Tool setting device

A tool setting device and tool adjustment technology, which is applied in the field of CNC lathes, can solve problems such as unequal height, hard to find gaskets, and tool installation errors, and achieve the effects of simple structure, improved speed and precision, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

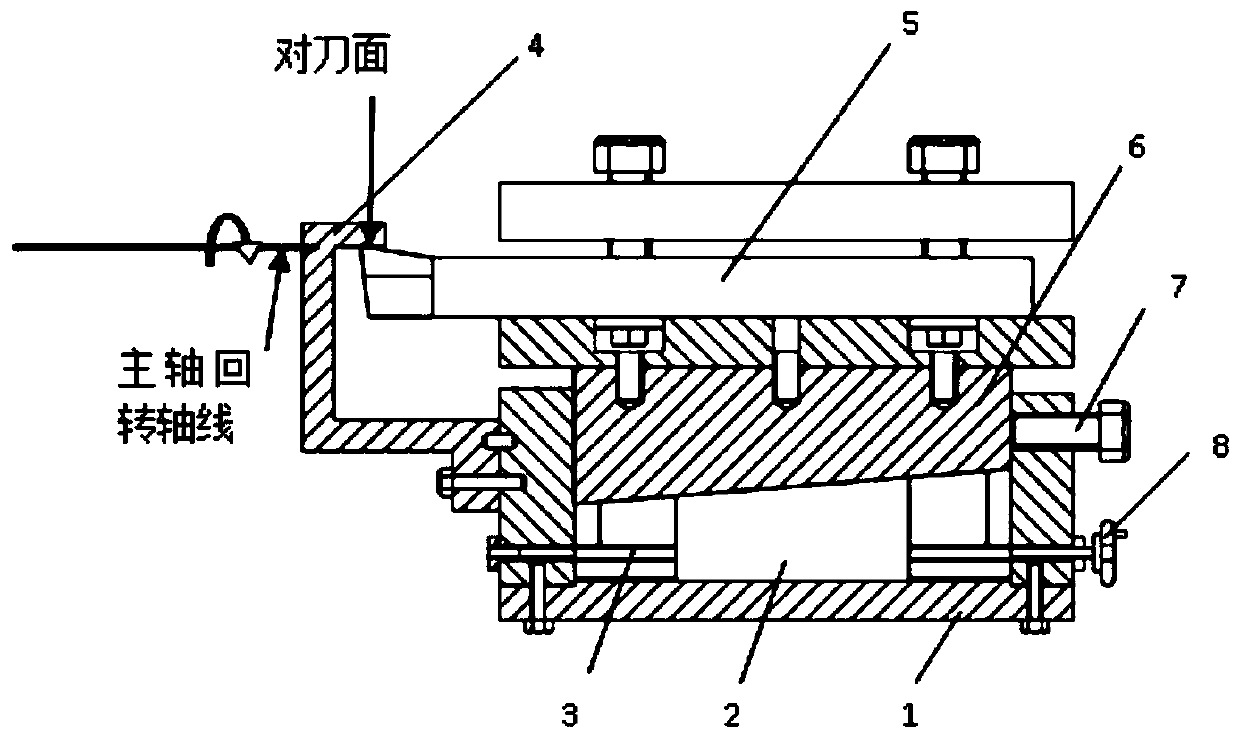

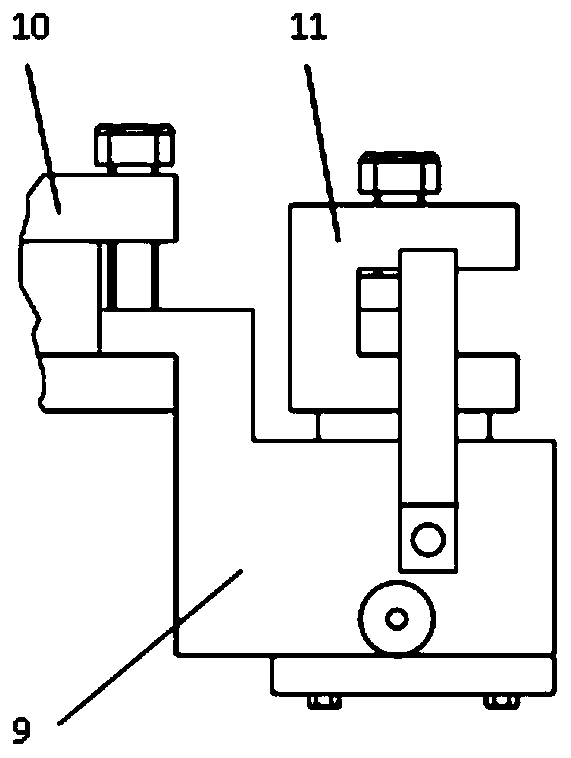

[0044] A tool setting device that participates in figure 1 , figure 2 , including guide base plate 1, first height adjustment block 2, height adjustment screw rod 3, tool setting block 4, turning tool 5, second height adjustment block 6, locking screw 7, height adjustment handwheel 8, knife adjustment body 9 , a square tool rest 10, a knife holder 11, an accommodating cavity is set in the said adjusting tool body 9, a first height adjusting block 2 and a second height adjusting block 6 are arranged in said accommodating cavity, said second adjusting The lateral width of the block is slightly smaller than the width of the accommodating cavity, and the lateral limit of the accommodating cavity inner wall of the knife adjusting body 9 to the second height adjusting block 6 is such that the second height adjusting block 6 can only move up and down. Move, the lateral width of the first height adjustment block 2 is smaller than the width of the accommodating cavity, so that the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com