High-performance torsion beam for pipe production stamping formation

A stamping and high-performance technology, applied in the field of torsion beams, can solve the problems of large overall mass of torsion beams, achieve the effects of increasing area, reducing weight, and ensuring the yield and quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

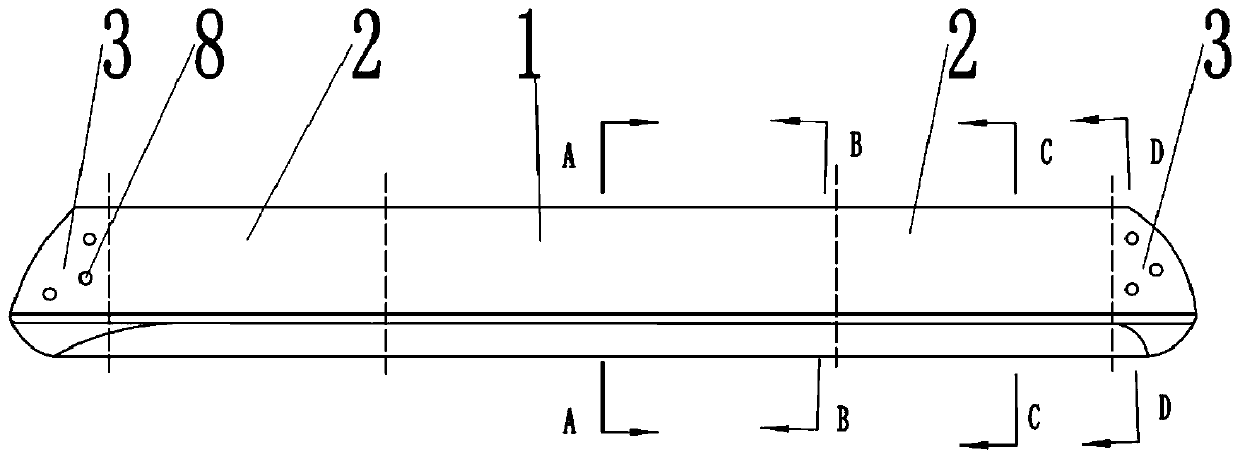

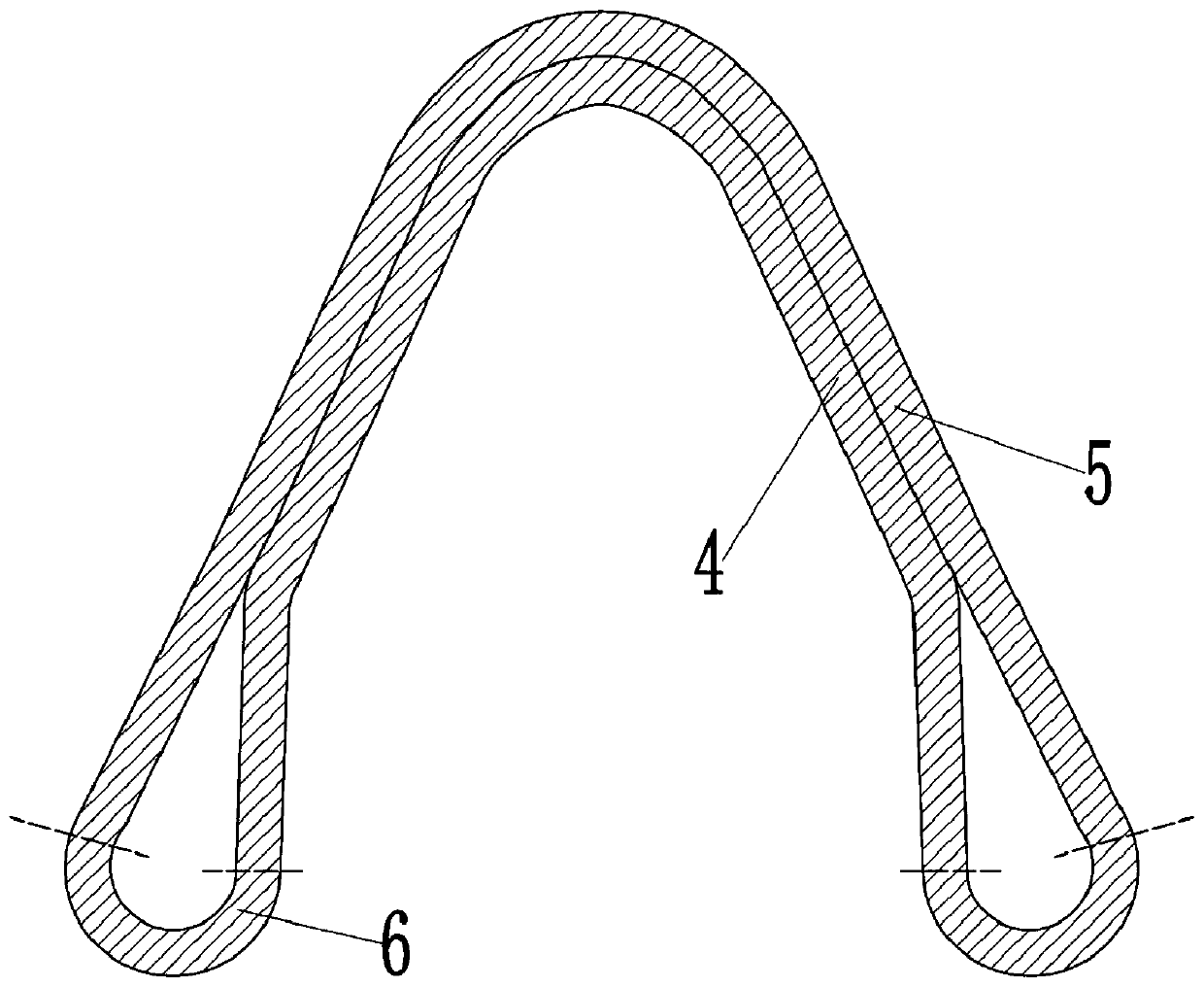

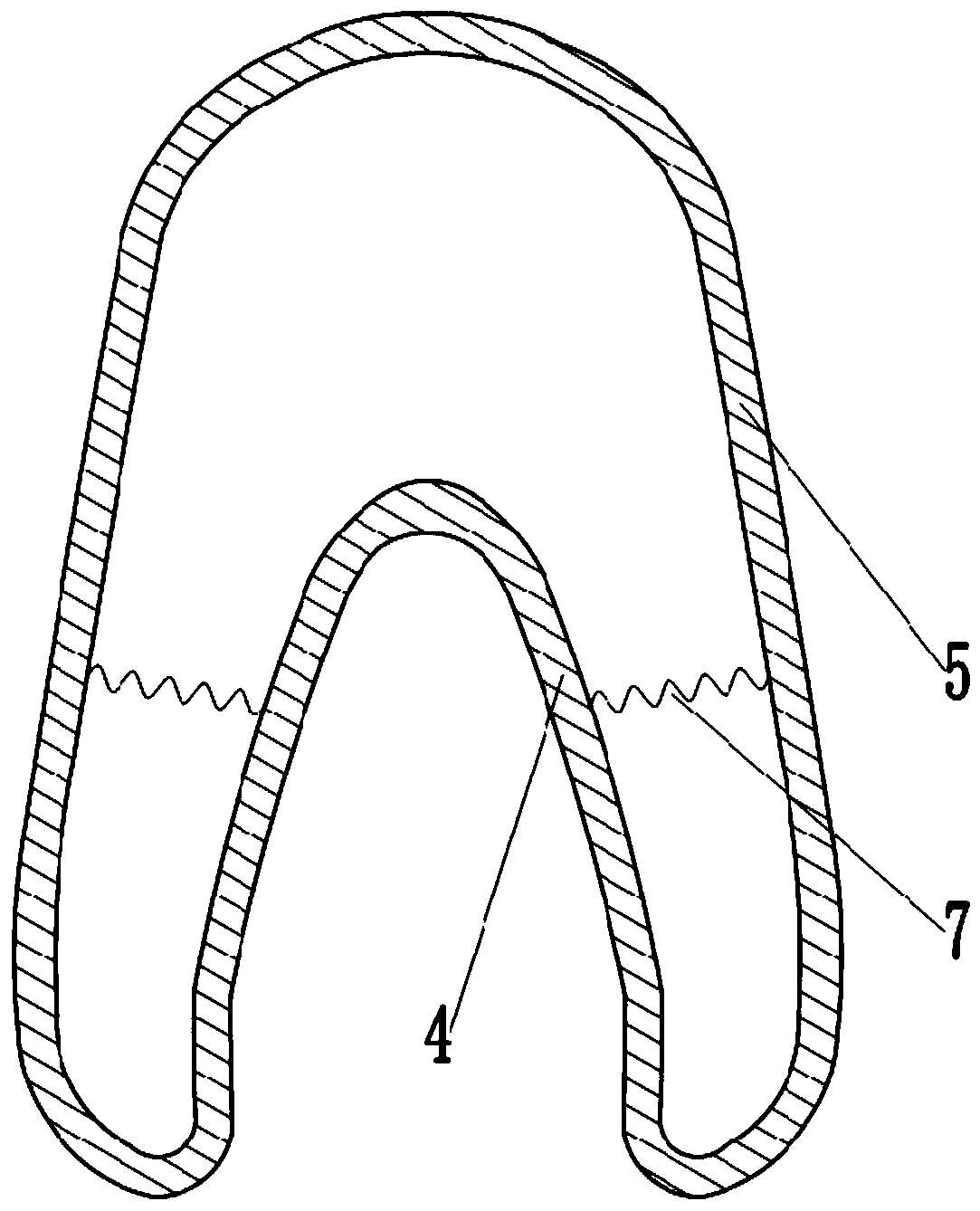

[0037] Basic as attached figure 1 Shown: high-performance torsion beam formed by control stamping, including the beam, which is divided into middle section 1, transition section 2 and outer section 3 from the middle to both ends, and the cross section of middle section 1, transition section 2 and outer section 3 are all closed sections, and the cross-sectional shapes of the middle section 1, the transition section 2 and the circumscribed section 3 are all different, such as figure 2 , image 3 , Figure 4 As shown, the cross-section of the middle section 1 is V-shaped (or U-shaped), the cross-section of the outer section 3 is square (or circular), and the transition section 2 is used to connect the middle section 1 and the outer section 3, and make the middle section 1 and the circumscribed segment 3 make a smooth transition. Such as figure 2 As shown, the beam includes the outer layer 5 and the inner layer 4, and there is a gap between the outer layer 5 and the inner la...

Embodiment 2

[0051] The difference between the present embodiment and the first embodiment is that the honeycomb wax stick is directly formed in the pipe. When stamping pipes, use such as Image 6 The cooling mechanism shown, the cooling mechanism includes a fixed disk 11, a cooling pipe 12 and a drive shaft 18, the cooling pipe 12 is evenly distributed on the right end surface of the fixed disk 11, the cooling pipe 12 includes a skeleton, a sealing film 17 and an inner rod 16, and the skeleton is composed of Several connecting rod groups are formed, and the connecting rod groups are distributed in a circular array with the inner rod 16 as the center, such as Figure 8 As shown, the connecting rod group includes a first strut 13 and a second strut 14 that are hinged to each other, the left end of the first strut 13 is hinged to the right end of the fixed plate 11, and the right end of the second strut 14 is hinged on the same On the limit ring; such as Figure 7 As shown, the first pole ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com