Special clamp used for circular hollow pipe drilling

A special fixture and hollow tube technology, used in the field of machining fixtures and fixtures for mechanical parts, can solve the problems of unguaranteed quality, fracture of processed parts, and reduced qualification rate, and achieve the advantages of convenient operation, reduction of hole diameter error, and improvement of productivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

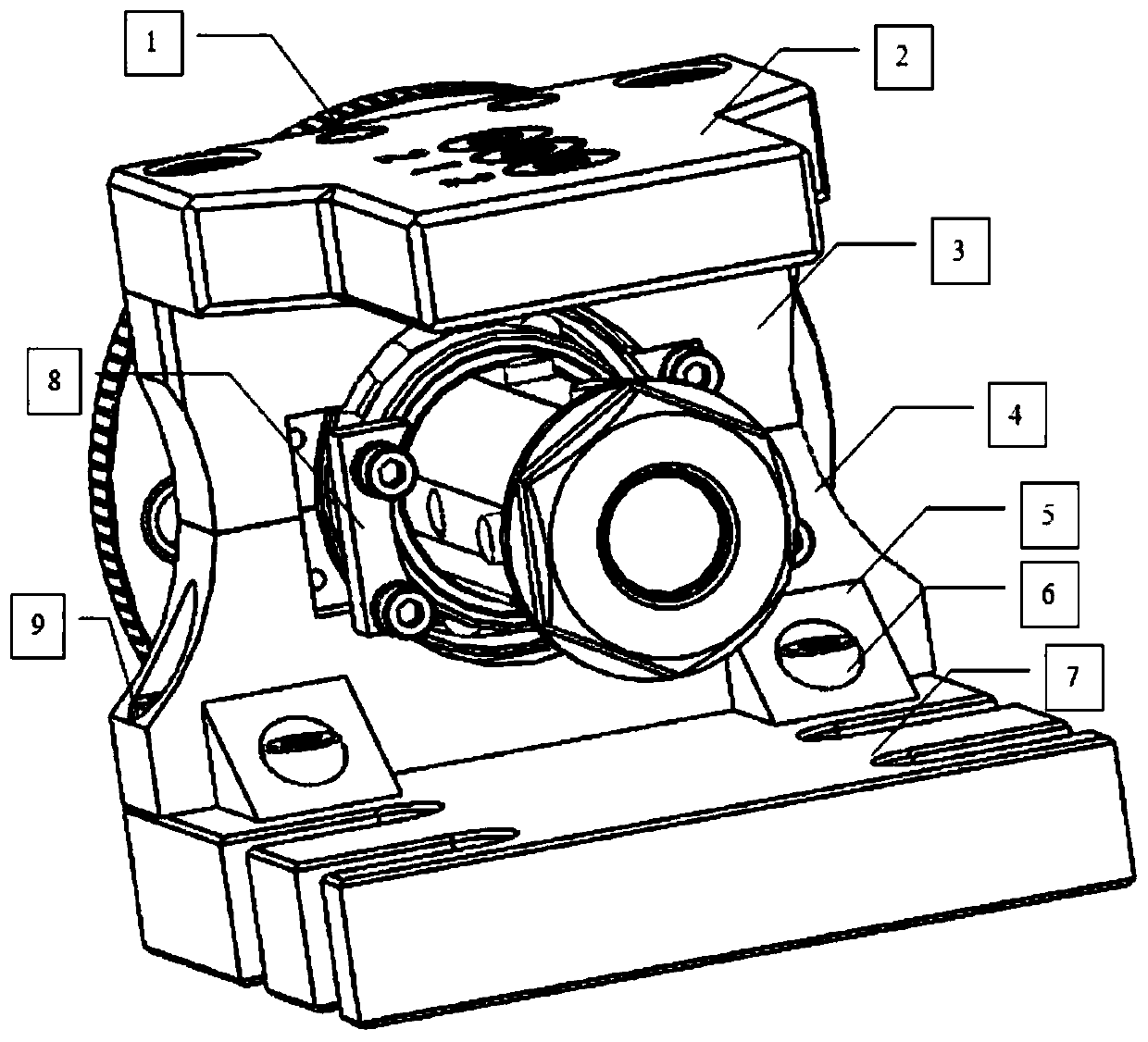

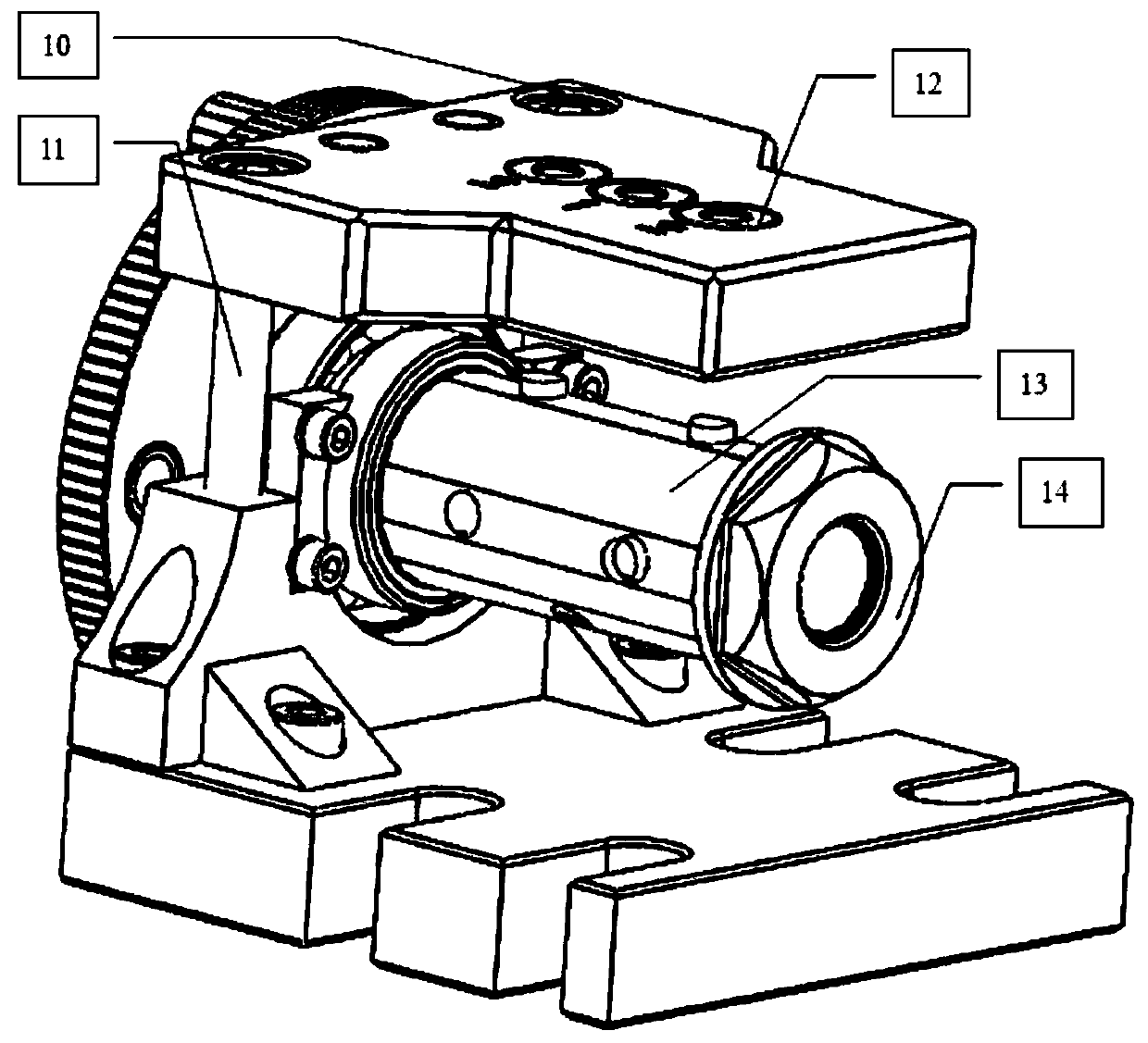

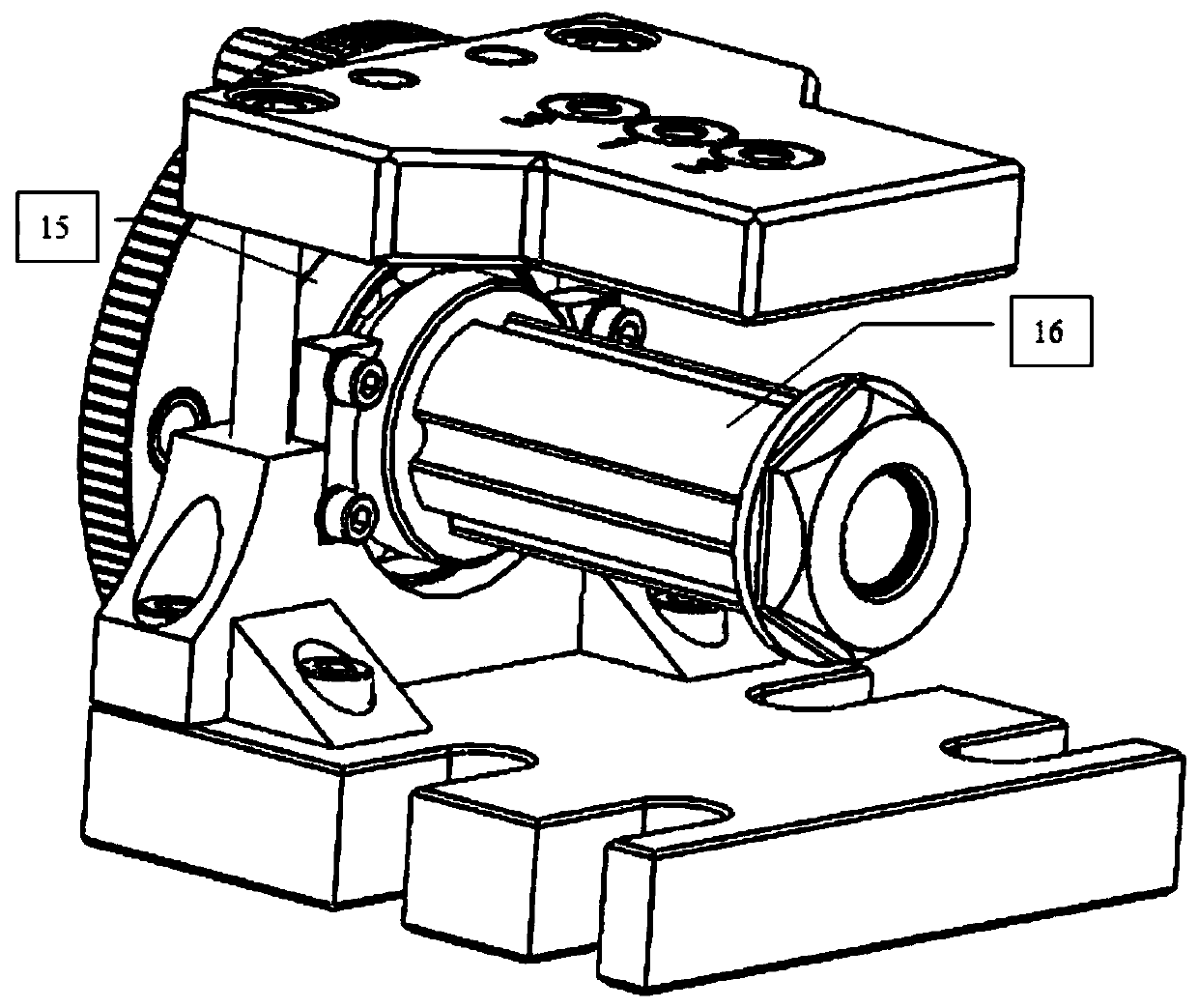

[0022] Embodiment 1: as attached Figure 1-7 As shown, a special fixture for drilling holes in circular hollow pipes, it includes a fixed base plate 7 and a top plate 2, the upper part of the fixed base plate 7 is connected to the bearing support base 4 by a bolt 9, and the upper part of the bearing support base 4 is connected by a bolt The second 11 is connected with the bearing support upper plate 3, and there is a bearing 15 in the middle, which is connected with the top plate 2 through the bolt three 10 above the bearing support upper plate 3, and the inner ring of the bearing 15 is covered with a pipe fitting fixing pipe seat 16, and the pipe fitting fixing pipe seat A circular hollow pipe fitting 13 to be drilled is placed on the outer side of one end of 16 and locked with a nut 14 at the end, and the other end of the fixed pipe seat 16 of the pipe fitting is connected with a rotating plate 18 by a linkage bolt 19, and the outer side of the rotating plate 18 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com