Calibration device and method for a laser cloud particle imager

A technology of laser cloud particles and calibration method, which is applied to measurement devices, instruments, scientific instruments, etc., can solve the problems of inability to measure the depth of field of cloud particle imaging and lack of accurate scale, and achieve the effect of simple structure, high precision and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

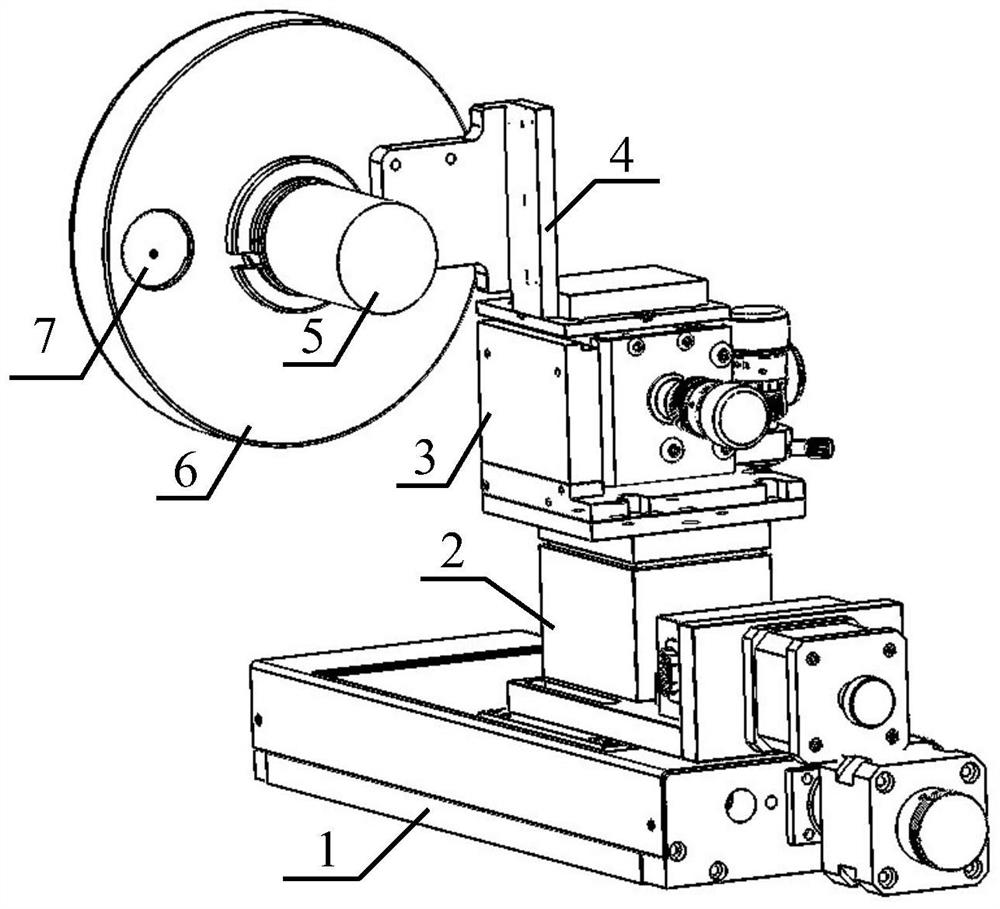

[0050] Example 1, such as figure 1 As shown, a calibration device of a laser cloud particle imager according to an embodiment of the present invention includes: an electric translation stage 1, an electric lift stage 2, a multi-axis displacement stage 3, a DC motor 5, a glass-carrying disc 6 and three Calibration glass beads7.

[0051] The electric translation platform 1 is placed horizontally and the table top is parallel to the ground. The electric lifting platform 2 is vertically placed on the electric translation platform 1, and the bottom surface is fixed on the table top of the electric translation platform 1. The multi-axis displacement platform 3 is vertically placed on the electric lifting platform 2, and the bottom surface is fixed on the table surface of the electric lifting platform 2. The DC motor 5 is fixed on the table top of the multi-axis translation stage 3 through the adapter plate 4 . The glass-carrying disc 6 is fixedly connected with the rotating shaft...

Embodiment 2

[0057] Embodiment 2, a calibration method of a calibration device of a laser cloud particle imager, which is used to calibrate the median comparison voltage of the laser cloud particle imager, the magnification of the imaging optical system, and the imaging depth of field for measuring particles of different sizes. The calibration method Include the following steps:

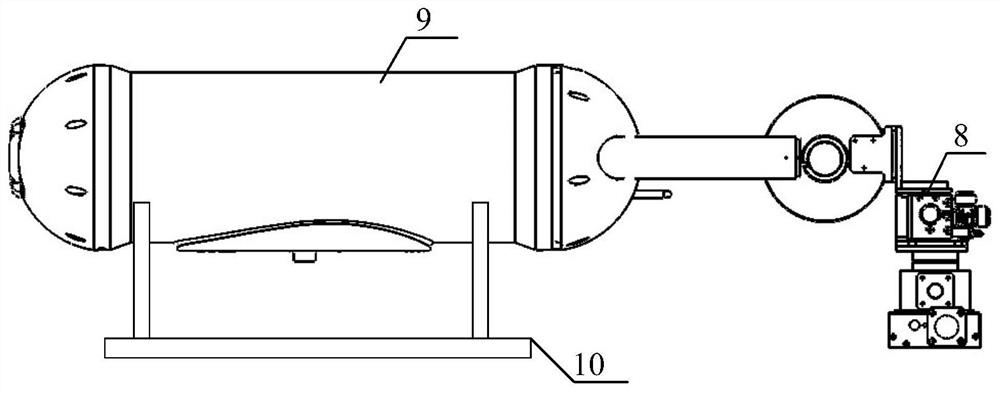

[0058] Step 1, place the laser cloud particle imager 9 horizontally on the support frame 10, and ensure that the light beam emitted by the laser cloud particle imager 9 can be kept horizontal along the X-axis direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com