Construction method and construction equipment for a single-gantry crane span oblique angle drop beam

A technology of gantry cranes and construction methods, which is applied in the directions of cranes, trolley cranes, transportation and packaging, etc., which can solve the problems of limitations and constraints on large-scale equipment, and achieve the effects of strong versatility, convenient leasing, and improved operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

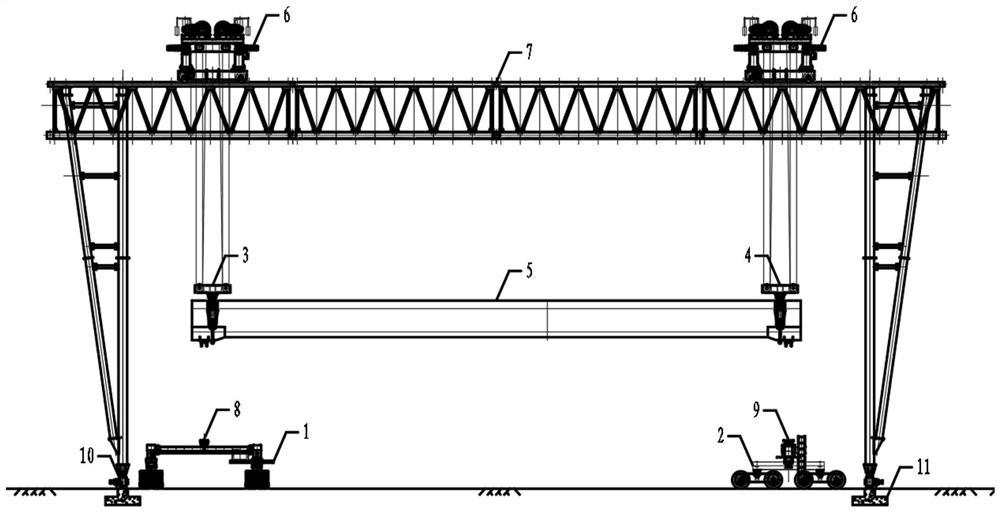

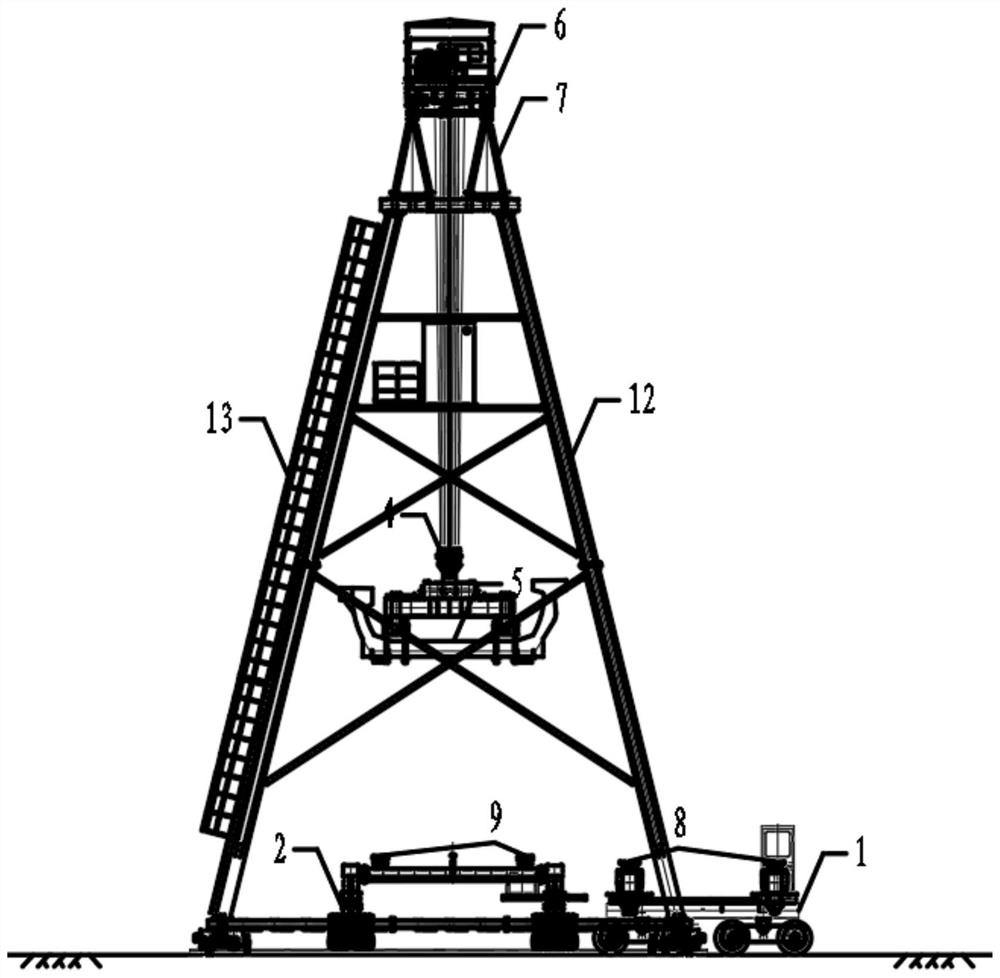

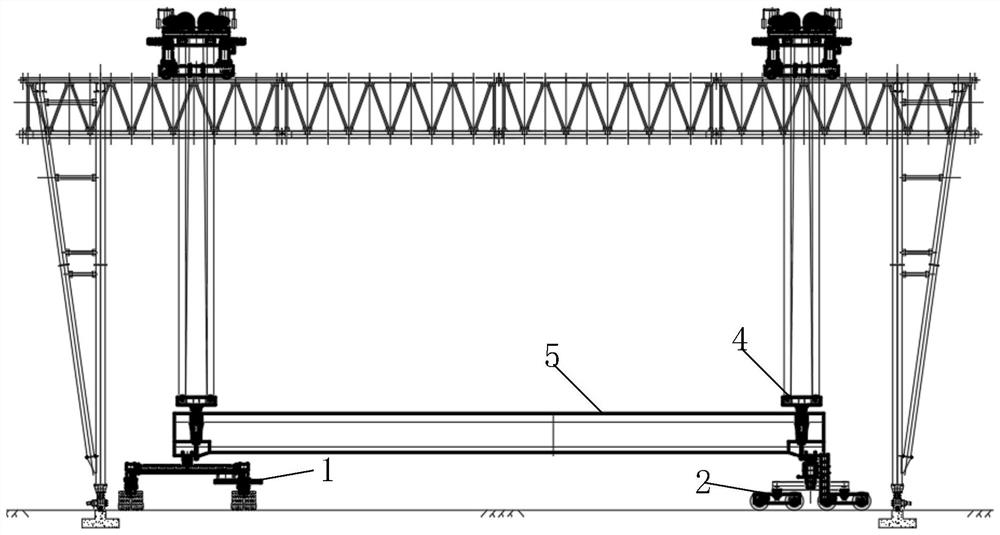

[0042] The embodiment of the present invention provides a construction method for falling beams at oblique angles within the span of a single-gantry crane. The construction method is carried out using construction equipment, such as Figure 1-2 As shown, the construction equipment includes a double spreader gantry crane, a crane track, a rotatable spreader 3, a fixed end spreader 4 and a beam carriage, and the double spreader gantry crane moves along the crane track , the beam-carrying cannon car includes a front car 1 of a beam-carrying cannon and a rear car 2 of a beam-carrying cannon, the front car 1 of the beam-carrying cannon and the rear car 2 of the beam-carrying cannon are arranged at intervals and the loading operation of the beam-carrying cannon When the total length of the profile is greater than the span of the double spreader gantry crane, the rotatable spreader 3 and the fixed end spreader 4 are respectively suspended on both sides of the double spreader gantry cra...

Embodiment 2

[0051] On the basis of Example 1, such as Figure 1-2 As shown, the double spreader gantry crane includes a gantry crane girder 7, two gantry crane flexible outriggers 12 connected under the two ends of the gantry crane girder 7 and a Two hoisting trolleys 6 above the beam 7 that can translate along the main beam 7 of the gantry crane, one of the hoisting trolleys 6 is connected with the rotatable spreader 3 located below and controls the rotatable spreader 3 The spreader 3 moves horizontally, moves up and down and rotates, and the other lifting trolley 6 is connected with the fixed end spreader 4 located below and controls the fixed end spreader 4 to move horizontally and move up and down. The crane track includes a steel rail 10 and a track foundation 11 arranged below the steel rail 10 , and the two flexible legs 12 of the gantry crane can translate along the steel rail 10 . A pedestrian ladder 13 is arranged on the flexible outrigger 12 of the gantry crane. The rotatable ...

Embodiment 3

[0053] On the basis of Example 1, such as Figure 1-2 As shown, the front carriage 1 of the beam-transporting artillery cart and the rear carriage 2 of the beam-transporting artillery carriage are respectively composed of a car body assembly, a bogie assembly, a braking device, a driving device, and a supporting and fixing device. The braking device and the driving device are arranged in the vehicle body assembly, and the bogie assembly and the supporting and fixing device are arranged on the vehicle body assembly. The bogie assembly is connected to the car body assembly through the pin shaft vertically arranged in the axial direction, and the friction pair is formed between the bottom through the wear plate and the car body assembly, and an oblique support or a fixed frame is arranged on the top, when the beam is transported When the gun carriage turns, the bogie assembly can form a relative rotation with the vehicle body. The beam transporting artillery cart is a tire-type b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com