Particle tracer for simulating inclusion in molten steel as well as preparation method and application of same

A production method and tracer technology, which is applied in the field of particle tracer production, can solve problems such as not easy to be stranded and aggregated, unsuitable for simulation research of inclusions in metallurgical reactors, etc., to achieve good formability, easy observation, and ensure uniformity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The preparation method of the particle tracer of the present embodiment comprises the following steps:

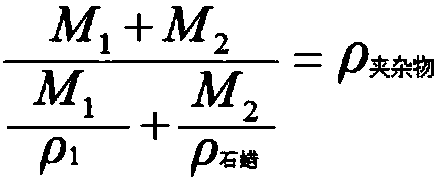

[0047] (1) Weighing M 1 The known polystyrene plastic particles of g are placed in a water bath and heated to 100°C for 10 minutes. After the particles become larger and float to the water surface, they are collected and dried; the polystyrene plastic particles obtained after heating in a water bath The diameter is 1-2mm, the density ρ of the collected polystyrene plastic particles 1 =0.143g / cm 3 .

[0048] (2) Weighing M 2 g of red paraffin, heated and melted in a ceramic crucible for 1-2 minutes;

[0049] (3) Pour the treated polystyrene plastic particles into a crucible for storing paraffin, and stir until evenly mixed;

[0050] (4) Pour the mixture of polystyrene plastic particles and paraffin wax into warm water at 40-42°C, and stir for 1 minute. The mixture is evenly dispersed on the water surface, and the above mixture is directly kneaded into the same sh...

Embodiment 2

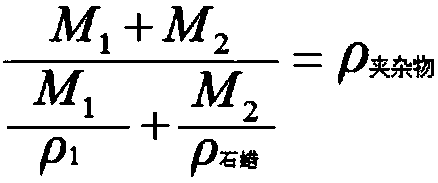

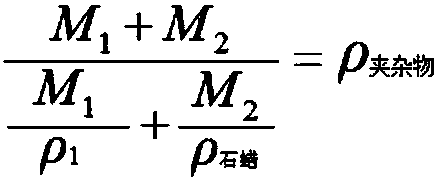

[0053] The production method of the particle tracer in this embodiment is basically the same as in Embodiment 1, the difference is that the density of the inclusion model to be simulated in this embodiment is 0.7g / cm 3 , then the mass of polystyrene plastic particles M 1 with paraffin mass M 2 Satisfy the following relationship: i.e. M 1 :M 2 = 0.05.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com