Uniform amplitude full-strain-life curve test method for metal material

A testing method, a technology of metal materials, applied in the direction of analyzing materials, using applied repetitive force/pulsation force to test the strength of materials, measuring devices, etc., can solve the problem of low efficiency, no definition of material short-life and long-life turning point strain range, low frequency and other issues to achieve the effect of improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation of the present invention will be described in detail by taking a metal thin plate as the test object to carry out the fatigue test.

[0030] The equal-amplitude full-strain-life curve test method for metal materials proposed by the present invention specifically comprises the following steps:

[0031] Step 1. Process fatigue samples according to GB / T 26077-2010 "Metal Material Fatigue Test Axial Strain Control Method", and the surface finish of the samples must meet the requirements of the standard.

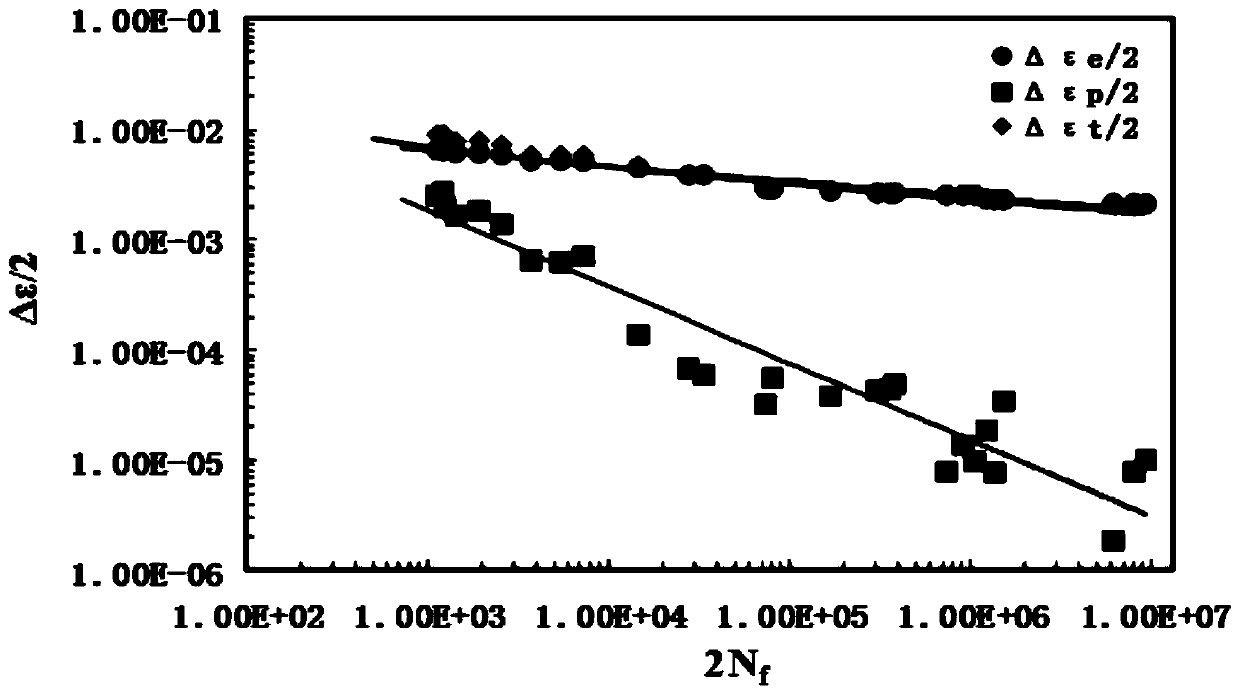

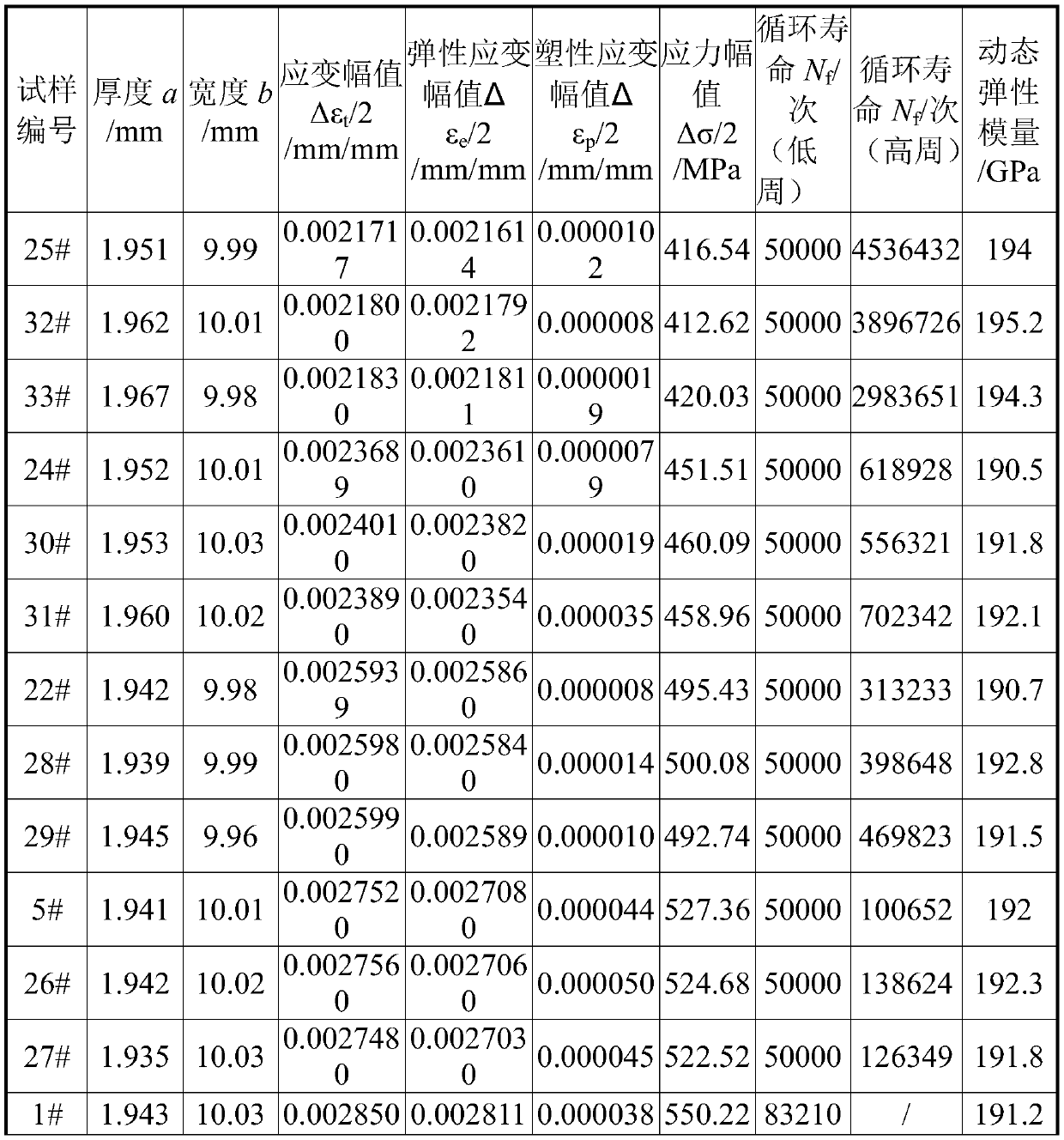

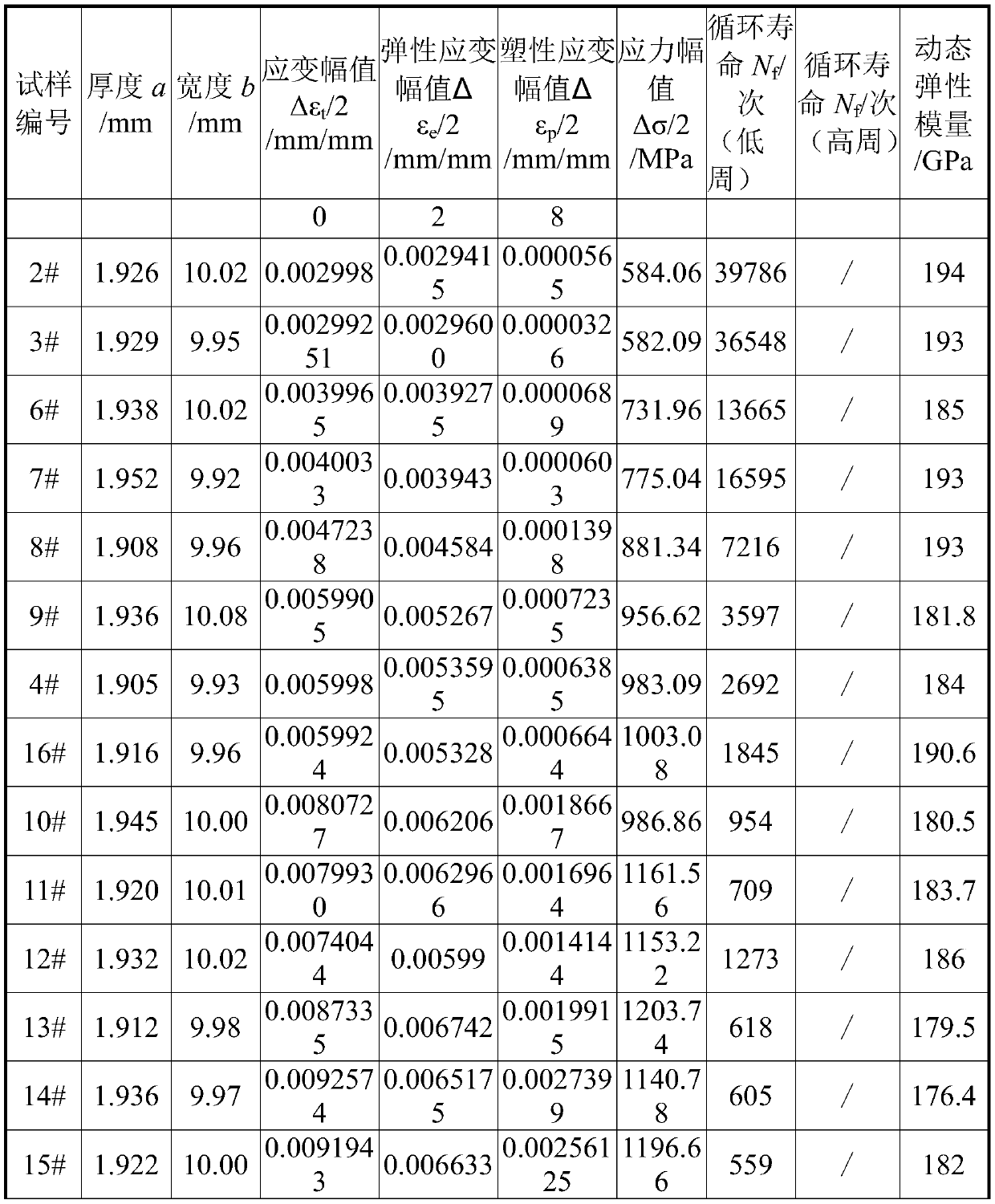

[0032] Step 2. Conduct short-life fatigue test: select different strain amplitudes with a total strain amplitude greater than 3‰ for the test, and the strain gradient is 1‰~2‰, so the selected control strain amplitudes are 3‰, 4‰, and 6‰ respectively , 8‰, 10‰. Since the number of cycles corresponding to a strain of 10‰ is only a fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com