Backlight unit and liquid crystal display device including the same

A backlight unit and device technology, applied in the direction of semiconductor devices, optical components, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

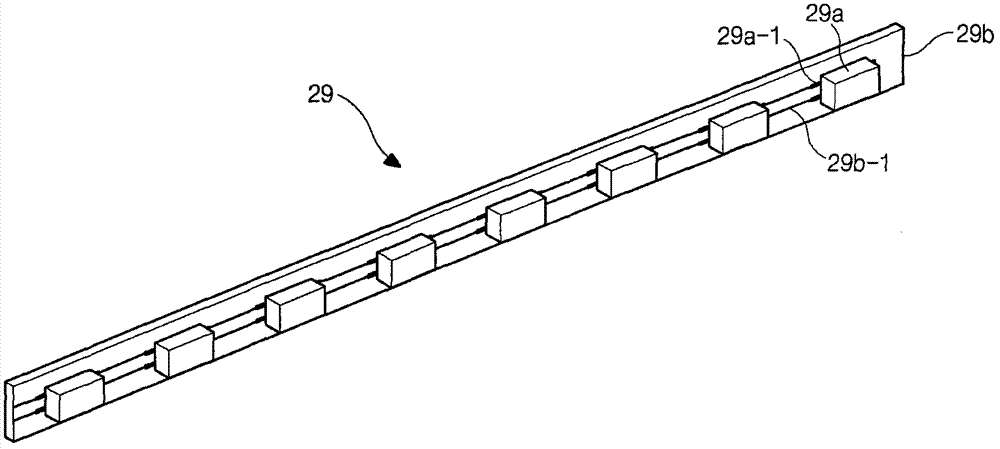

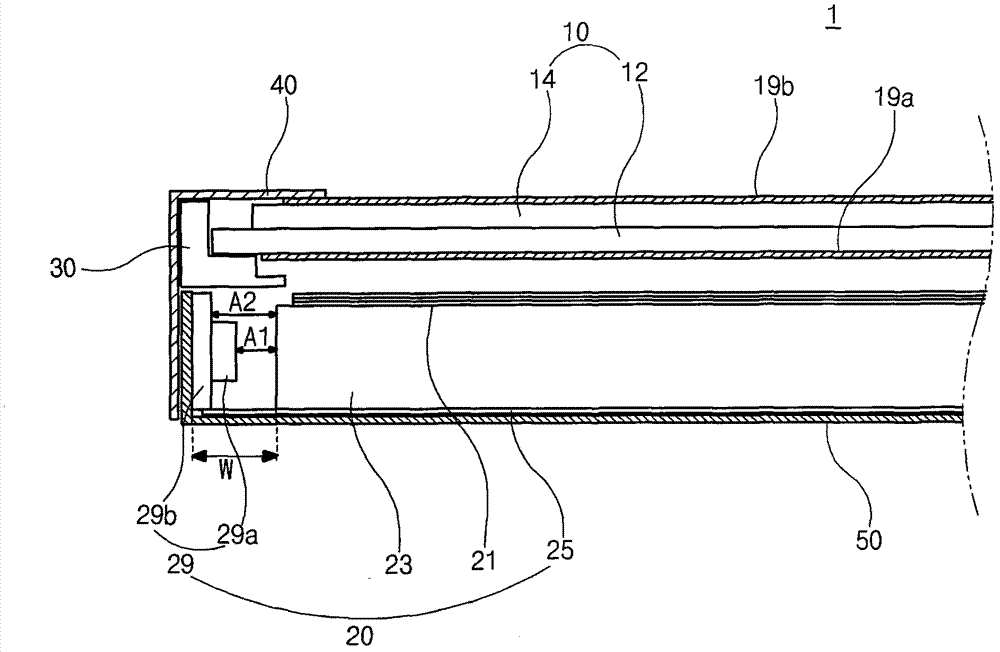

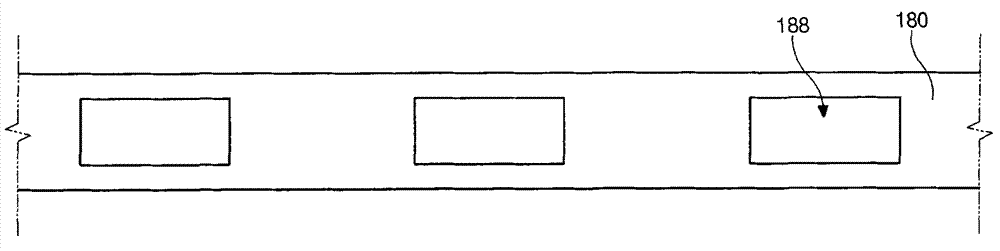

[0050] exist Figure 6 In this case, the leads 298 of the plurality of LEDs 290 do not protrude beyond the lower surface of the LED PCB 280 . Similar to the first embodiment of the present invention, the LED PCB 280 includes a base layer 281 , an insulating layer 282 on the base layer 281 , a circuit pattern layer 283 on the insulating layer 282 , and a protection layer 284 on the circuit pattern layer 283 . In addition, a plurality of through holes 288 are formed in the LED PCB 280 along the long sides of the LED PCB 280 . The lead groove 286 surrounding each of the plurality of through holes 288 is formed such that the base layer 281, the insulating layer 282, and the circuit pattern layer 283 each have a step difference.

[0051] The LED assembly 200 includes an LED PCB 280 and a plurality of light emitting diodes 290 inserted into a plurality of through holes 288 of the LED PCB 280 . The base layer 281 may include a metal material having relatively high thermal conductiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com