Patents

Literature

54results about How to "Reduce gap distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

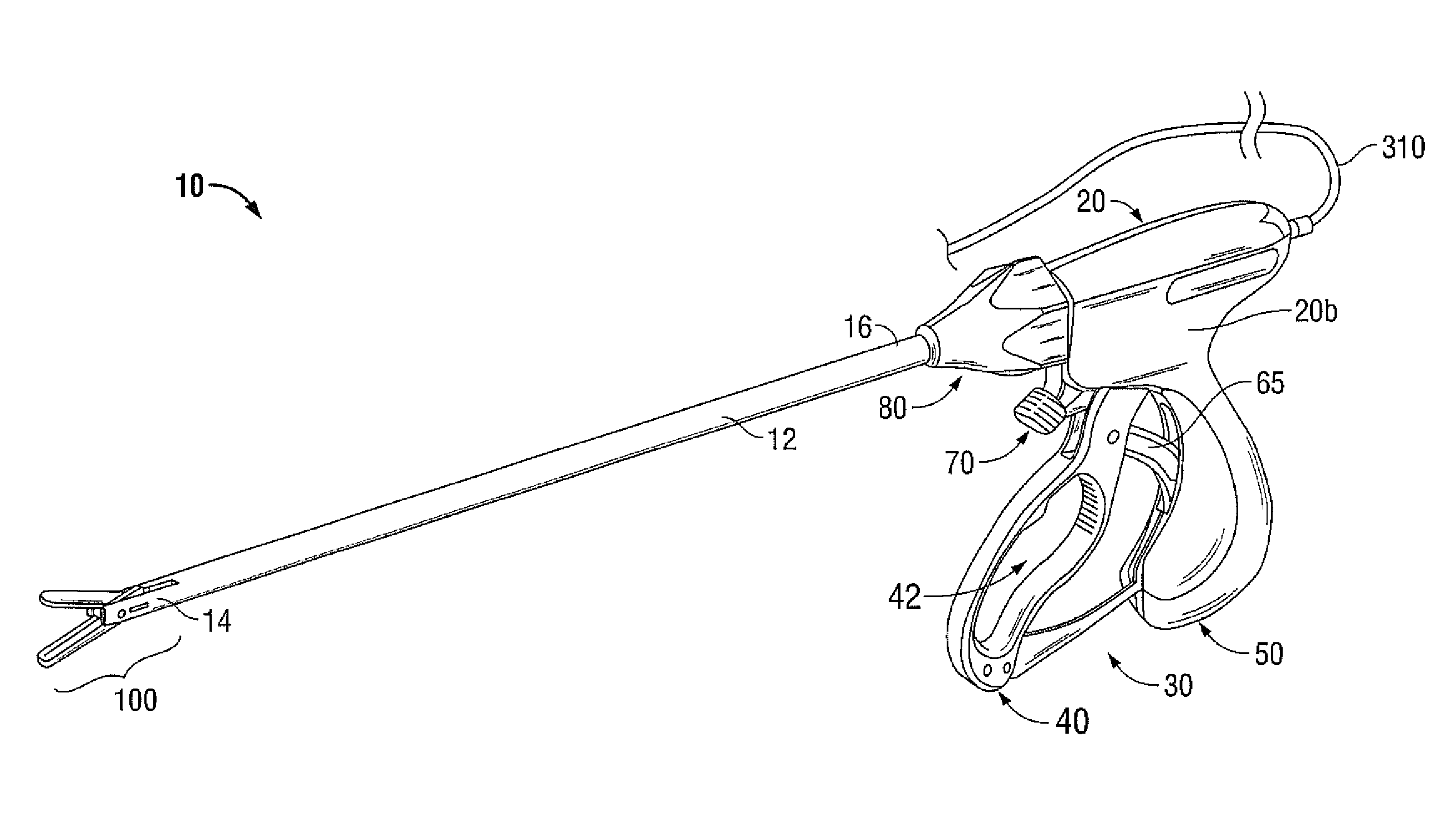

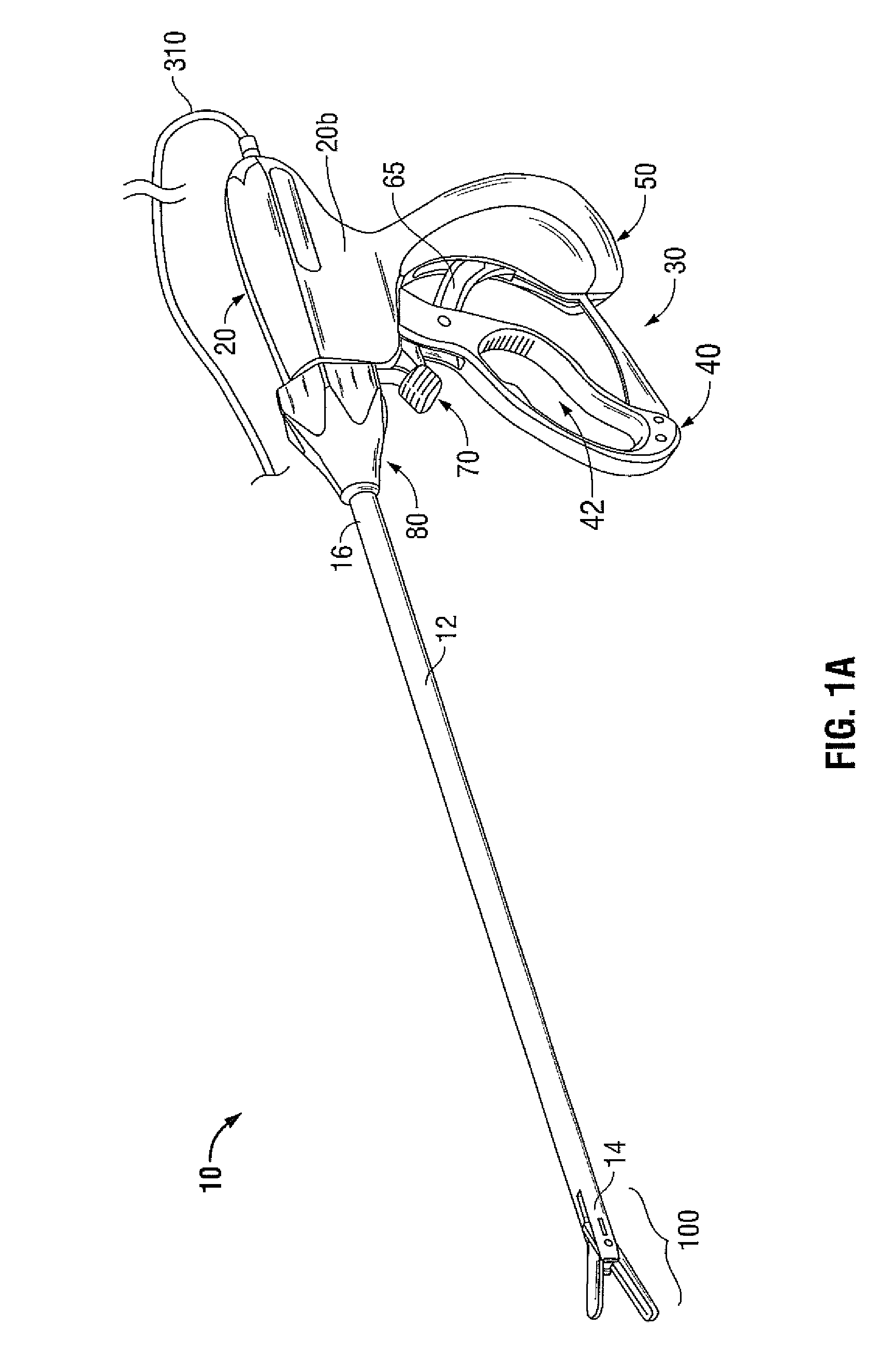

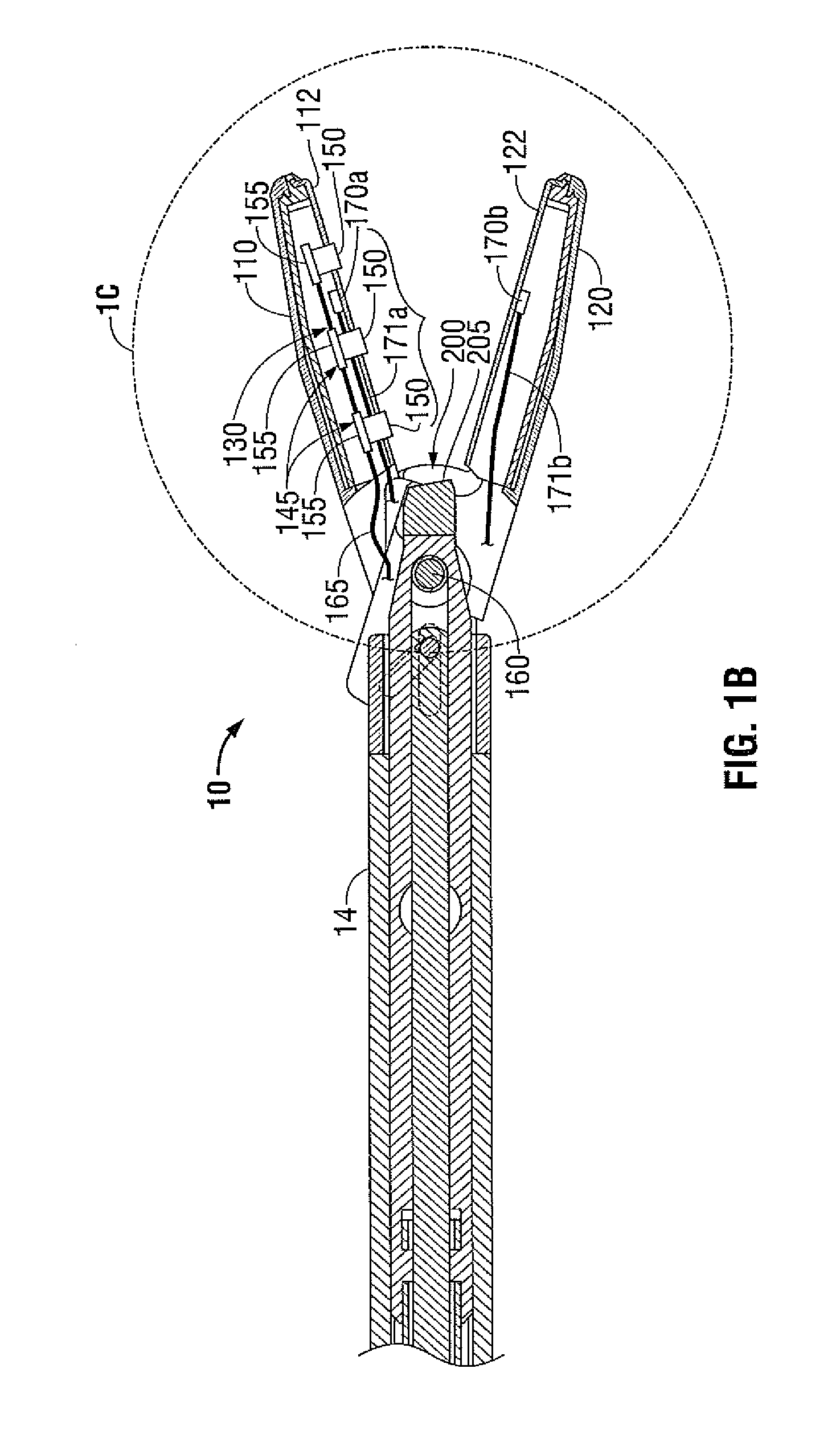

Electrosurgical Forceps with Slow Closure Sealing Plates and Method of Sealing Tissue

InactiveUS20090204114A1Reduce gap distanceDiagnosticsSurgical instruments for heatingEnergy basedActuator

An electrosurgical system for sealing tissue includes electrosurgical bipolar forceps and an electrosurgical generator. The electrosurgical bipolar forceps includes a shaft member having an end effector assembly disposed at a distal end. The end effector assembly includes jaw members movable from a first position in spaced relation relative to one another to a subsequent position. The jaw members are adapted to cooperate to grasp tissue therebetween. The jaw members each include a sealing plate that communicates electrosurgical energy through the held tissue. The gap sensor is adapted to sense the gap distance between the jaw members. The electrosurgical generator is operatively coupled to the electrosurgical bipolar forceps and generates the electrosurgical energy. The electrosurgical generator is in operative communication with the gap sensor and monitors a sensed gap distance therefrom. The electrosurgical generator generates the electrosurgical energy based on the sensed gap distance as a function of time.

Owner:COVIDIEN AG

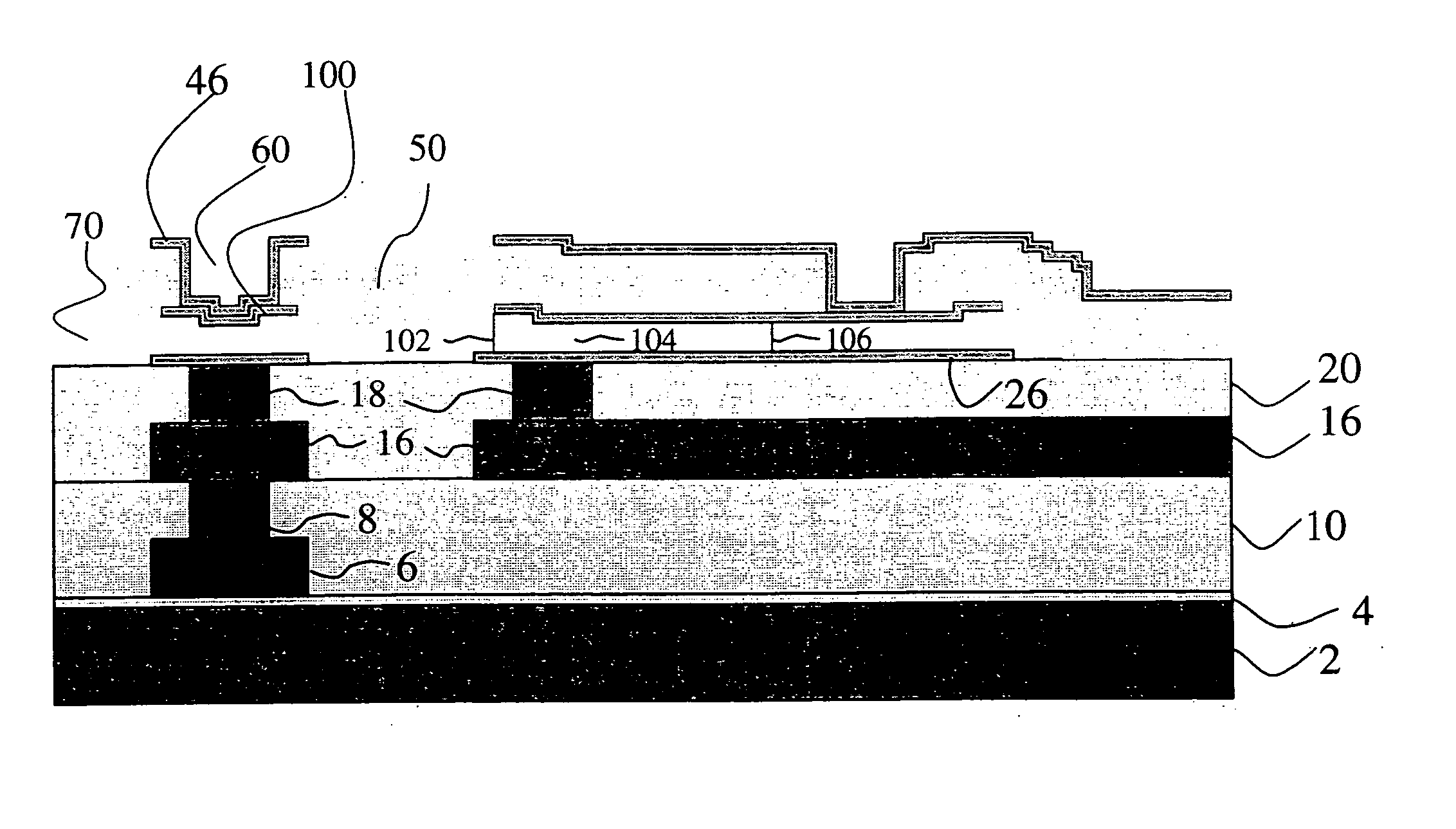

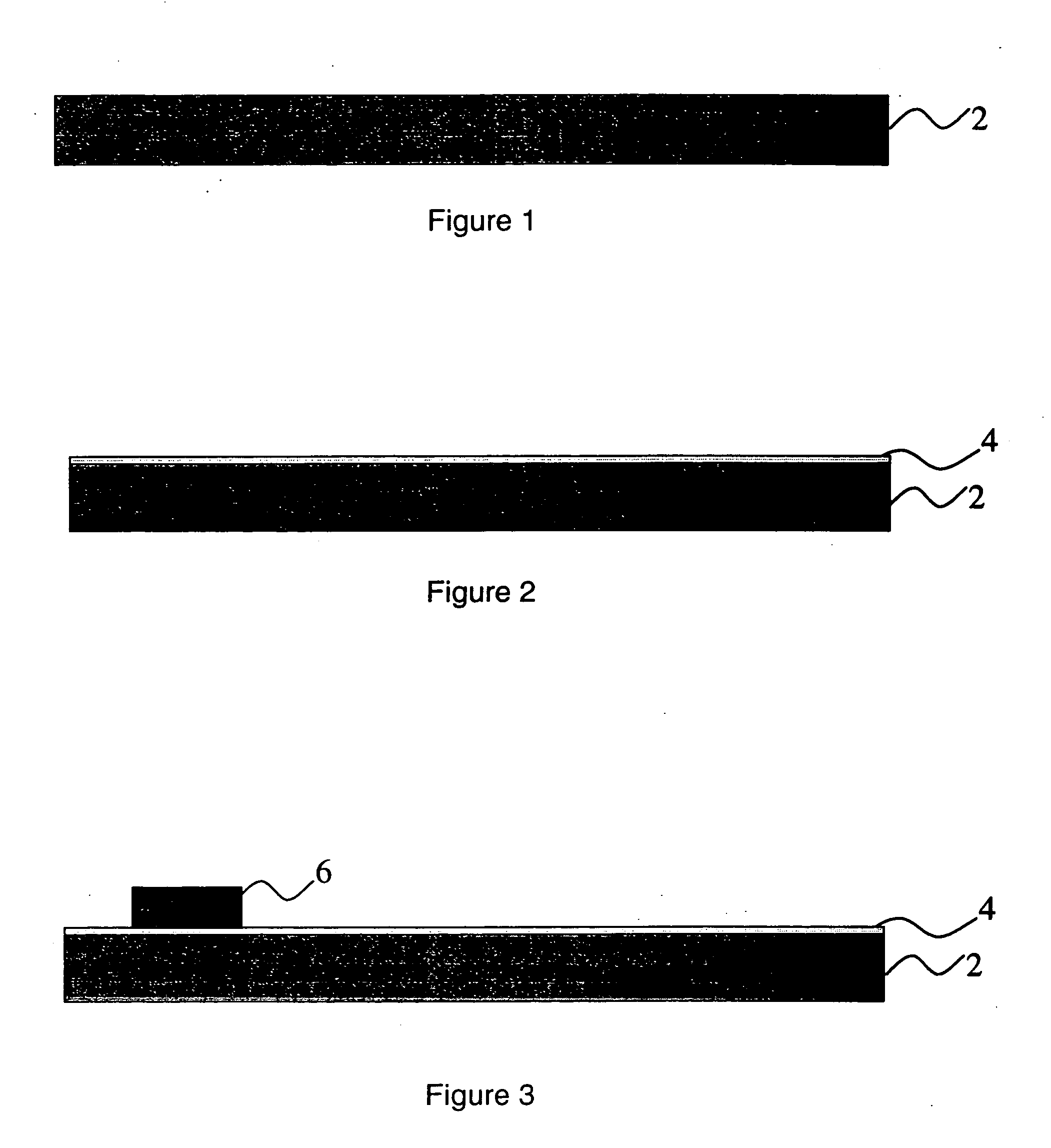

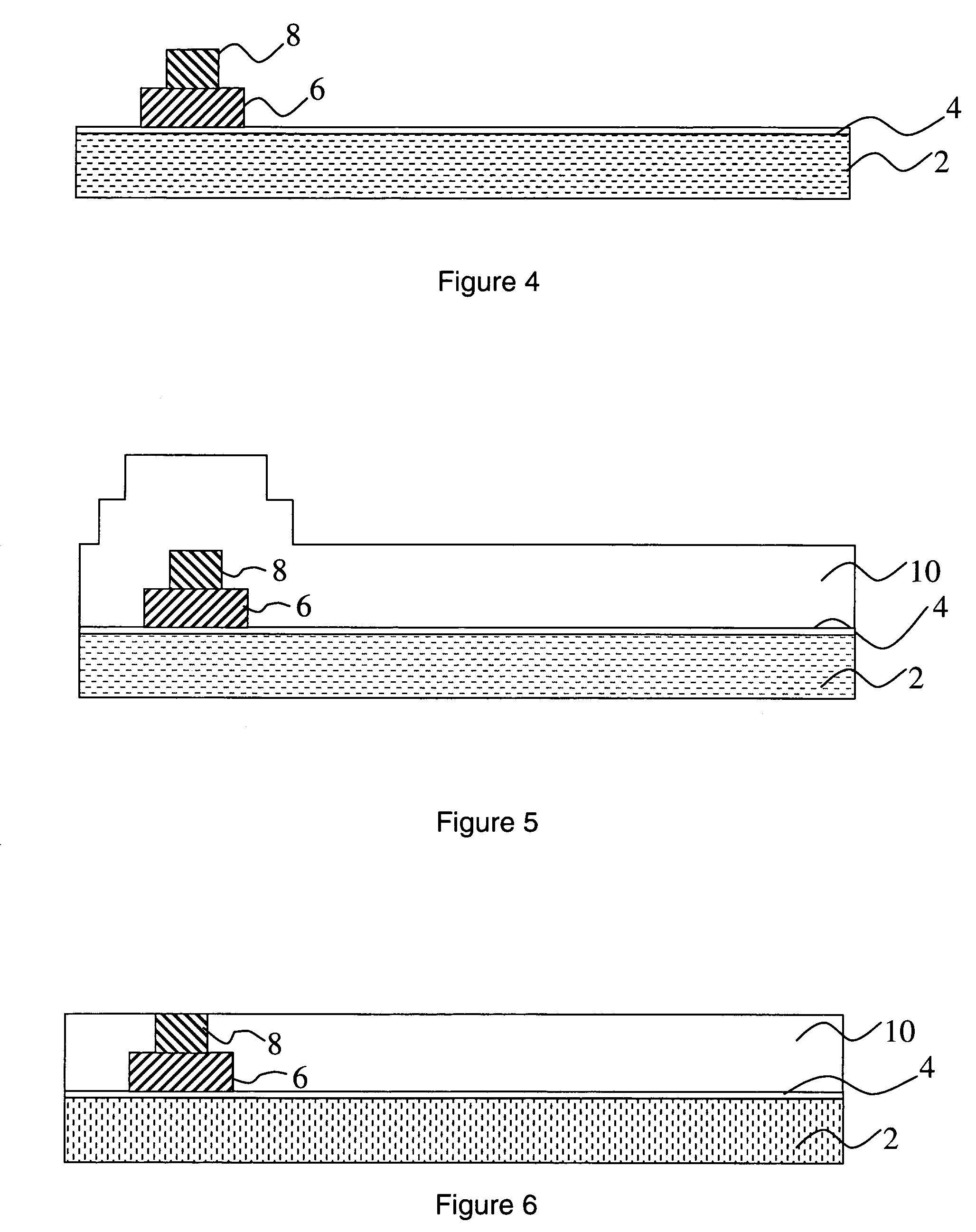

Recessed electrode for electrostatically actuated structures

InactiveUS20050048687A1Reduce the starting voltageReduce gap distanceElectrostatic/electro-adhesion relaysWave amplification devicesEmbedded systemVoltage

The present invention relates to micro-electro-mechanical systems (MEMS). The present invention relates to a design feature that allows lower actuation voltage for electrostatically actuated structures (i.e., switches or mirrors). The present invention further relates to a method for fabricating such a design that allows lower actuation voltage.

Owner:WISPRY INC

Recessed electrode for electrostatically actuated structures

InactiveUS7064637B2Reduce the starting voltageReduce gap distanceElectrostatic/electro-adhesion relaysElectrostrictive/piezoelectric relaysStictionVoltage

An electro-statically actuated switch having a reduced gap distance between electrodes for reducing actuation voltage is provided. The invention provides more reliable electro-statically actuated switches. The invention provides a micro-electro-mechanical system (MEMS) that includes a recessed, movable electrode. The invention provides electro-statically actuated switches that reduce the likelihood of stiction and beam deformation and that allows lower actuation voltage for electrostatically actuated structures such as switches and mirrors. A method for fabricating such a design is provided that allows lower actuation voltage.

Owner:AAC TECH PTE LTD

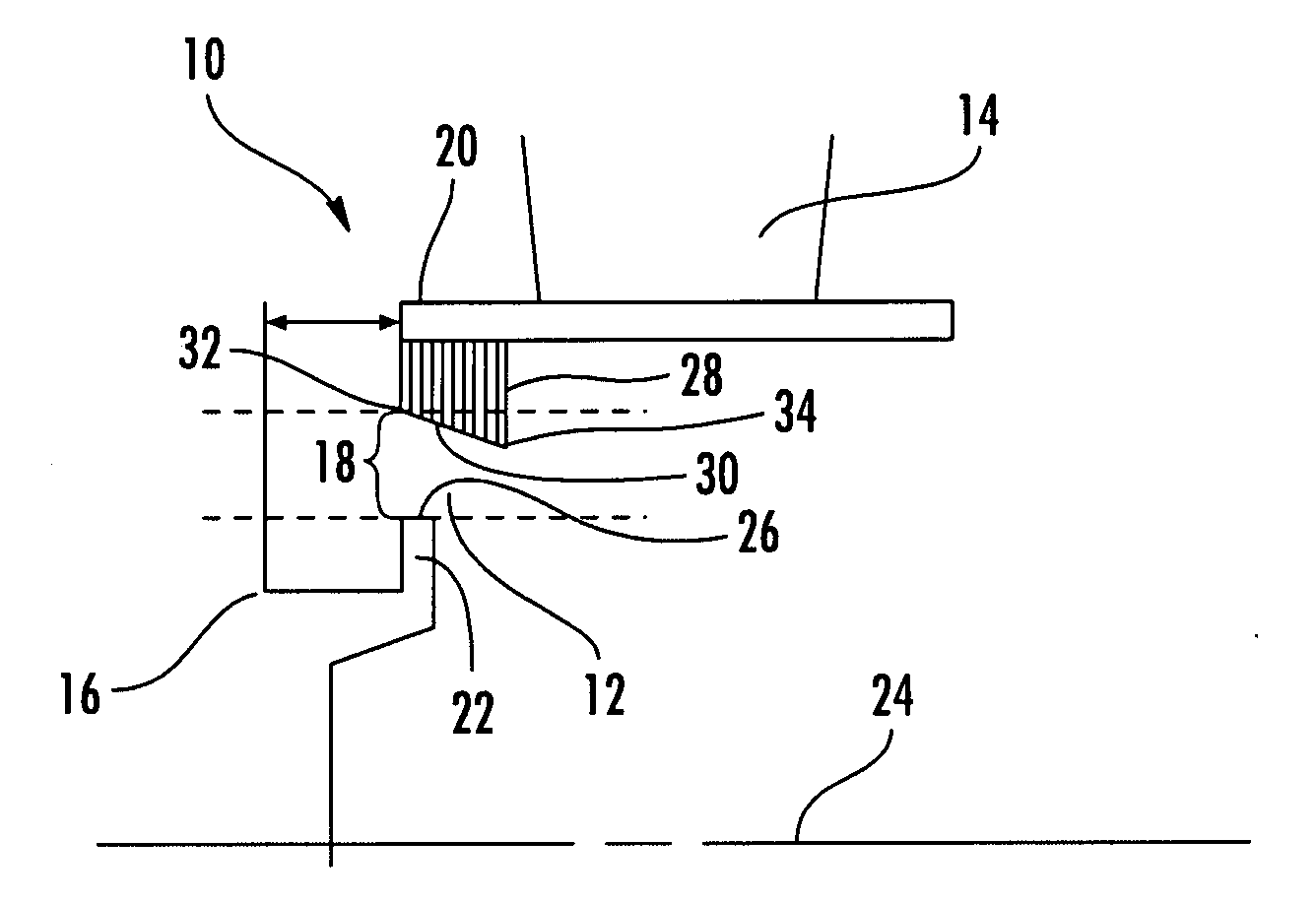

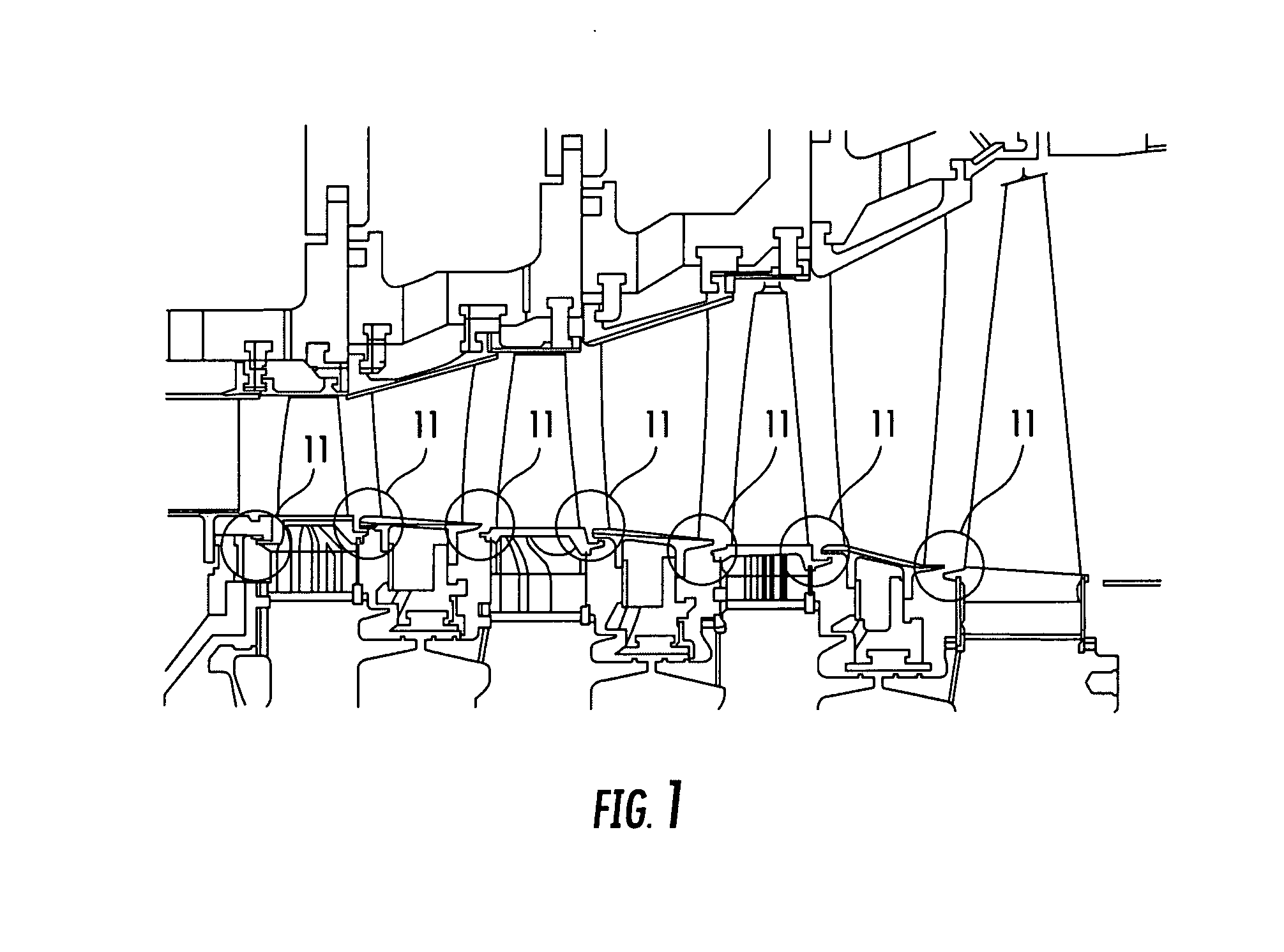

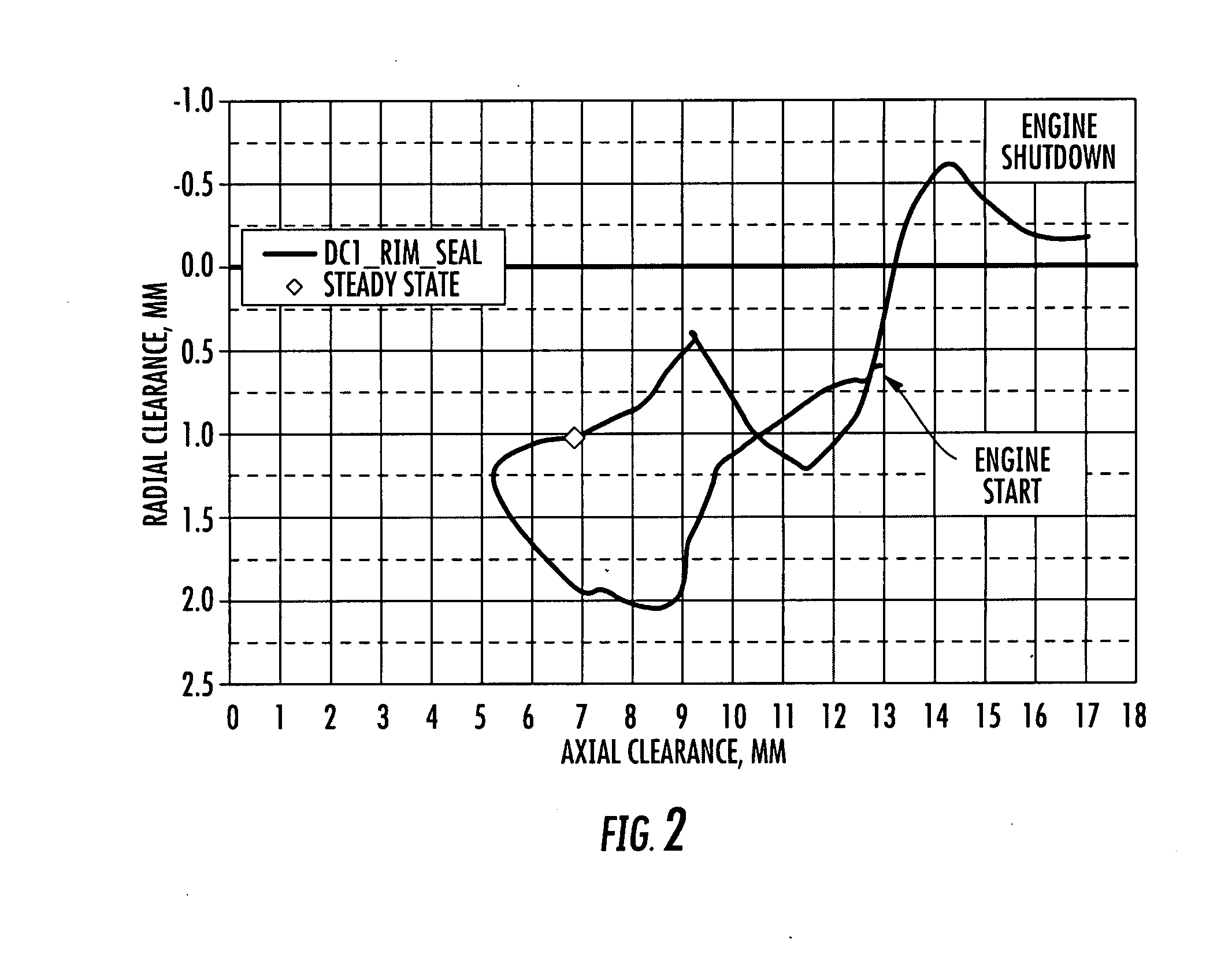

Angled honeycomb seal between turbine rotors and turbine stators in a turbine engine

InactiveUS20090014964A1Reduce distanceDistance across the gap between the turbine stator and the turbine rotor is reducedEngine sealsPump componentsHoneycombCooling fluid

A seal system for an intersection between a turbine stator and a turbine rotor to seal cooling fluids. The seal system may be formed from a seal base extending from the turbine stator, an arm extending radially outward from the turbine rotor and toward the seal base but terminating short of the seal base thereby creating a gap between the seal base and the arm. The seal system may include a honeycomb shaped seal attached to the seal base and extending radially inward from the seal base toward the arm. An outer sealing surface of the seal may be nonparallel with a longitudinal axis about which the turbine rotor rotates thereby enabling the distance of the gap to be reduced with axial movement of the turbine rotor.

Owner:SIEMENS ENERGY INC

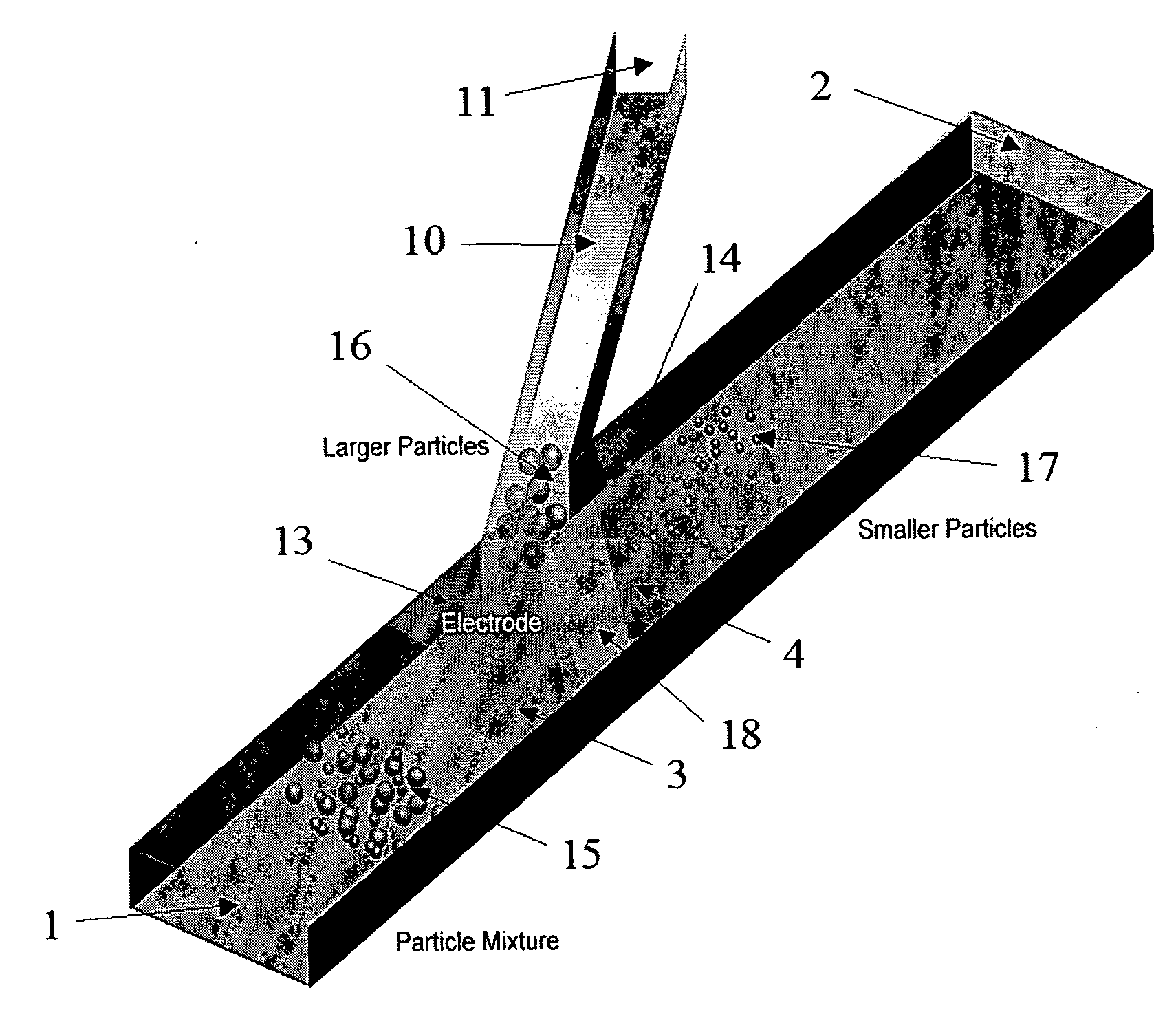

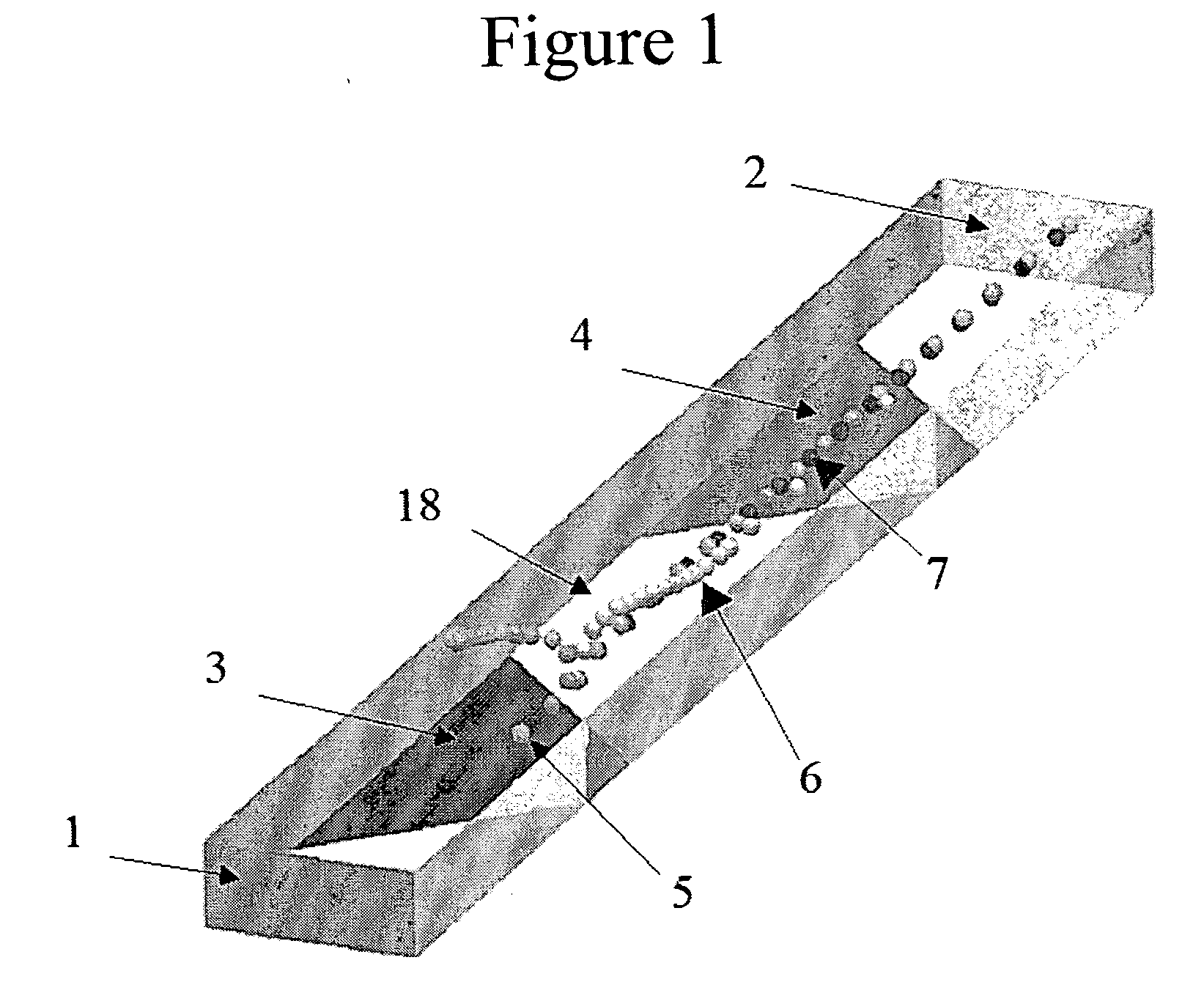

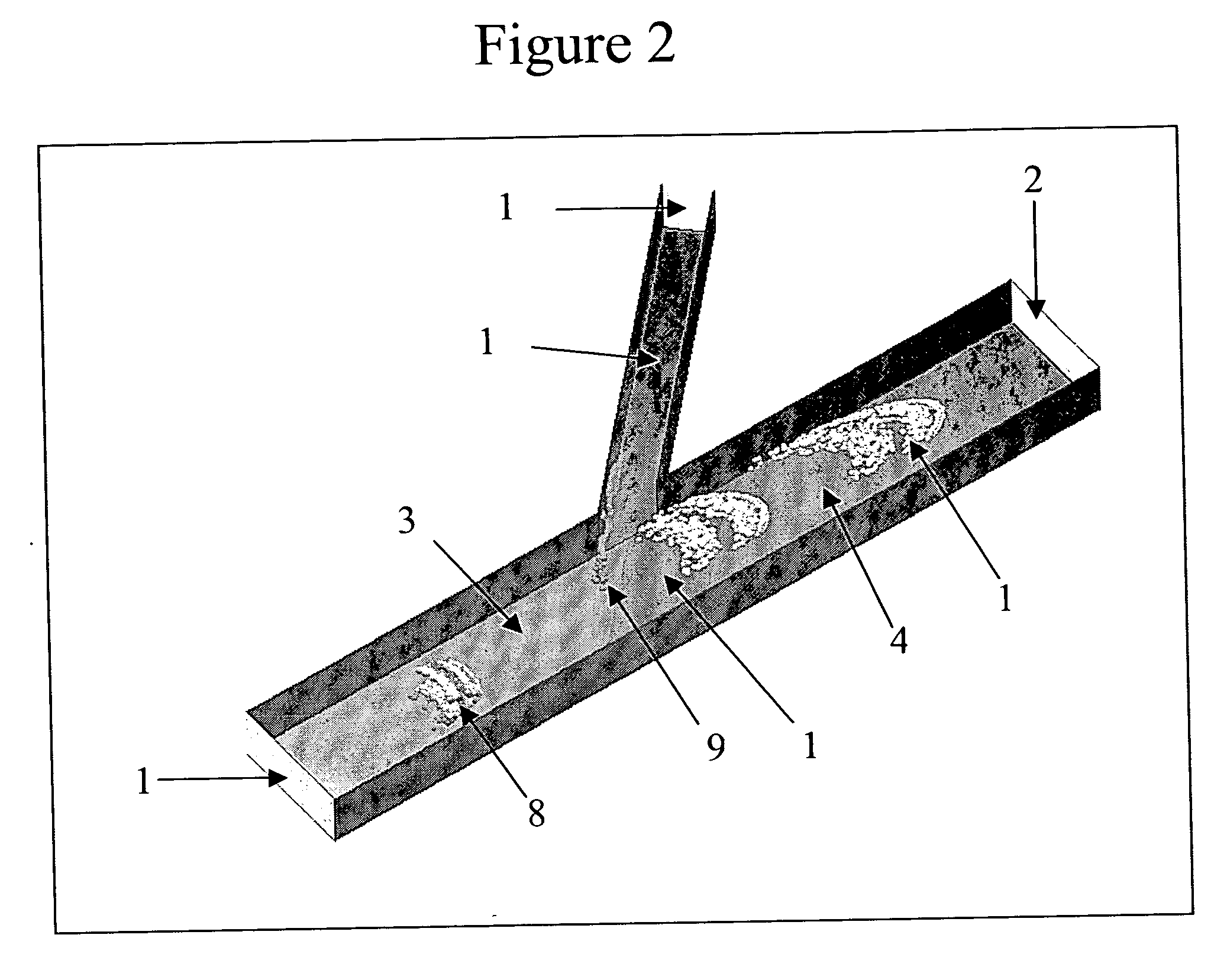

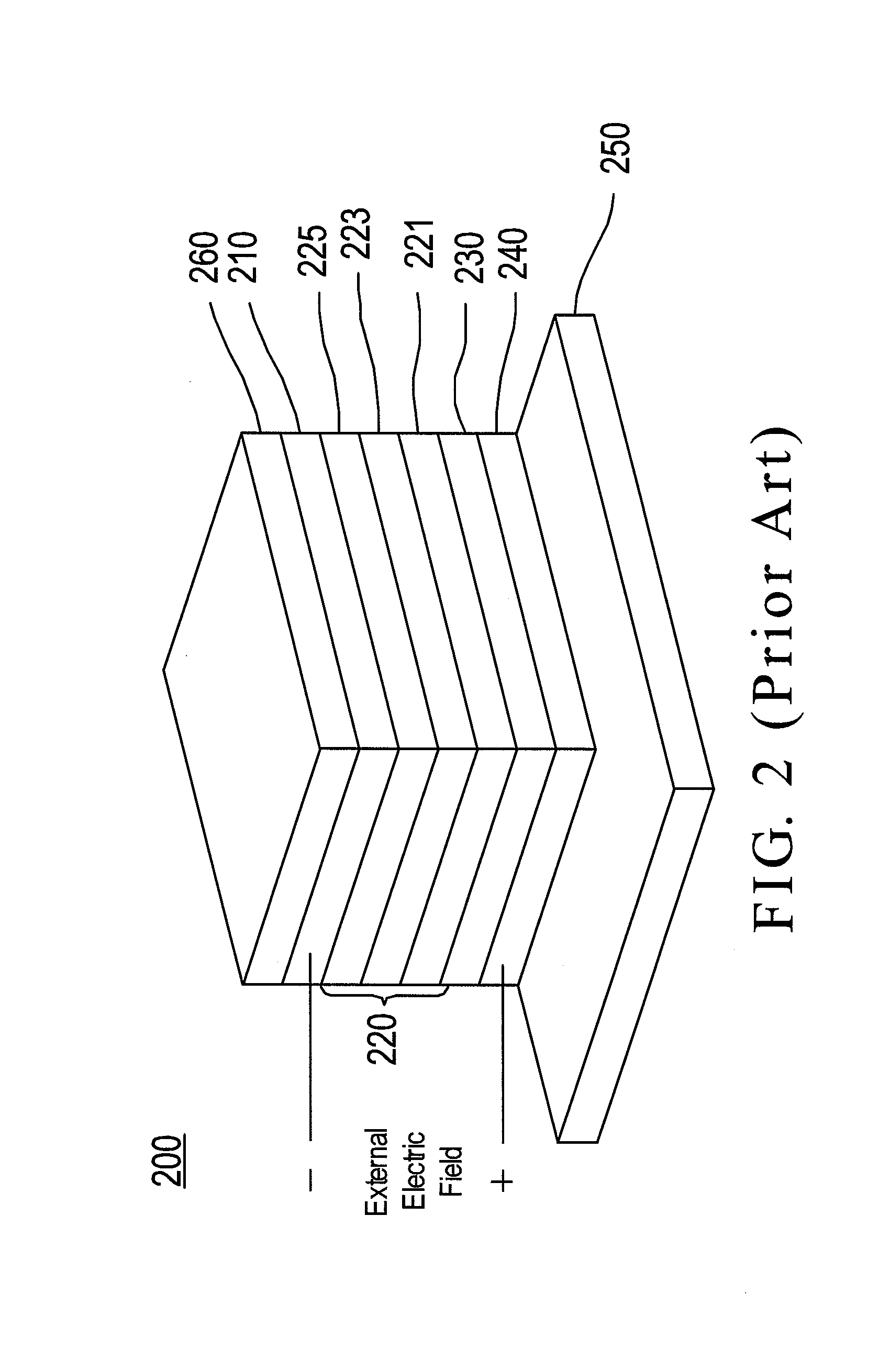

Method and apparatus for separating particles by dielectrophoresis

ActiveUS20060290745A1Easy to adjustHigh strengthDielectrophoresisElectrostatic separatorsElectricityPlanar electrode

Methods and apparatus for the micro-scale, dielectrophoretic separation of particles are provided. Fluid suspensions of particles are sorted and separated by dielectrophoretic separation chambers that have at least two consecutive, electrically coupled planar electrodes separated by a gap in a fluid flow channel. The gap distance as well as applied potential can be used to control the dielectrophoretic forces generated. Using consecutive, electrically coupled electrodes rather than electrically coupled opposing electrodes facilitates higher flow volumes and rates. The methods and apparatus can be used, for example, to sort living, damaged, diseased, and / or dead cells and functionalized or ligand-bound polymer beads for subsequent identification and / or analysis.

Owner:CFD RES CORP

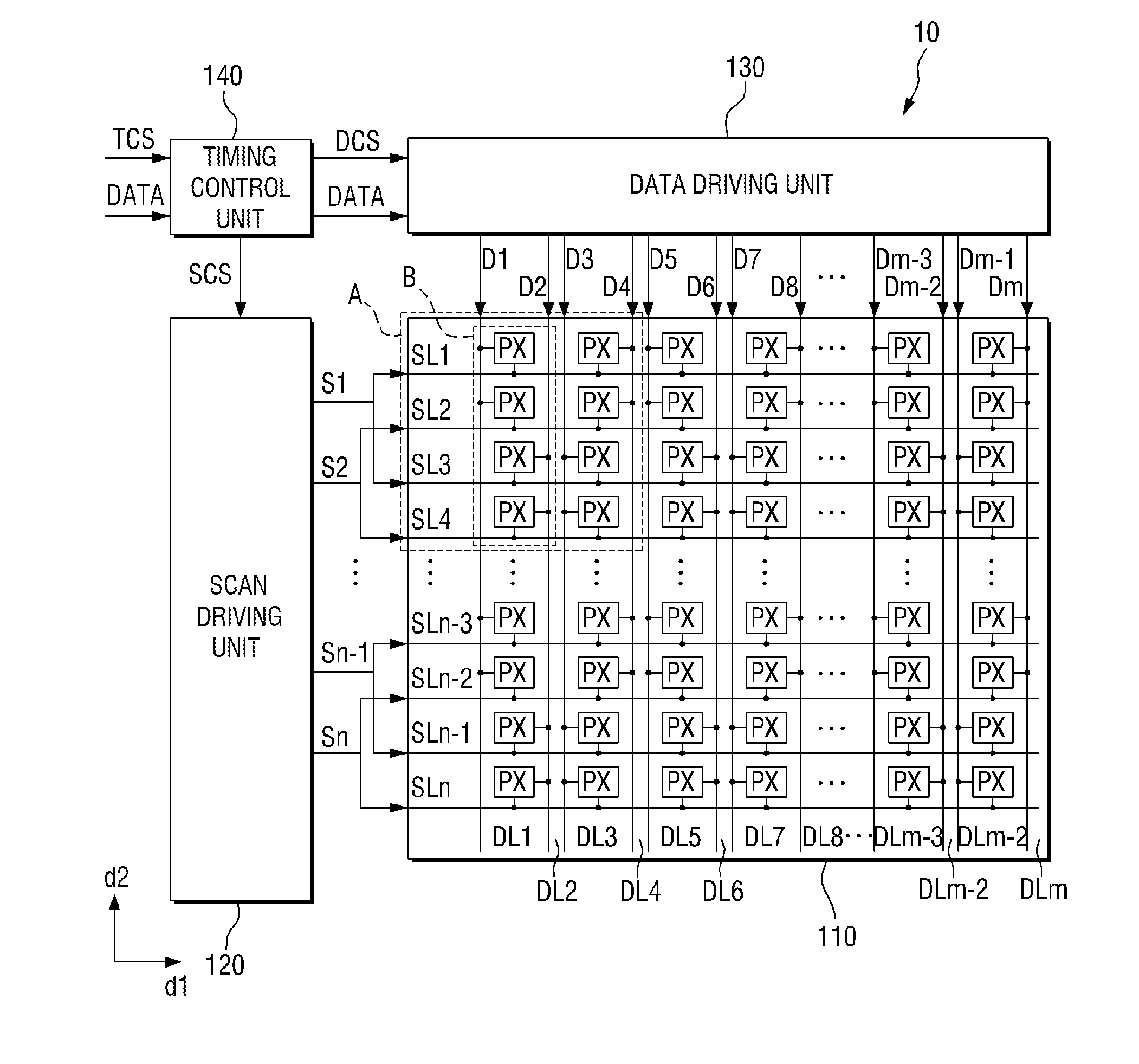

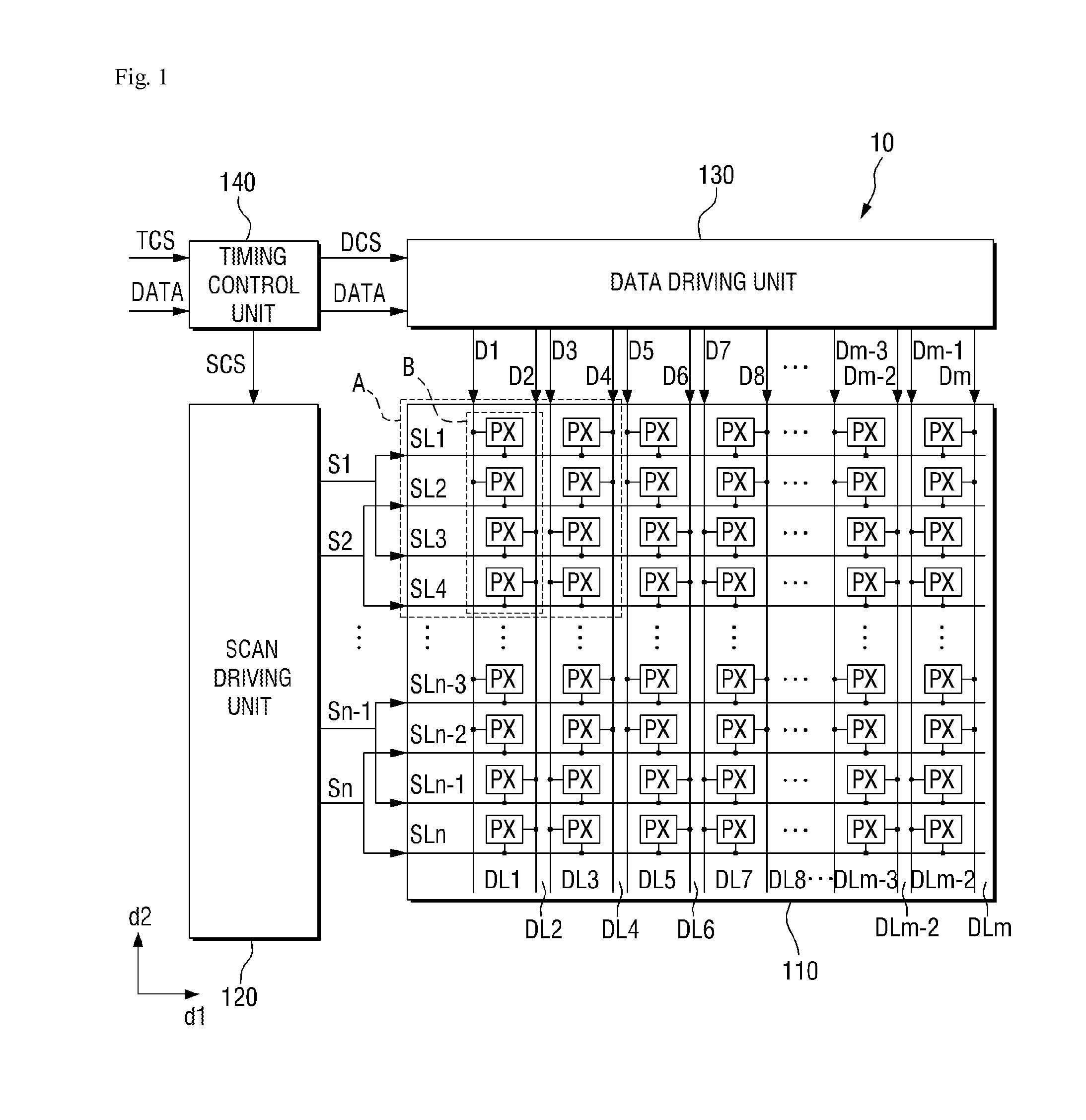

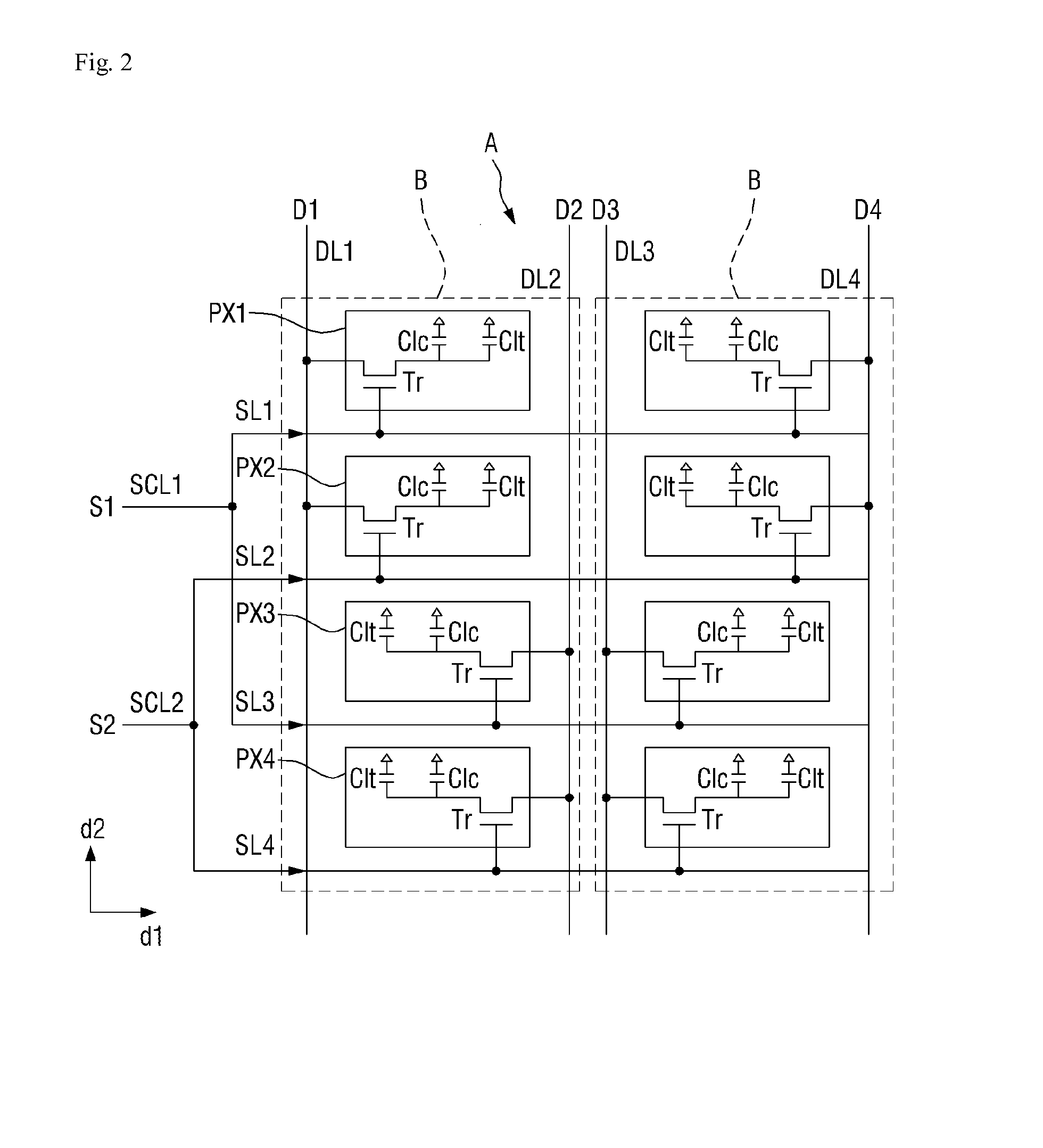

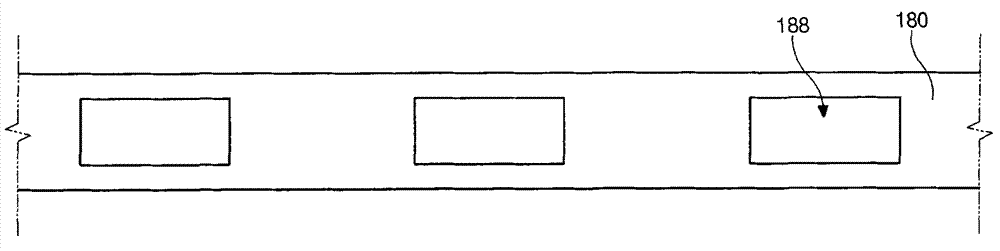

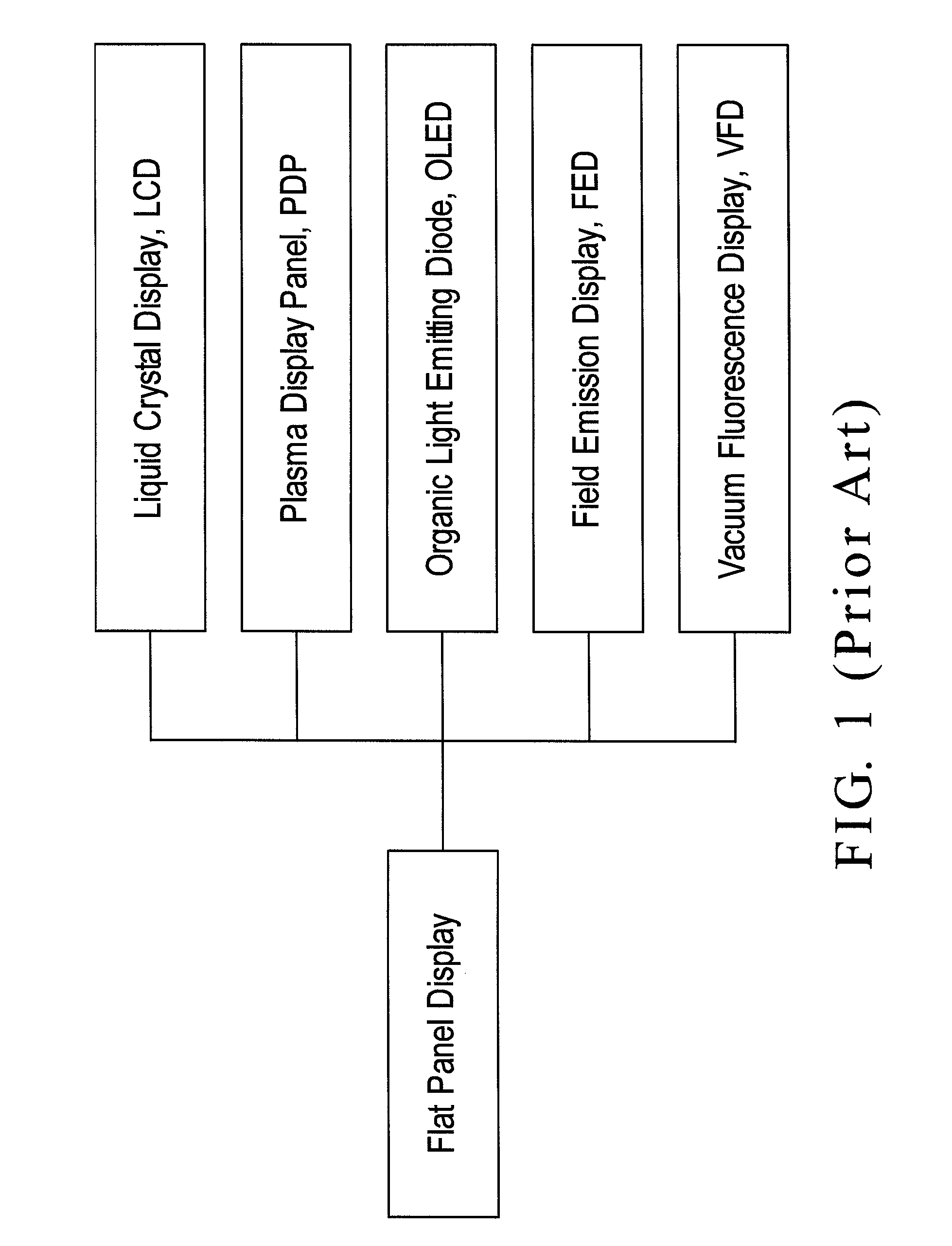

Liquid crystal display device and method for driving the same

ActiveUS20150221273A1Extension of timeImprove display qualityCathode-ray tube indicatorsInput/output processes for data processingLiquid-crystal displayElectrical polarity

A liquid crystal display device includes a plurality of pixels arranged substantially in a matrix form, where a part of the plurality of pixels defines a pixel column block, a first scan signal is simultaneously applied to an n-th row pixel and an (n+2)-th row pixel of the pixel column block, a second scan signal, which is applied prior to the first scan signal, is simultaneously applied to an (n+1)-th row pixel and an (n+3)-th row pixel of the pixel column block, a first data voltage is applied to the n-th row pixel and the (n+1)-th row pixel, a second data voltage having a polarity different from a polarity of the first data voltage is applied to the (n+2)-th row pixel and the (n+3)-th row pixel, and the polarities of the first data voltage and the second data voltage are inverted on a frame-by-frame basis.

Owner:SAMSUNG DISPLAY CO LTD

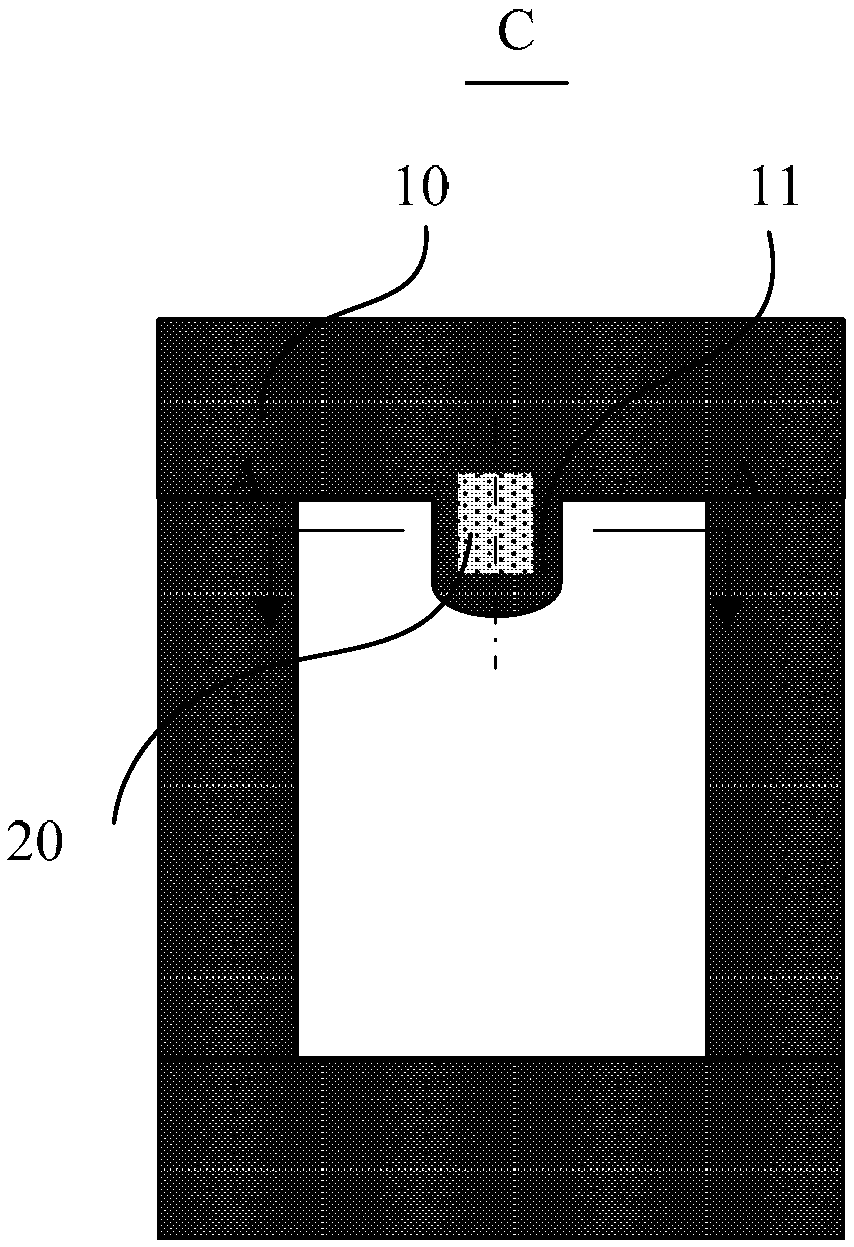

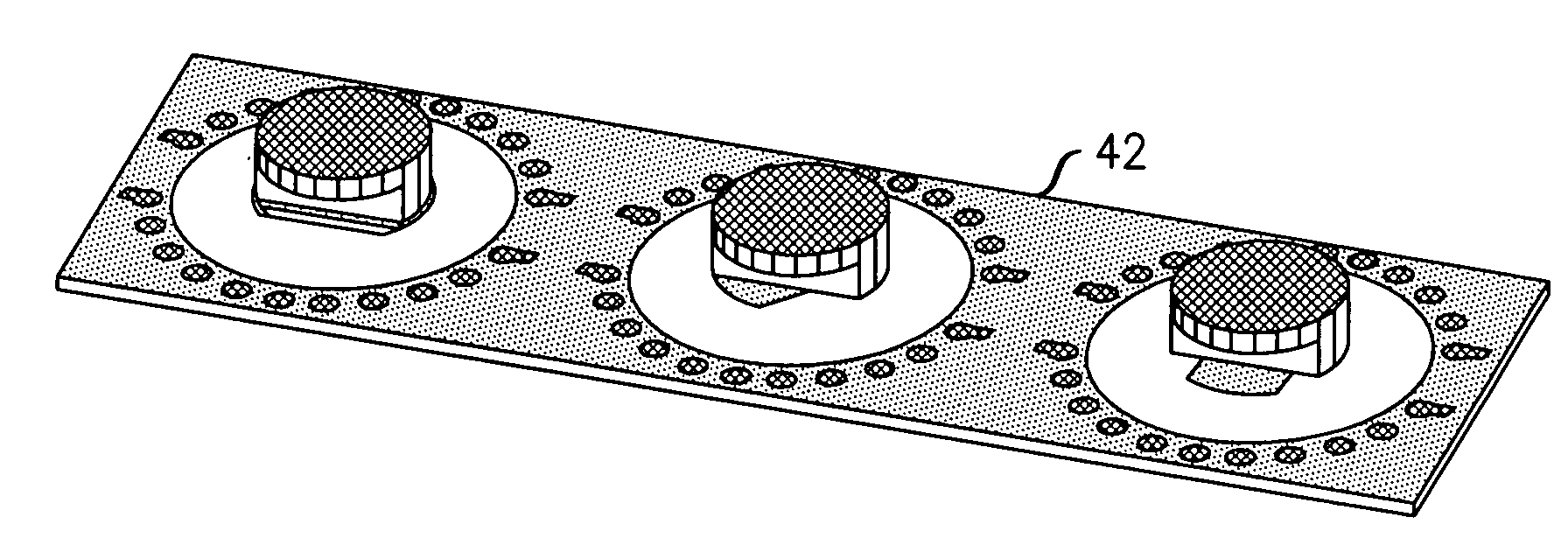

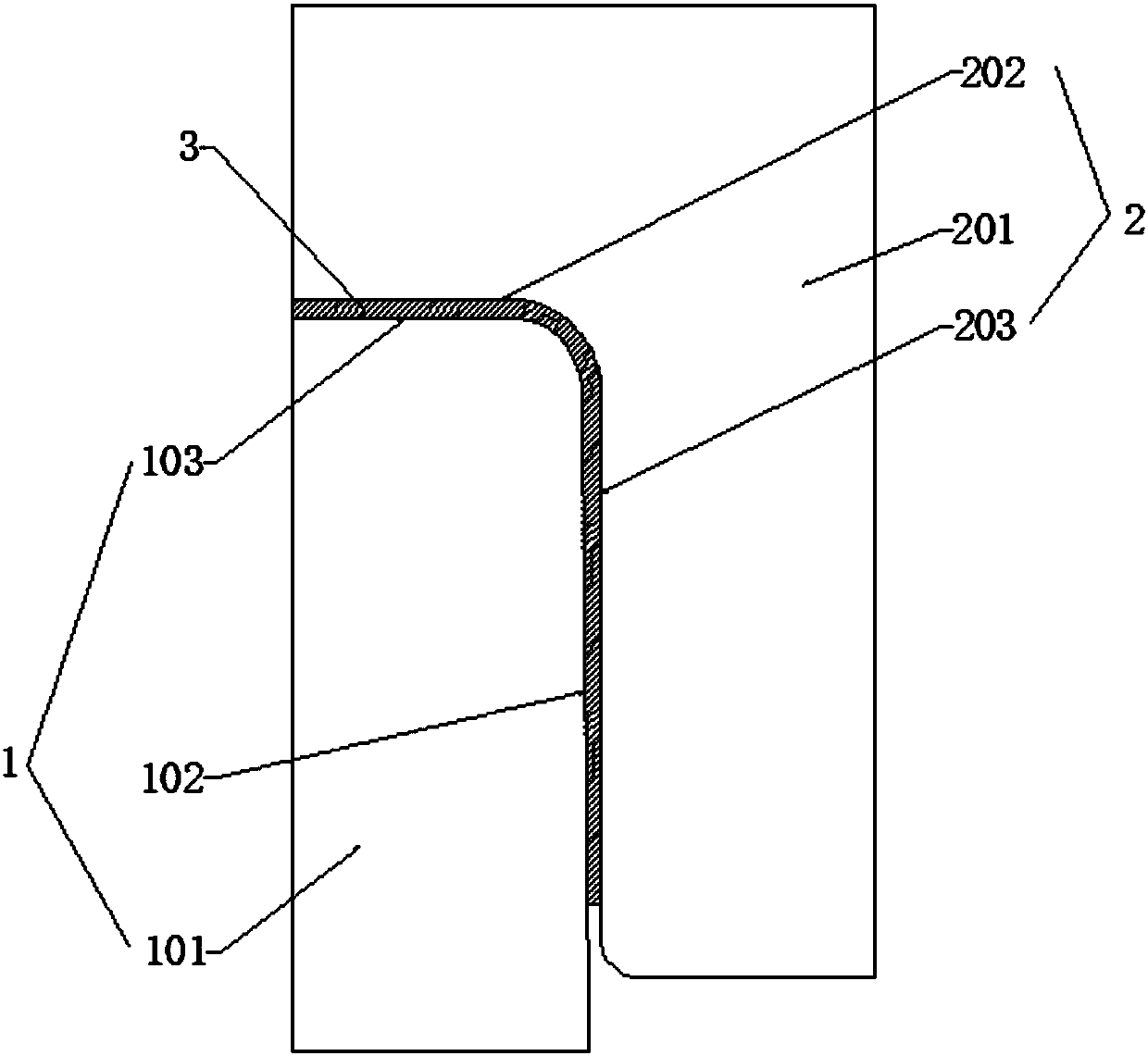

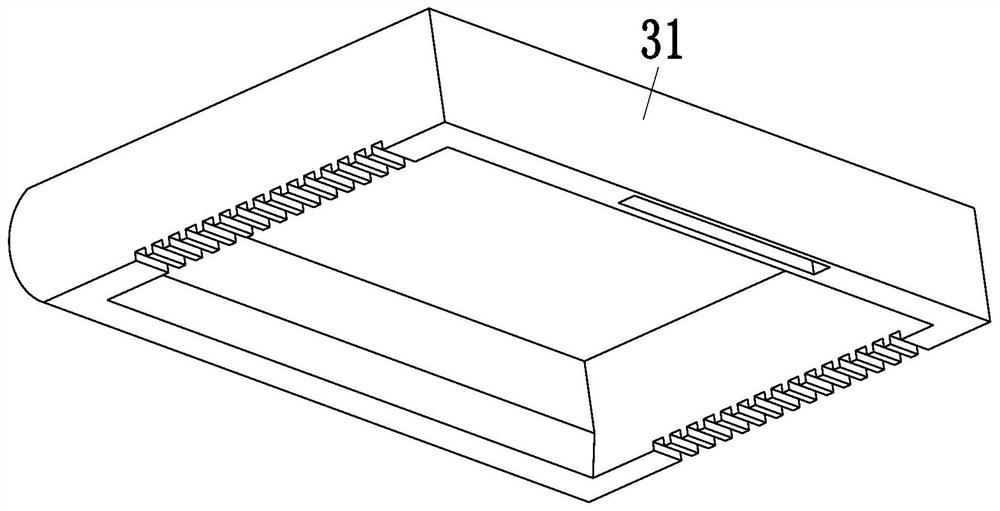

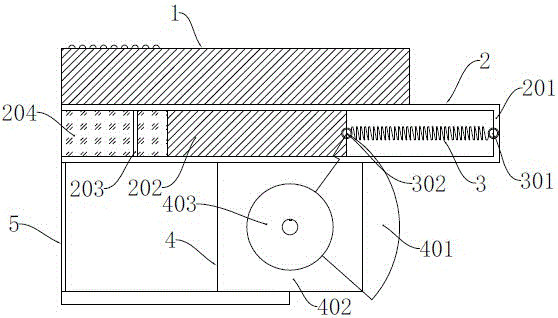

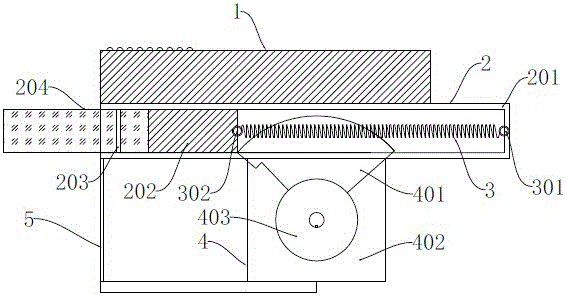

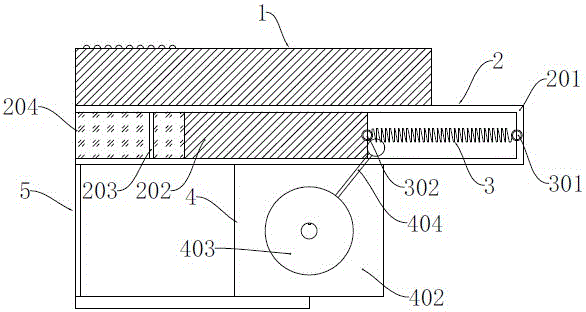

Mask and filming method and filming device thereof

ActiveCN107740065AReduce gap distanceIntrusion range reductionSolid-state devicesVacuum evaporation coatingFilm baseEngineering

The invention provides a mask and a filming method and a filming device thereof, and relates to the technical field of display and can solve the problem that if a mask pattern in the mask includes aninner convex pattern, when the mask is spread and fixed, the inner convex pattern can be cocking-up due to the uneven tensile force, so that the gap distance between the to-be-filmed base plate and the inner convex pattern is large. The mask includes a shielding part and a hollow area. The shielding part includes a shielding strip and a convex part stretching into the hollow area along the width direction of the shielding strip. The upper surface or the lower surface of the mask pattern is provided with a concave area, wherein the concave area is located or partly located in the convex part.

Owner:BOE TECH GRP CO LTD +1

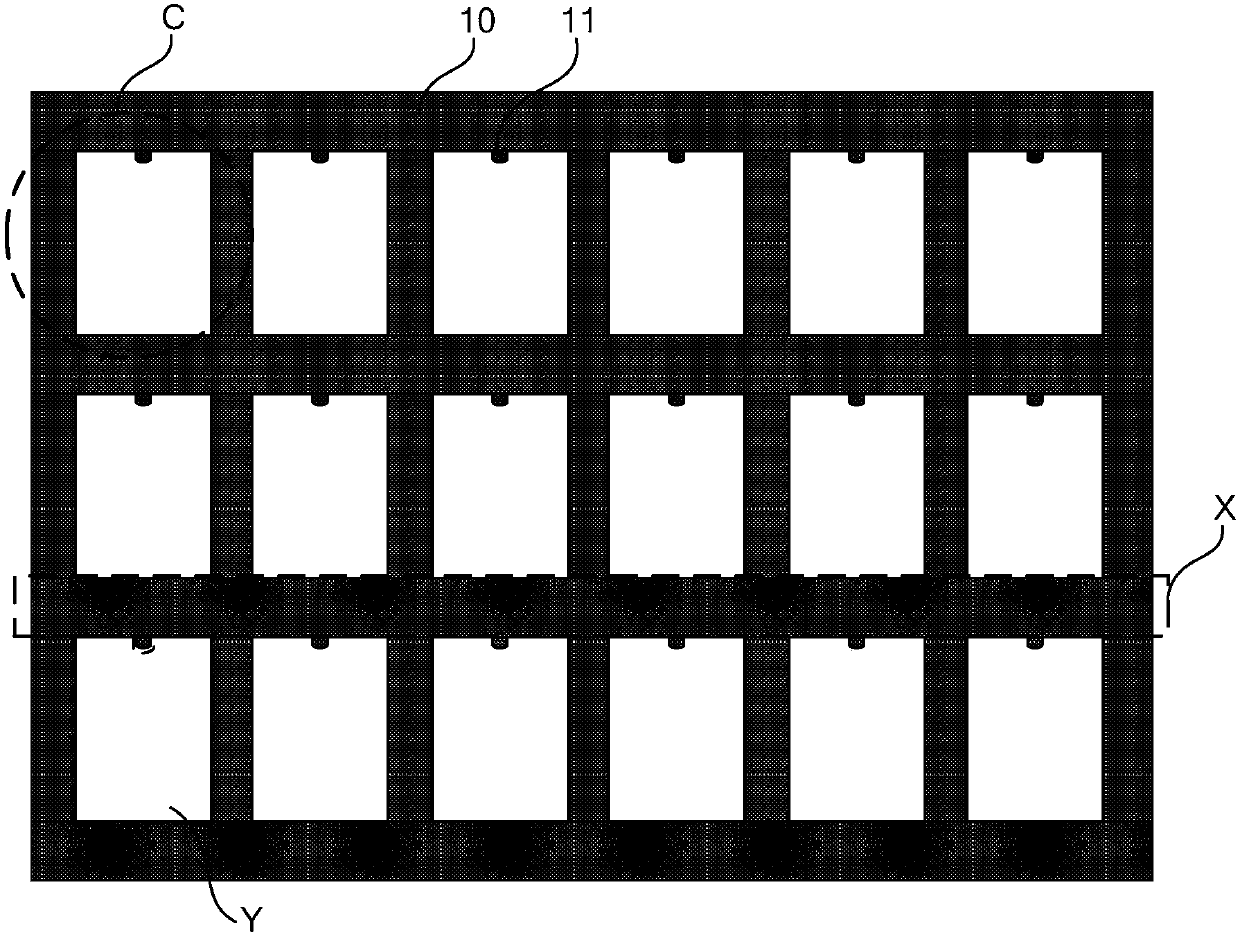

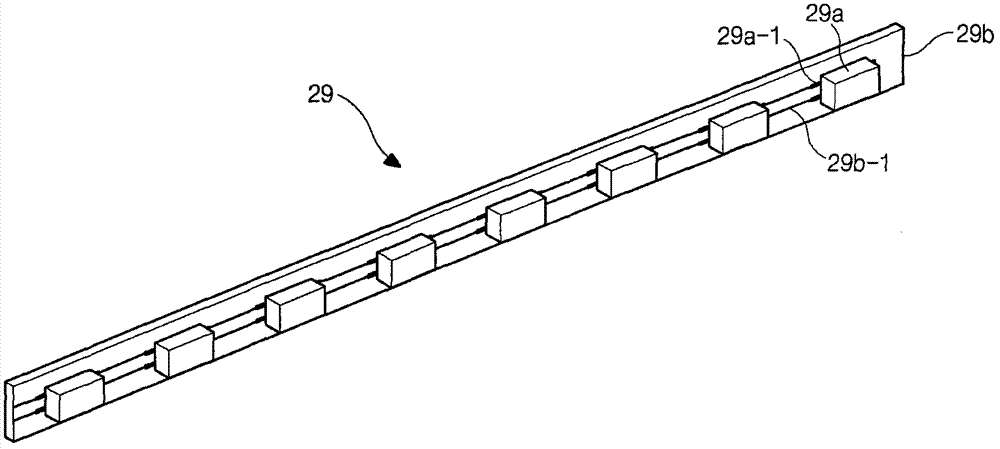

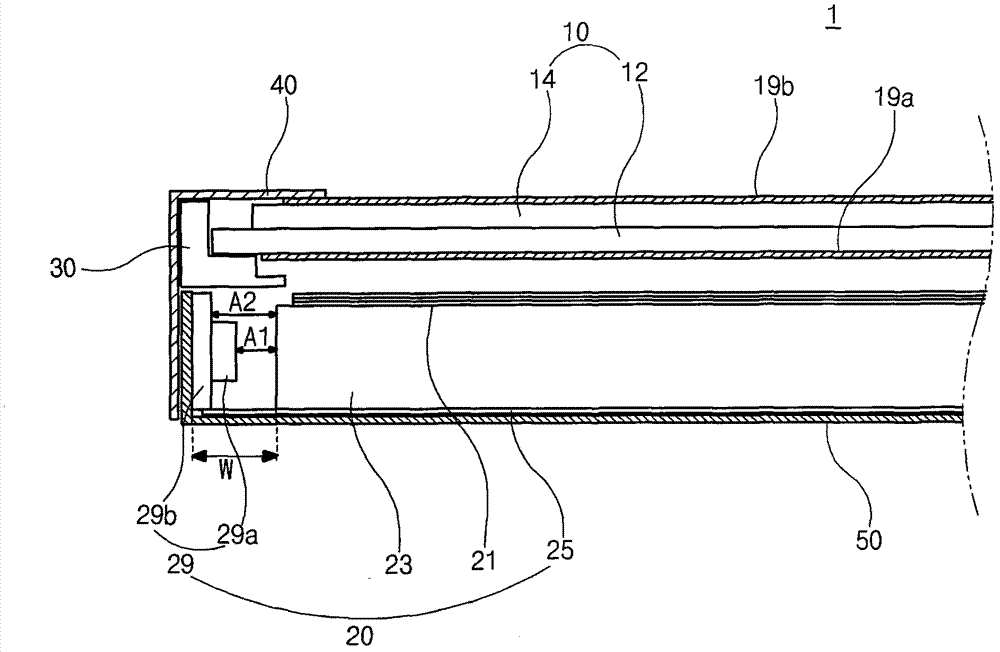

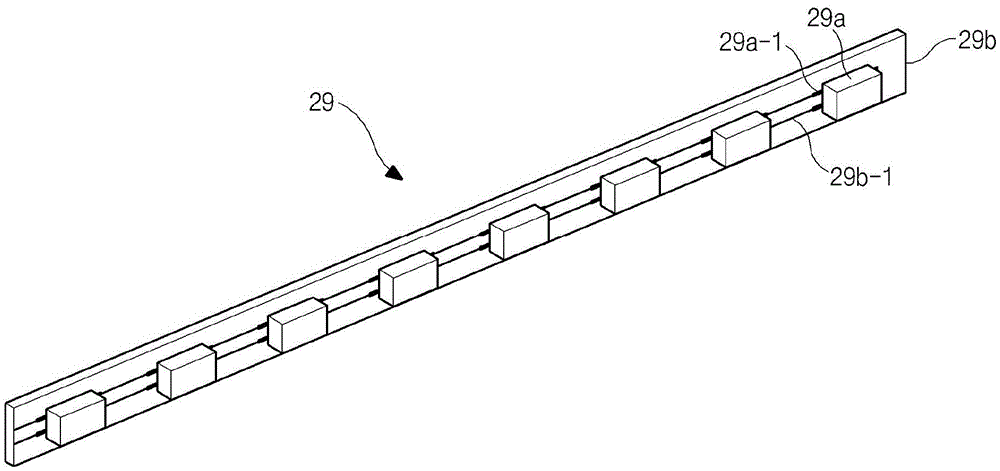

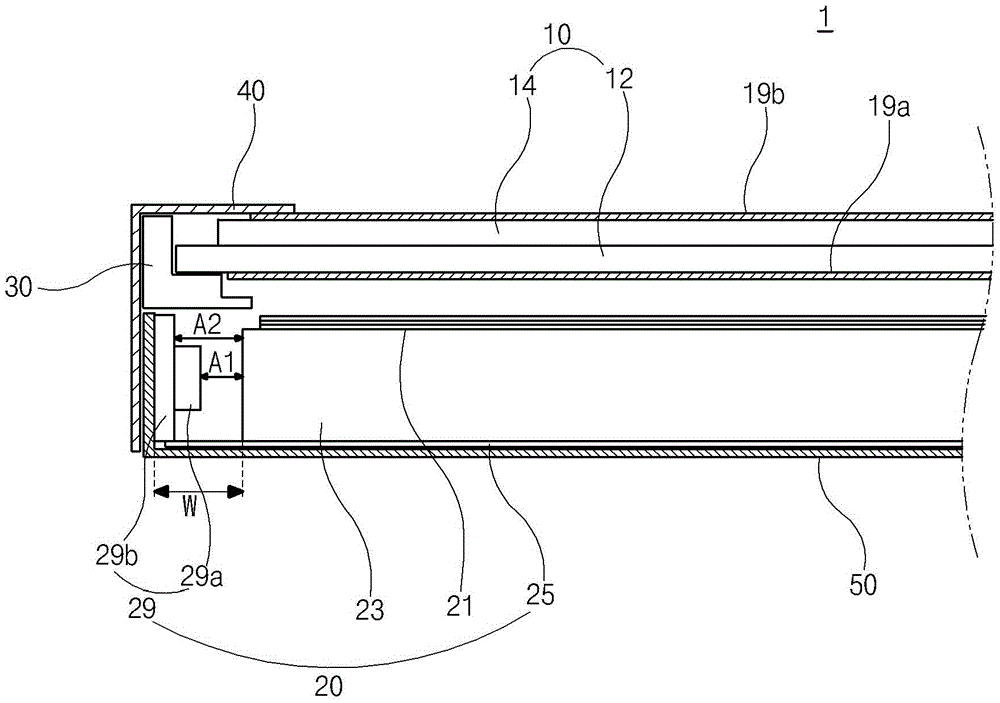

Backlight unit and liquid crystal display device including the same

InactiveCN102734699AReduce gap distanceSolve the low heat dissipation efficiencyPoint-like light sourceElongate light sourcesLiquid-crystal displayPrinted circuit board

The invention relates to a light emitting diode assembly, a backlight unit and a liquid crystal display device comprising the light emitting diode assembly. The light emitting diode assembly includes: a light emitting diode (LED) printed circuit board (PCB) and a plurality of LEDs. The light emitting diode (LED) printed circuit board (PCB) has a base layer, an insulating layer on the base layer and a circuit pattern layer on the insulating layer and a protecting layer on the circuit pattern layer, and wherein the LED PCB includes a plurality of through holes spaced apart from each other along the length direction; and the plurality of light emitting diodes (LEDs) are inserted into the plurality of through holes, respectively, from a bottom surface of the LED PCB, each of the plurality of LEDs including a lead contacting the circuit pattern layer, and wherein the plurality of LEDs are electrically connected with the LED PCB via the leads.

Owner:LG DISPLAY CO LTD

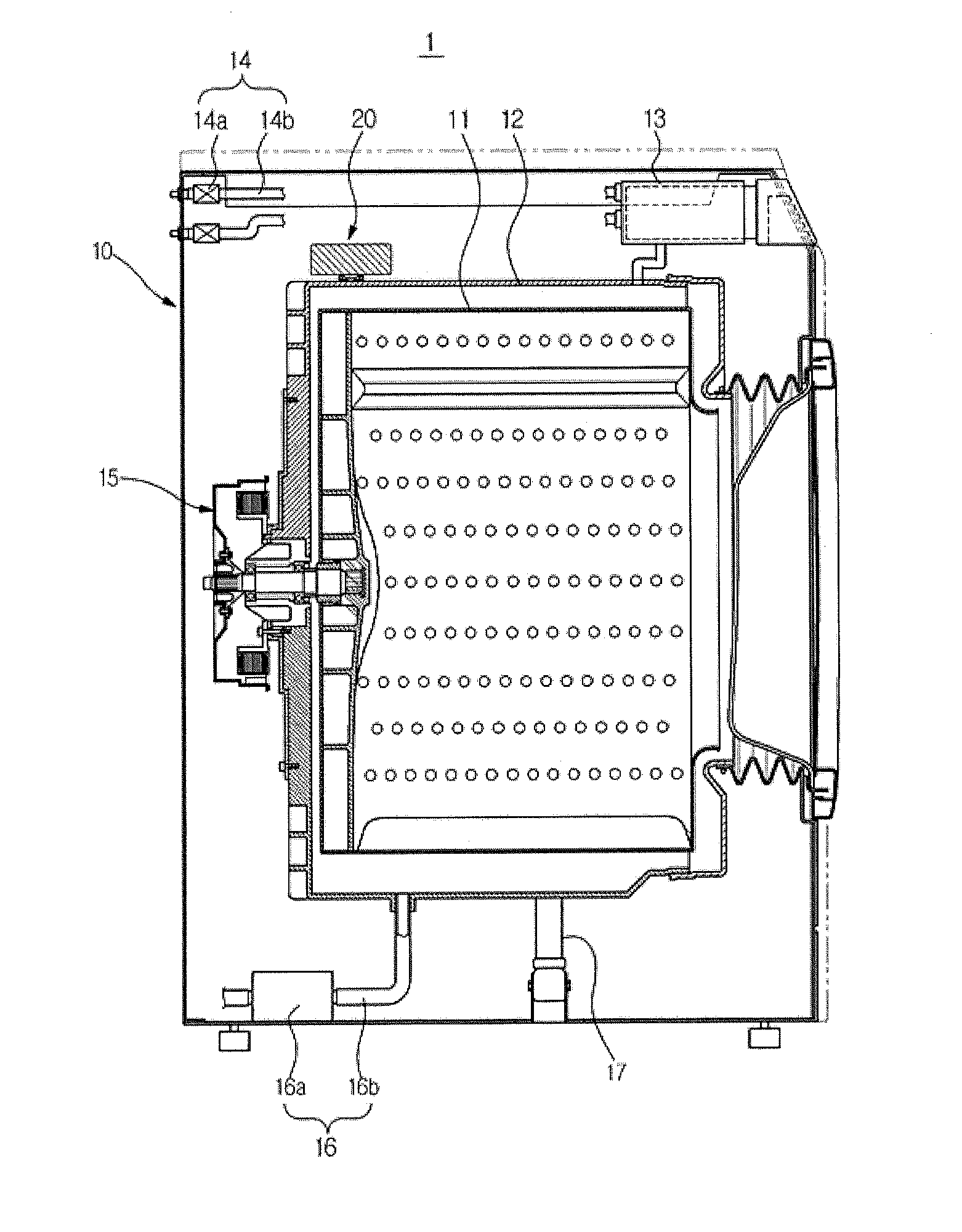

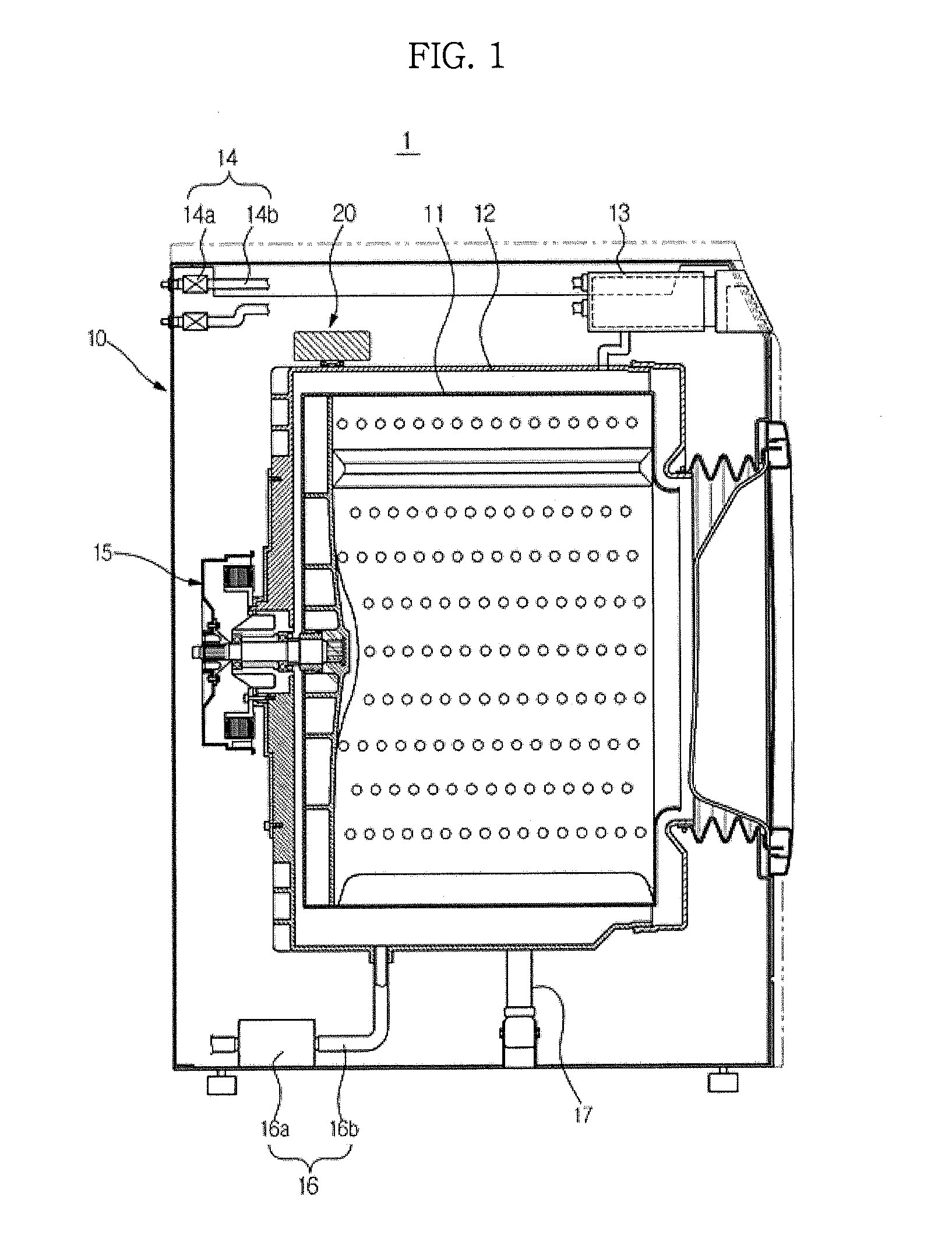

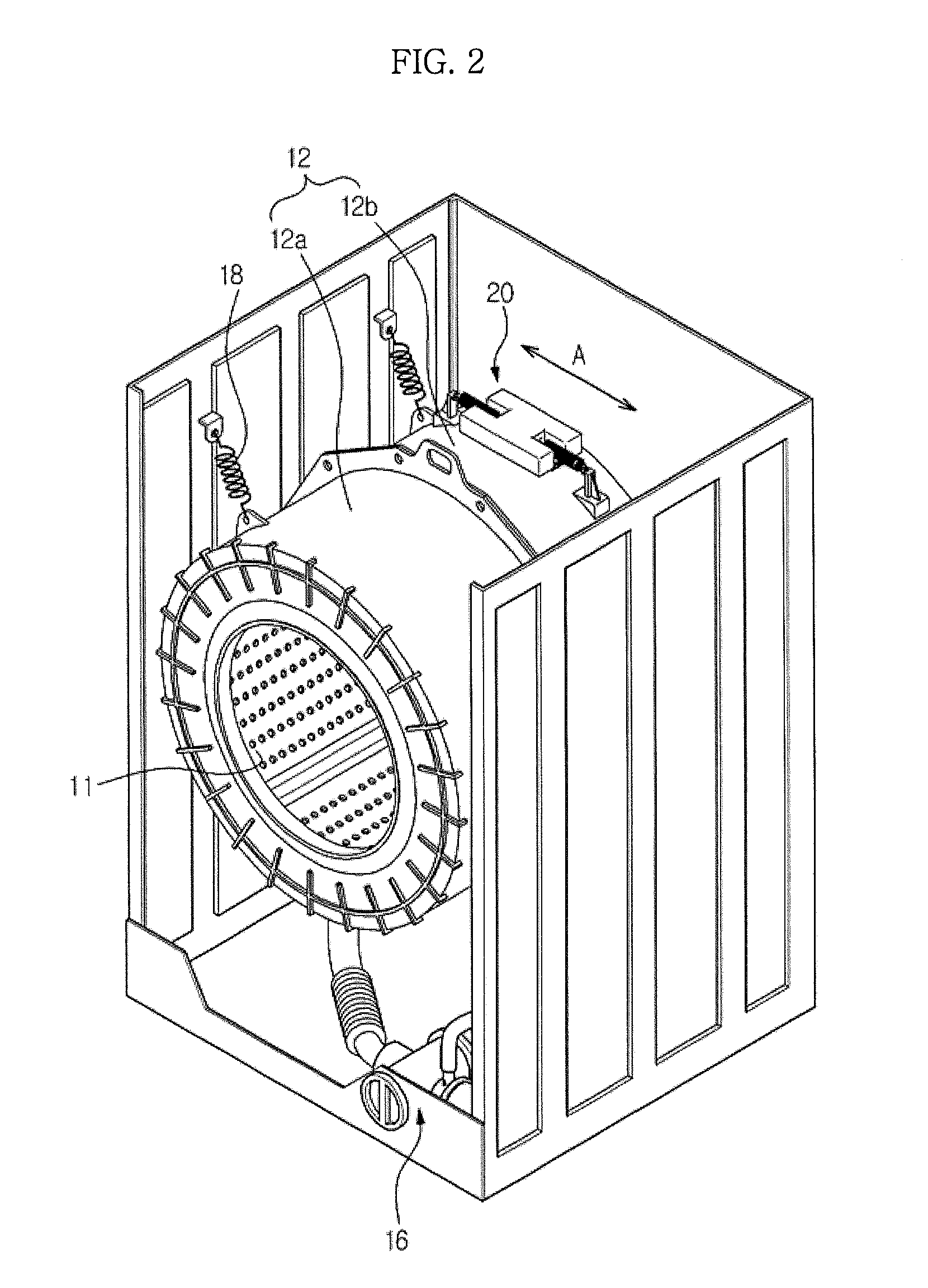

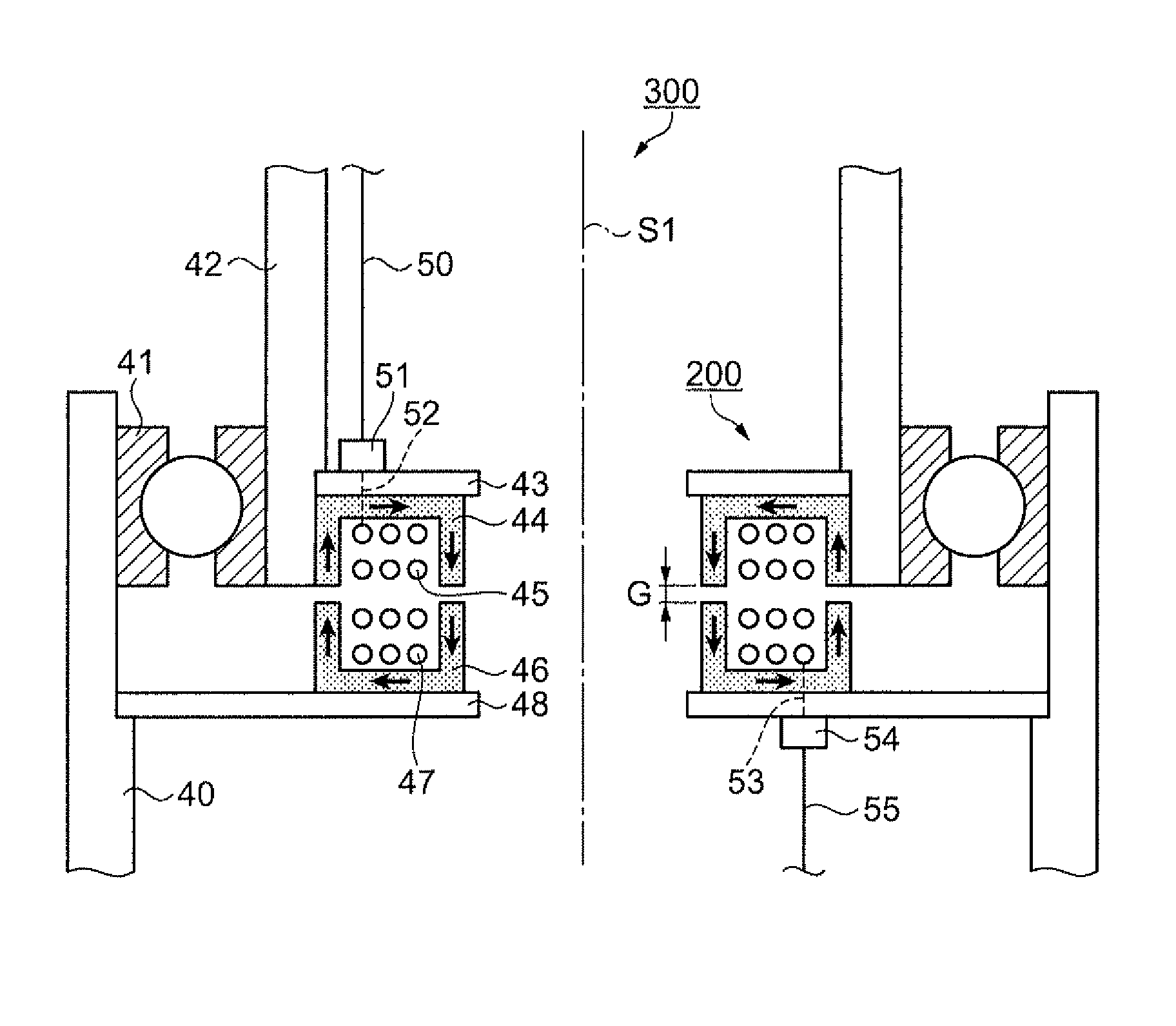

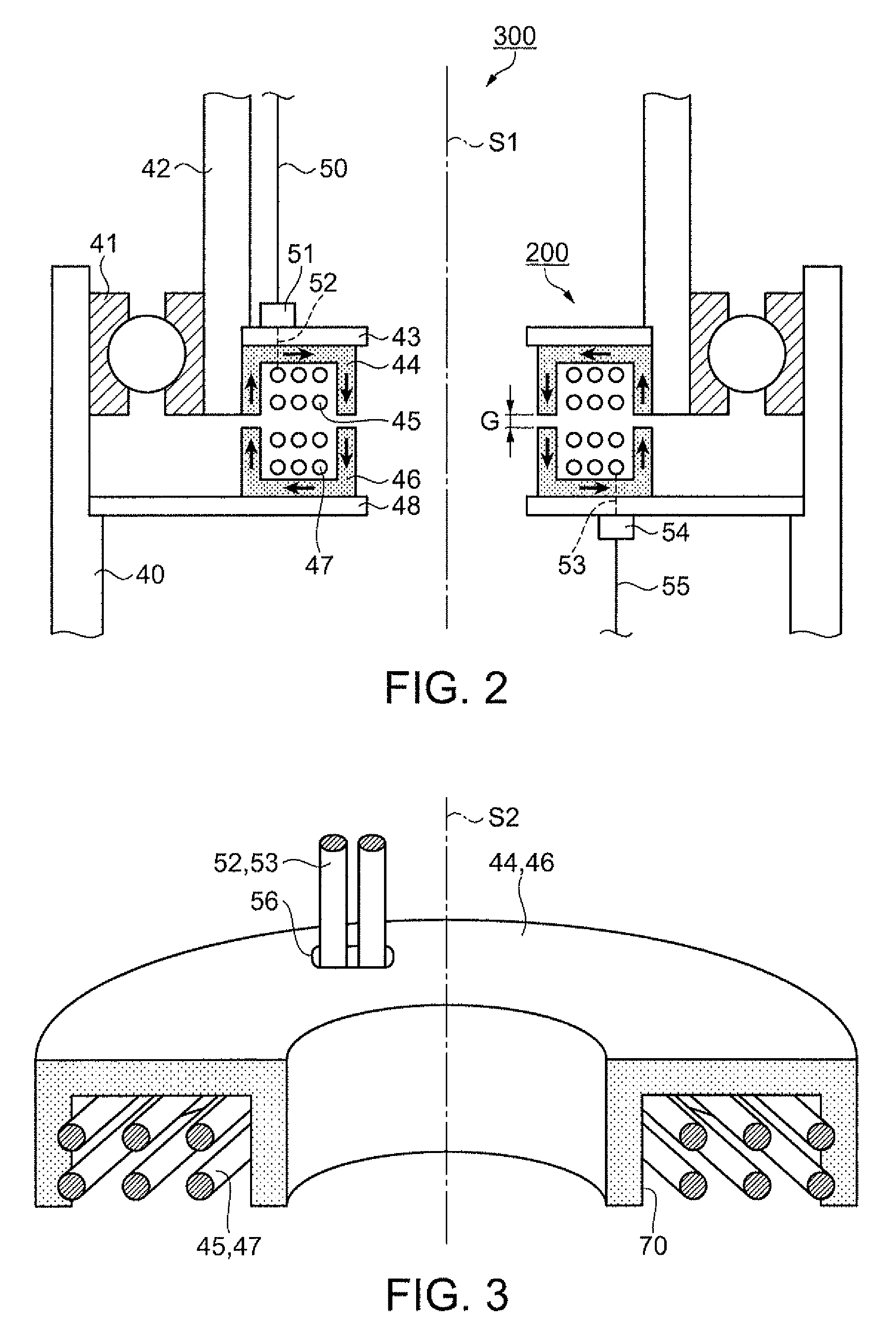

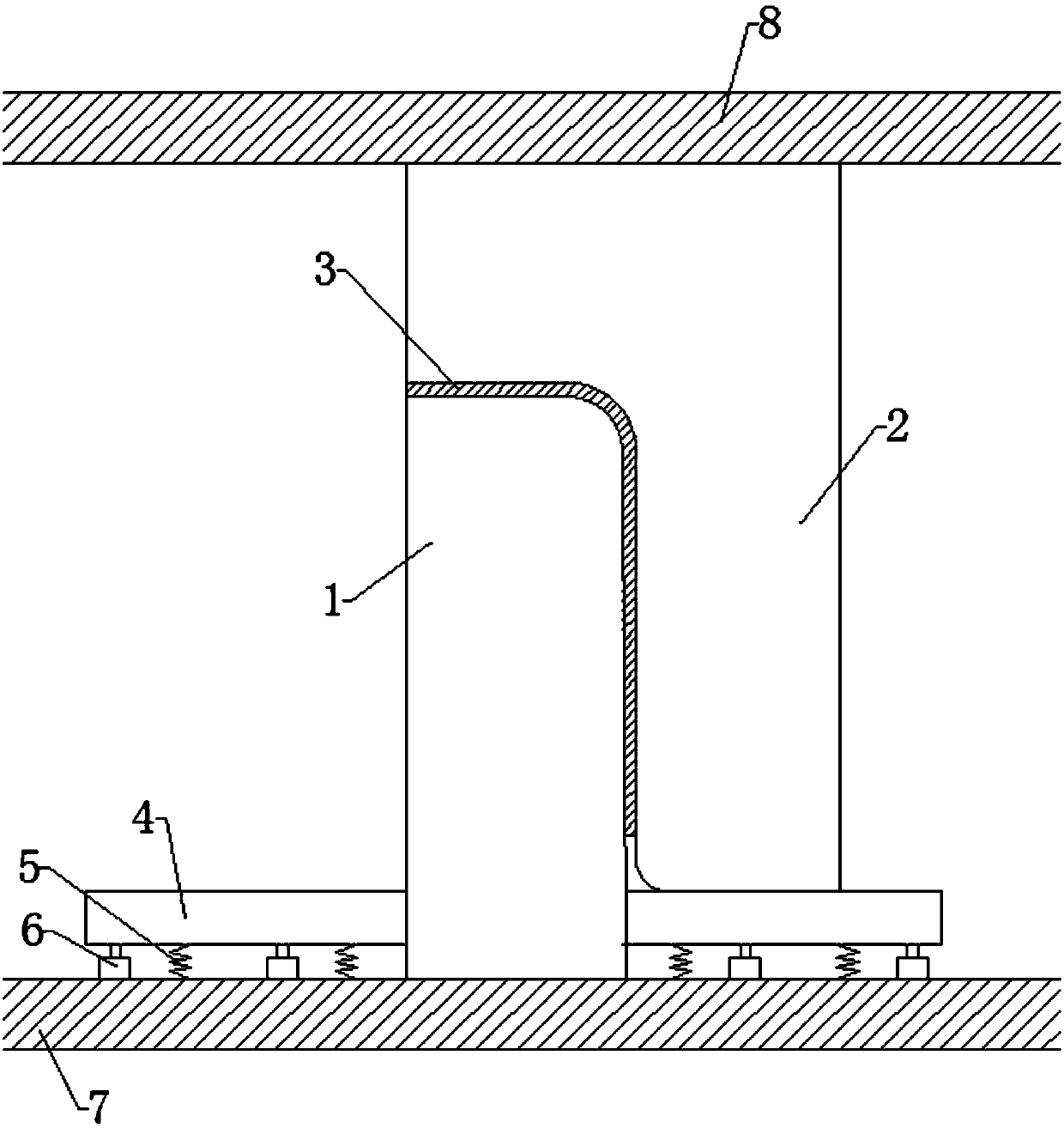

Drum washing machine

InactiveUS20130118211A1Excessive vibrationReduce vibrationRotating vibration suppressionNon-rotating vibration suppressionLow frequency bandEngineering

A drum washing machine provided with a dynamic absorber capable of reducing the vibration of a low frequency band, the drum washing machine including a body, a drum rotatably installed at an inside the body, a tub installed to vibrate while surrounding the drum, and a dynamic absorber installed at the tub to directly reduce vibration delivered to the tub, wherein the dynamic absorber includes a mass body and an elastic member configured to elastically support the mass body for the mass body to move toward a direction of the vibration of the tub to reduce the vibration of the tub.

Owner:SAMSUNG ELECTRONICS CO LTD

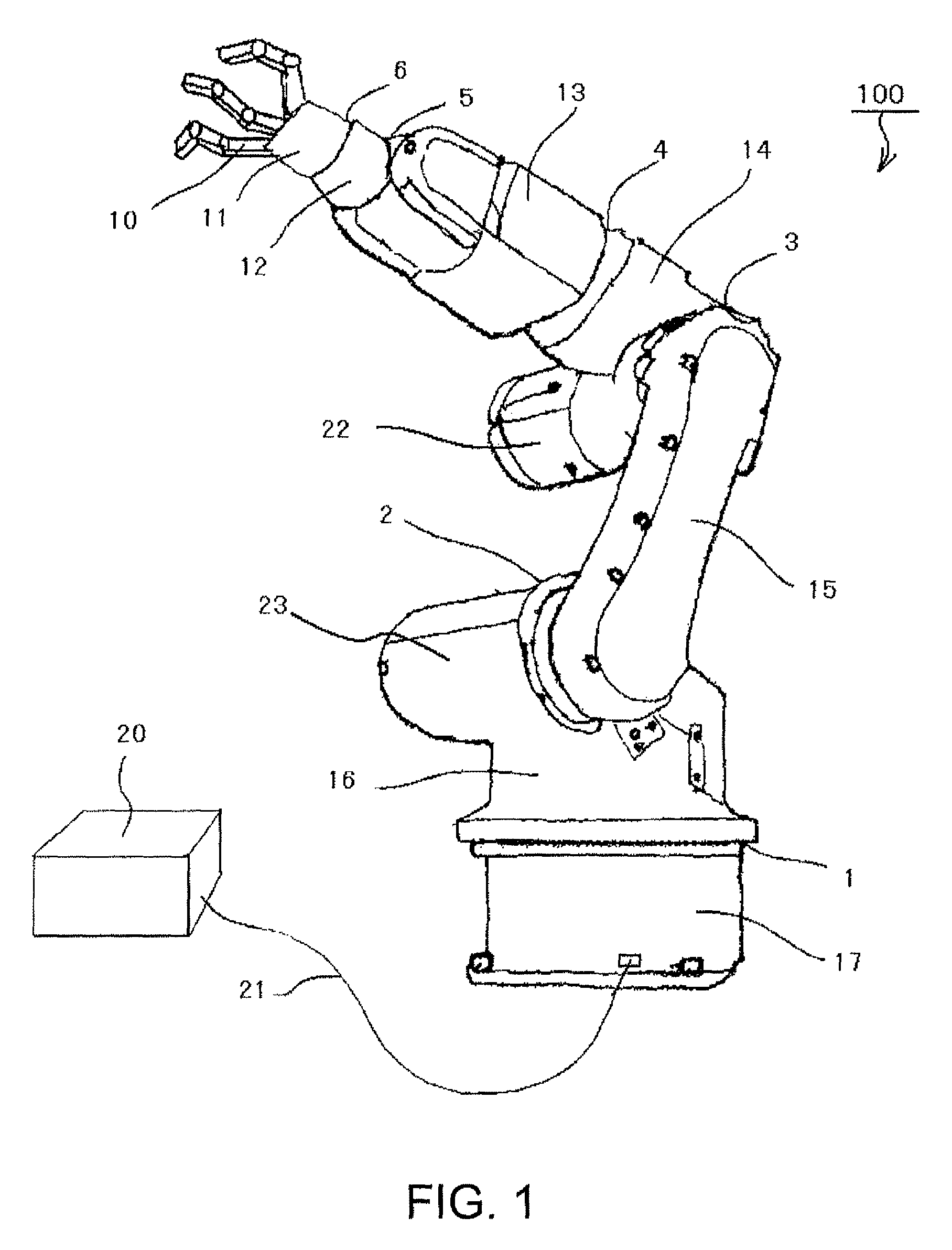

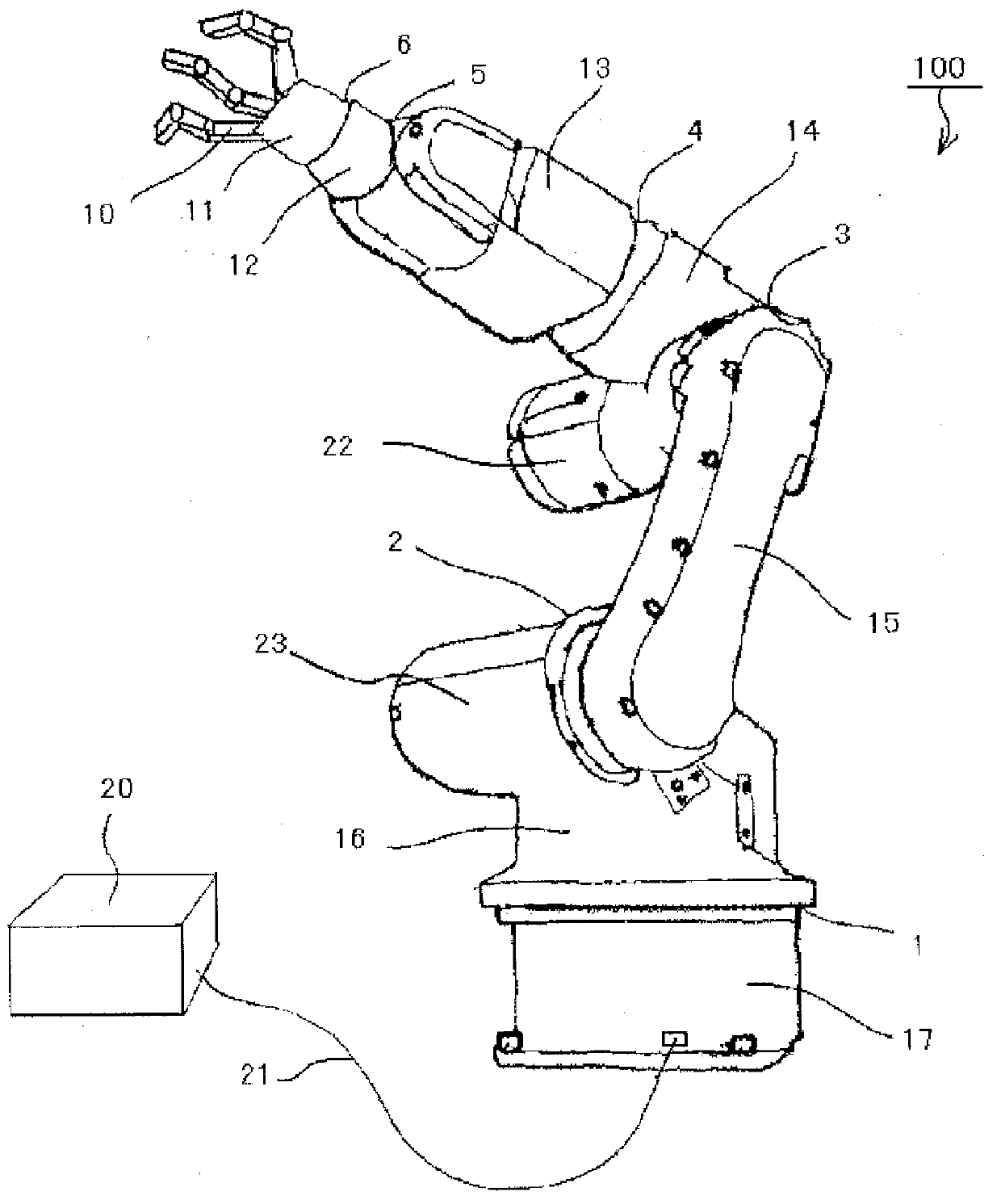

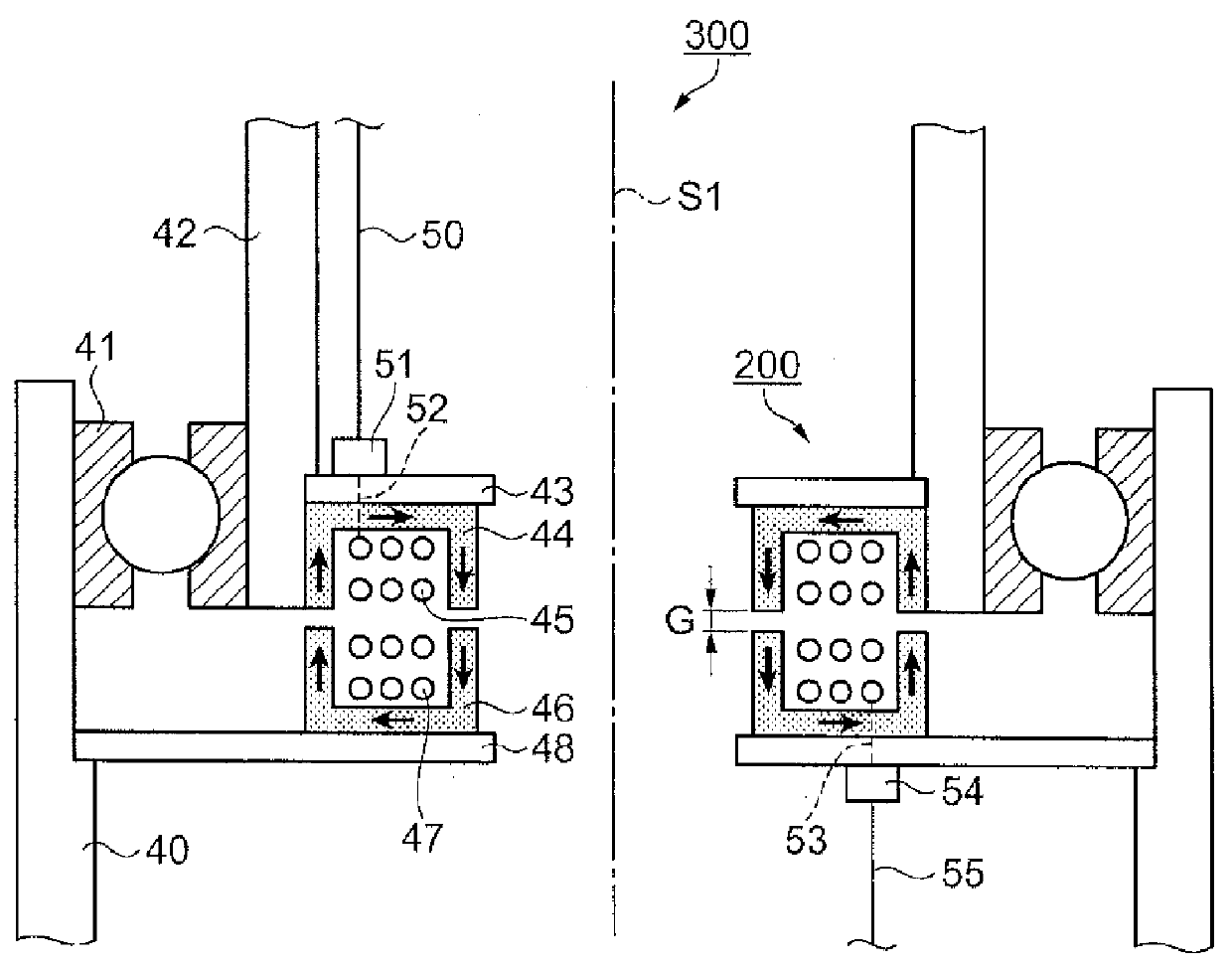

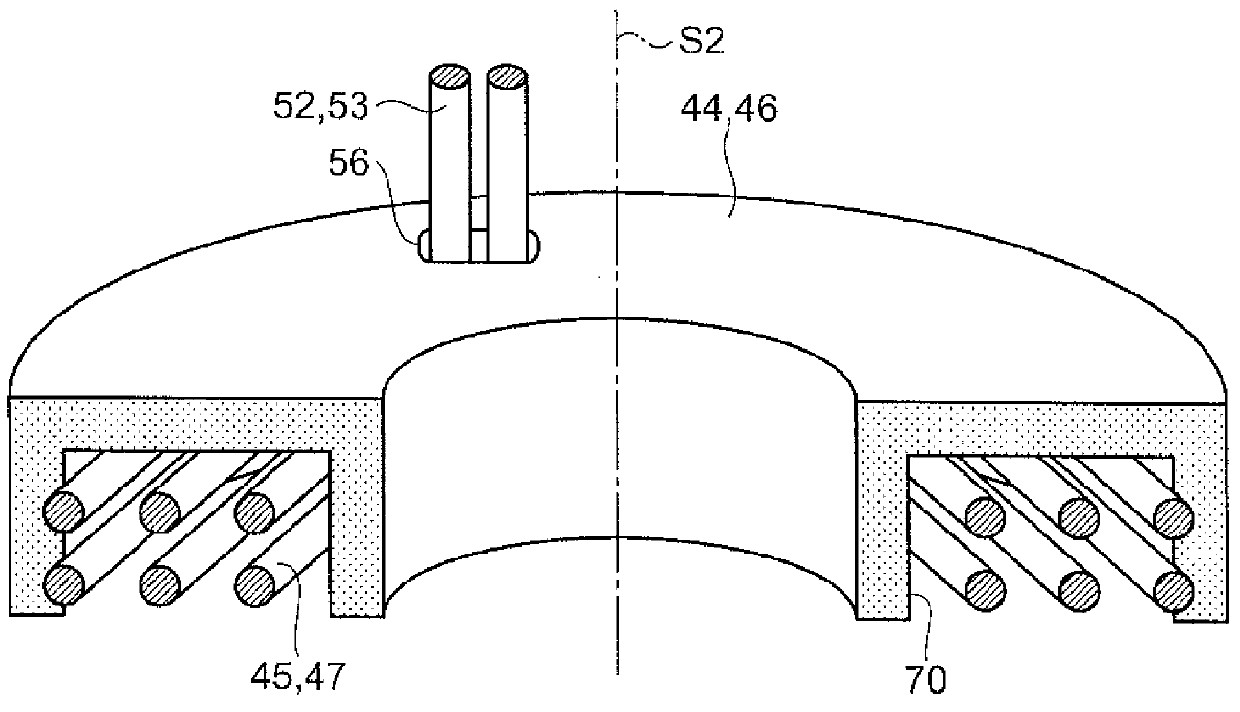

Rotating device and robot arm device

InactiveUS8166844B2Suppress damage caused by contactSuppress instability in communicationNear-field transmissionMechanical apparatusCommunication unitEngineering

A rotating device includes a communication unit including a transmitting portion having a first ring-shaped coil, a first ring-shaped magnetic body covering the first ring-shaped coil and a first terminal connected to the first ring-shaped coil, and a receiving portion having a second ring-shaped coil, a second ring-shaped magnetic body covering the second ring-shaped coil and a second terminal connected to the second ring-shaped coil, and a bearing connecting a hollow fixed portion to a hollow rotating portion, which is capable of rotating with respect to the fixed portion, in which the first ring-shaped coil and the second ring-shaped coil are formed so as to be wound around a rotation axis of the bearing, the first ring-shaped magnetic body and the second ring-shaped magnetic body face each other with a gap formed in the direction of the rotation axis, and the communication unit is provided inside the fixed portion and the rotating portion.

Owner:SEIKO EPSON CORP

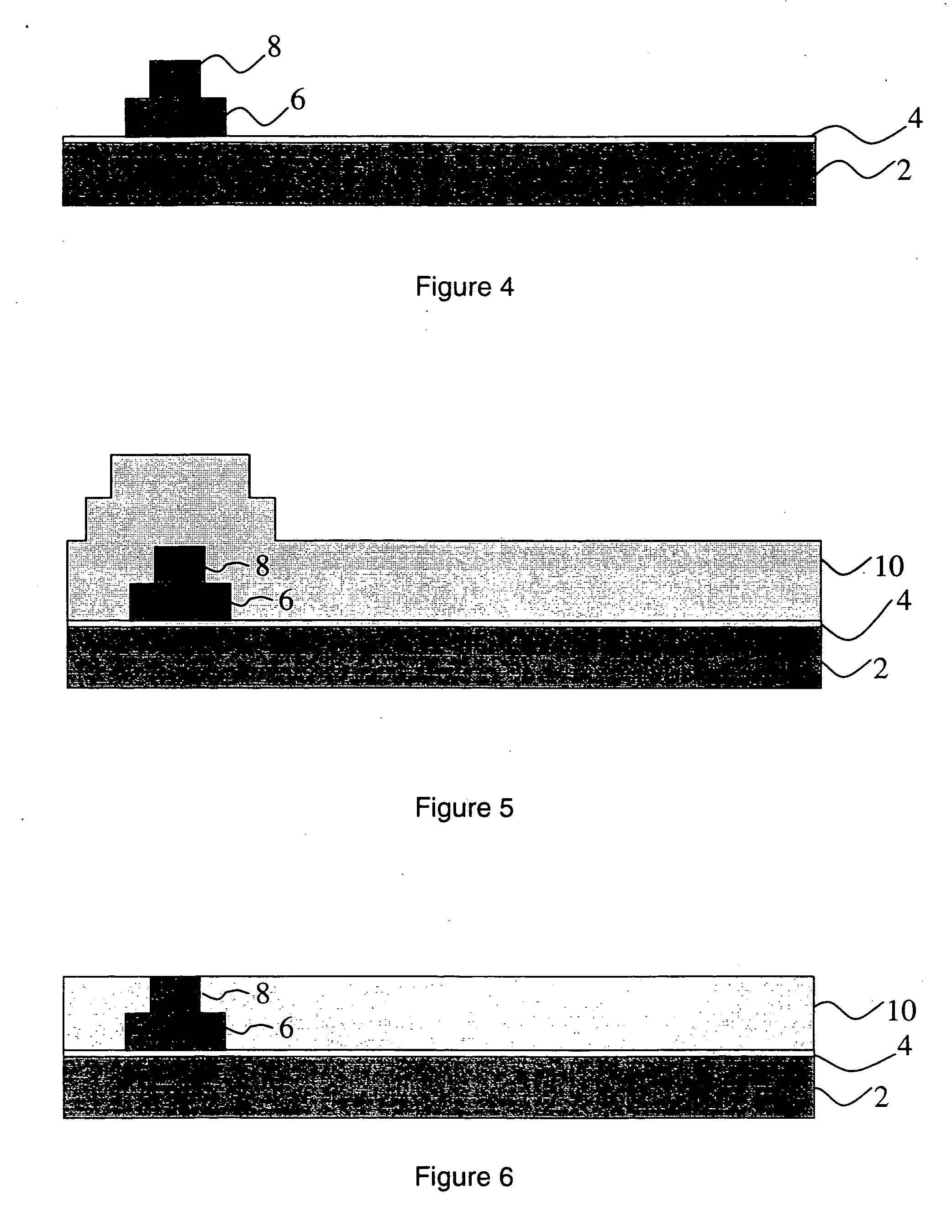

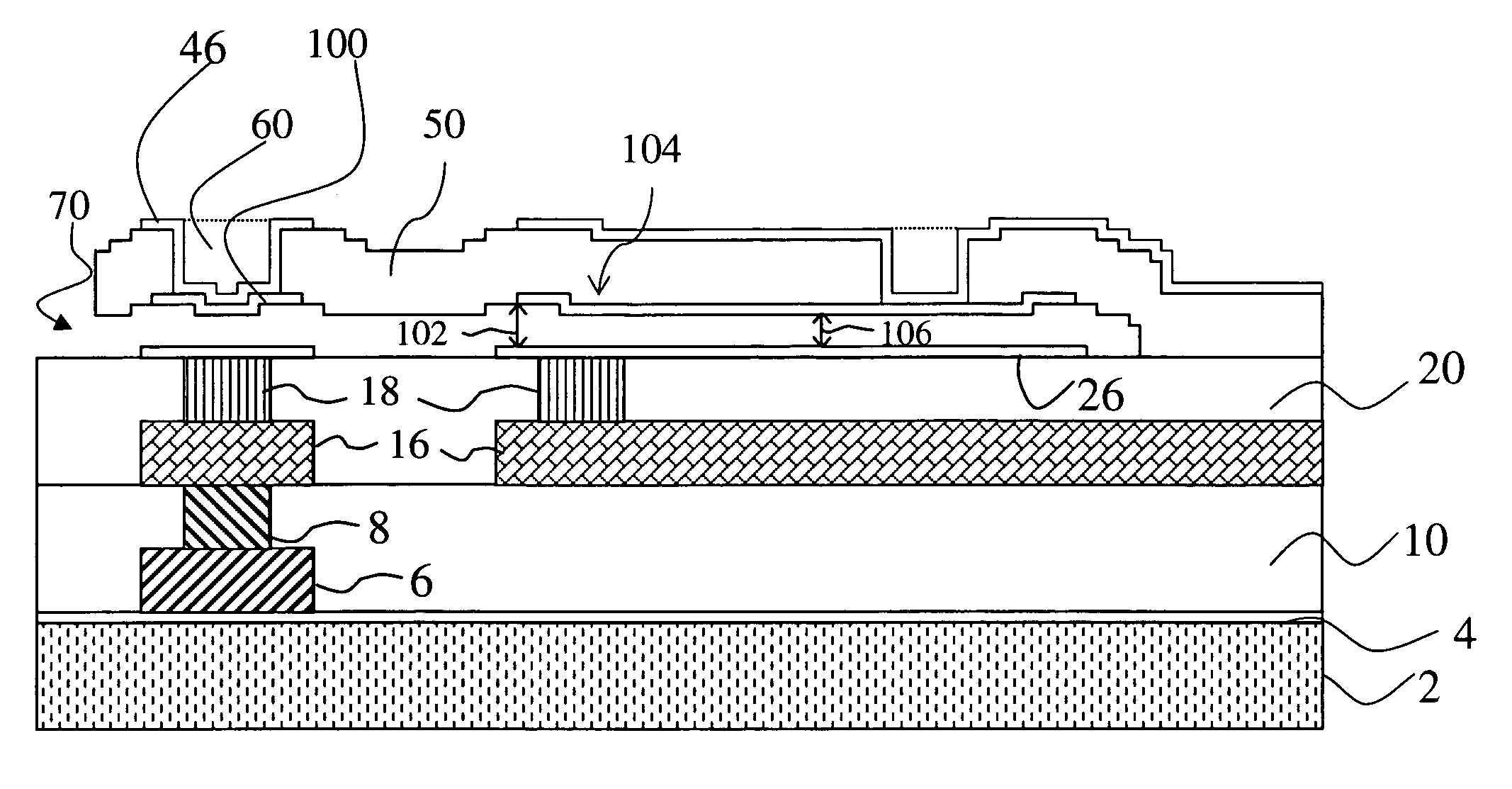

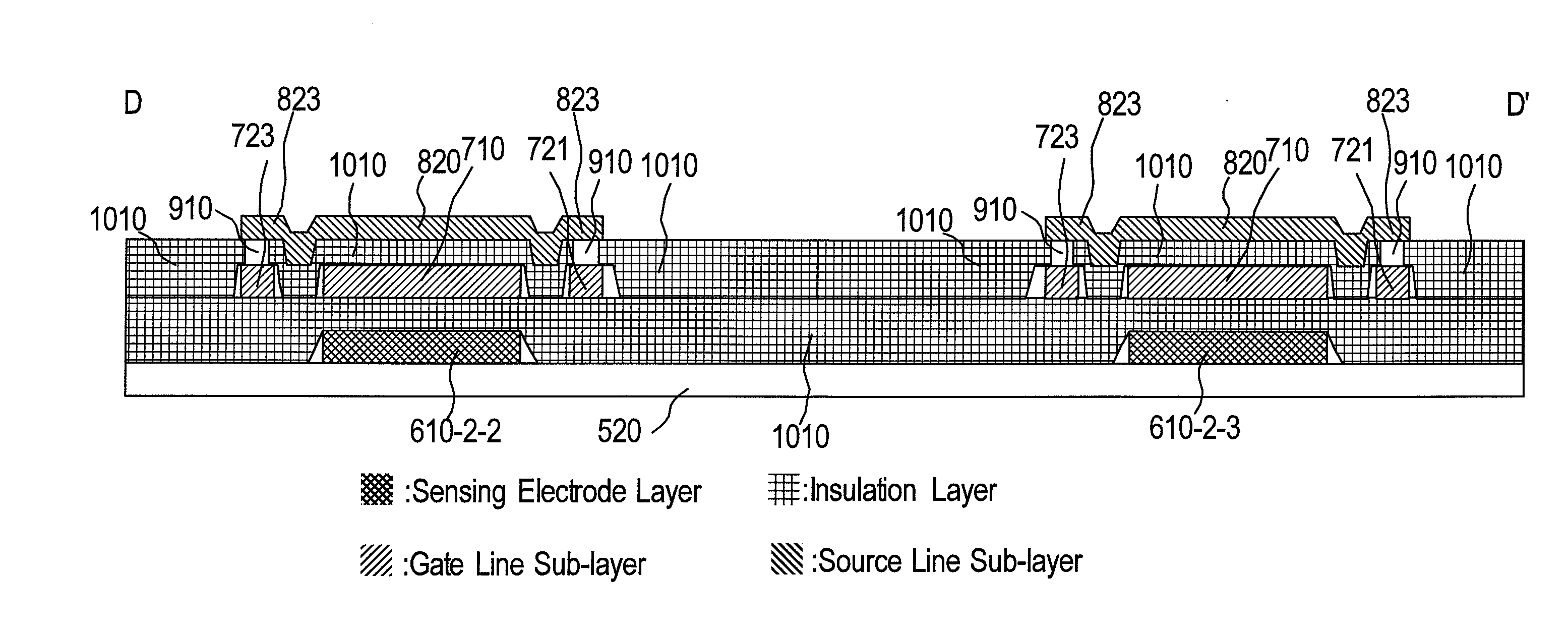

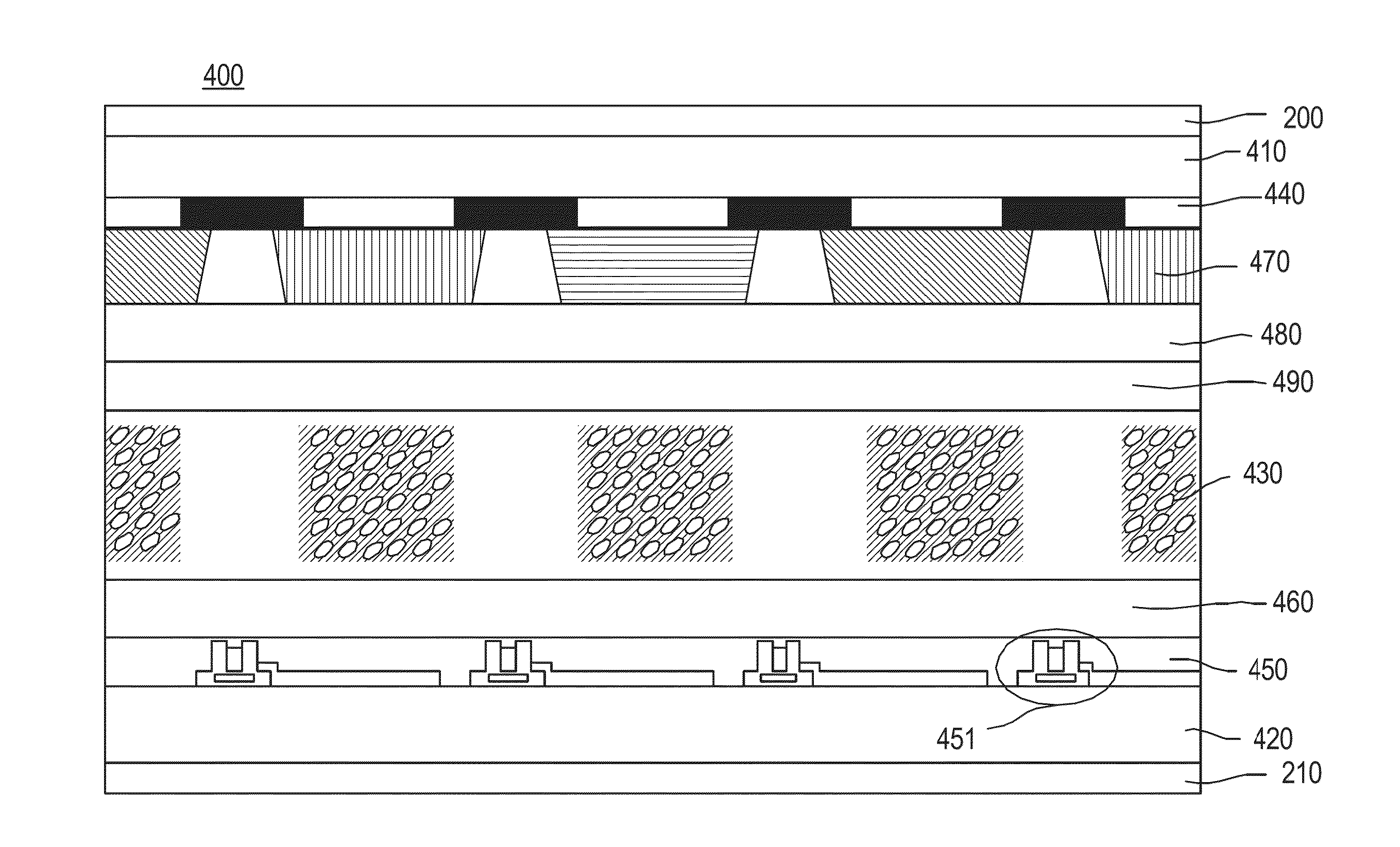

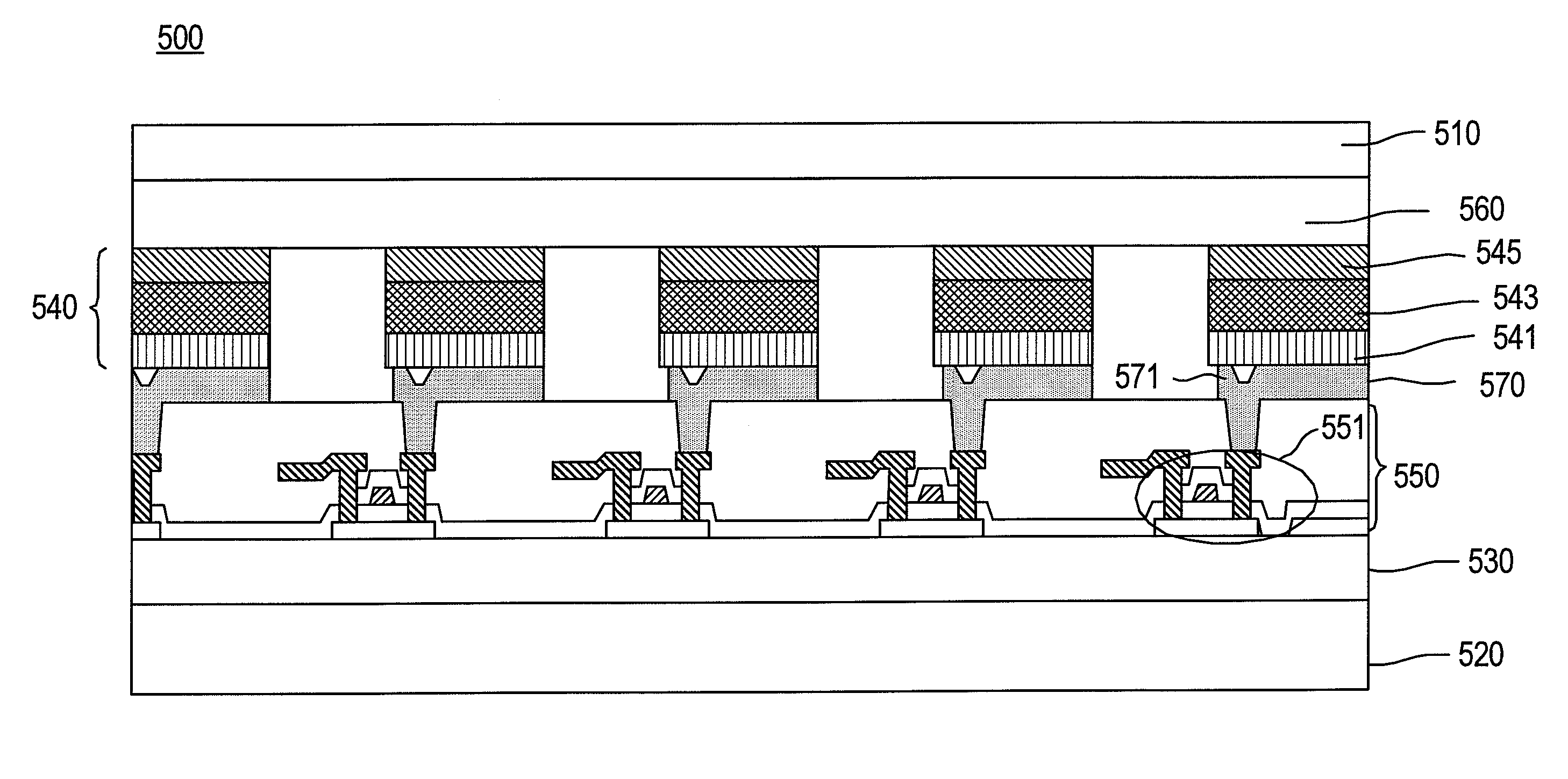

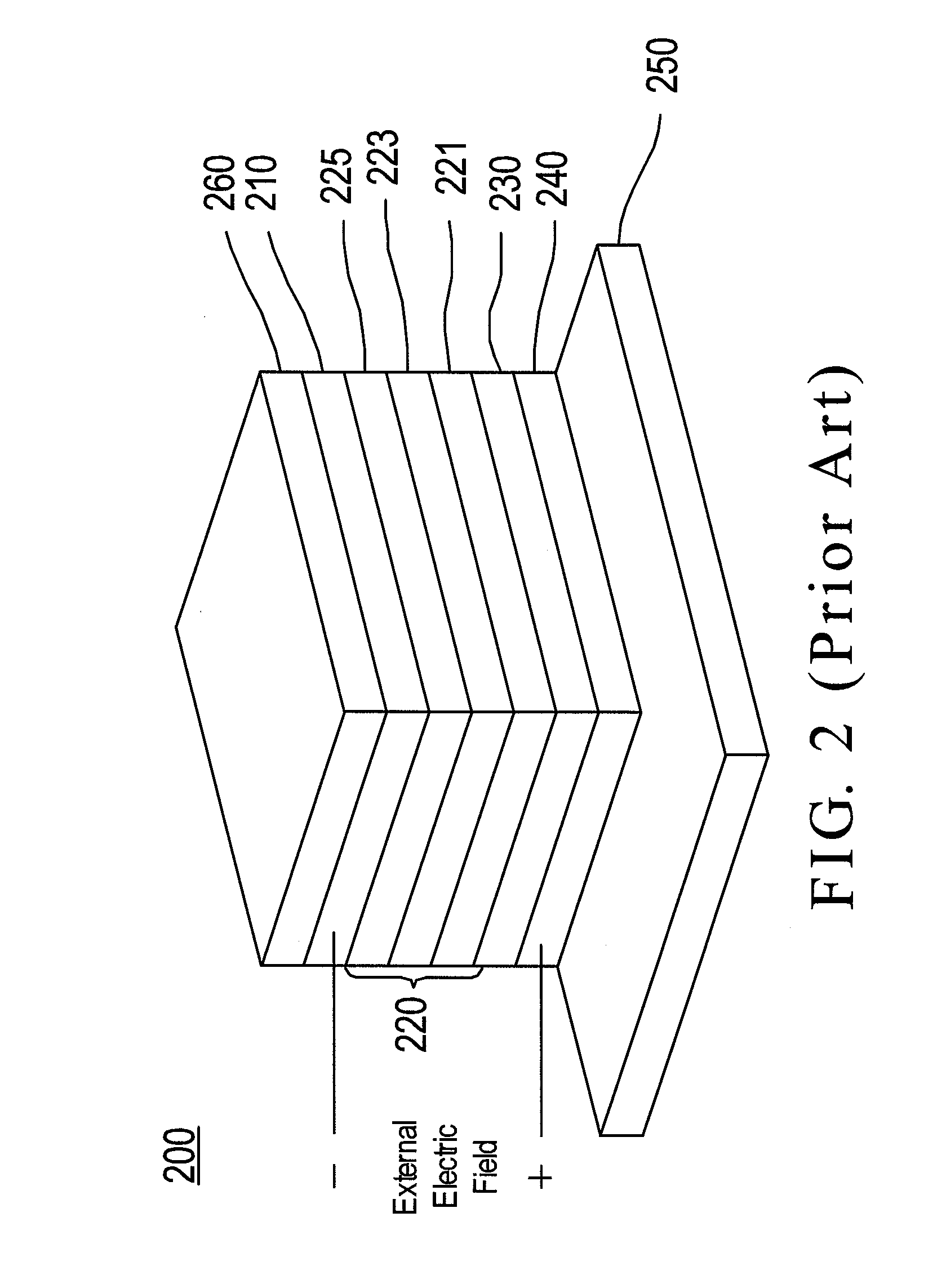

High-accuracy OLED touch display panel structure

ActiveUS20140361277A1Reduce measurementReduce gap distanceSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringTransistor

A high-accuracy OLED touch display panel structure includes an upper substrate, a lower substrate, an OLED layer configured between the upper and lower substrates, a sensing electrode layer, a thin film transistor and wiring layer, a cathode layer, and an anode layer. The sensing electrode layer has a plurality of sensing conductor lines for sensing an approaching external object. The thin film transistor and wiring layer includes a plurality of gate lines, a plurality of source lines, and a plurality of wirings. The plurality of sensing conductor lines are disposed corresponding to positions of the plurality of gate lines and the plurality of source lines.

Owner:SUPERC TOUCH CORP

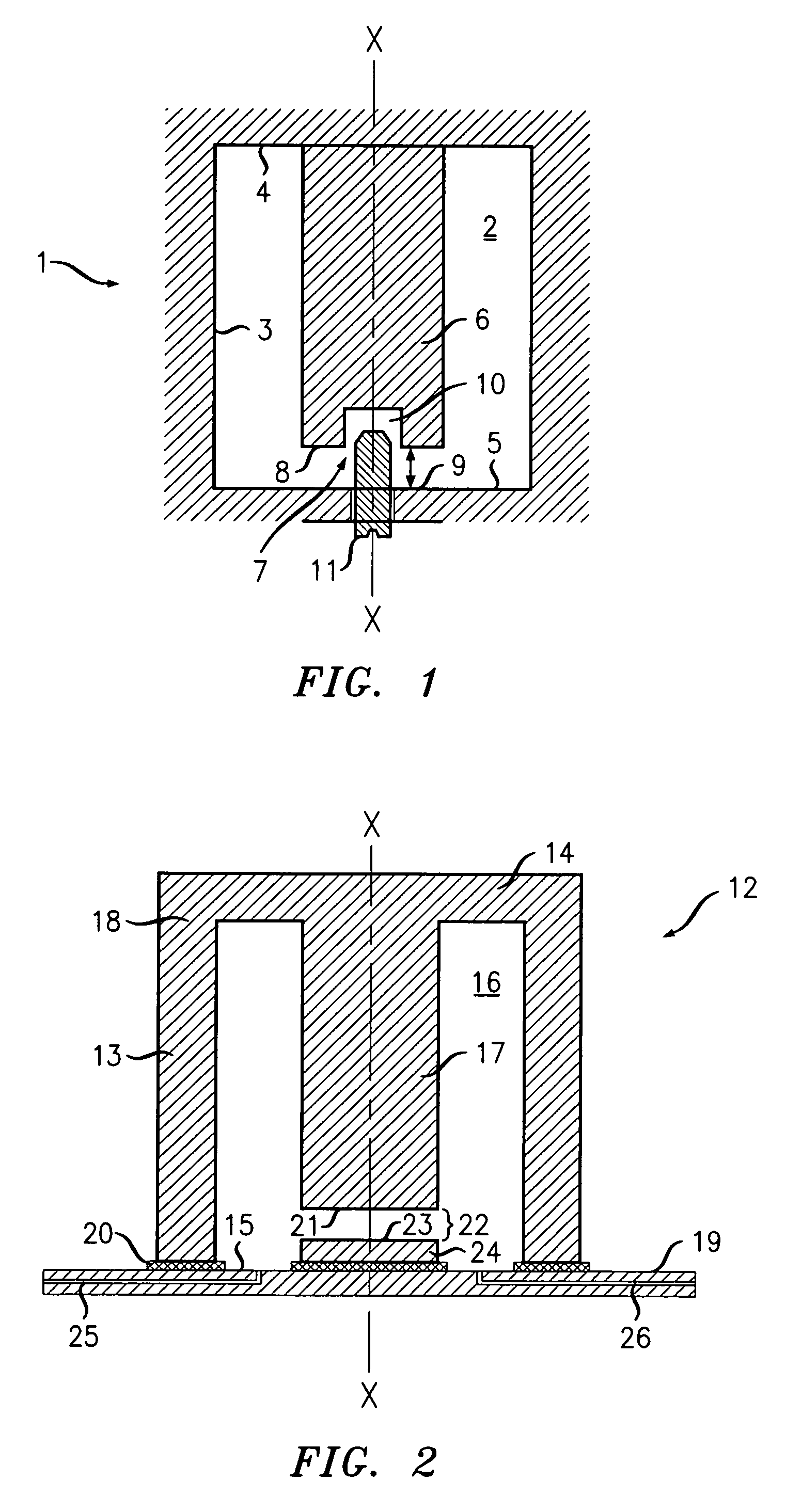

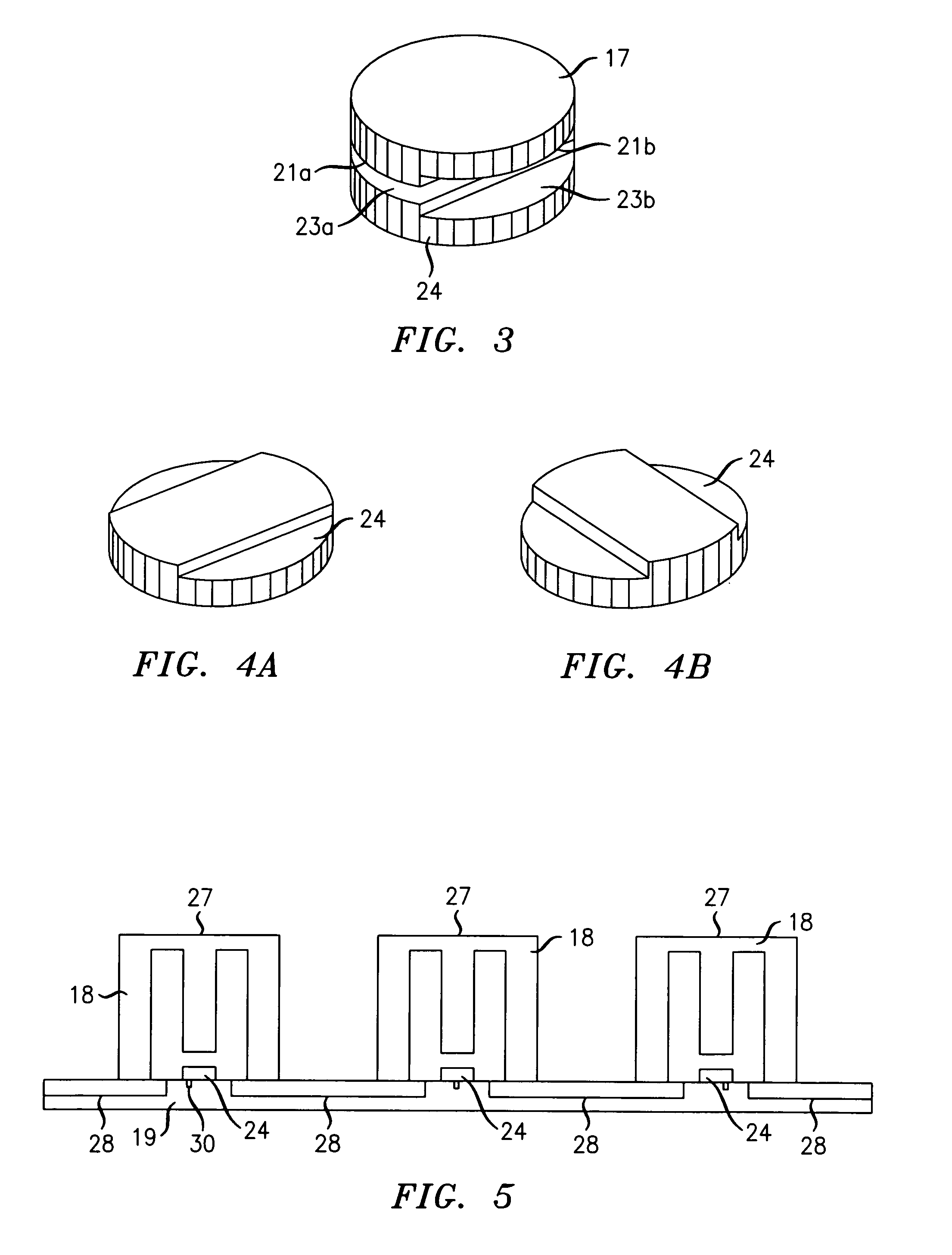

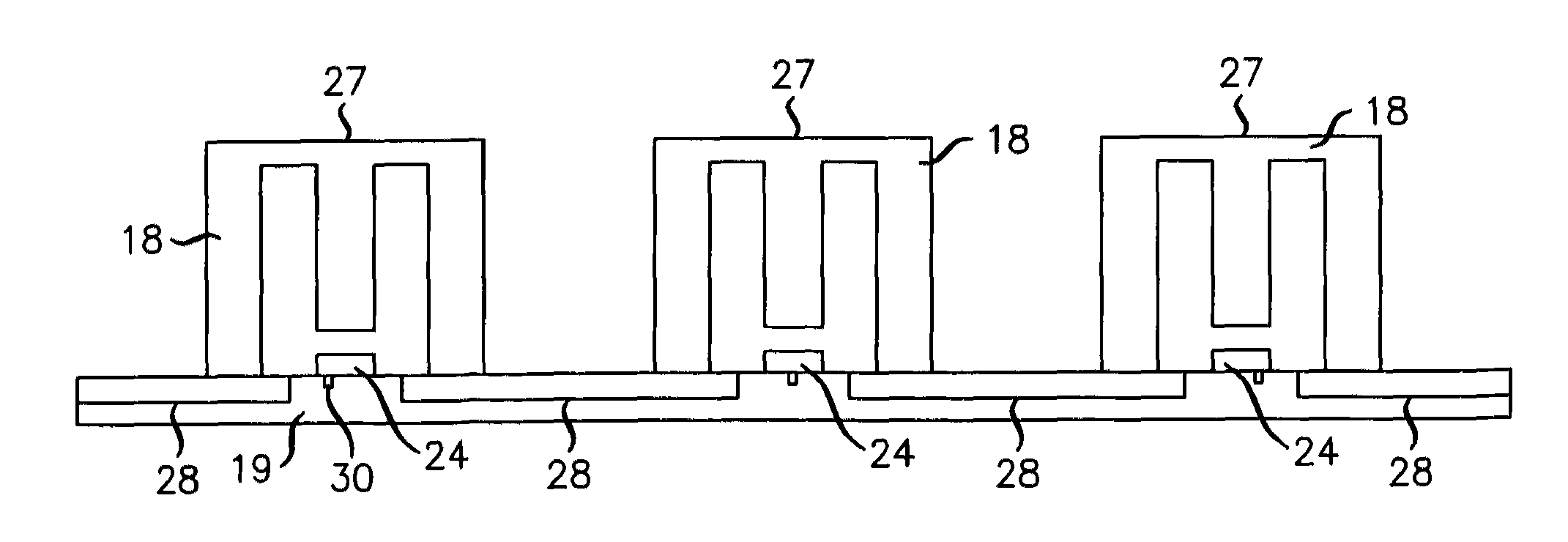

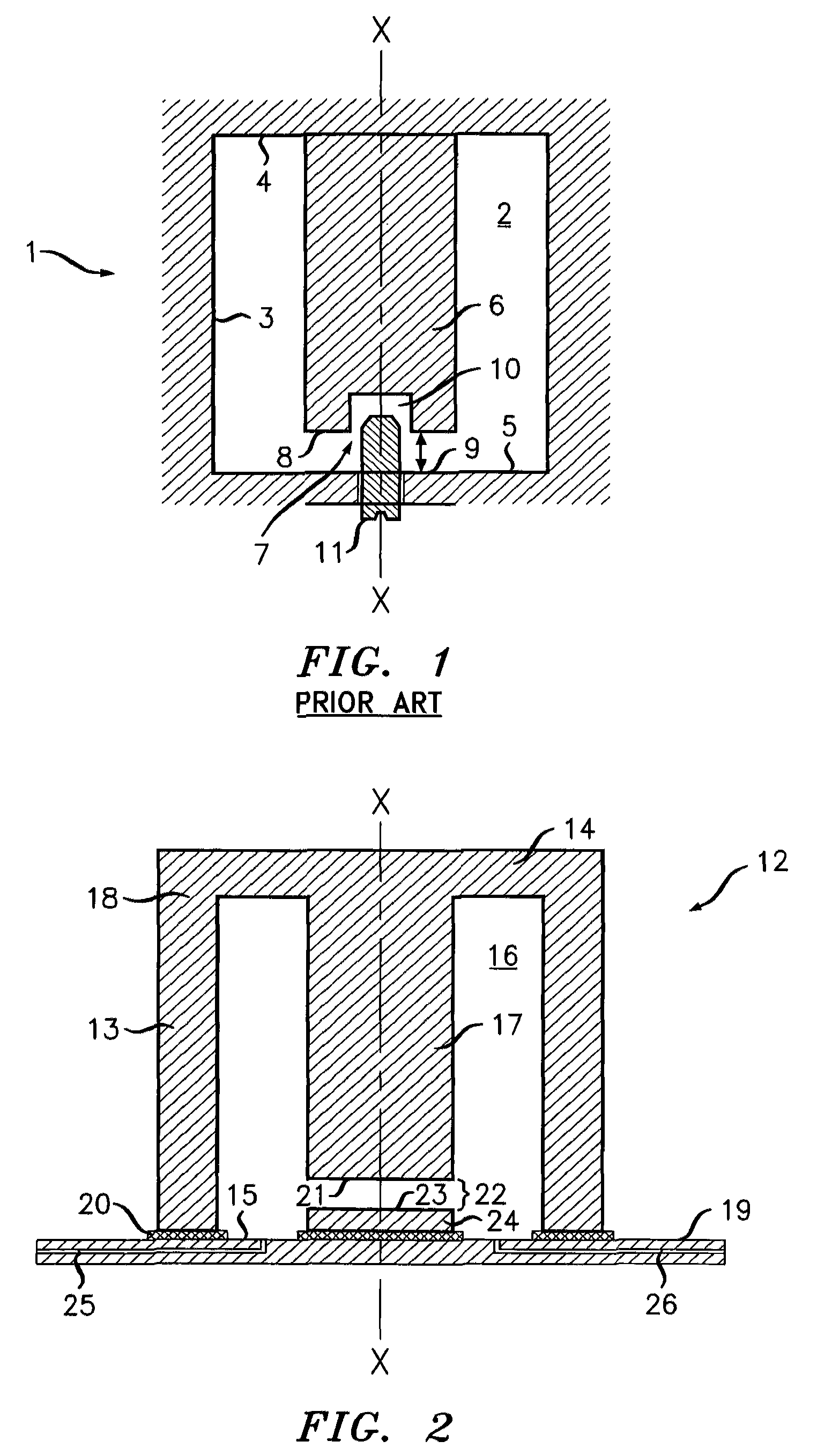

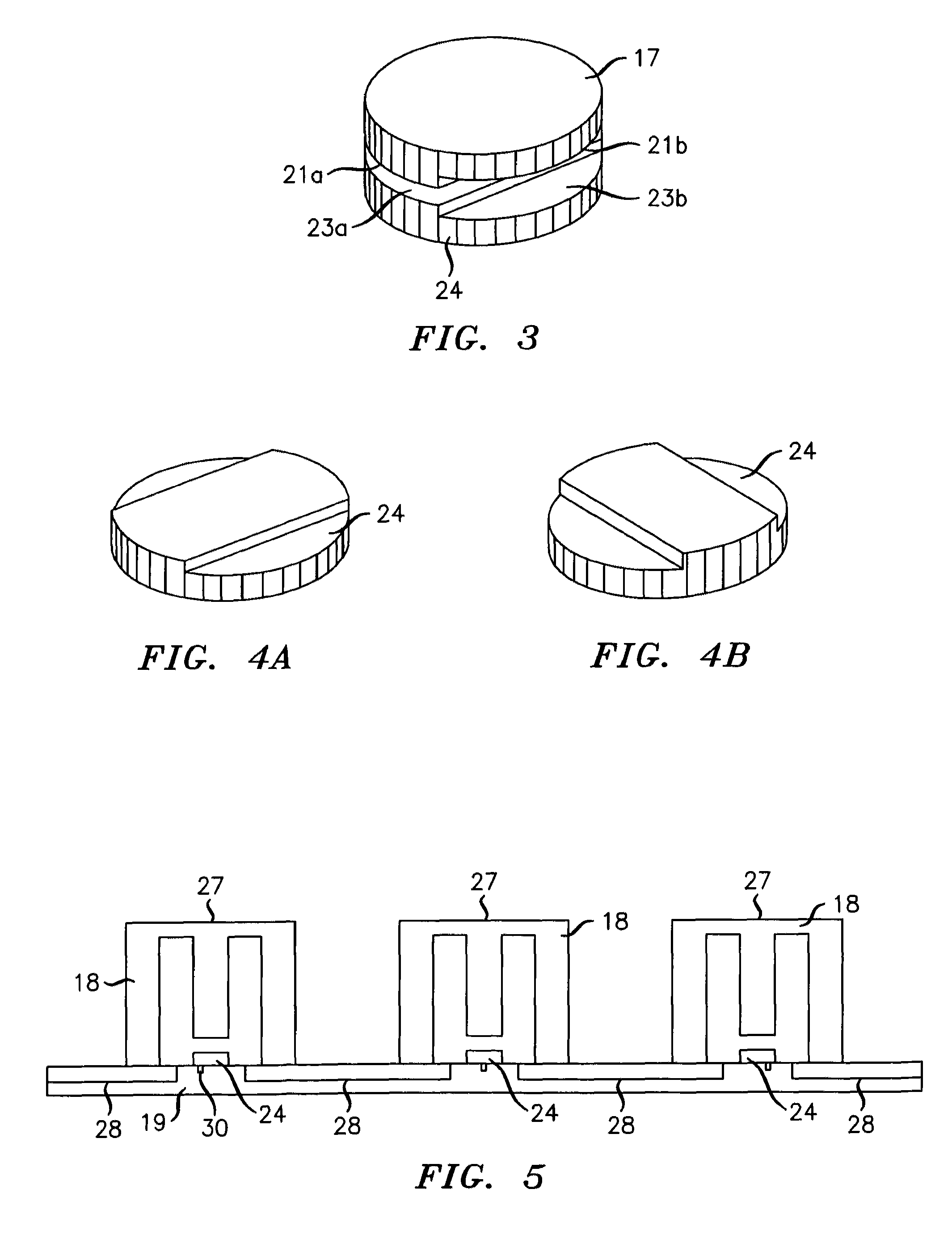

Re-entrant resonant cavities and method of manufacturing such cavities

InactiveUS20080067948A1Compact and robust arrangementReducing and eliminating need for manual interventionElectric lighting sourcesConductive pattern formationResonant cavityCapacitance

A re-entrant resonant cavity 12 includes a first metallized molded plastic component 18, which comprises a re-entrant stub 17, an end wall 14 and a cylindrical side wall 13. The component 18 is surface mount soldered to a metallized PCB substrate 19. A rostrum 24 is located facing the end face 21 of the stub 17 to define a capacitive gap 22 with it.The end face 21 of the stub 17 and the rostrum 24 are configured such that relative rotation between them changes the profile of the gap 22 and hence the gap capacitance. By suitably locating the two parts during manufacture, a particular capacitance may be chosen to give a desired resonance frequency from a selection available depending on the relative angular position of the stub 17 and rostrum 24. In another cavity, the rostrum is replaced by an etched metallization layer of a printed circuit board.

Owner:ALCATEL LUCENT SAS

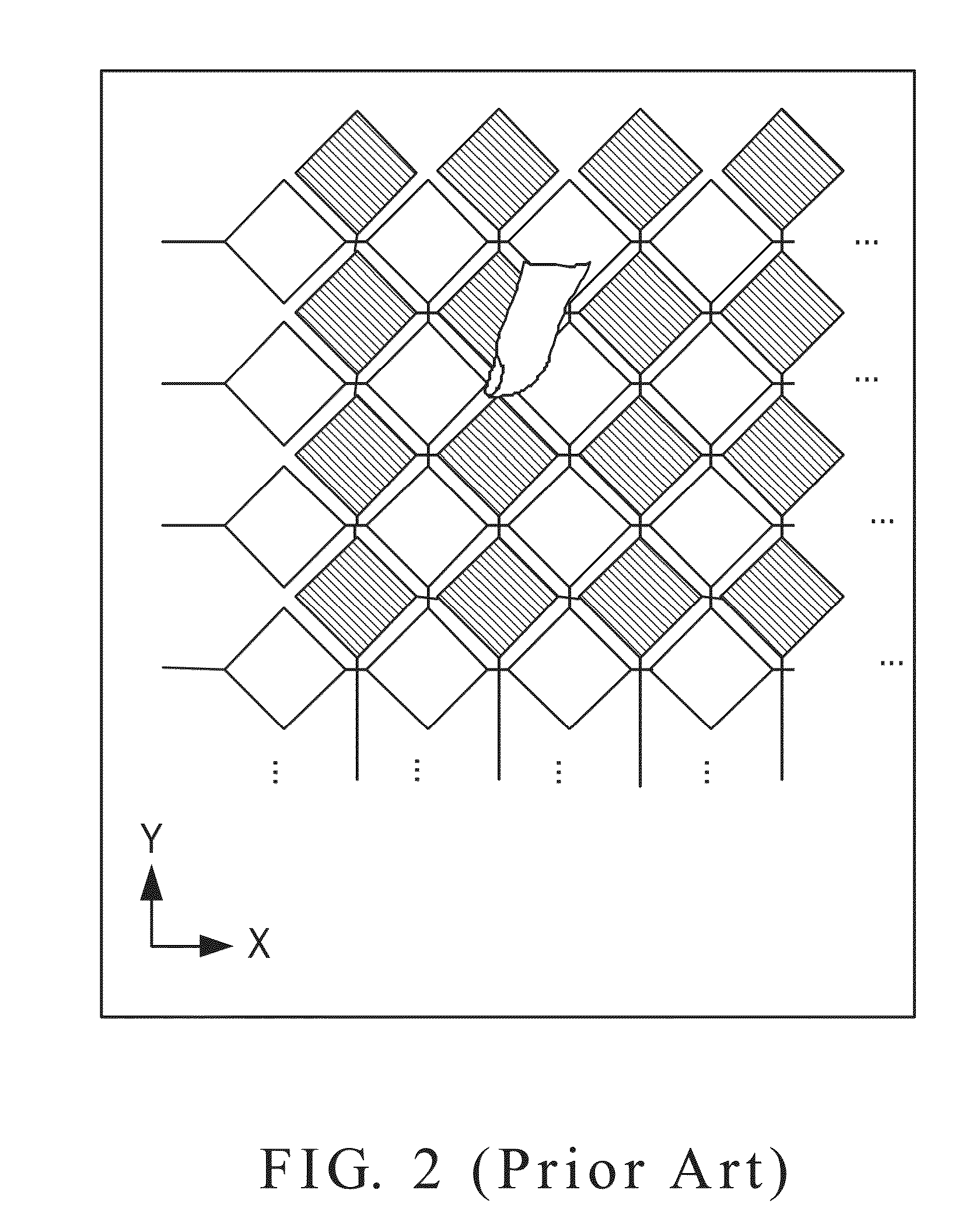

High-accuracy flat touch display panel structure

ActiveUS20140368756A1Reduce gap distanceReduce measurementSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringLiquid crystal

A high-accuracy flat touch display panel structure includes an upper substrate, a lower substrate, a liquid crystal layer configured between the upper and lower substrates, a thin film transistor and wiring layer, and a sensing electrode layer. The thin film transistor and wiring layer is disposed at one side of the lower substrate facing the liquid crystal layer, and includes a plurality of gate lines, a plurality of source lines, and a plurality of wirings. The sensing electrode layer is disposed at one side of the thin film transistor and wiring layer facing the liquid crystal layer, and has a plurality of sensing conductor lines. The plurality of sensing conductor lines are disposed corresponding to positions of the plurality of gate lines and the plurality of source lines.

Owner:SUPERC TOUCH CORP

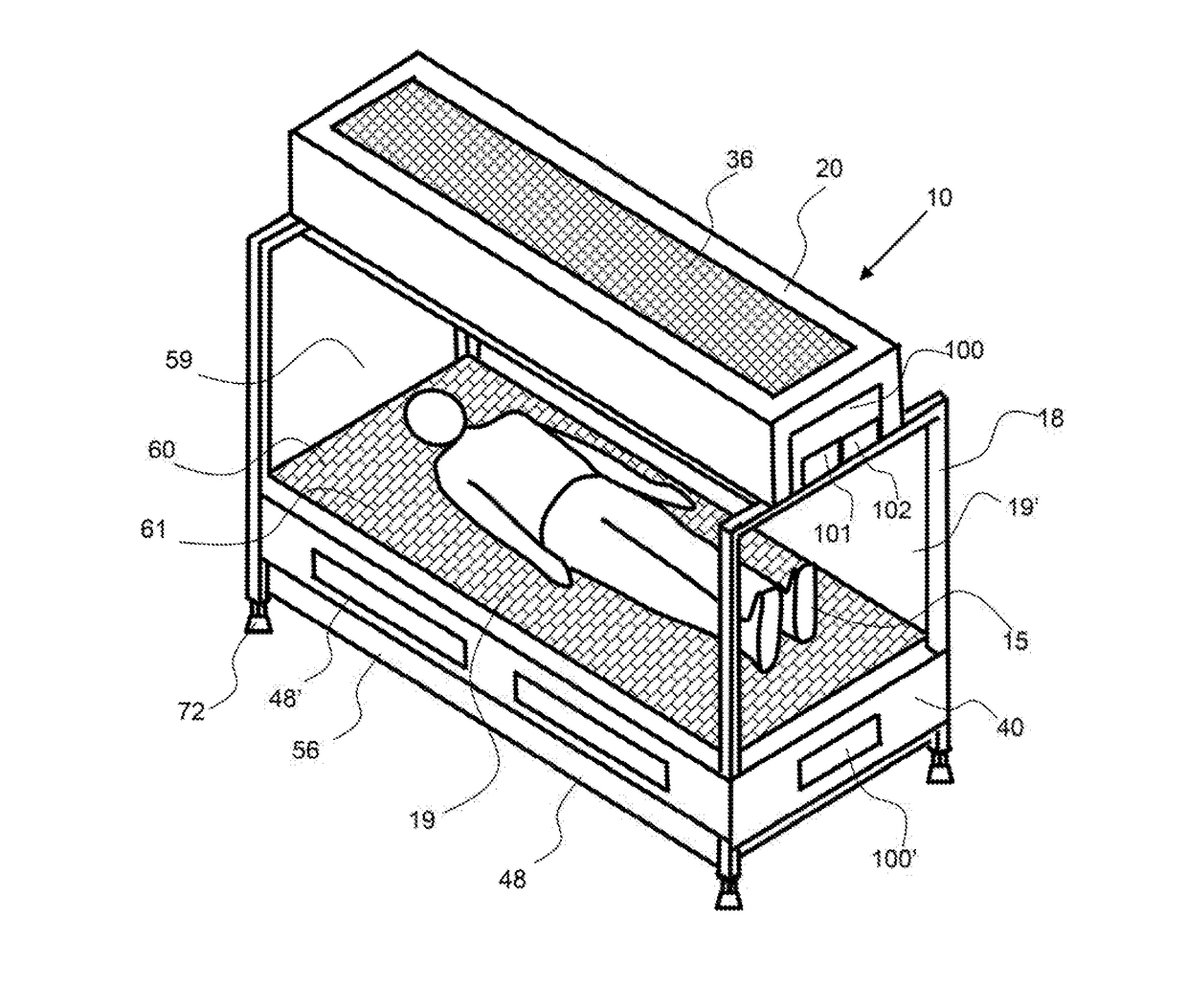

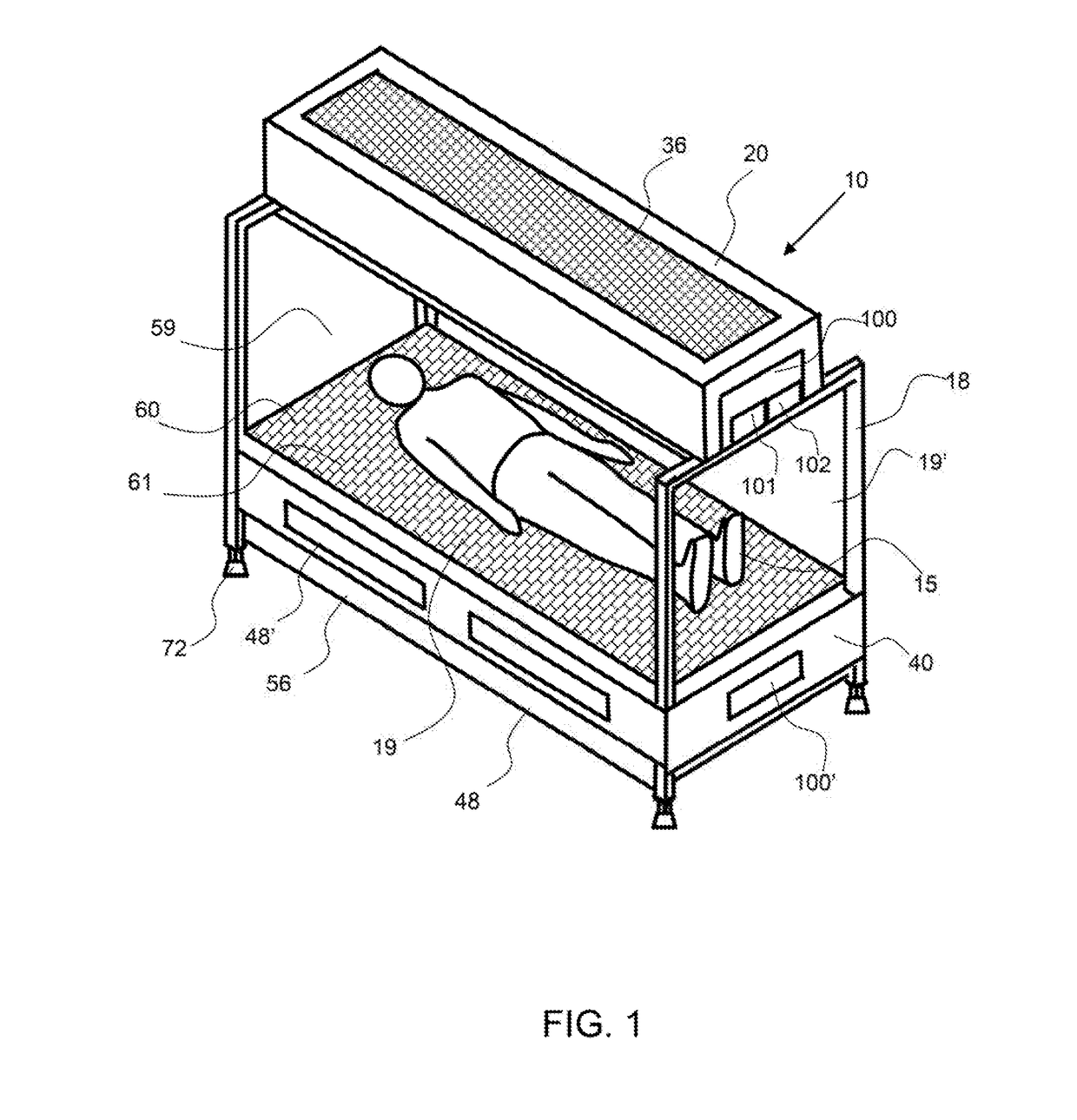

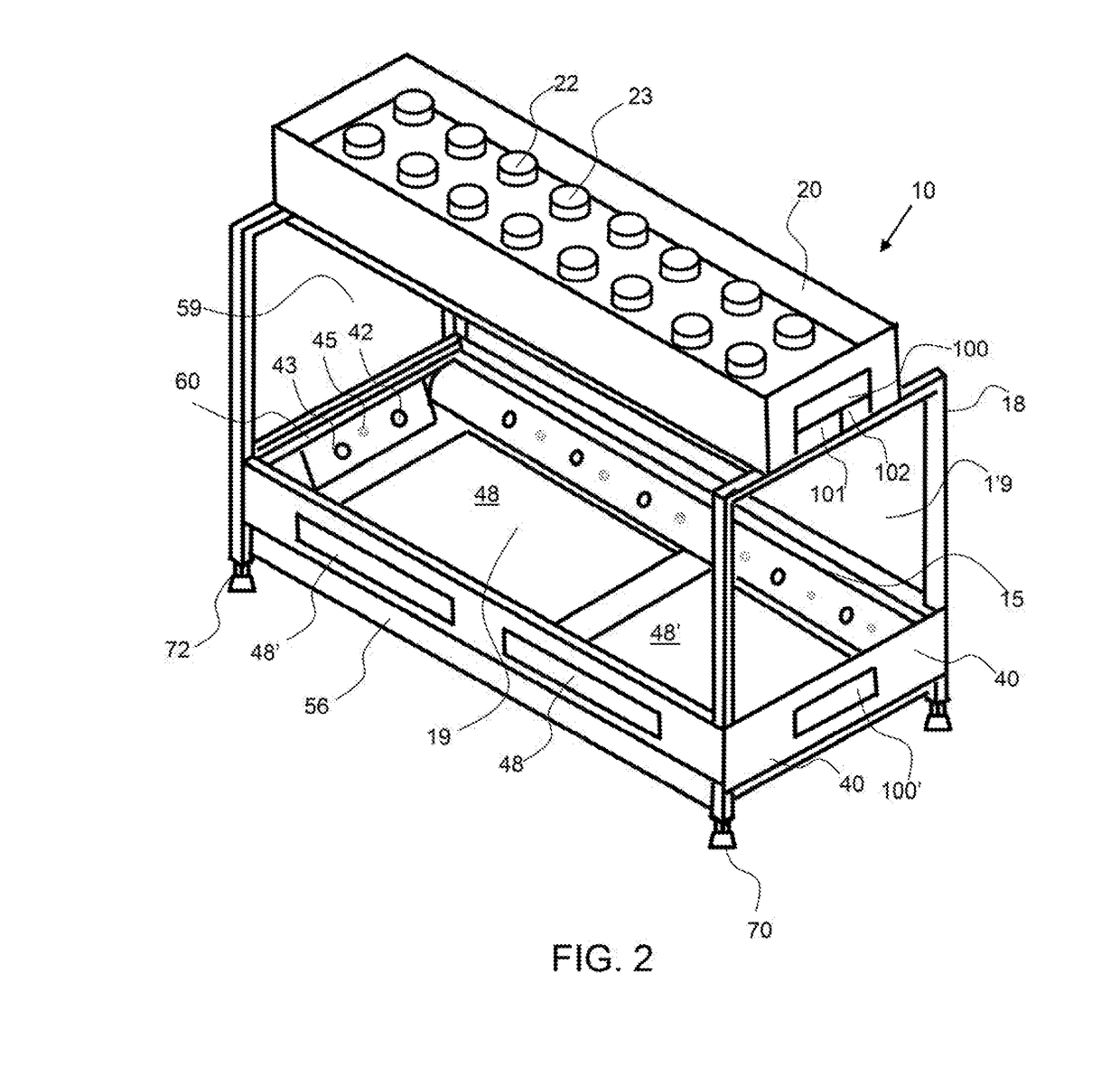

Cooling bed system

ActiveUS20180049911A1Effective and safe coolingEasy to cleanTherapeutic coolingIsolation chambersEngineeringRisk stroke

A cooling bed system is configured to provide a cooling airflow around a patient suffering from heat exhaustion, heat stroke and or burns. A cooling bed system produces an airflow over a patient and preferably an airflow from both above and below the patient to more effectively and quickly cool the patient. A cooling bed system may also include a liquid dispenser that creates mist that is carried by the airflow to further cool the patient. A patient may be supported by a platform having a plurality of openings to allow airflow and mist to pass therethrough. A controller controls the airflow rate and / or temperature of the air, and may also control the liquid dispensing rate and / or temperature of the liquid as a function of an input from a temperature sensor to effectively and safely cool the patient.

Owner:MAZ MEDICAL LLC

Backlight unit and liquid crystal display device including the same

InactiveCN105607341AReduce gap distanceSolve the low heat dissipation efficiencyElongate light sourcesPrinted circuit aspectsLiquid-crystal displayEngineering

The invention relates to a light emitting diode assembly, a backlight unit including the light-emitting diode component and a liquid crystal display device. The light emitting diode assembly includes: a light emitting diode (LED) printed circuit board (PCB) and a plurality of LEDs. The PCB has a base layer, an insulating layer,a circuit pattern layer and a protection layer from top to bottom, wherein LED PCB includes a plurality of through holes spaced apart from each other along a long side direction; and a plurality of light emitting diodes (LEDs) are inserted into the plurality of through holes, respectively, from a bottom surface of the LED PCB, wherein the LEDs comprise leads on two sides of the LEDs, and are in electric connection with the LED PCB through the leads.

Owner:LG DISPLAY CO LTD

Rotating device and robot arm device

InactiveUS20120186382A1Suppress damage caused by contactSuppress instability in communicationNear-field transmissionMechanical apparatusCommunication unitElectrical and Electronics engineering

A rotating device includes a communication unit including a transmitting portion having a first ring-shaped coil, a first ring-shaped magnetic body covering the first ring-shaped coil and a first terminal connected to the first ring-shaped coil, and a receiving portion having a second ring-shaped coil, a second ring-shaped magnetic body covering the second ring-shaped coil and a second terminal connected to the second ring-shaped coil, and a bearing connecting a hollow fixed portion to a hollow rotating portion.

Owner:SEIKO EPSON CORP

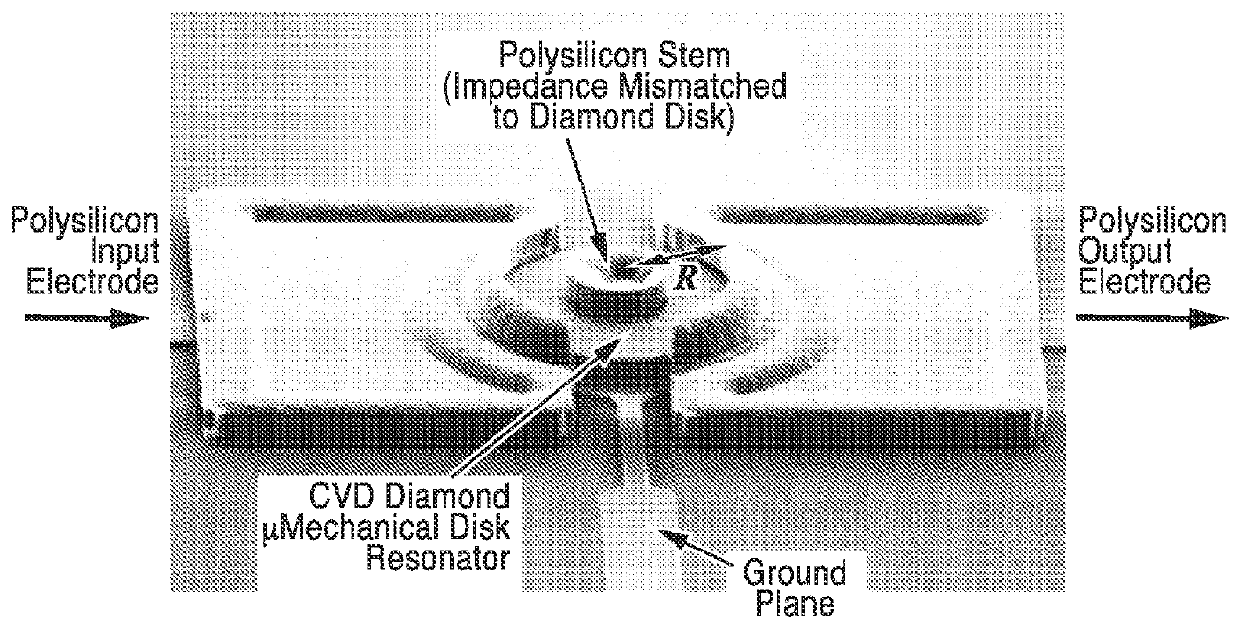

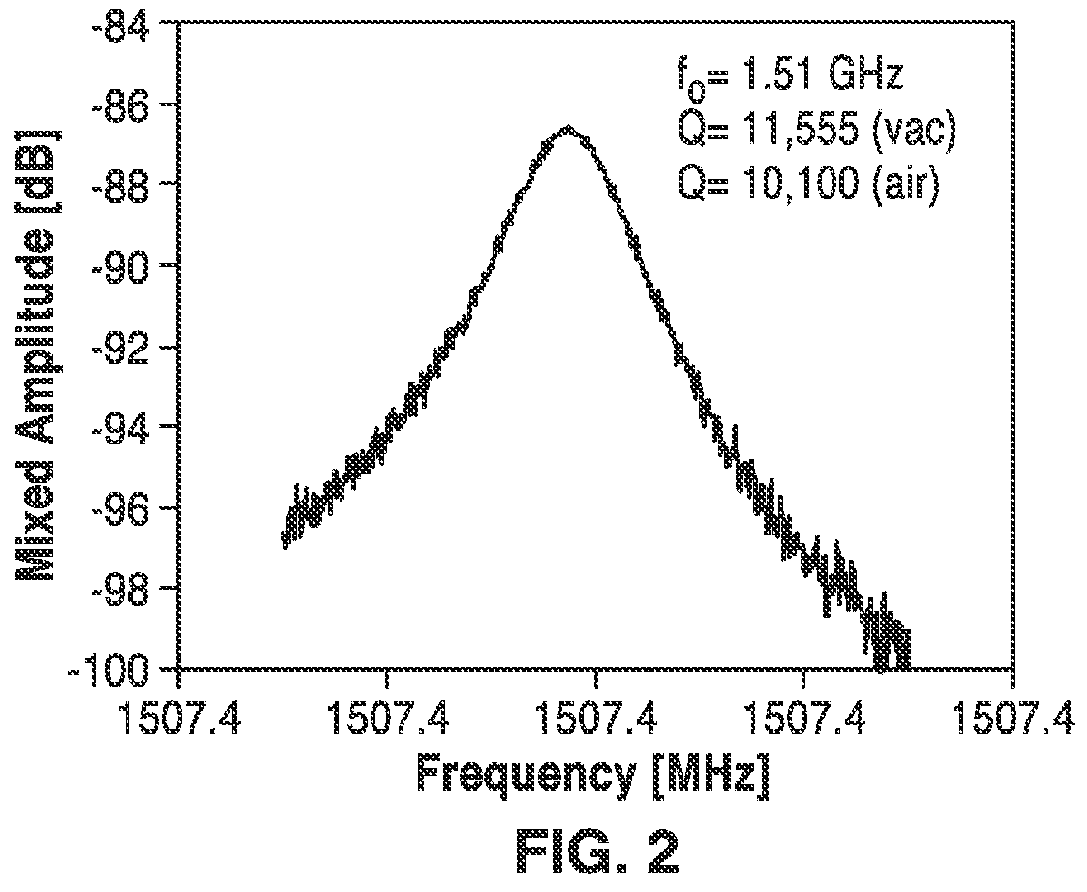

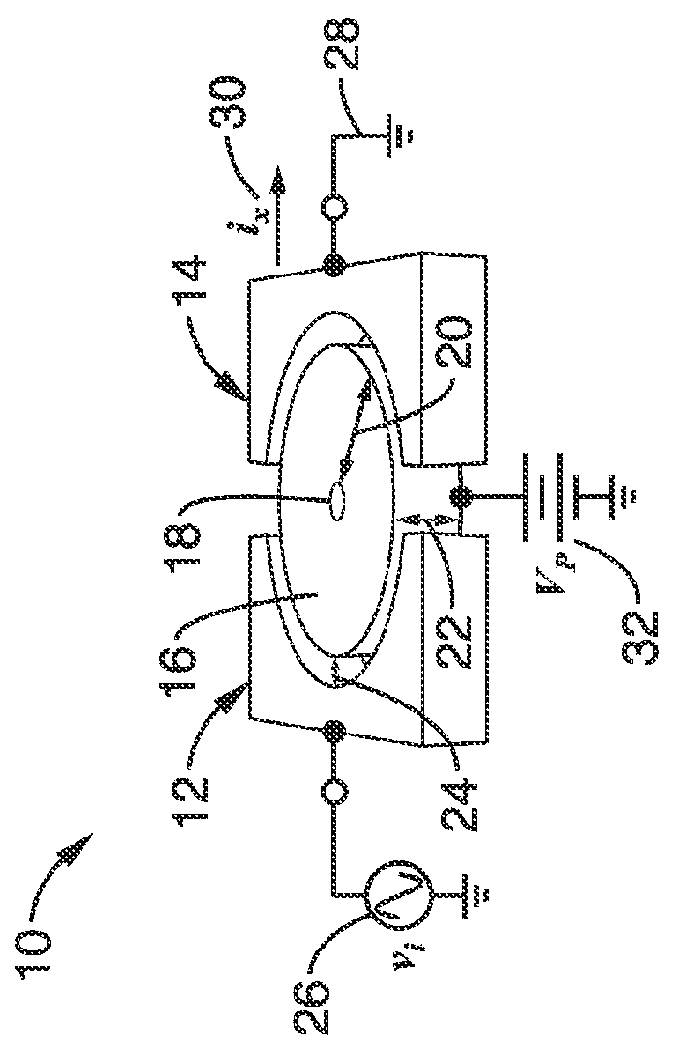

Partially-filled electrode-to-resonator gap

InactiveUS20120176207A1Reduce decreaseReduction of motional resistanceImpedence networksCapacitanceRadar systems

Method and apparatus for lowering capacitively-transduced resonator impedance within micromechanical resonator devices. Fabrication limits exist on how small the gap spacing can be made between a resonator and the associated input and output electrodes in response to etching processes. The present invention teaches a resonator device in which these gaps are then fully, or more preferably partially filled with a dielectric material to reduce the gap distance. A reduction of the gap distance substantially lowers the motional resistance of the micromechanical resonator device and thus the capacitively-transduced resonator impedance. Micromechanical resonator devices according to the invention can be utilized in a wide range of UHF devices, including integration within ultra-stable oscillators, RF filtering devices, radar systems, and communication systems.

Owner:RGT UNIV OF CALIFORNIA

High-accuracy OLED touch display panel structure

ActiveUS9412796B2Reduce measurementReduce gap distanceSolid-state devicesInput/output processes for data processingEngineeringTransistor

A high-accuracy OLED touch display panel structure includes an upper substrate, a lower substrate, an OLED layer configured between the upper and lower substrates, a sensing electrode layer, a thin film transistor and wiring layer, a cathode layer, and an anode layer. The sensing electrode layer has a plurality of sensing conductor lines for sensing an approaching external object. The thin film transistor and wiring layer includes a plurality of gate lines, a plurality of source lines, and a plurality of wirings. The plurality of sensing conductor lines are disposed corresponding to positions of the plurality of gate lines and the plurality of source lines.

Owner:SUPERC TOUCH CORP

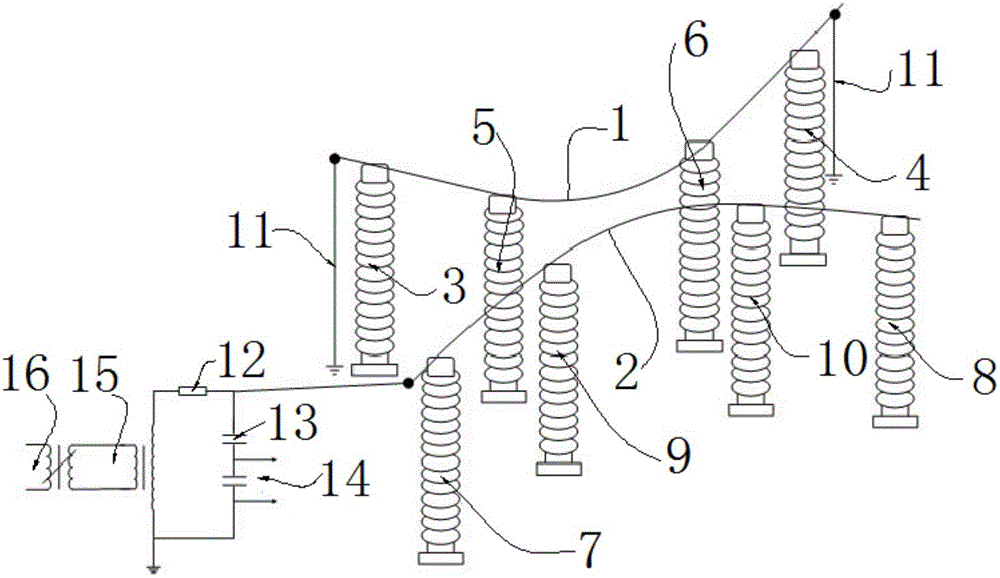

Test model for simulating wind-deviation inter-phase flashover of single-conductor power transmission lines and method for applying test model

PendingCN106291298AReduce gap distanceAvoid breakdown voltage effectsElectrical testingGround lineAluminium

The invention discloses a test model for simulating wind-deviation inter-phase flashover of single-conductor power transmission lines and a method for applying the test model. The test model comprises a first aluminum stranded wire (1) and a second aluminum stranded wire (2). The first aluminum stranded wire is supported by at least four insulating support columns, and the second aluminum stranded wire is supported by at least four insulating support columns; grounding wires (11) are connected with two ends of the first aluminum stranded wire, and a power-frequency test voltage transformation system is connected with the second aluminum stranded wire. The test model and the method have the advantages that conditions that gap distances of a certain portion of two phases of conductors are reduced to a great extent while safety gap distances among other portions are still kept after the conductors are deviated by wind can be effectively simulated by the test model; insulator strings can be repositioned, so that the minimum inter-line gap distances can be changed by the test model, and flashover characteristics of the two phases of conductors at different gap distances in span under wind-deviation conditions can be simulated.

Owner:湖北省超能电力有限责任公司

Biological ceramic artificial joint spherical surface cyclic polishing machine

ActiveCN110216529APlay a role in promotingReduce processing difficultyEdge grinding machinesPolishing machinesArtificial jointsLiquid state

The invention discloses a biological ceramic artificial joint spherical surface cyclic polishing machine. A first through hole is formed in a polished main body. A conveying screw is arranged in the first through hole in a penetrating manner. A circular arc-shaped first conveying groove is formed in the polished main body. Second conveying grooves are formed by two opposite side walls of the polished main body and end covers respectively. The top ends of the second conveying grooves communicate with the first conveying groove, and the bottom ends of the second conveying grooves communicate with the first through hole. Coils are located inside the polished main body. A magneto-rheological polishing liquid is located in the first conveying groove, the second conveying grooves and the first through hole. The biological ceramic artificial joint spherical surface cyclic polishing machine has the advantages that the conveying screw arranged in the first through hole in a penetrating manner plays a pushing part; cyclic polishing is conducted on a polished body placed in the first through hole in a closed cyclic channel; while the magneto-rheological polishing liquid is utilized for polishing; the magneto-rheological polishing liquid is in a liquid state form if not under the action of a magnetic field, and the closed cyclic channel wall can be covered completely by the magneto-rheological polishing liquid; and the magneto-rheological polishing liquid is transformed into a solid state form, numerous magneto-rheological brushes are formed, and omni-directional polishing is conductedon the periphery of the rotating polished body.

Owner:ZHEJIANG CANWELL MEDICAL DEVICES CO LTD

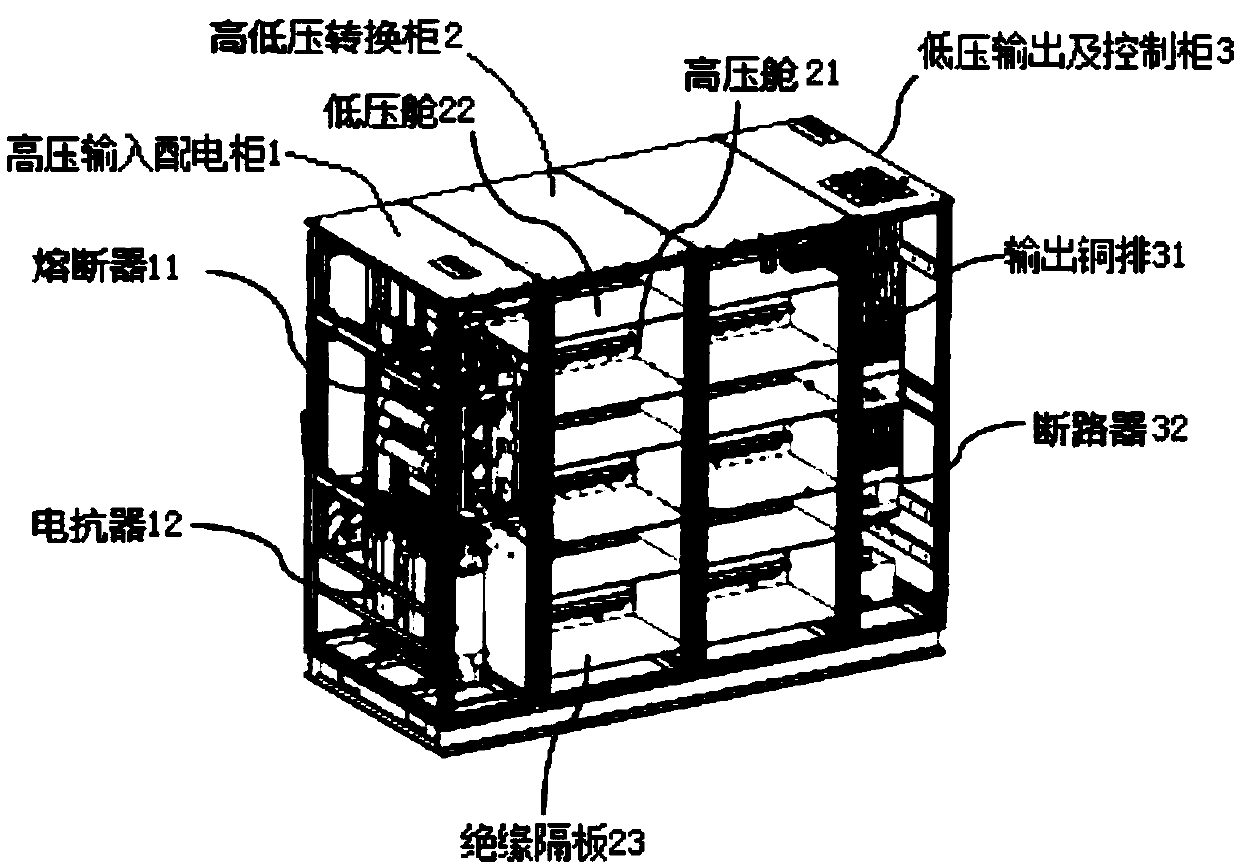

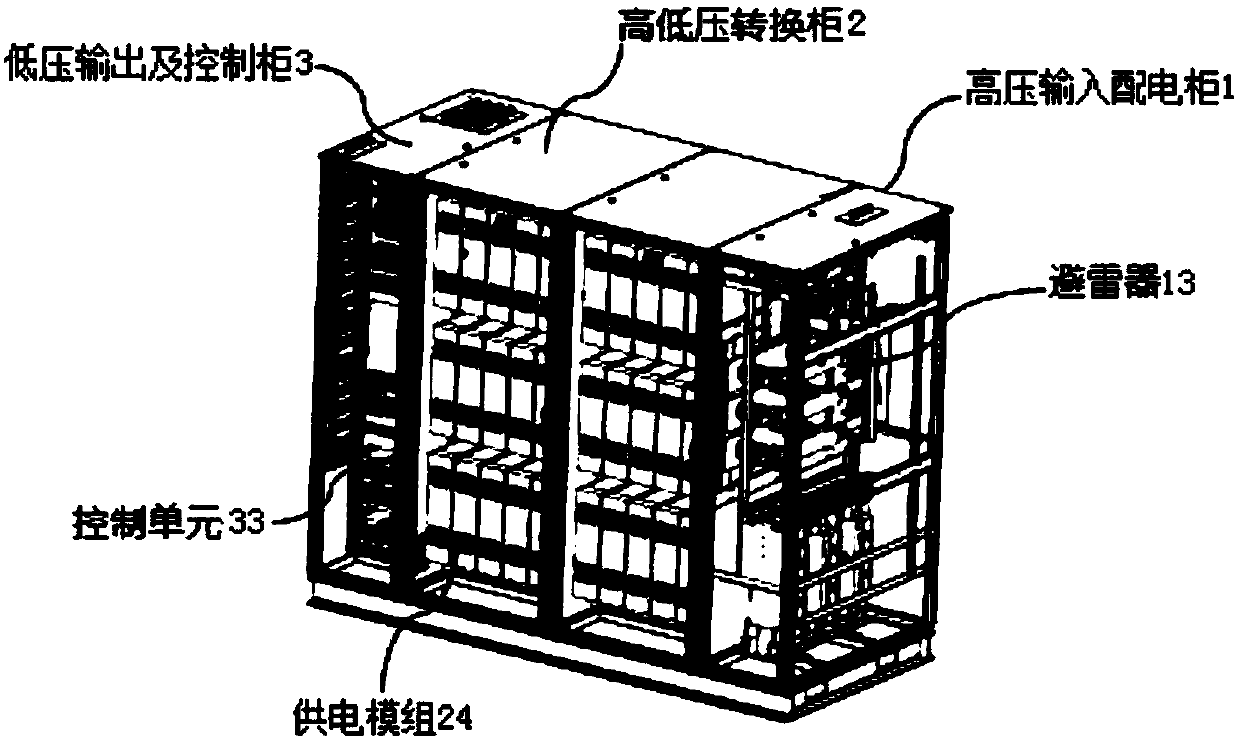

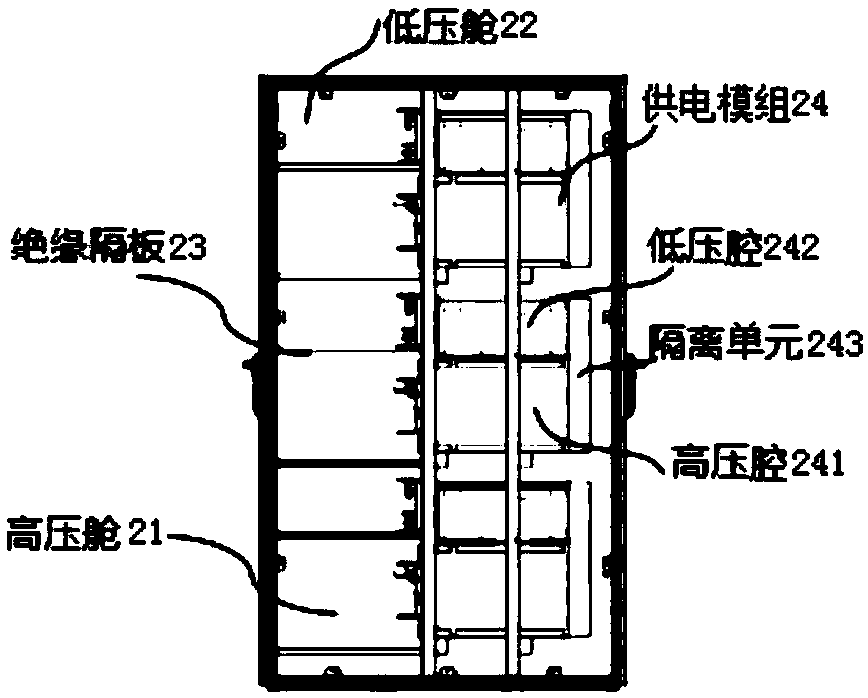

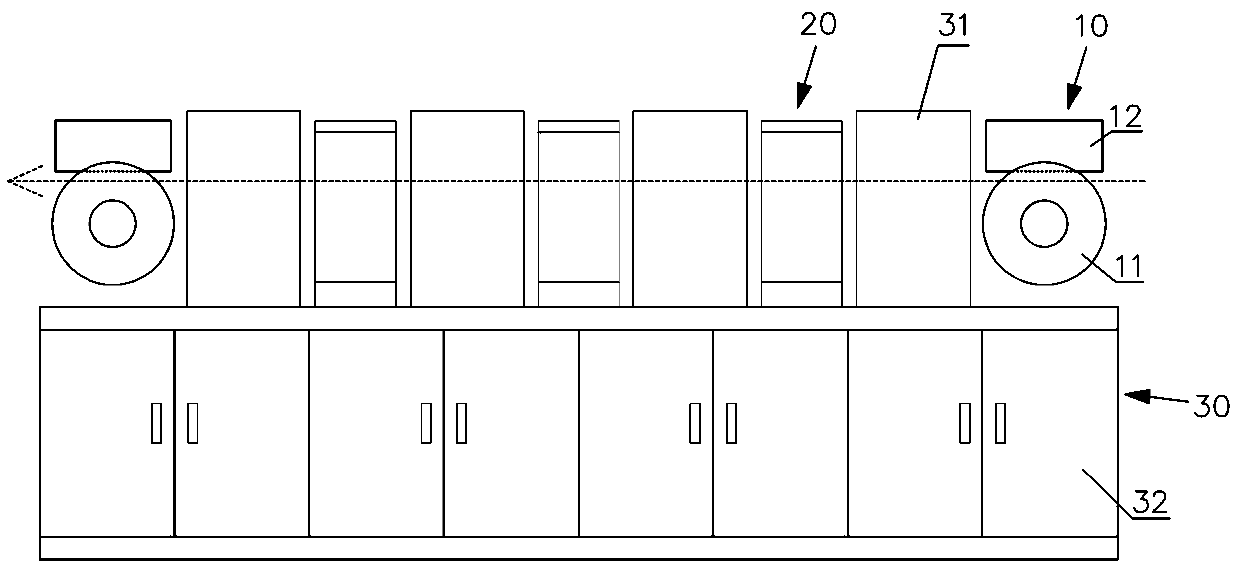

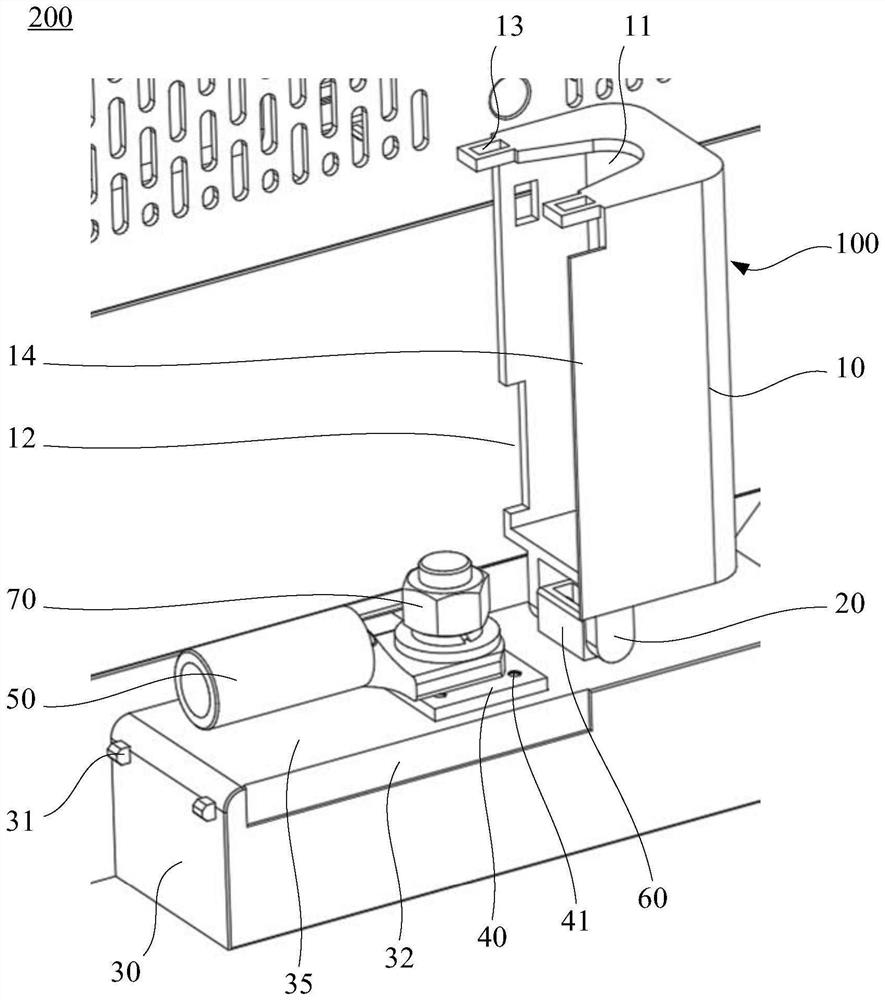

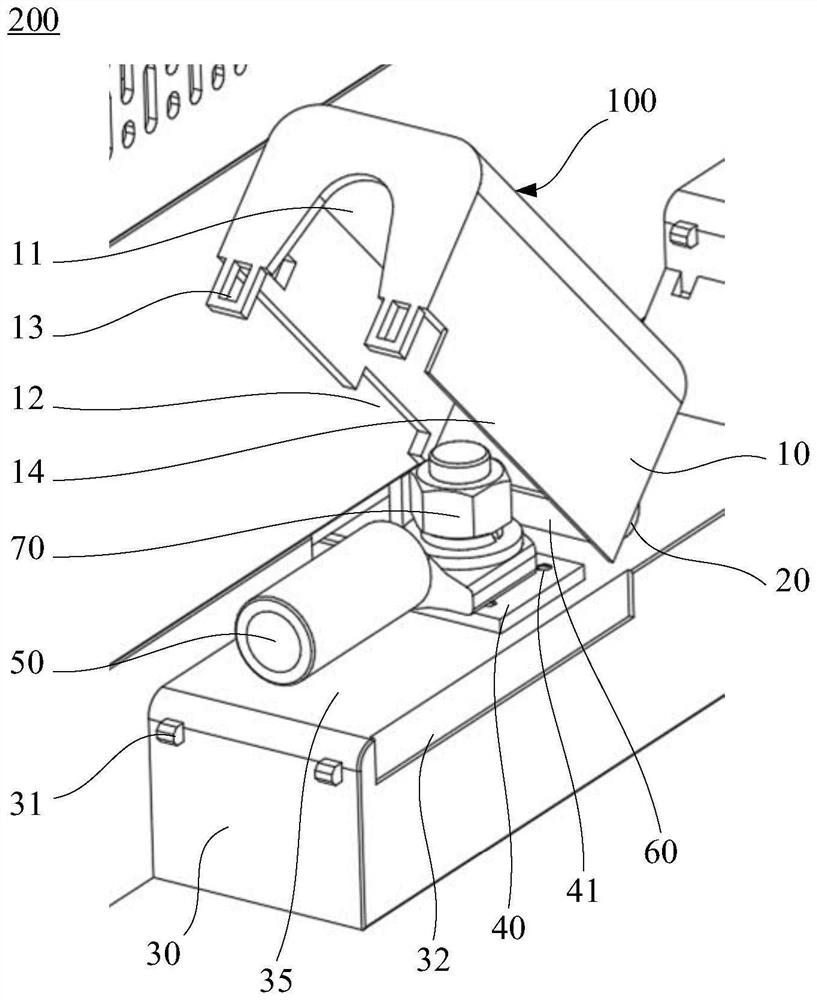

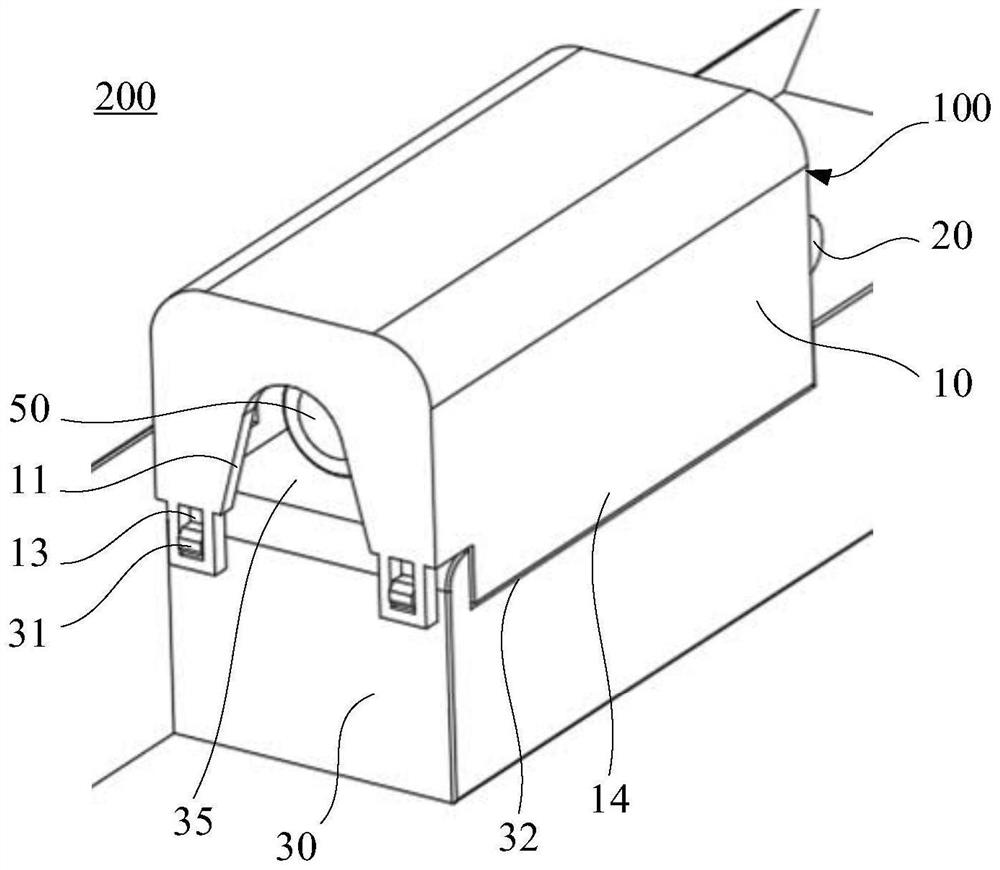

Power supply system

ActiveCN110875580AImprove securityReduce in quantityBus-bar/wiring layoutsServersLow voltageControl theory

The invention relates to the technical field of power electronics, and provides a power supply system. The power supply system comprises a high-voltage input power distribution cabinet, a high-low voltage conversion cabinet and a low-voltage output and control cabinet, wherein the high-low voltage conversion cabinet is internally provided with at least one high-voltage cabin and at least one low-voltage cabin, the high-low voltage conversion cabinet is further internally provided with an insulating partition plate located between the high-voltage cabin and the low-voltage cabin, the low-voltage cabin is internally provided with a low-voltage bus, and the high-voltage cabin is internally provided with a high-voltage bus; and the high-low voltage conversion cabinet is also internally provided with a plurality of power supply modules, each power supply module is in bridge connection with the high-voltage cabin and the low-voltage cabin, the power supply module comprises a high-voltage cavity, a low-voltage cavity and an isolation unit, the high-voltage cavity and the low-voltage cavity are arranged corresponding to the high-voltage cabin and the low-voltage cabin respectively and electrically connected with the high-voltage bus and the low-voltage bus respectively, and the isolation unit is connected with one end of the high-voltage cavity and one end of the low-voltage cavity. According to the invention, the input high voltage is isolated from the output low voltage and the control low voltage so as to improve the safety.

Owner:DELTA ELECTRONICS INC

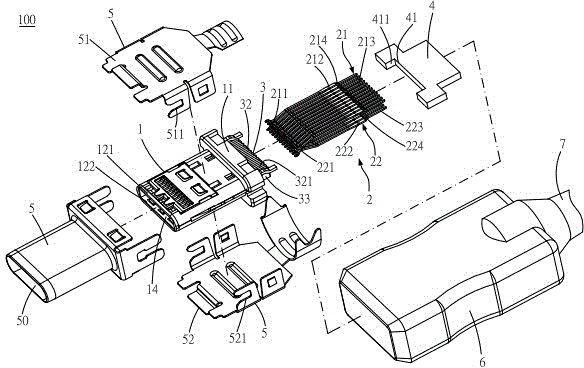

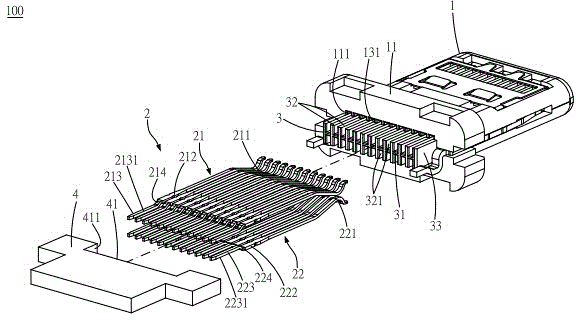

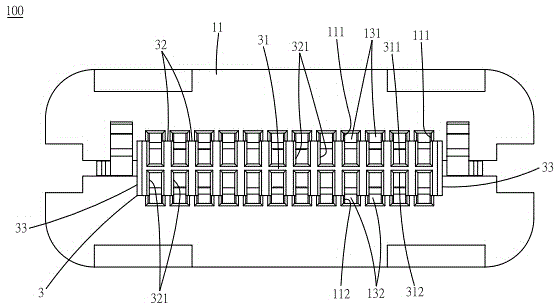

Plug electrical connector

ActiveCN104966922AReduce gap distancePrevent overflowSecuring/insulating coupling contact membersSoldered/welded conductive connectionsEngineeringElectrical connector

A plug electrical connector provided by the invention comprises an insulation body, a terminal and a fixed base. The insulation body includes a base and a terminal slot which passes through the base. The terminal is located at the insulation body, and includes an extension part which is located at the terminal slot and a welding part which is extendedly formed behind the extension part and passes through out of the rear side of the base. The fixed base is located at the rear side of the base, and includes a clapboard and a barrier, the clapboard defining two corresponding side surfaces, the barrier extending from surfaces of each side and forming a penetration slot between barriers, the penetration slot being communication with terminal slots of the upper row and the lower row corresponding to the terminal slots of the upper the lower rows. An upper welding part and a lower welding part are located at the penetration slot, and barriers are covered at two sides of the upper welding part and two sides of the lower welding part.

Owner:连展科技电子(昆山)有限公司

Automobile covering part springback treatment mold structure

Owner:柳州市钜嘉机械有限公司

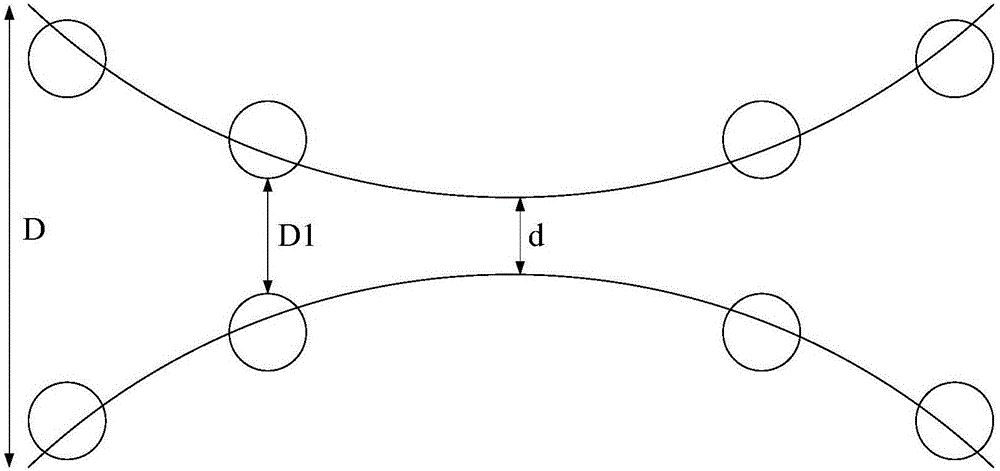

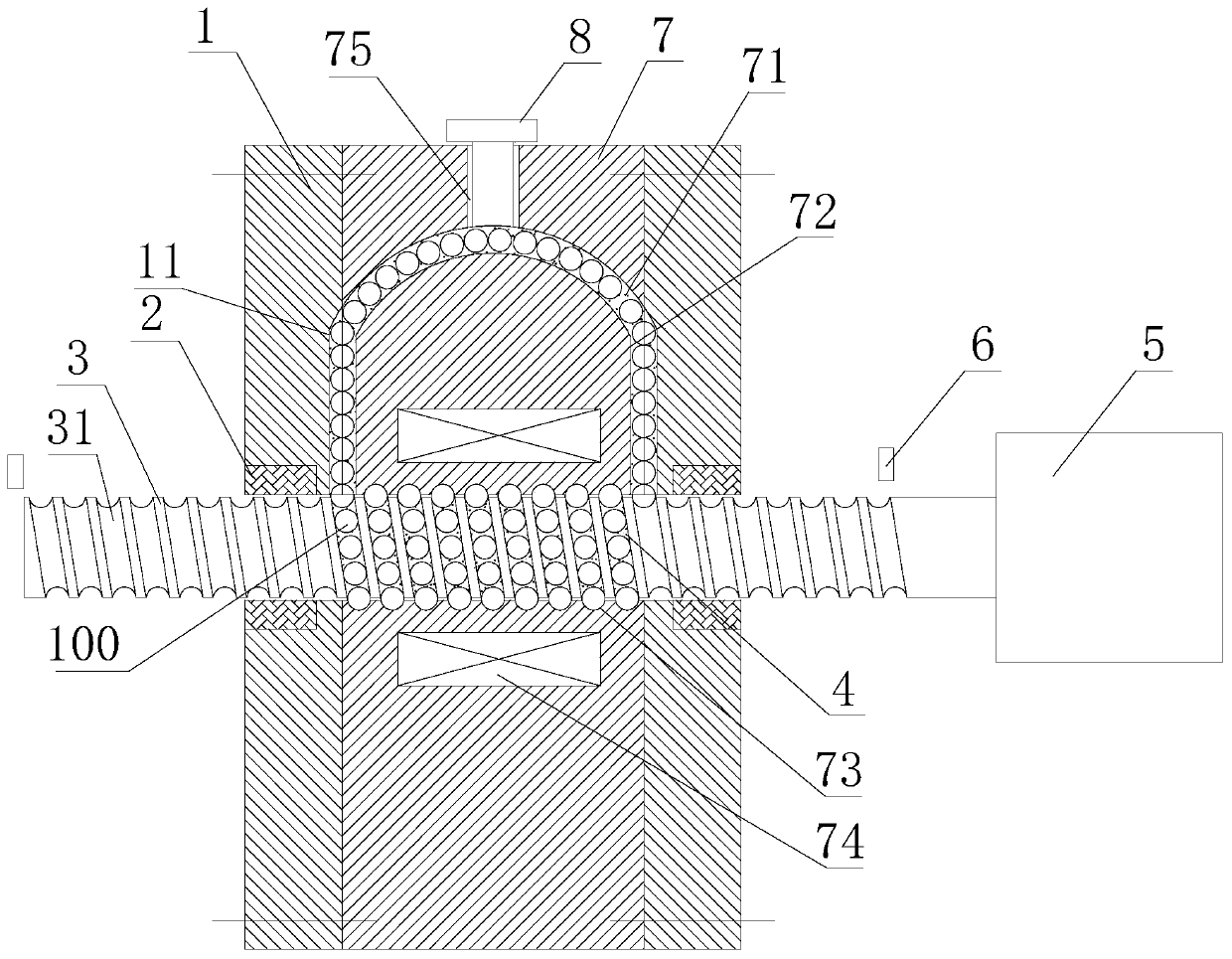

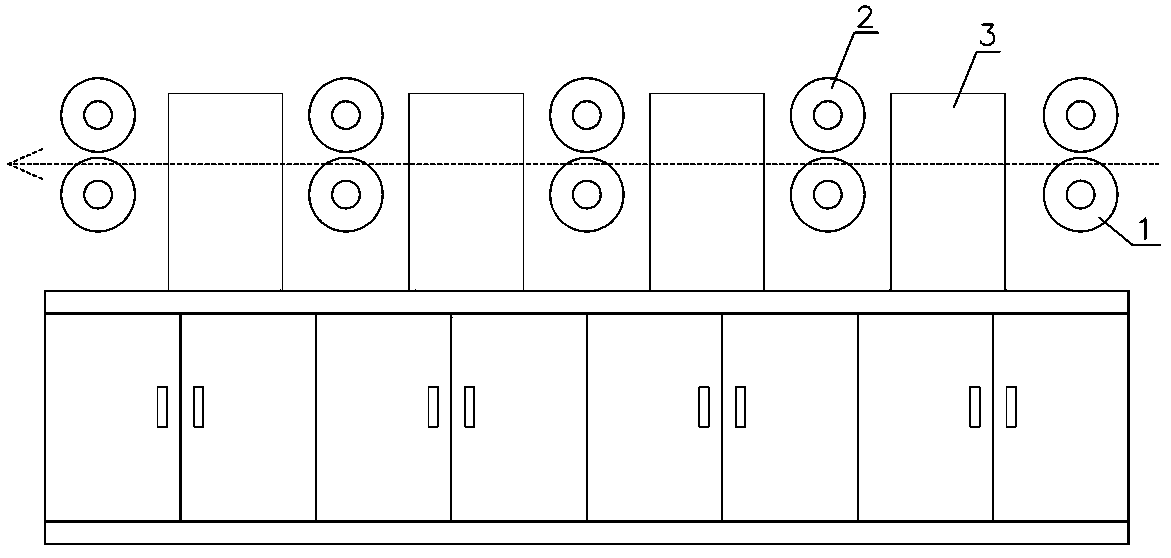

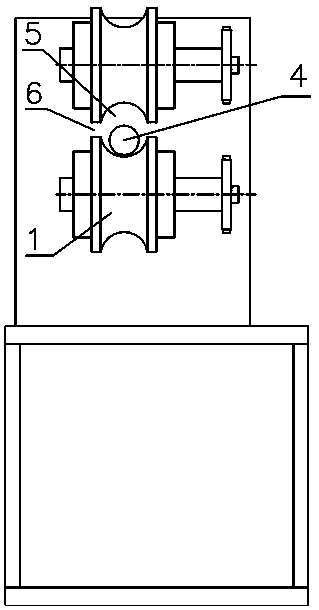

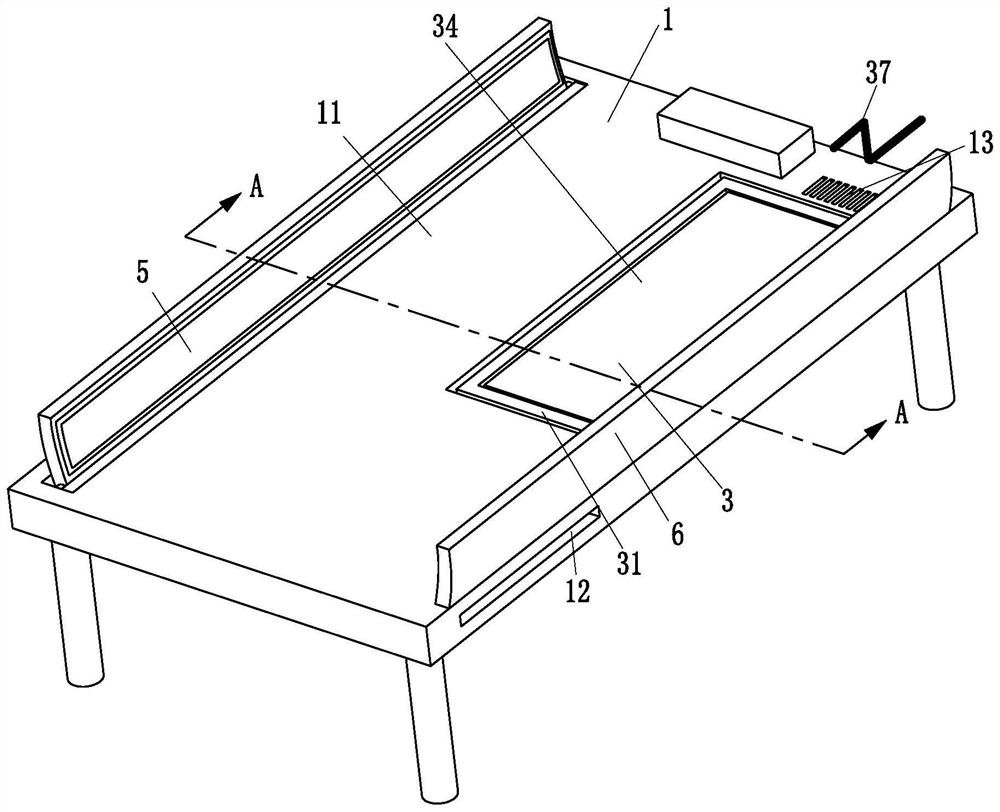

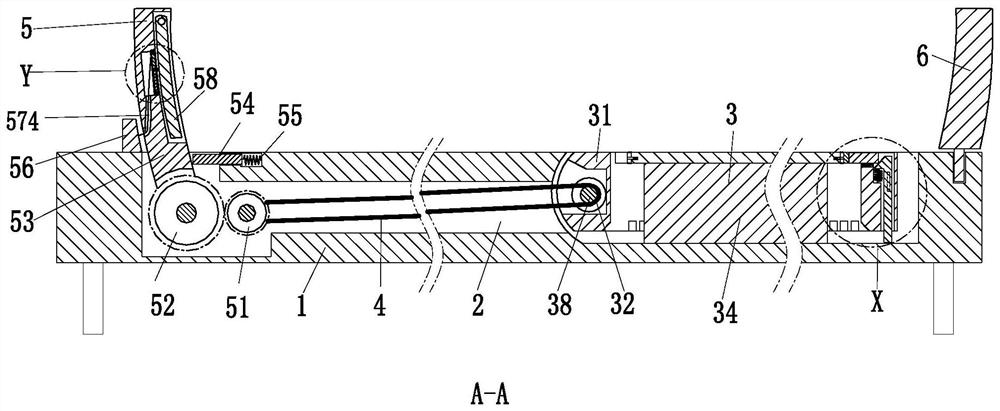

Feeding and fixing core device for steel ball rolling mill production line

PendingCN110238333AFree from damageReduce gap distanceBearing componentsWork heating devicesProduction lineStrip mill

The invention relates a feeding and fixing core device for steel ball rolling mill production line. The device comprises an intermediate frequency heating furnace assembly, a feeding roller wheel assembly and a fixed core assembly, wherein the intermediate frequency heating furnace assembly comprises at least one heating coil mechanism, the feeding roller wheel assembly is arranged at the input end and / or the output end of the medium-frequency heating furnace assembly, the feeding roller wheel assembly comprises a rotatable roller wheel, a circle of groove I for supporting bar materials is formed in the circumferential surface of the roller wheel, the fixed core assembly is arranged between the adjacent heating coil mechanisms and comprises a sliding block and a groove II arranged above the sliding block, the groove II is provided with a third inclined surface and a fourth inclined surface which are formed on the surface of the sliding block, and when the bar materials are placed in the groove II, the bar materials is correspondingly simultaneously in contact with the third inclined surface and the fourth inclined surface. According to the feeding and fixing core device for the steel ball rolling mill production line, the material throwing problem of the bar materials of a rolling mill can be solved, the gap distance between the adjacent heating coil mechanisms can be reduced, and the heat loss of the bar materials can be reduced.

Owner:CHANGSHU LONGTE WEAR RESISTING BALL CO LTD +1

Re-entrant resonant cavities and method of manufacturing such cavities

InactiveUS8324989B2Reducing and eliminating need for manual interventionImprove accuracyElectric lighting sourcesConductive pattern formationCapacitanceResonant cavity

A re-entrant resonant cavity 12 includes a first metallized molded plastic component 18, which comprises a re-entrant stub 17, an end wall 14 and a cylindrical side wall 13. The component 18 is surface mount soldered to a metallized PCB substrate 19. A rostrum 24 is located facing the end face 21 of the stub 17 to define a capacitive gap 22 with it. The end face 21 of the stub 17 and the rostrum 24 are configured such that relative rotation between them changes the profile of the gap 22 and hence the gap capacitance. By suitably locating the two parts during manufacture, a particular capacitance may be chosen to give a desired resonance frequency from a selection available depending on the relative angular position of the stub 17 and rostrum 24. In another cavity, the rostrum is replaced by an etched metallization layer of a printed circuit board.

Owner:ALCATEL LUCENT SAS

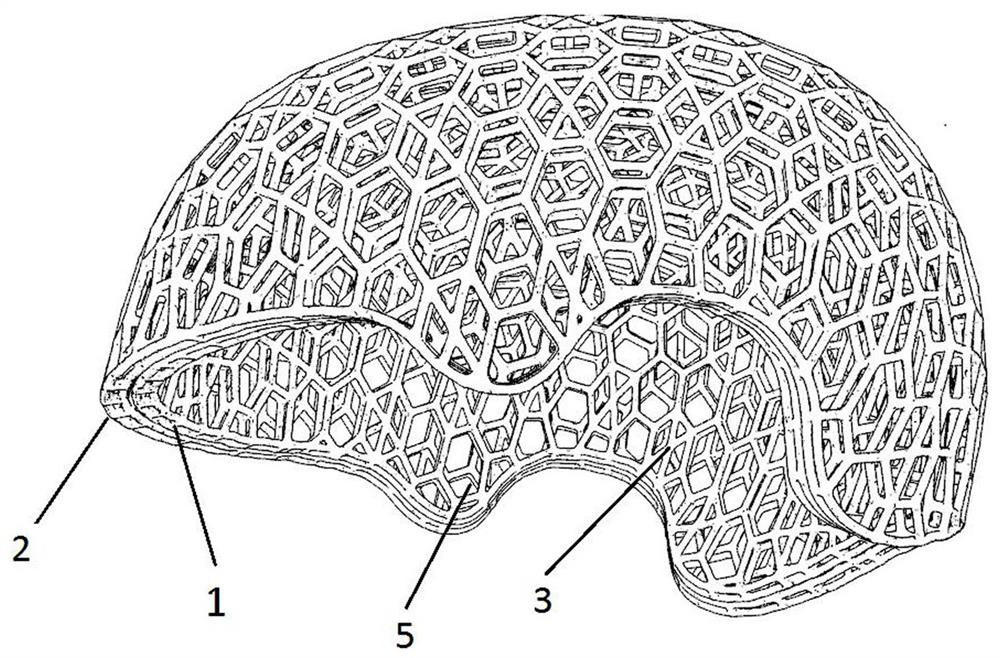

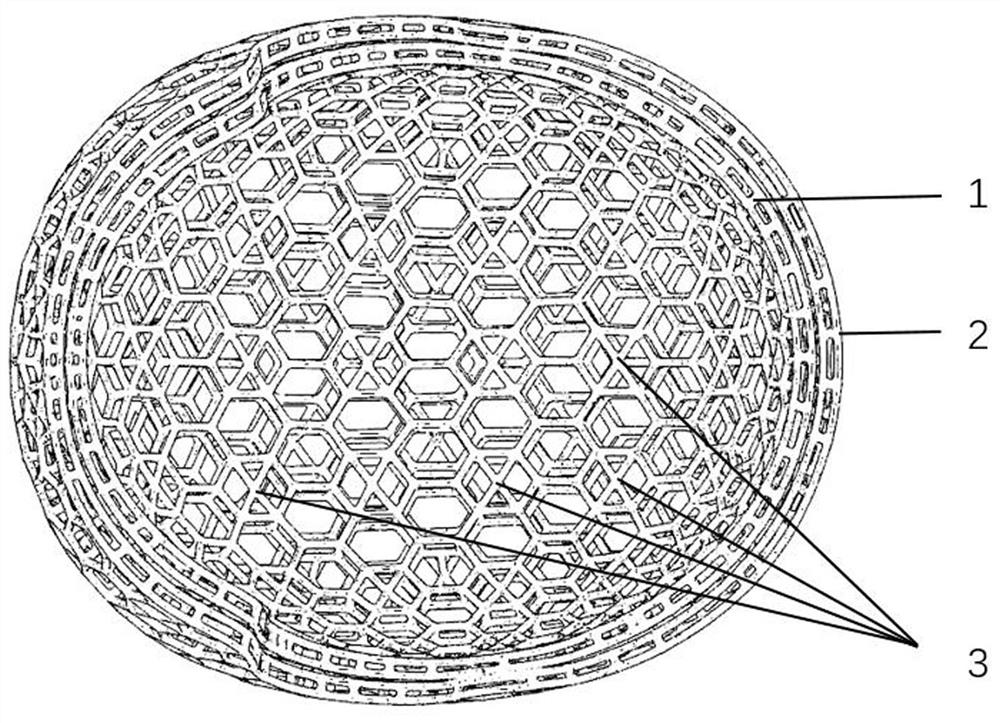

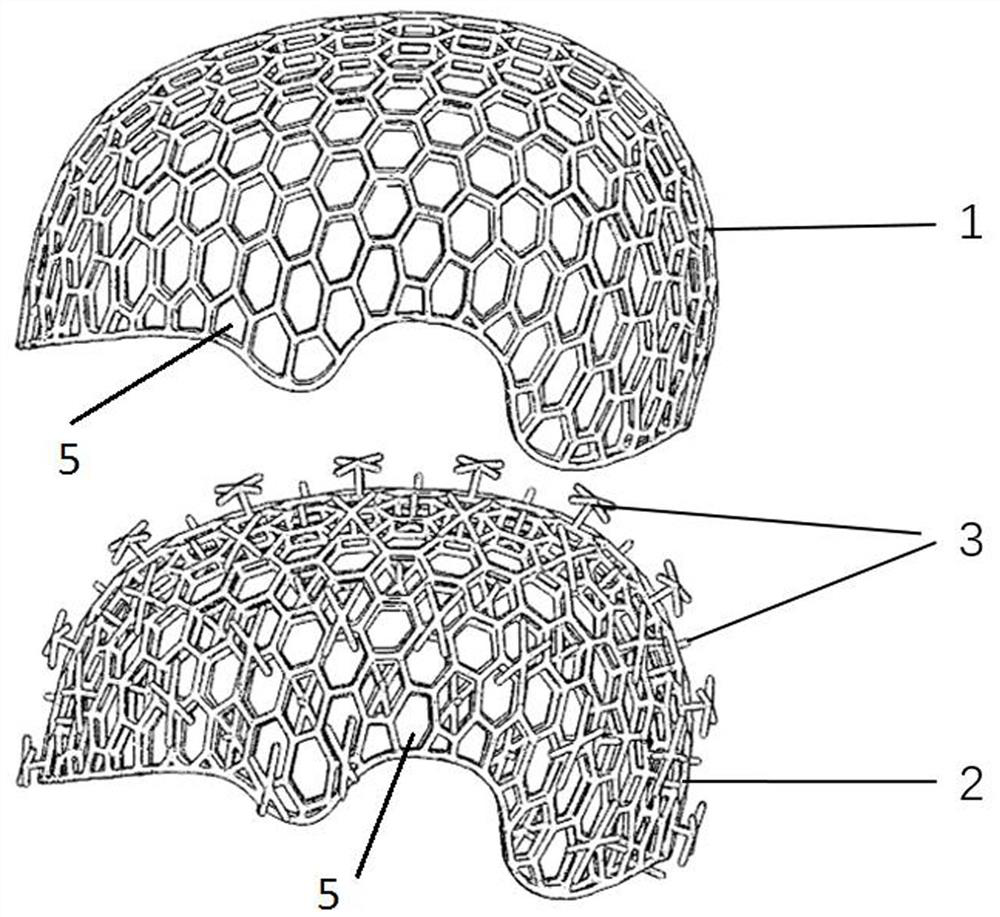

Self-adaptive lattice type 3D printing helmet buffer layer and manufacturing method thereof

PendingCN112716089AEasy to transformReduce the risk of injuryAdditive manufacturing apparatusManufacturing data aquisition/processingHuman bodyTangential force

The invention relates to the technical field of buffer damping structures, in particular to a self-adaptive lattice type 3D printing helmet buffer layer and a manufacturing method thereof. The buffer layer comprises an inner layer truss and an outer layer truss, the outer layer truss is arranged on the outer side of the inner layer truss and connected to the inner layer truss through a supporting unit, the rigidity of the supporting unit is smaller than that of the outer layer truss and the inner layer truss, and a gap allowing the inner layer truss and the outer layer truss to relatively generate tangential sliding is formed between the inner layer truss and the outer layer truss; when the buffer layer is impacted by the outside, the outer layer truss and the inner layer truss slide relatively and can play a role in buffering tangential force, so that the risk that the tangential force causes damage to the neck and the spine of a human body is reduced; and the rod pieces of the truss structures are subjected to tensile deformation, and can also perform buffering effect on the normal impact force.

Owner:NANJING AMEBA ENG STRUCTURE OPTIMIZATION RES INST CO LTD

Auxiliary turning device for bedridden examination

ActiveCN111437139BPrevent discomfortEasy to operateOperating tablesMedical transportPhysical medicine and rehabilitationEngineering

The invention relates to an auxiliary turning device for bed-ridden inspection, which includes a bed body group, a working tank, a turning device, a linkage belt, a left stop frame and a right stop frame. The middle part of the bed body group is provided with a working slot, The right end of the working trough is provided with a stand-up device, which is connected with the left block frame through a linkage belt, the left block frame is installed on the left end of the bed body group, and the right block frame is embedded in the right end of the bed body group. The invention can solve the problem that it is difficult for the person in charge of the rollover to ensure the same rollover angle of the bedridden person during the whole inspection process, and it is easy to cause the physical discomfort of the bedridden person. In this case, the bedridden person may continue to turn and fall to the ground. In order to prevent the person from falling out of bed, the staff needs to hold the bedridden person firmly. During the process of grasping, it may be difficult to ensure the rollover position of the bedridden person due to hand soreness and other reasons. Consistent and so on.

Owner:JILIN UNIV

A telescopic car door sill and telescopic control method

ActiveCN104355210BReduce frictionLower performance requirementsBuilding liftsRotational axisEngineering

The invention provides a telescopic car-door sill and a flexing control method, belonging to the technical field of elevator sills and solving the problem that a sill is fixed so as to be inconvenient to install. The telescopic car-door sill is characterized in that a driver is a stepper motor, the stepper motor is provided with an angular rotary shaft, a rotary pushing block is arranged on the angular rotary shaft, and the end of the rotary pushing block is movably connected with the bottom of a shielding plate. When a control cabinet sends an angle rotation signal to the stepper motor, the rotary pushing block rotates, and the shielding plate extends out along a pedal slideway or returns to an initial position along the pedal slideway. According to the telescopic car-door sill and the flexing control method, the interval can be largely reduced, even completely eliminated; the structure is simple, so that sundries are prevented from falling down through the interval; the running of the telescopic car-door sill is safe and reliable.

Owner:HITACHI ELEVATOR CHENGDU

Outgoing line terminal cover and bar-shaped switch

PendingCN114695007AIncrease gap distanceIncrease creepage distanceAir-break switch detailsContact electric connectionBusbarStructural engineering

An outgoing line terminal cover and a bar-shaped switch relate to the technical field of electric appliance switches, the outgoing line terminal cover comprises a shell and a connecting assembly fixedly connected with the shell, the shell is internally provided with a fixed end for accommodating an outgoing line busbar and an accommodating space for a wiring terminal, the shell is provided with a first opening, and the first opening is used for a lead connected with the wiring terminal to pass through; the connecting assembly is used for being hinged to a base of the strip-shaped switch so that the shell can rotate relative to the base. According to the outgoing line terminal cover and the bar-shaped switch, the structure of the bar-shaped switch can be simplified and the size of the bar-shaped switch can be reduced on the premise of increasing interphase electrical gaps and creepage distances.

Owner:SHANGHAI LIANGXIN ELECTRICAL

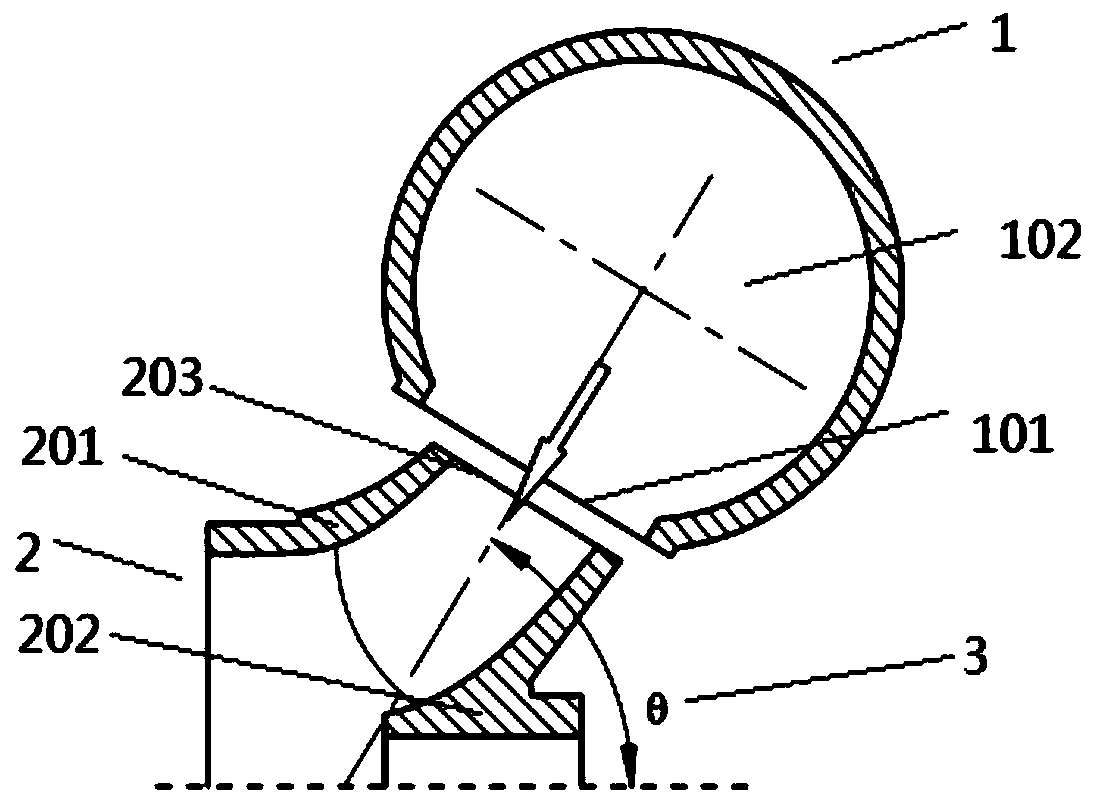

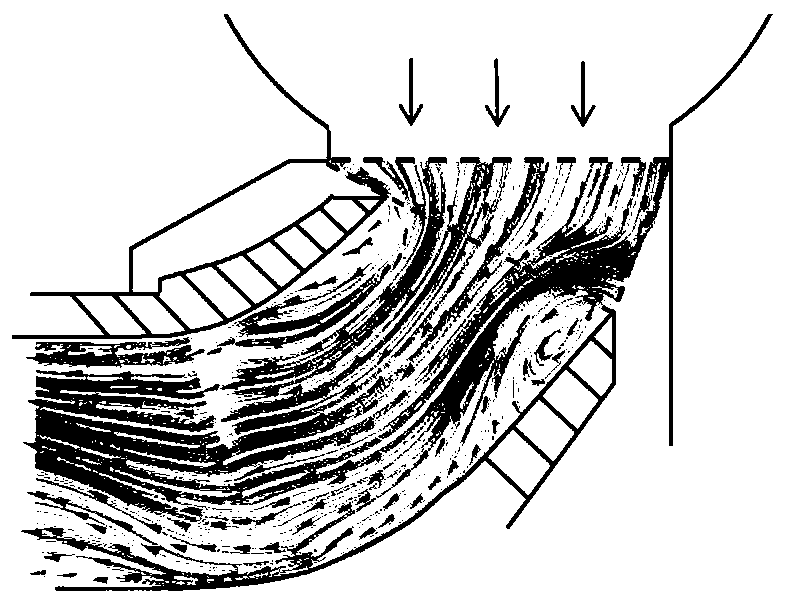

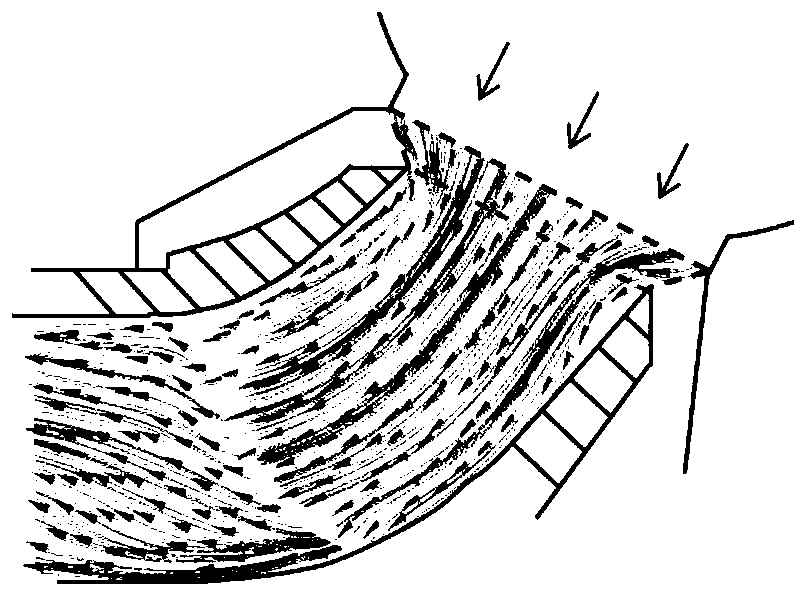

Mixed-flow pump

The invention discloses a mixed-flow pump. The mixed-flow pump comprises a volute and an impeller; the outlet of the volute is communicated with the inlet of the impeller; the volute is inclined relative to a center line at a rotation shaft of the impeller so that a center line of the outlet of the volute has a flowing taper angle theta relative to a center line at the rotation shaft of the impeller. The inclination of the outlet of the volute is capable of playing a role in improving the incoming flow at the inlet of the mixed-flow pump as a turbine impeller, thereby decreasing the hydraulicloss and enhancing the performance of the mixed-flow pump as a turbine set. The mixed-flow pump can be widely applied in the large-flow and low-water head micro hydropower stations.

Owner:JIANGSU UNIV ZHENJIANG RES INST OF FLUID ENG EQUIP TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com