Waste heat hydrogen acquiring boiler

A waste heat and boiler technology, applied in the directions of hydrogen, lighting and heating equipment, combustion methods, etc., to achieve the effects of clean emissions, reduced hydrogen production costs, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

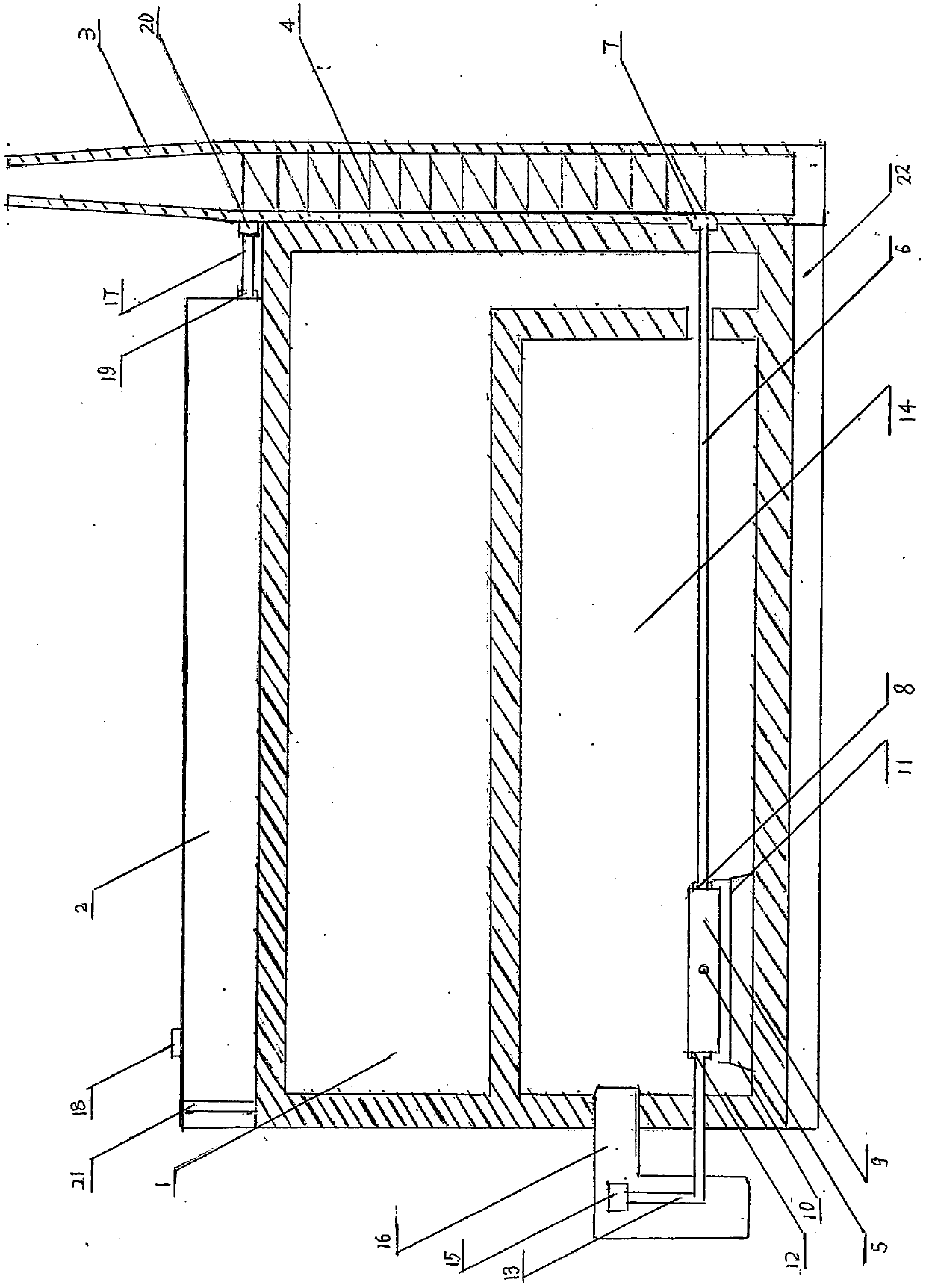

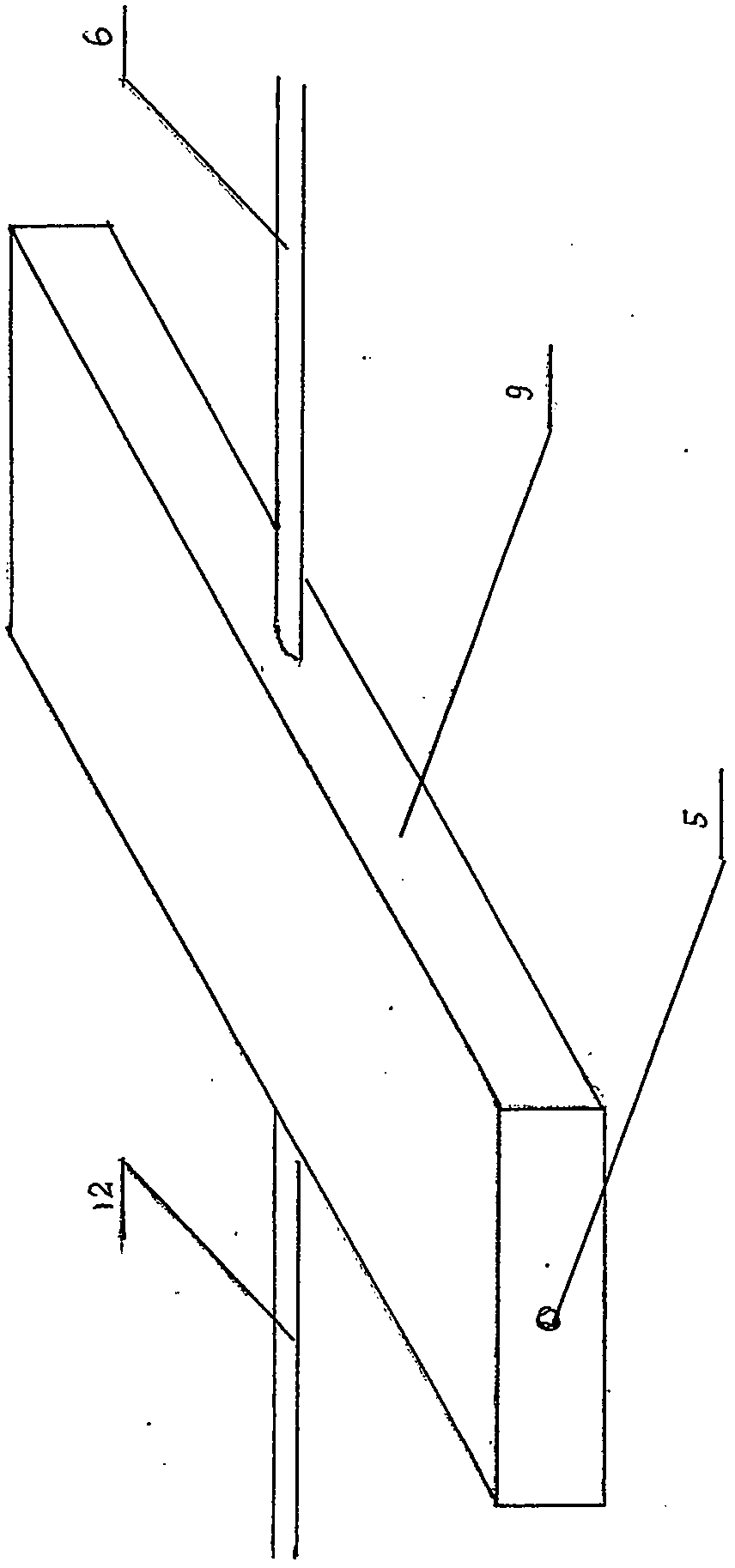

[0013] see figure 1 and figure 2 , the present invention is an internal combustion boiler 1 utilizing waste heat to extract hydrogen. There are multiple metal manifolds arranged in the oxidation reactor 9 and assembled in the boiler furnace 14. A multi-turn rotating metal manifold is installed in the chimney 3. Pipe 4, the multi-turn rotating metal pipe 4 inlet joint 20, connects the metal water inlet pipe 17, and connects the main water tank 2 outlet valve 19. The high-temperature waste heat in the chimney 3 gradually heats the multi-turn rotating metal pipe 4 to produce steam. The three-way valve 7 connects the steam pipe 6, the steam inlet 8, and transports the steam to the oxidation reactor 9, where the furnace 14 reacts with iron powder particles at high temperature to produce hydrogen and oxygen, and the outlet on the second outer surface of the oxidation reactor 9 and the hydrogen outlet 12, output hydrogen, through the hydrogen pipe 13, for boiler 1 to burn. At this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com