Omnidirectional perfectly matched transparent material conforming to uniaxial perfectly matched layer model

A technology of perfect matching layer and transparent material, applied in the field of artificial medium, can solve the problem of decreased transmission efficiency, and achieve the effect of light weight, simple structure and thin thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

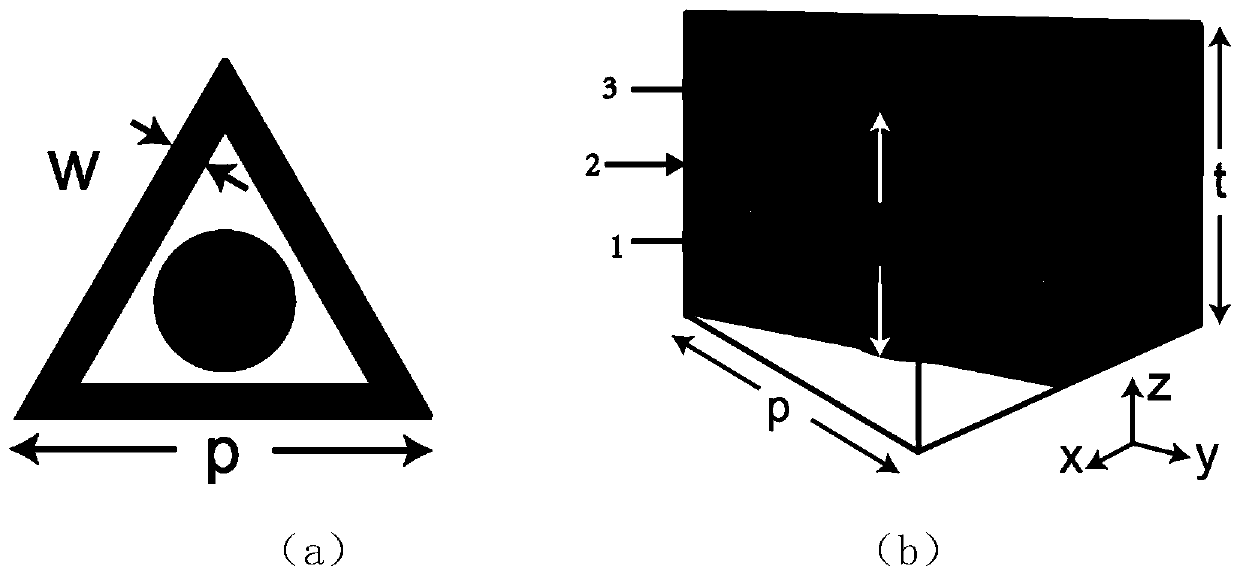

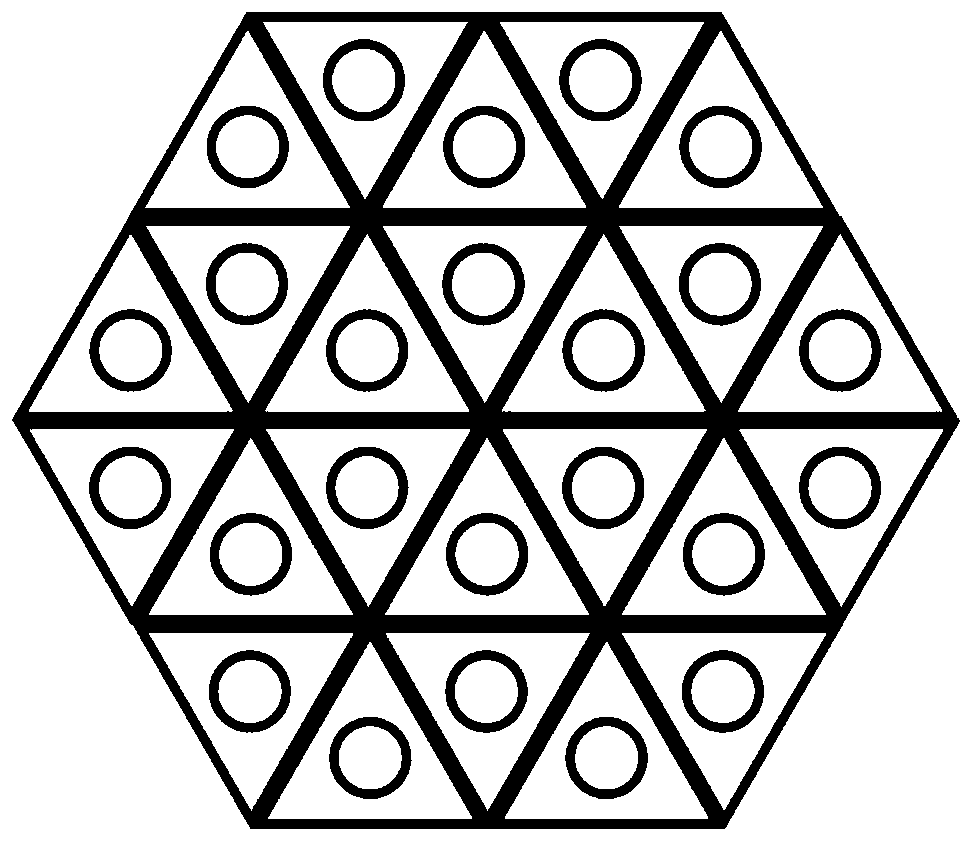

[0027] Such as figure 2 As shown, in the present invention, an equilateral triangle with a side length of 10 mm is used as a triangular sub-wavelength unit to obtain a free space full-angle perfect matching transparent material arranged in an array. In this embodiment, the thickness of the triangular metal copper ring is 0.035mm, the length of three sides is equal to 10mm, and the width of the side is 0.98mm, which mainly plays the role of adjusting the dielectric constant. The metal copper cylinder is 7mm high and has a radius of 1.878mm, which mainly plays the role of adjusting the magnetic permeability. The thickness of the two layers of PTFT medium is 5mm, the relative permittivity is 3.3, the relative permeability is 1, and the loss tangent angle is 0.003. Such as figure 1 As shown, w=0.98mm, r=1.878mm, h=7mm, p=10mm, t=10.035mm.

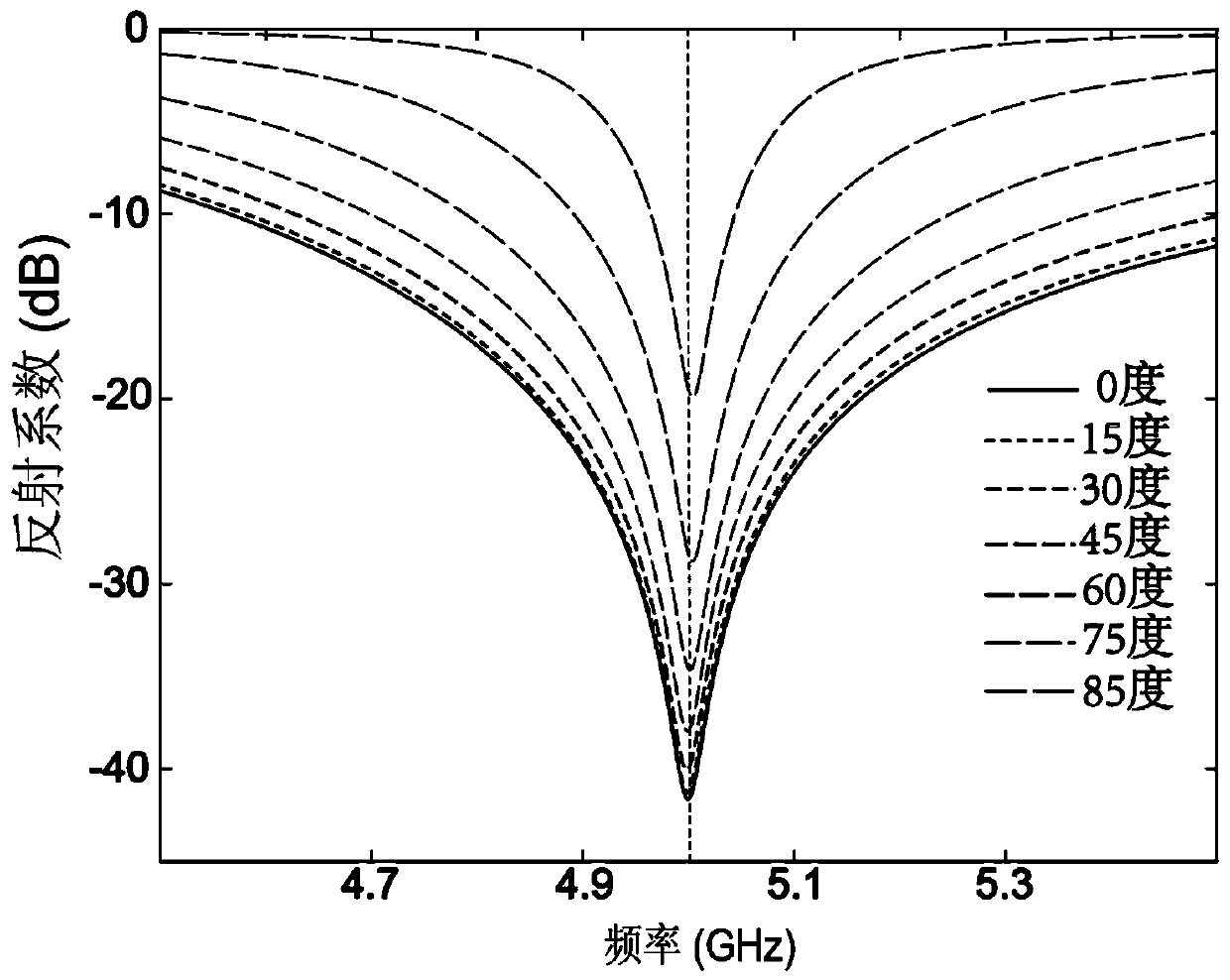

[0028] Simulation results such as image 3 As shown, the omnidirectional perfectly matched transparent material conforming to the uniaxia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com