Variable nozzle for turbocharger and control method of variable nozzle as well as turbocharger

A turbocharger and nozzle technology, which is applied to machines/engines, stators, engine components, etc., can solve the problems of high failure rate or failure rate, not popularized, complex mechanical structure, etc., to achieve cost and failure rate reduction, Simple structure and reduced risk of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The following examples of the present invention are described in detail below. The following examples are implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the embodiment.

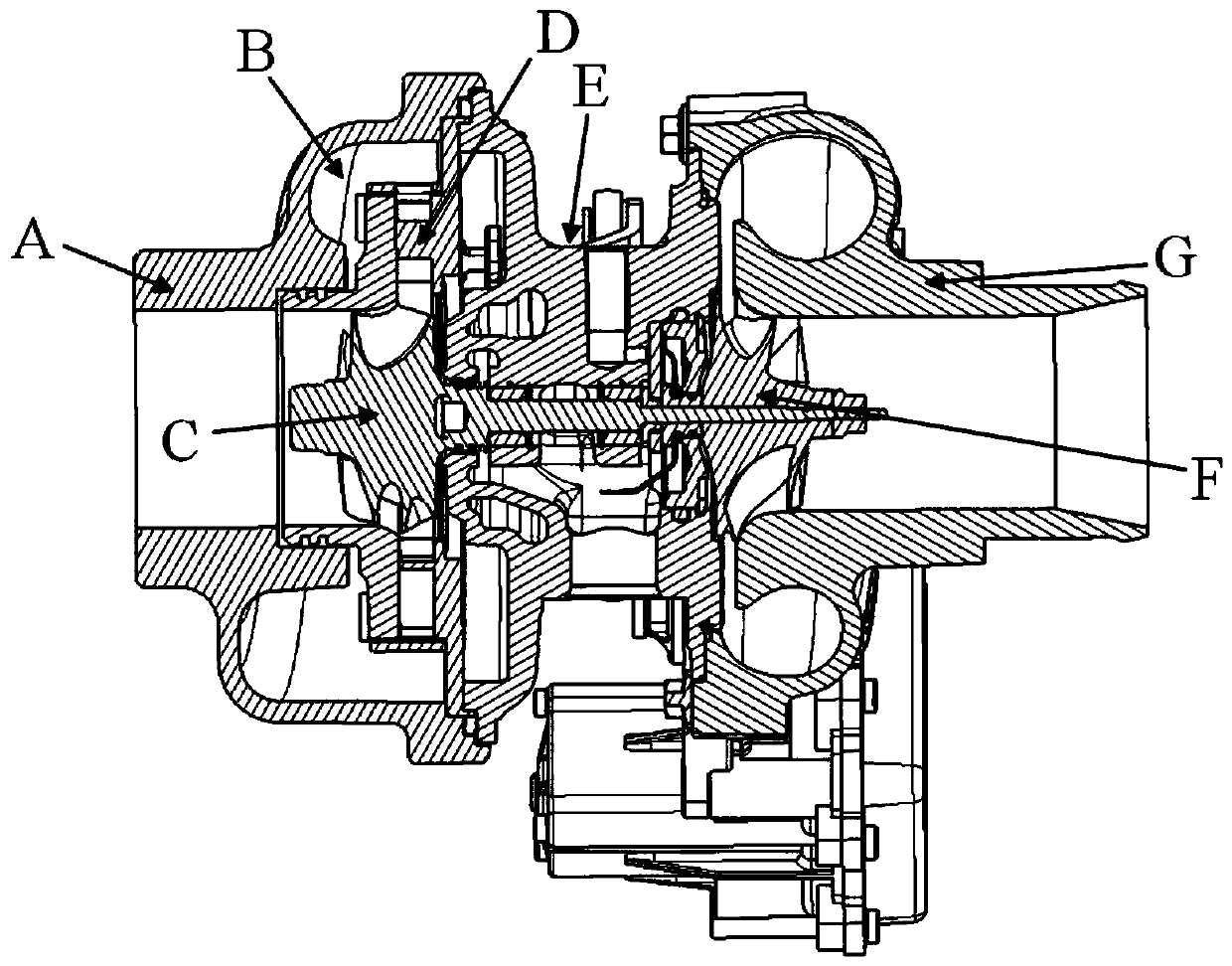

[0062] figure 1 It is a schematic cross-sectional structure diagram of a typical variable nozzle turbocharger. Wherein, the volute A includes a volute channel B, and the volute channel B is an annular cavity surrounding the turbine C for collecting exhaust gas from the engine and using the exhaust gas to drive the turbine C to rotate. The turbine C driven by the exhaust gas drives the coaxial pressure wheel F to rotate in the pressure shell G, and compresses the air collected in the pressure shell G to provide boost pressure for the engine intake. The pressure and density of the compressed air increase, bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com