U-shaped bolt feeding compressing device for automobile chassis

A technology of automobile chassis and pressing device, applied in the direction of presses, manufacturing tools, etc., can solve the problems of affecting the production quality of bolts and poor pressing effect, and achieve good shock absorption effect, avoid waste, and good stamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

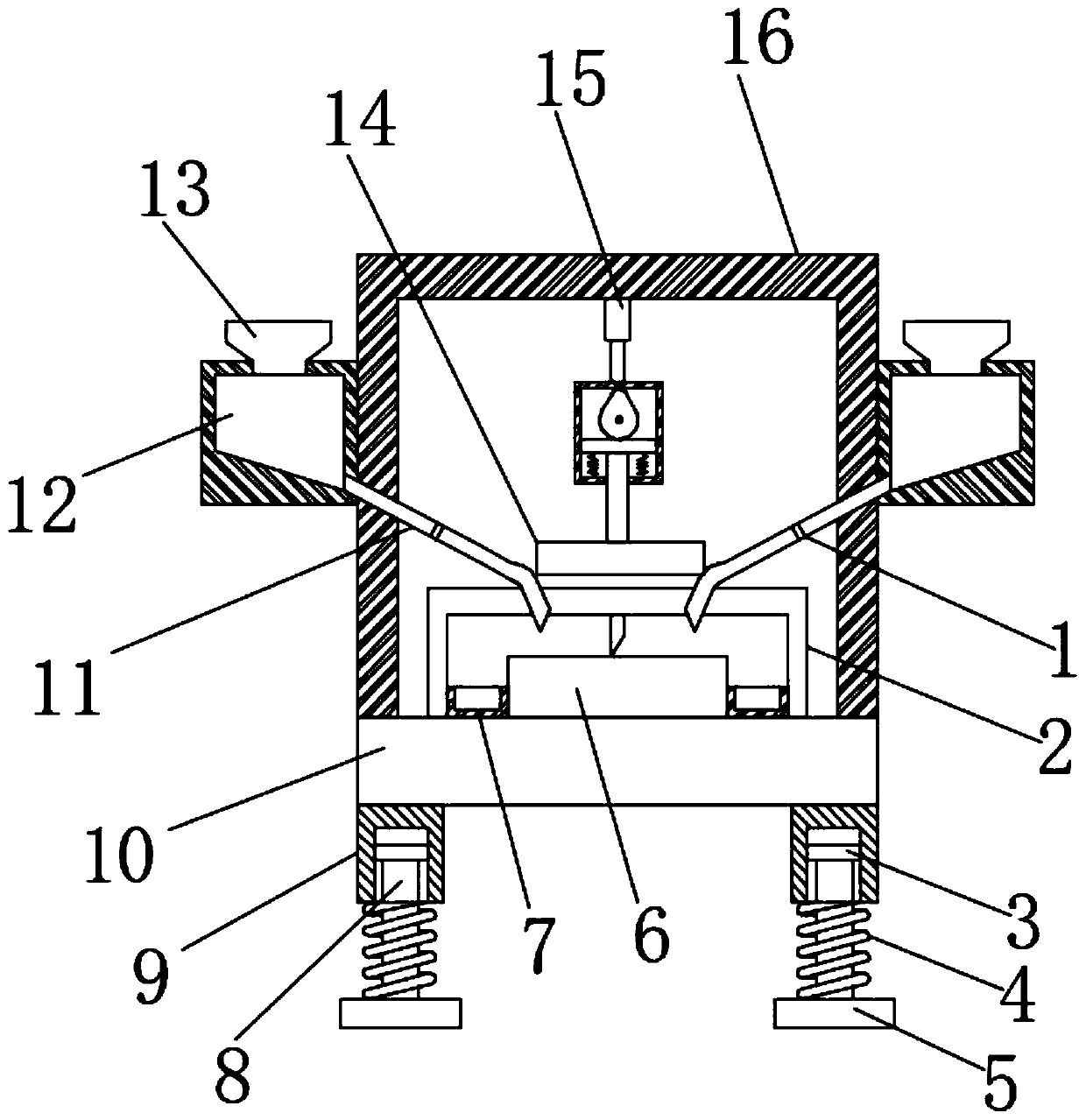

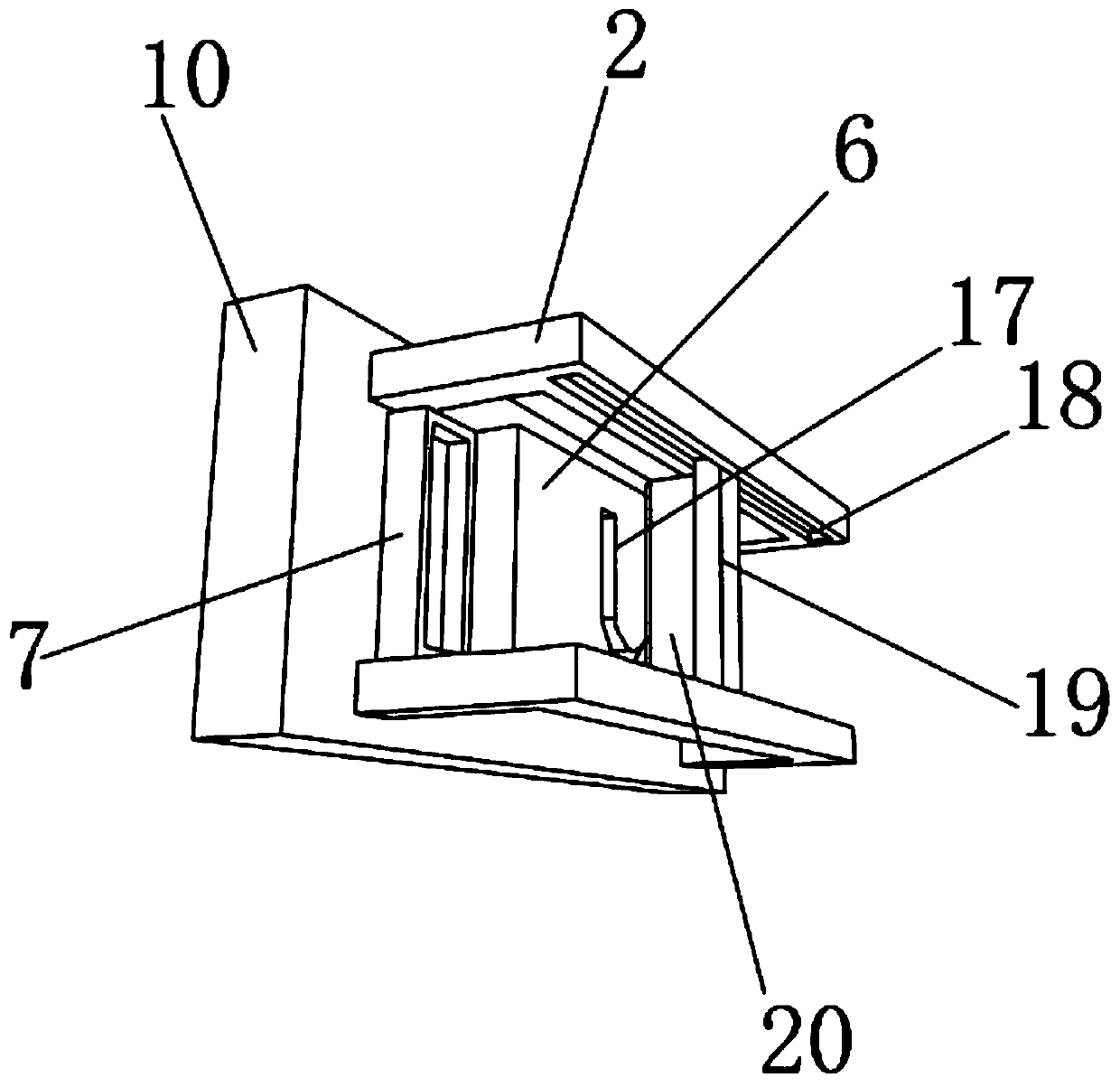

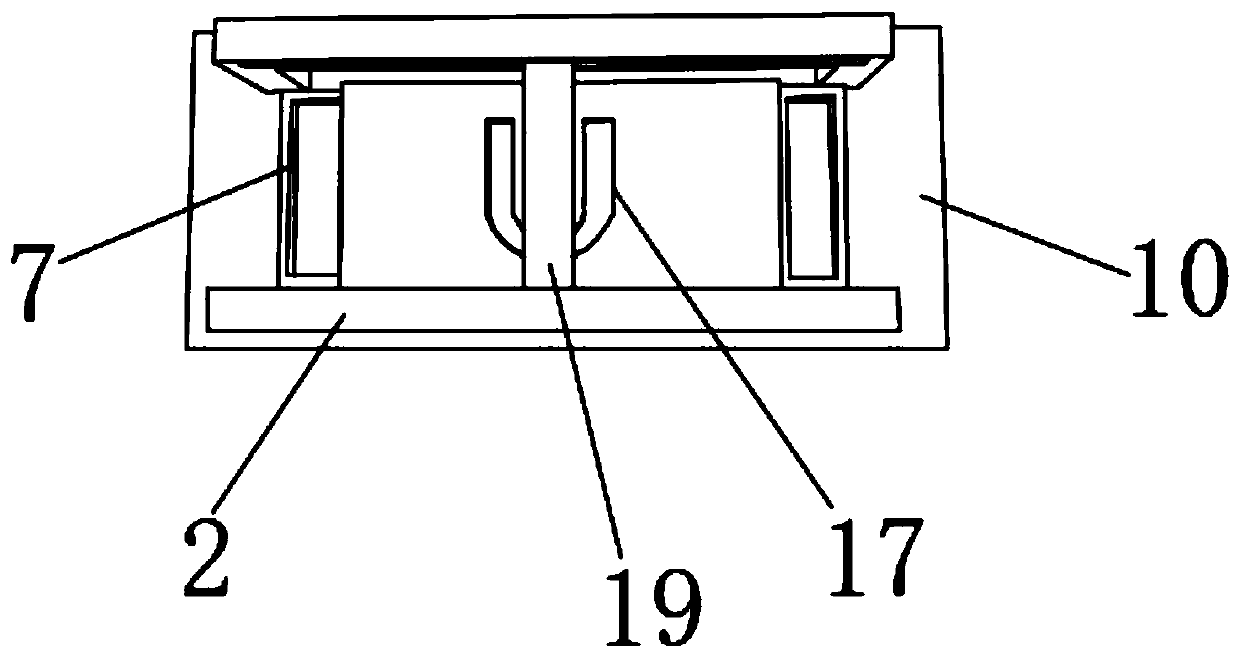

[0025] refer to Figure 1-3 , a U-shaped bolt blanking and pressing device for an automobile chassis, comprising a workbench 10, the same gantry 16 is fixed by screws on both sides of the top outer wall of the workbench 10, and the top inner wall of the gantry 16 is fixed by screws. Cylinder 15, one end of the piston rod of hydraulic cylinder 15 is fixed with a fixed cylinder by a screw, and the inner wall of the fixed cylinder is slidably connected with a slide plate, the bottom outer wall of the slide plate is fixed with a connecting rod through a screw, and the bottom outer wall of the connecting rod is fixed with a compression pin through a screw. Plate 14, the bottom outer wall of the slide plate located on both sides of the connecting rod is fixed with a return spring by screws, and the bottom end of the return spring is connected with the bottom inner wall of the fixed cylinder.

[0026] In the present invention, the top outer wall of the workbench 10 is fixed with the ...

Embodiment 2

[0032] refer to figure 1 , a U-shaped bolt blanking and pressing device for an automobile chassis. Compared with Embodiment 1, this embodiment also includes that the four corners of the outer wall of the bottom of the workbench 10 are fixed with a buffer tube 9 by screws, and the inner wall of the buffer tube 9 Slidingly connected with piston 3, the bottom outer wall of piston 3 is welded with buffer rod 8, the outer wall of buffer rod 8 is sleeved with damping spring 4, and the bottom outer wall of buffer rod 8 is fixed with support plate 5 by screws.

[0033] During the stamping process, the device will vibrate violently, and the shock-absorbing spring 4 can have a good shock-absorbing effect, so as to avoid damage to the device itself due to excessive vibration.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap