Method of preparing wound cell electrode through compositing process and lithium-ion battery

A composite process and cell technology, which is applied to secondary batteries, battery electrodes, circuits, etc., can solve problems such as uneven tension of winding bare cells, inability to fully protect the diaphragm, and changes in the distance between tabs, so as to reduce the risk of short circuit , high pass rate and improved cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

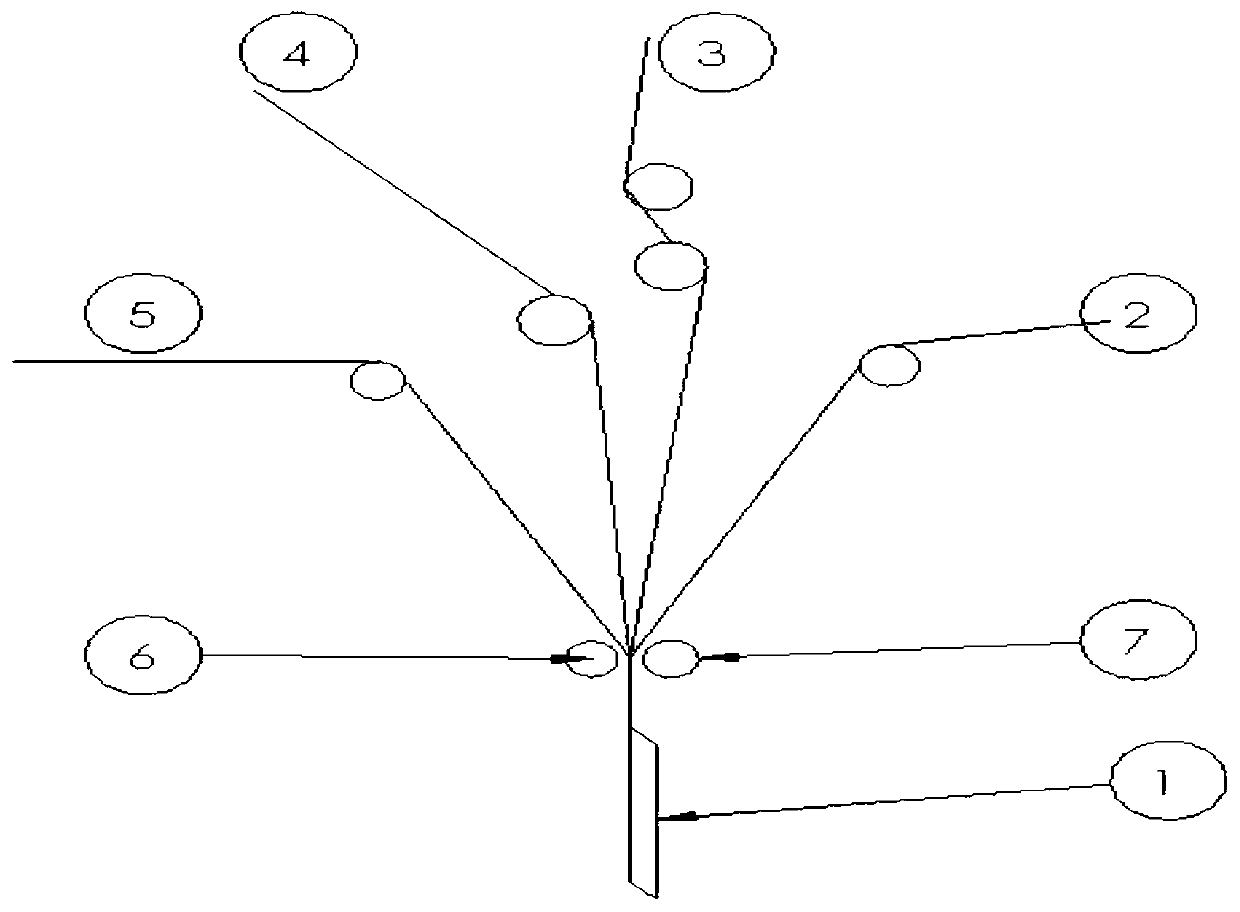

[0028] First, the upper separator (3), the lower separator (5) and the negative electrode sheet (4) are heated and compounded by the heating press rollers (6) and (7), and then the positive electrode sheet (2) is passed through the one-way roller (8) And (9), take shape by rolling pin (1). The heating press rollers (6), (7) are heated at a constant temperature, and the heating temperature is 35-60° C.; the isolation film is composed of a polyvinylidene fluoride polymer coating and a polypropylene base film. The negative electrode is graphite, and the positive electrode is lithium iron phosphate. The battery pole piece obtained by the above method can be used to prepare a lithium ion battery through assembly, liquid injection and chemical conversion. The battery can be cycled for a long time without deformation and has a long cycle life. Since the upper and lower separators are adhered to the surface of the negative electrode sheet, the separators at the end section are adhere...

Embodiment 2

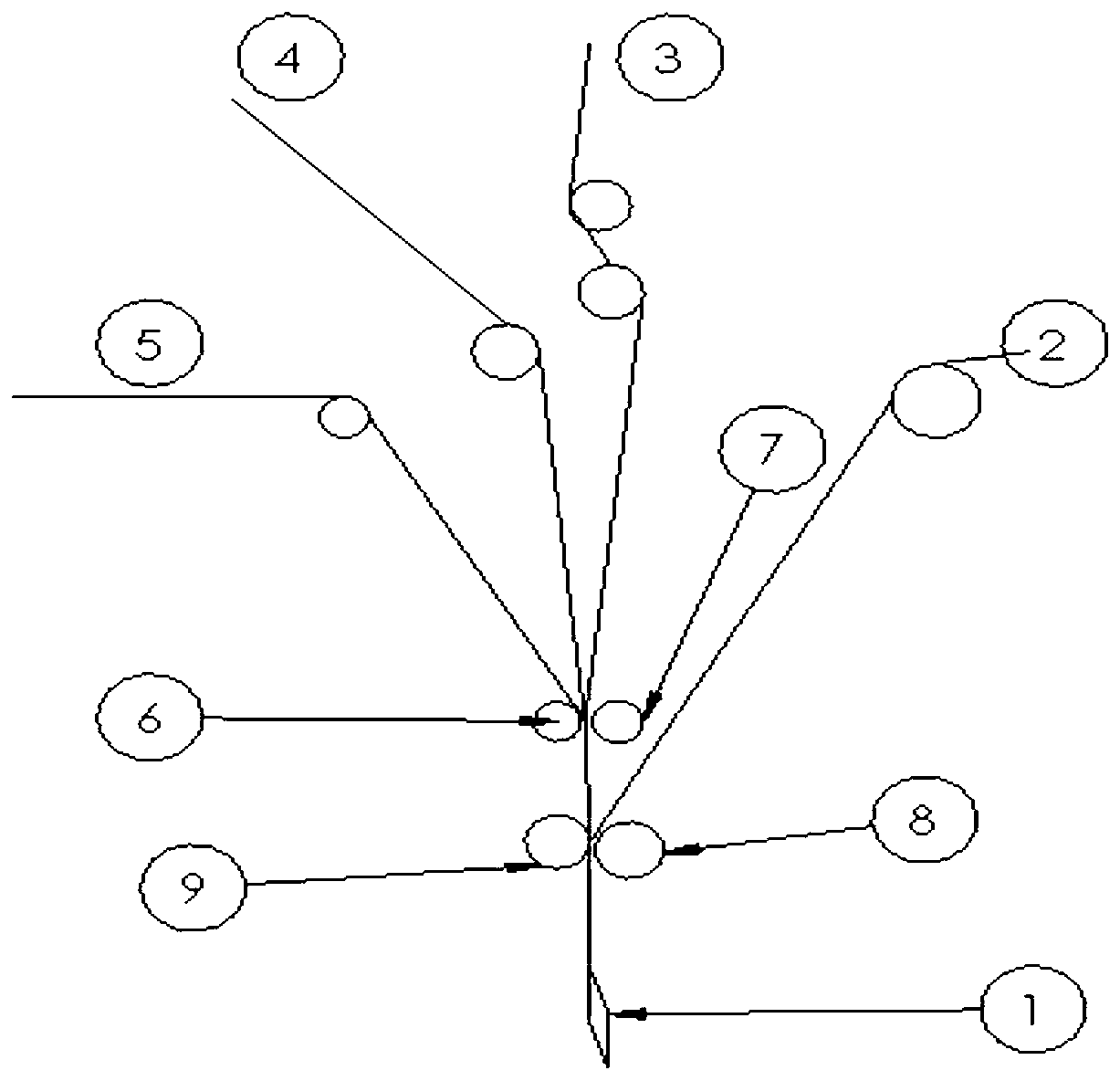

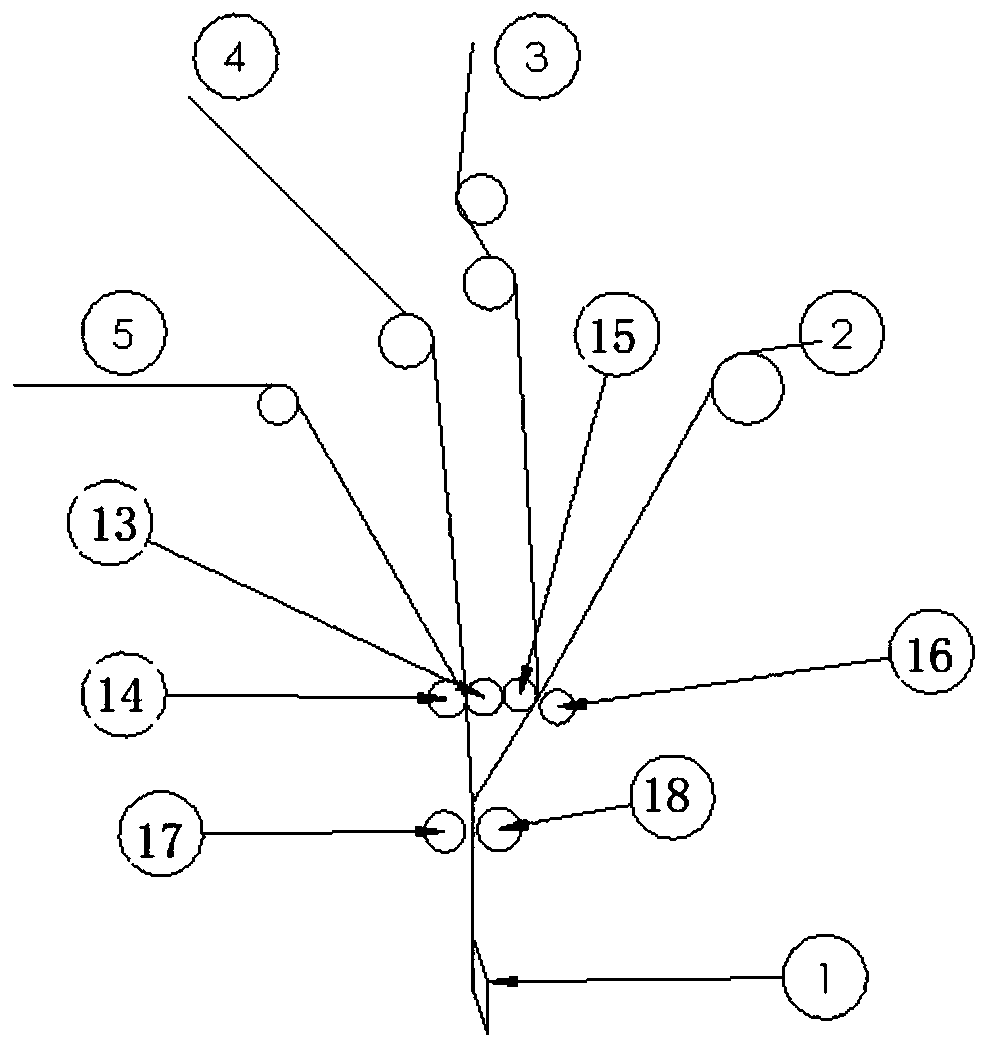

[0032] First, the lower separator (5) and the negative electrode sheet (4) are compounded through the heating roller (13) and the top roller (14), and the upper separator (3) and the positive electrode sheet (2) are passed through the heating roller (15) and the unidirectional The top (16) rolls are compounded, and then the left and right heating rollers (17) and (18) are compounded together, and are wound and formed by the needle (1); the heating press rollers (6), (13), (15), (17), and (18) are heated at a constant temperature, and the heating temperature is 35-60° C.; the isolation membrane is composed of polyvinylidene fluoride and polyoxyethylene ether. The isolation film is composed of polyethylene and polypropylene base film and polyvinylidene fluoride and polyoxyethylene ether polymer coating. The negative electrode active material is graphite, and the positive electrode is lithium iron phosphate. The battery pole piece obtained by the above method is assembled, injec...

Embodiment 3

[0035] The difference between this embodiment and Embodiment 2 lies in that the bare cell used as a component has a full tab structure.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap