Carbon fiber composite plate molding device for automobile

A molding equipment and composite board technology, which is applied in the field of carbon fiber composite board molding equipment for automobiles, can solve problems such as poor internal composite, cracking of composite boards, uneven molding, etc., and achieve the goal of ensuring performance, improving toughness, and improving uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

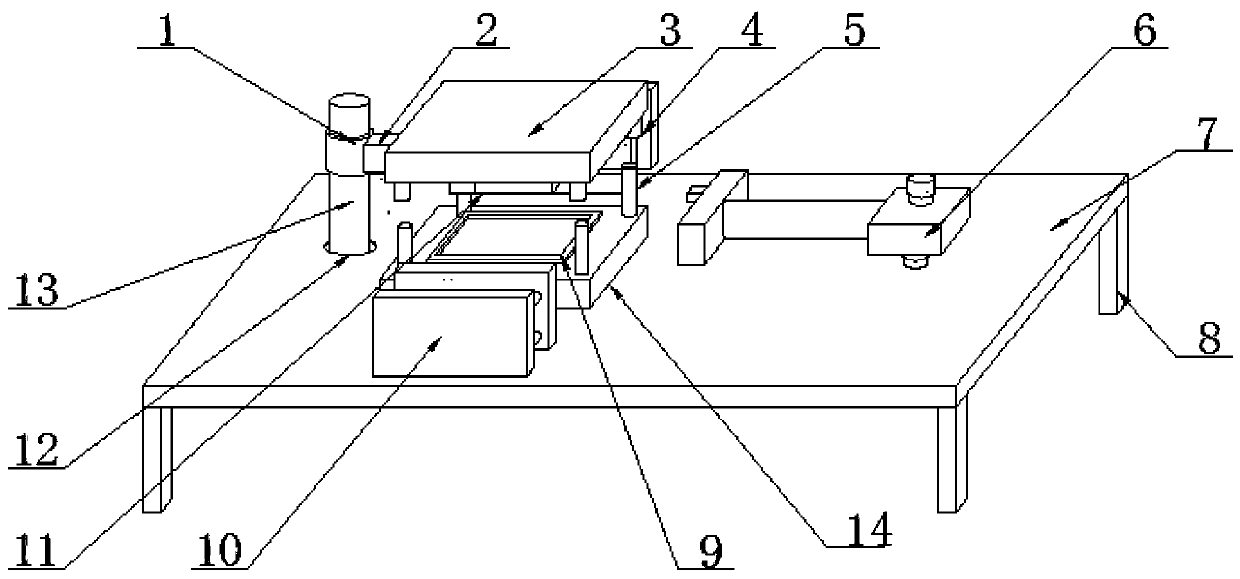

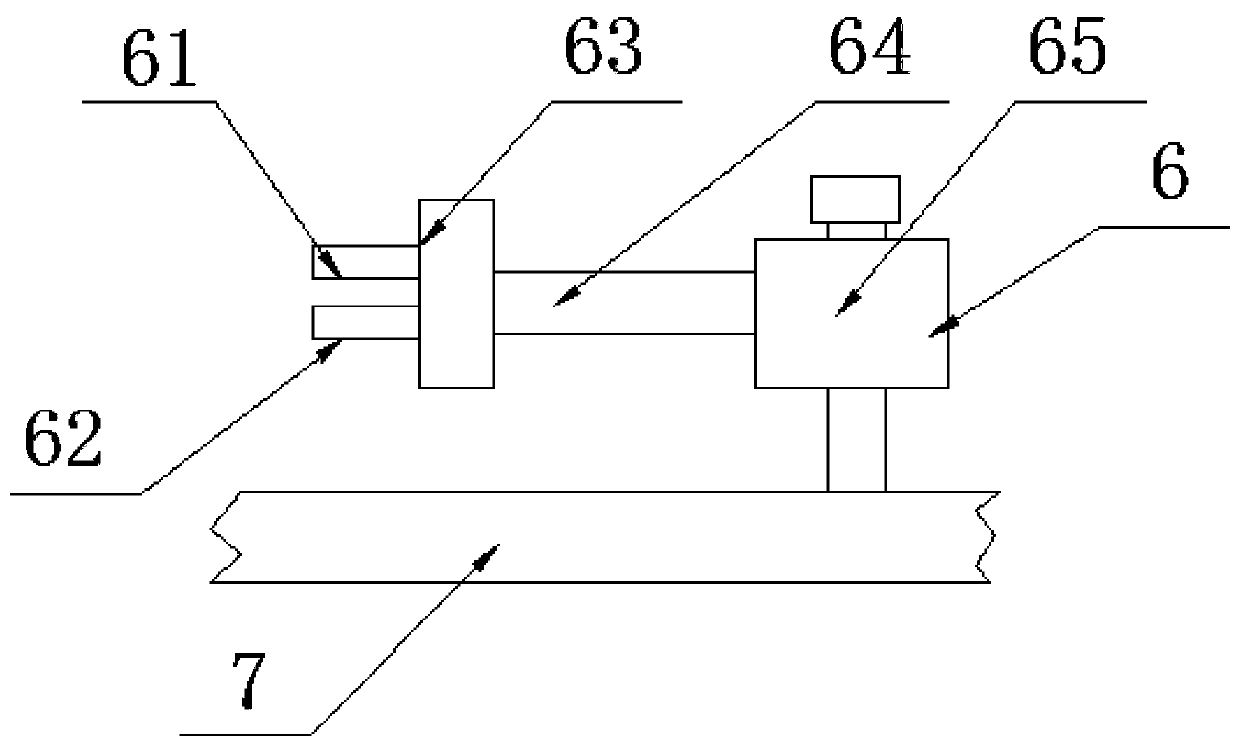

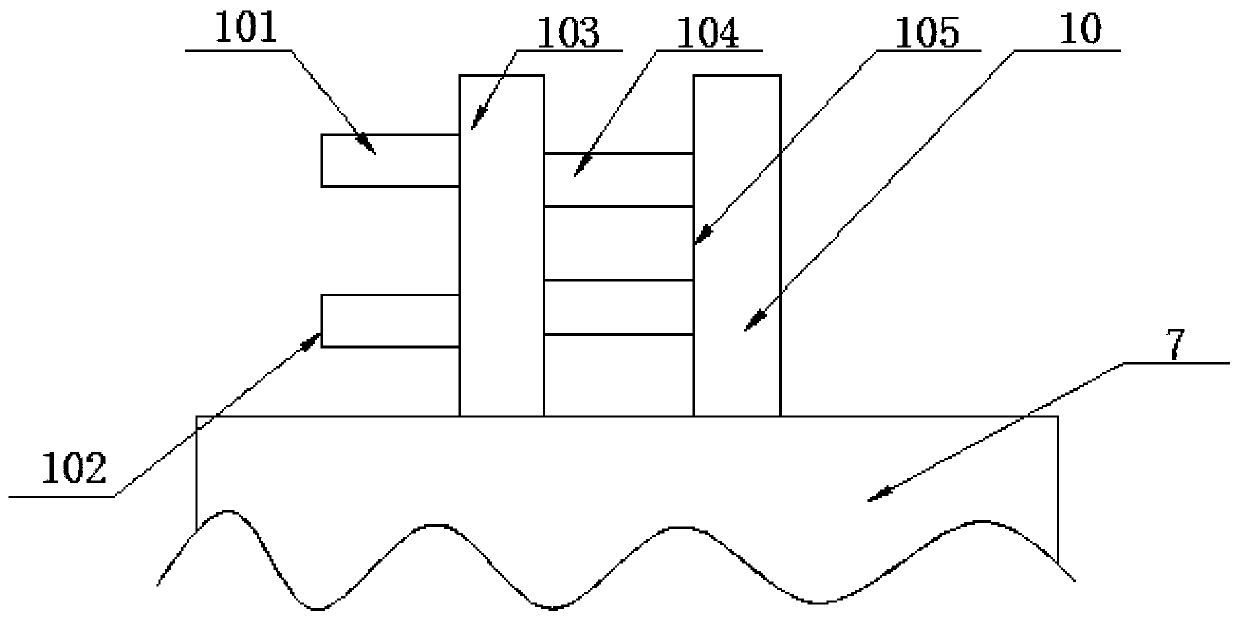

[0026] see Figure 1~6 , in an embodiment of the present invention, a carbon fiber composite panel forming equipment for automobiles, which includes an upper forming die base 3, a lower forming die base 14, a lower adsorption bending assembly, and a top bending assembly, wherein the lower forming die base The bottom is provided with a lower adsorption bending assembly, and a molding cavity 9 is formed between the upper end surface of the upper forming die base, the lower forming die base and the lower adsorption bending assembly. It is characterized in that the outer part of the lower forming die base 14 The top bending components are arranged on both sides;

[0027] It also includes a controller. After the upper forming die base and the lower forming die base are initially formed to form the composite panel 15, the controller first controls the upper forming die base to open and close upwards, and then controls the lower adsorption bending assembly 1. The top bending assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com