Wire-broken PCCP water-nonstop prestress CFRP external wrapping and high polymer grouting compound repair method

一种复合修复、预应力的技术,应用在管道铺设和维修、刚性管、管子等方向,能够解决影响管道受力和稳定性、不均匀沉降、耗时长等问题,达到根治管道病害、防止工后沉降的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

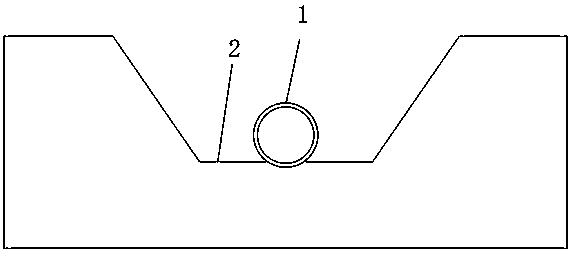

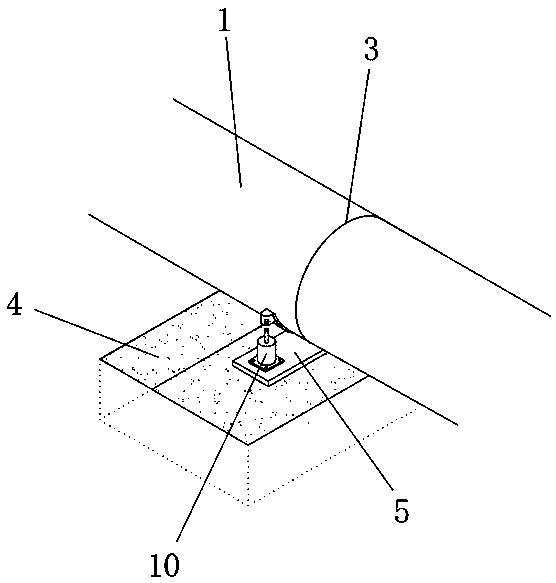

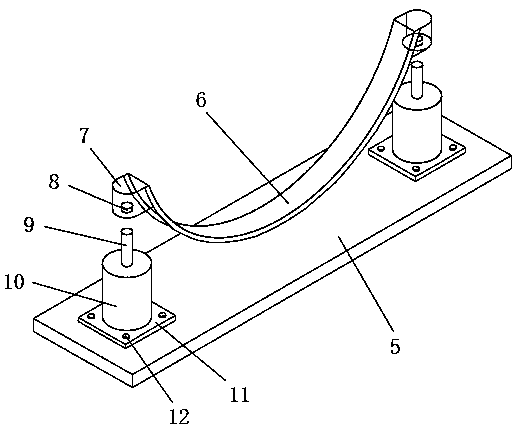

[0042] A composite repair method for broken wire PCCP with prestressed CFRP and polymer grouting, including PCCP excavation, PCCP support, PCCP outer wall treatment, PCCP outsourcing prestressed FRP repair, grouting pipe laying, backfilling and The grouting is dense. Excavate the PCCP pipeline that needs to be repaired and support it through the support device. Smooth the outer wall of the PCCP pipeline at the position where the wire is broken and apply primer. Wrap FRP around the damaged part of the PCCP pipeline. The stress application device stretches and applies prestress to the FRP, applies dipping glue to the tensioned FRP to make the FRP stick to the pipe wall, then lays the grouting pipe, backfills the repaired pipe, and finally passes through the pre-buried grouting pipe Inject high polymer into the backfilled soil to compact the soil.

[0043] The composite repair method of broken wire PCCP non-stop water pasting prestressed CFRP and polymer grouting includes the fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com