Bipolar Molecular Derivatives for Organic Light Emitting Devices

An organic light-emitting element and bipolar molecule technology, which is applied in the field of bipolar molecule derivatives, can solve the problems of unstable process, low brightness, and the driving voltage needs to be improved, so as to achieve the effect of improving the efficiency index.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example

[0035] A-1 synthesis example

[0036] Place acenaphthenequinone (182g, 1mol), 4-bromo-o-phenylenediamine (187g, 1mol) and acetic acid (1.8L) in a reaction flask, set up a condenser tube and a temperature controller device, and raise the temperature to 115 ℃, heated for 16 hours, cooled to room temperature after the reaction, added water and stirred for one hour, filtered the crude product by suction, took the solid and added toluene, heated and stirred until completely dissolved, then purified by column chromatography to obtain light yellow The solid was purified by recrystallization from toluene and methanol to obtain 198 g of solid product A-1.

[0037] A-2 synthesis example

[0038] Place phenanthrenequinone (208g, 1mol), 4-bromo-o-phenylenediamine (187g, 1mol) and acetic acid (1.8L) in a reaction flask, set up a condenser tube and a temperature controller device, and raise the temperature to 115 ℃, heated for 16 hours, cooled to room temperature after the reaction, added...

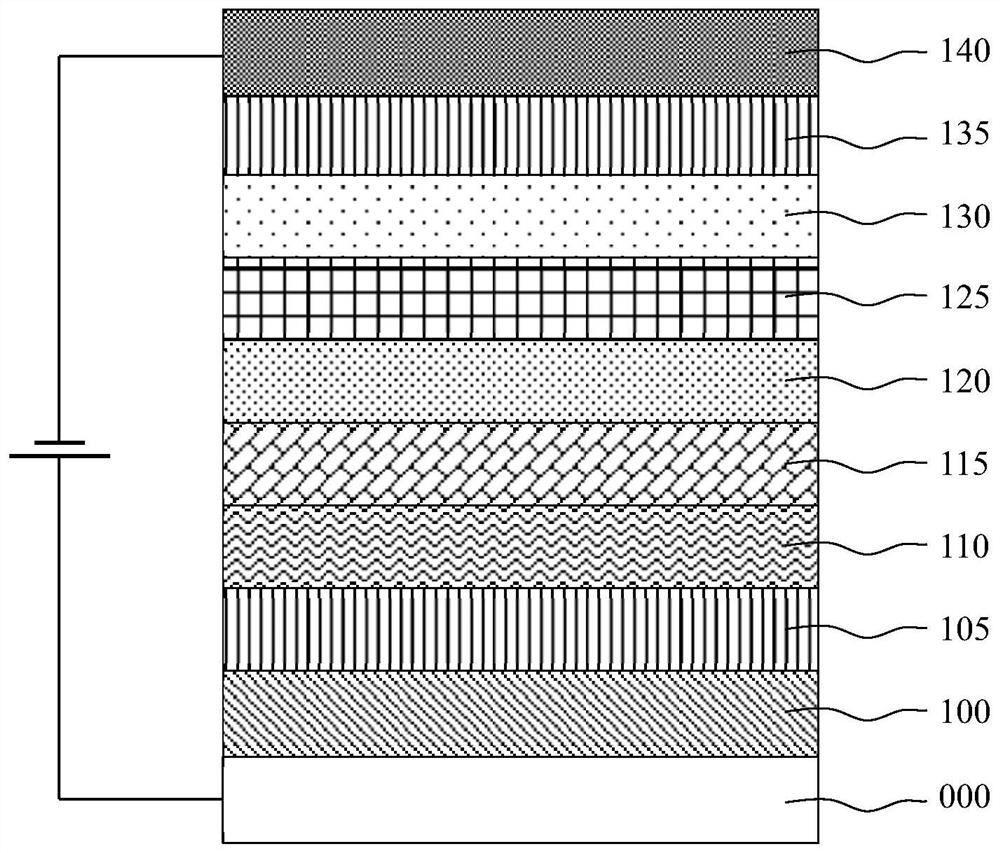

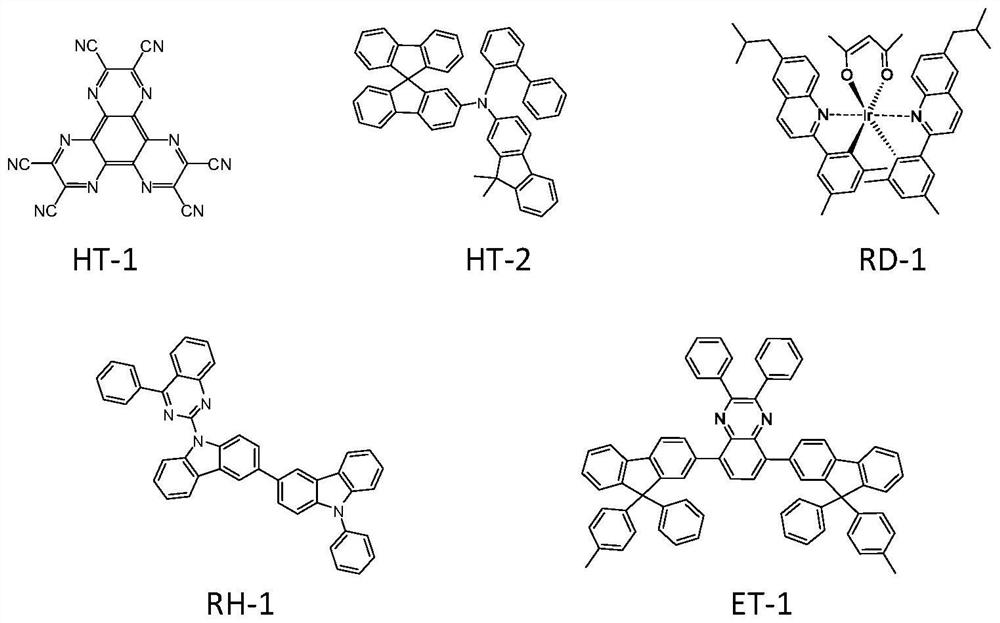

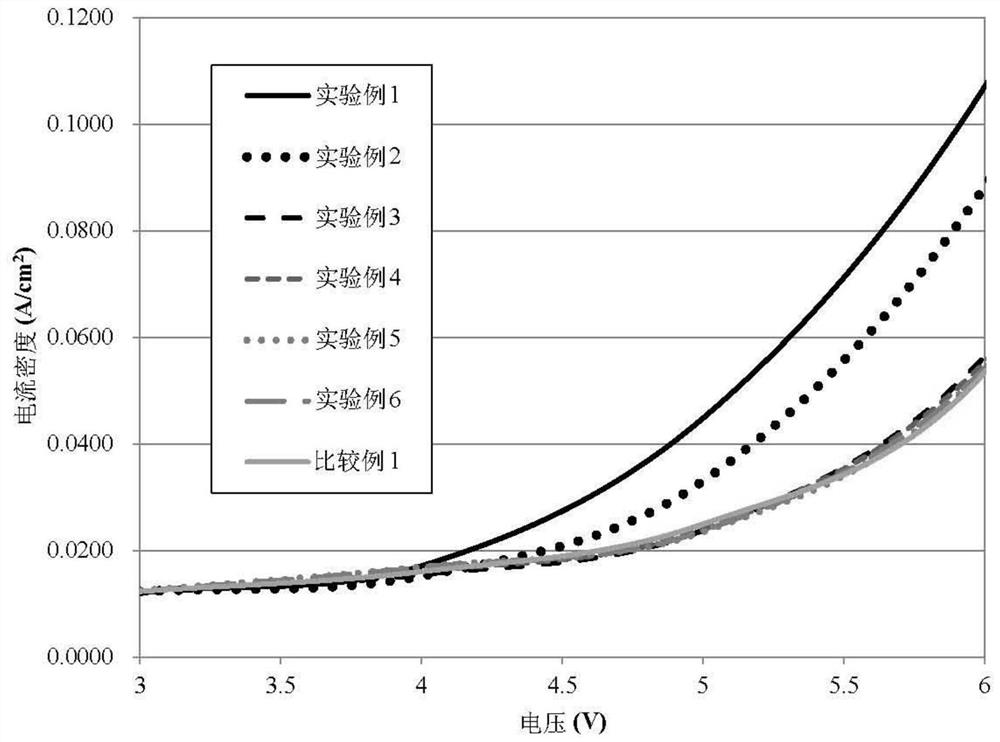

experiment example 1

[0062] Using compound I-1 as the host material of the light-emitting layer, an organic light-emitting device structure was fabricated for testing. The detailed production method is as follows: firstly, a 3nm hole injection layer is evaporated on the indium tin oxide anode, and the material is HT-1; followed by a 65nm hole transport layer, and the material is HT-2, and then a 30nm light emitting layer, and the material is 10 % RD-1 doped in I-1; followed by electron transport layer 10nm, the material is 50% ET-1 and 50% Liq (8-Quinolinolato lithium) for co-evaporation; finally the metal cathode 100nm, The material is Aluminum.

experiment example 2

[0064] Using compound I-2 as the host material of the light-emitting layer, an organic light-emitting device structure was fabricated for testing. The detailed production method is as follows: firstly, a 3nm hole injection layer is evaporated on the indium tin oxide anode, and the material is HT-1; followed by a 65nm hole transport layer, and the material is HT-2, and then a 30nm light emitting layer, and the material is 10 % of RD-1 doped in I-2; followed by electron transport layer 10nm, the material is 50% of ET-1 and 50% of Liq (8-Quinolinolato lithium) for co-evaporation; finally the metal cathode 100nm, The material is Aluminum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com