on the volute outlet of the centrifugal pump used as the turbine, that is, the volute outlet is radial, and the specific volute The included angle between the centerline of the shell outlet and the axis of the rotating shaft is 90°. In the present invention, the outlet flow direction of the volute 1 can be changed by setting the flow cone angle θ3. On the one hand, according to the actual impell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com