Sealing assembly

A technology of sealing components and sealing parts, which is applied in the direction of electrical components, parts of connecting devices, base/housing, etc., can solve the problems of high cost, large tightening torque, and no obvious advantages of rubber sealing rings, and achieve low cost and applicable Strong performance, guaranteed performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further illustrate the technical means and technical effects adopted by the present invention, the present invention will be described in detail below in conjunction with specific embodiments.

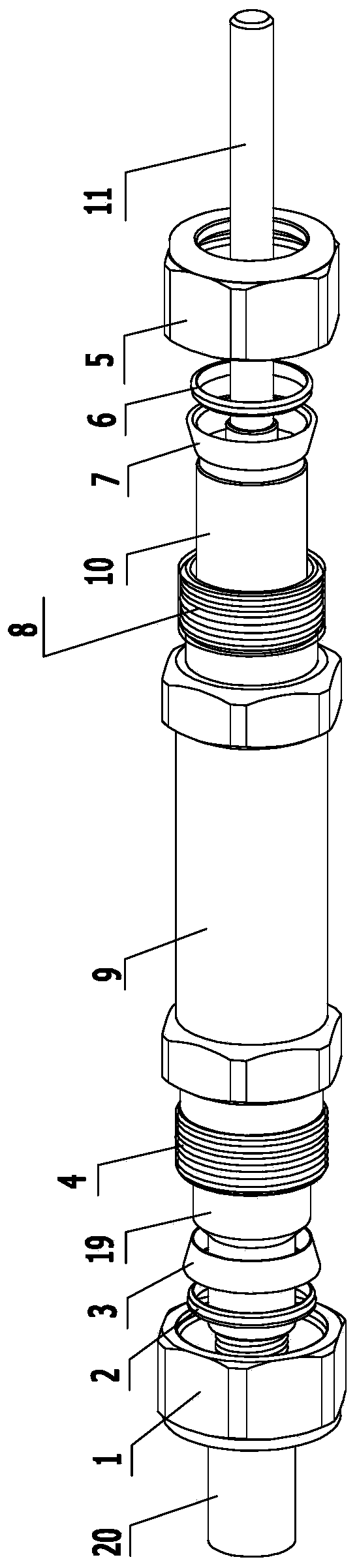

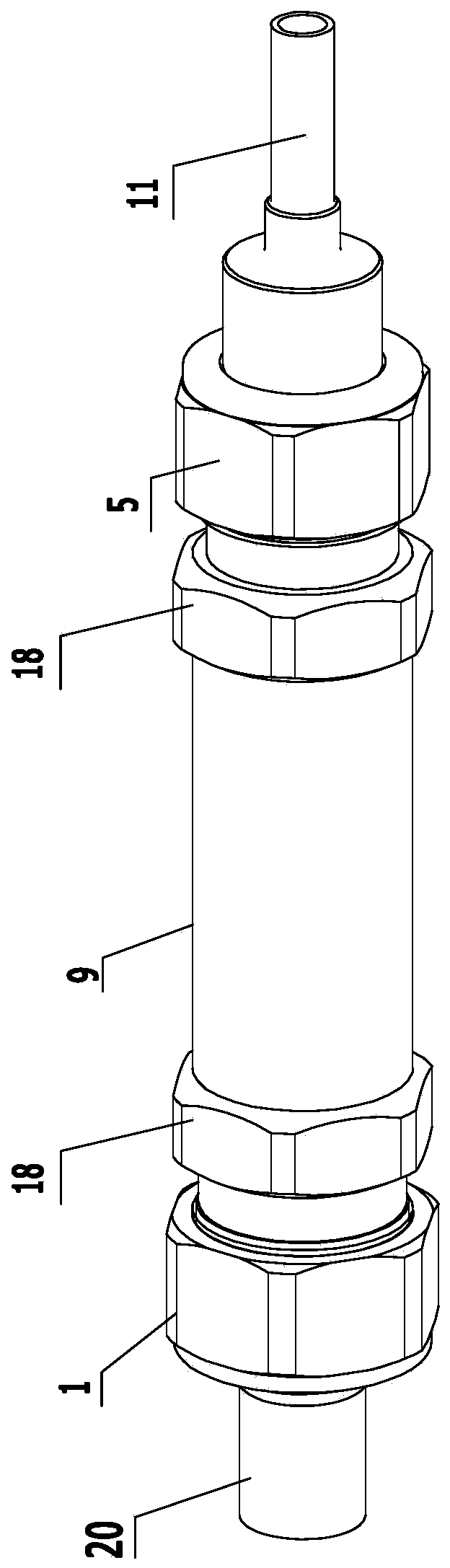

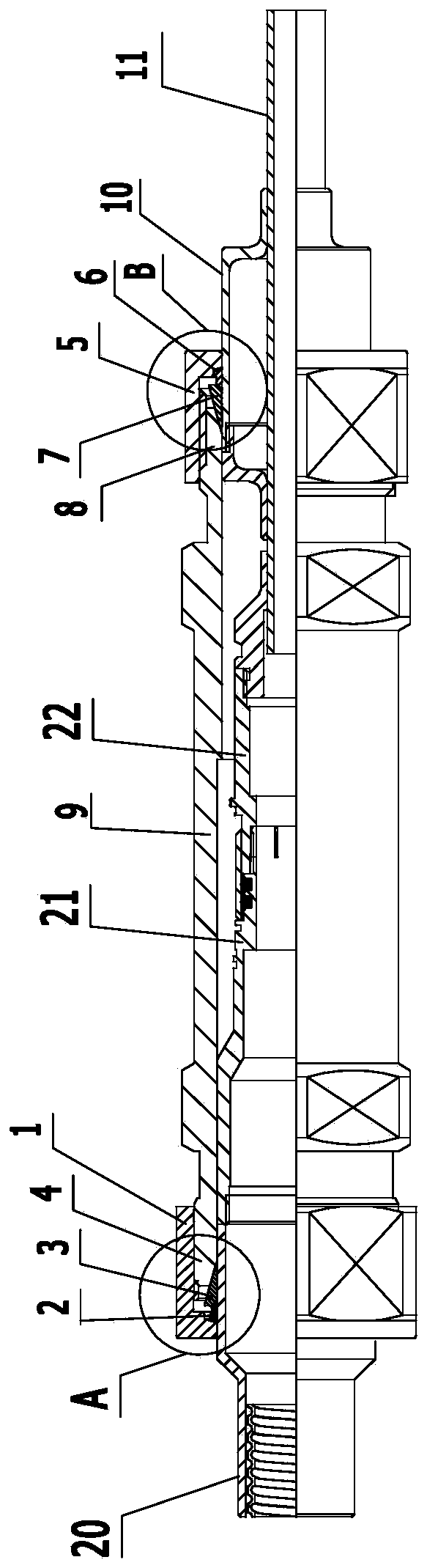

[0032] Such as figure 1 As shown, the present invention includes a straight sleeve for wrapping and sealing the plug and socket of the connector, a nut for threaded connection with the threaded connecting portion at both ends of the straight sleeve, and a nut arranged on the screw. The front sleeve and the rear sleeve which play a sealing role between the cap and the corresponding connecting part. For the convenience of description, the sealing assembly at the left end of the straight sleeve 9 is marked as nut A 1, rear sleeve A 2, front sleeve A 3, and connecting part A 4, and the sealing assembly at the right end of the straight sleeve is marked as nut B 5, rear sleeve B 6, front cover B 7, connecting part B 8, and define that the front cover A is located in front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com