electric VALVE AND refrigerating CYCLE SYSTEM

A technology of electric valves and valve ports, which is applied in the direction of irreversible cycle compressors, lift valves, refrigerators, etc., can solve the problems of sliding deterioration of valve parts, deformation and deformation of guide holes, etc., and achieve the effect of stable action characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

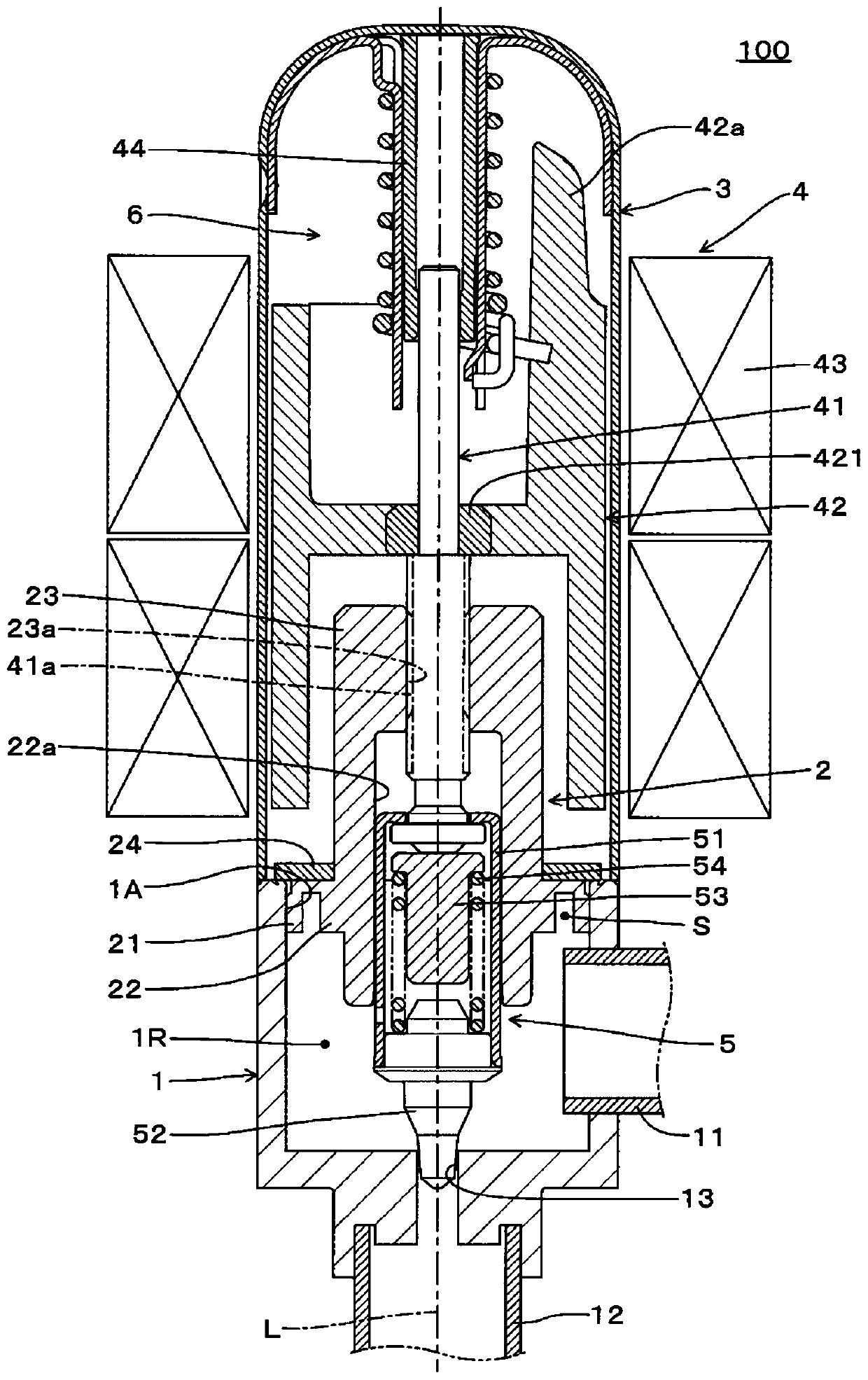

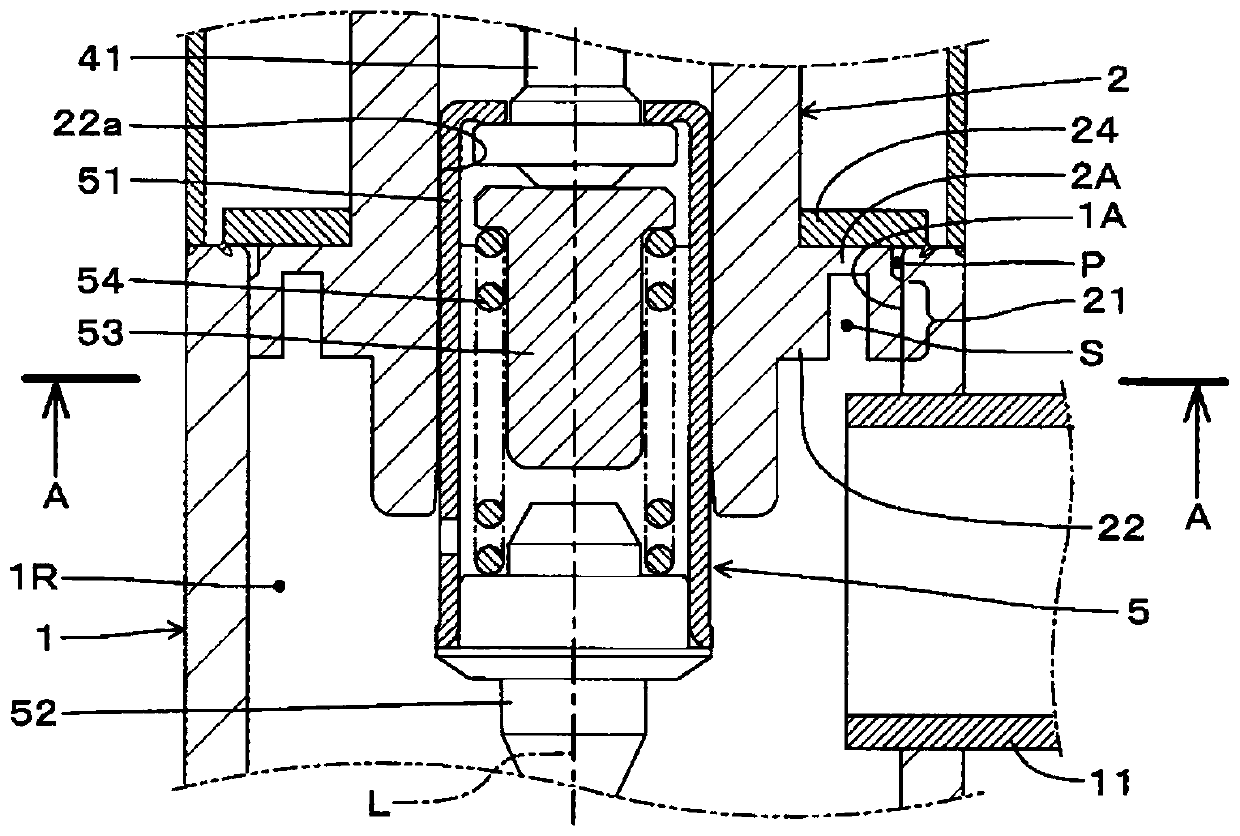

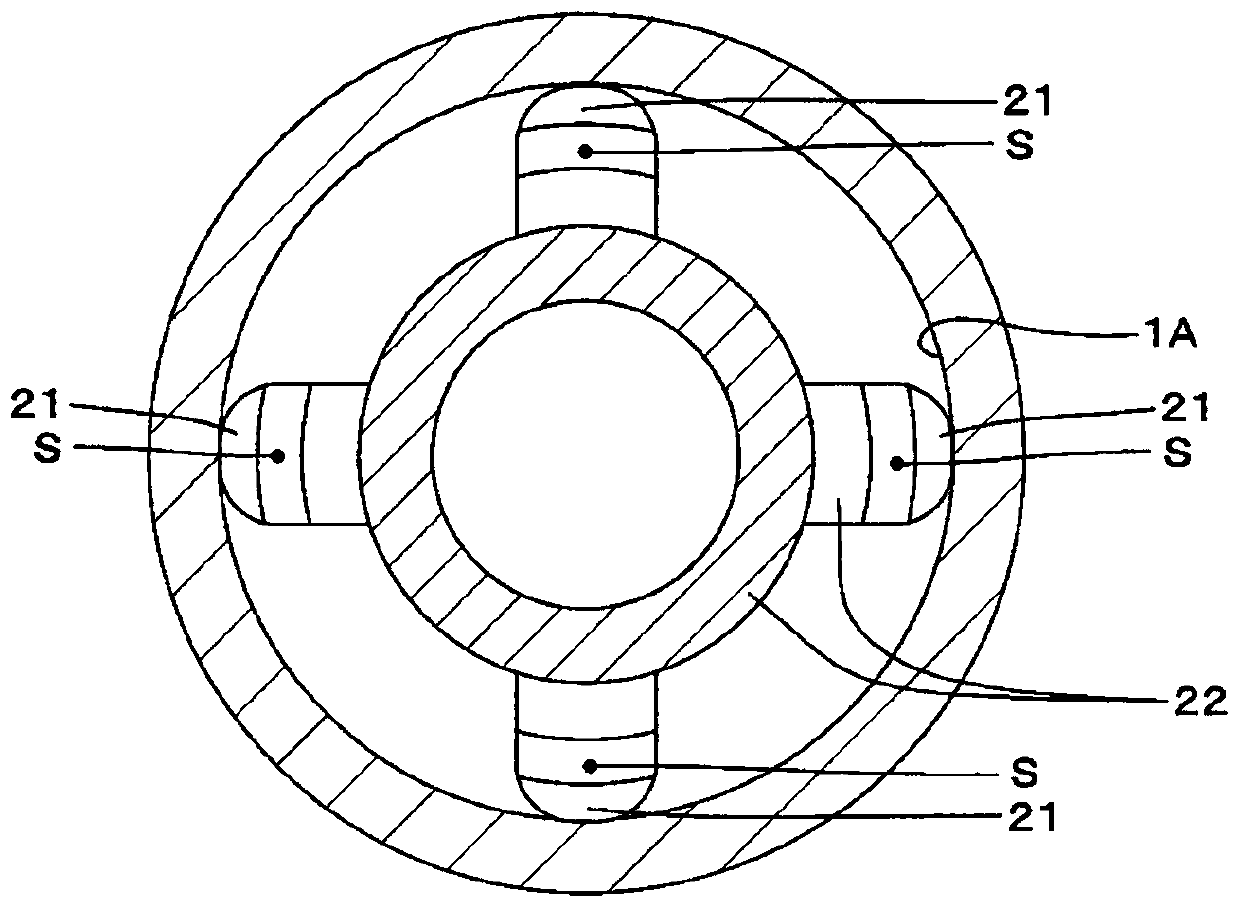

[0032] Next, embodiments of an electric valve and a refrigeration cycle system according to the present invention will be described with reference to the drawings. figure 1 is a longitudinal sectional view of the electric valve of the first embodiment, figure 2 It is an enlarged cross-sectional view of an assembled portion of a valve casing and a guide member in the electric valve of the first embodiment, image 3 yes means figure 2 The A-A sectional view of the valve housing and guide parts, Figure 4 yes figure 2 An enlarged view of the main part. Also, the concept of "up and down" in the following description is the same as figure 1 The upper and lower correspondences in the figure.

[0033] The electric valve 100 includes a valve case 1 , a guide member 2 , a sealing case 3 , a stepping motor 4 as a “motor unit”, and a valve member 5 .

[0034] The valve case 1 is formed in a substantially cylindrical shape from metal such as brass or stainless steel, for example,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com