Mould for hollow sealing piece with fabric and continuous moulding method thereof

A molding method and technology of sealing parts, applied in the field of rubber processing, can solve the problems of high mold investment cost, high size requirements of vulcanization equipment, poor positioning of long mold cores, etc., and achieve the effect of good positioning, good strength, and smooth splicing parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0049]Silicone rubber hollow belt fabric seals are usually compounded and vulcanized by silicone rubber and fabric materials. The composite fabric can improve the wear resistance, tear resistance, stiffness, durability, etc. of the seal. The hollow structure will produce large deformation under small stress, effectively avoiding the shear damage caused by too much interference of the rubber profile, or the seal failure caused by too small interference, and at the same time, it is safe for mechanical installation parts. The requirements for machining accuracy can be relaxed appropriately. Silicone rubber hollow belt fabric seals can be used for aviation rubber seals, such as: long straight strip seals, door frame seals, etc.

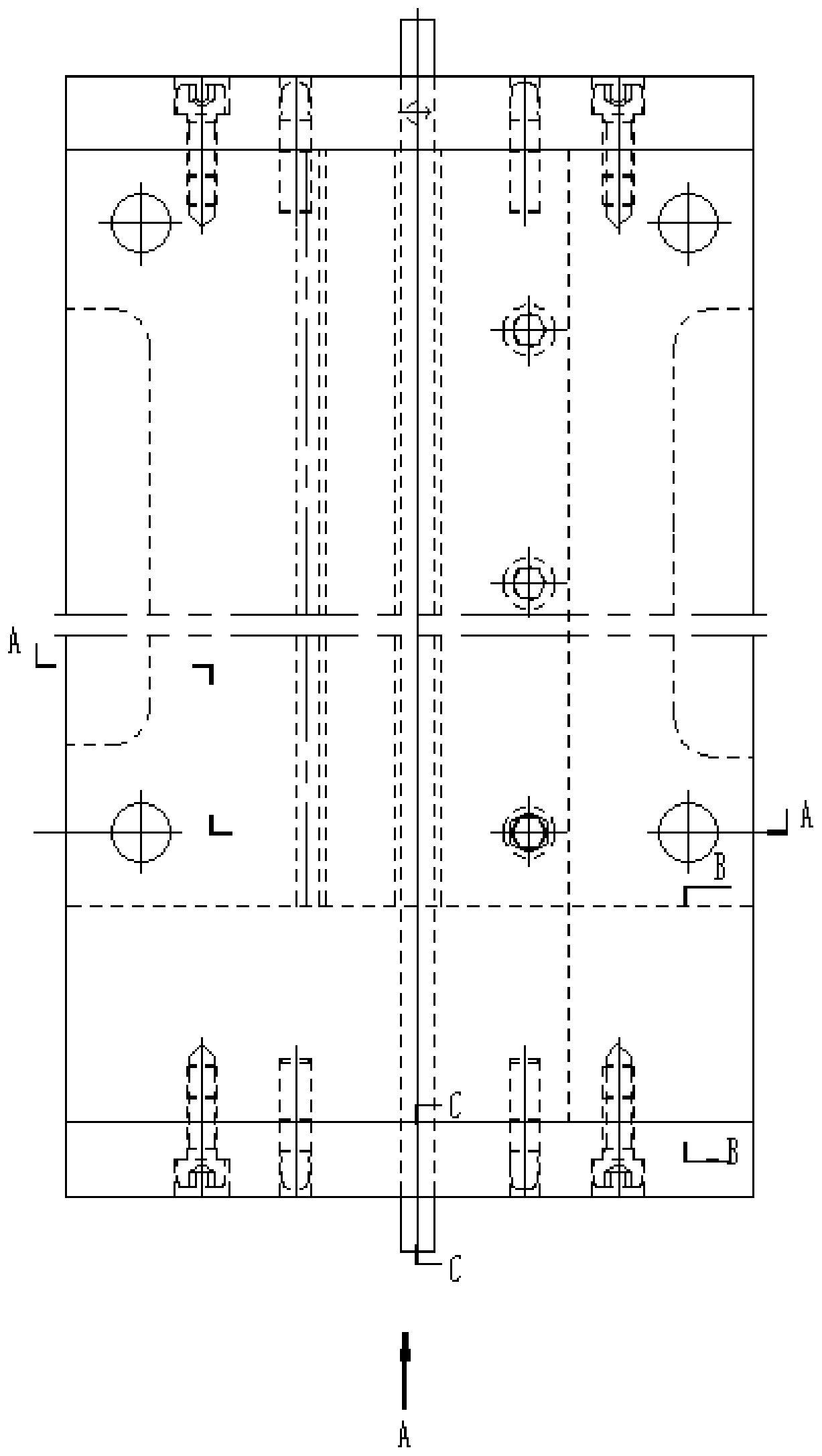

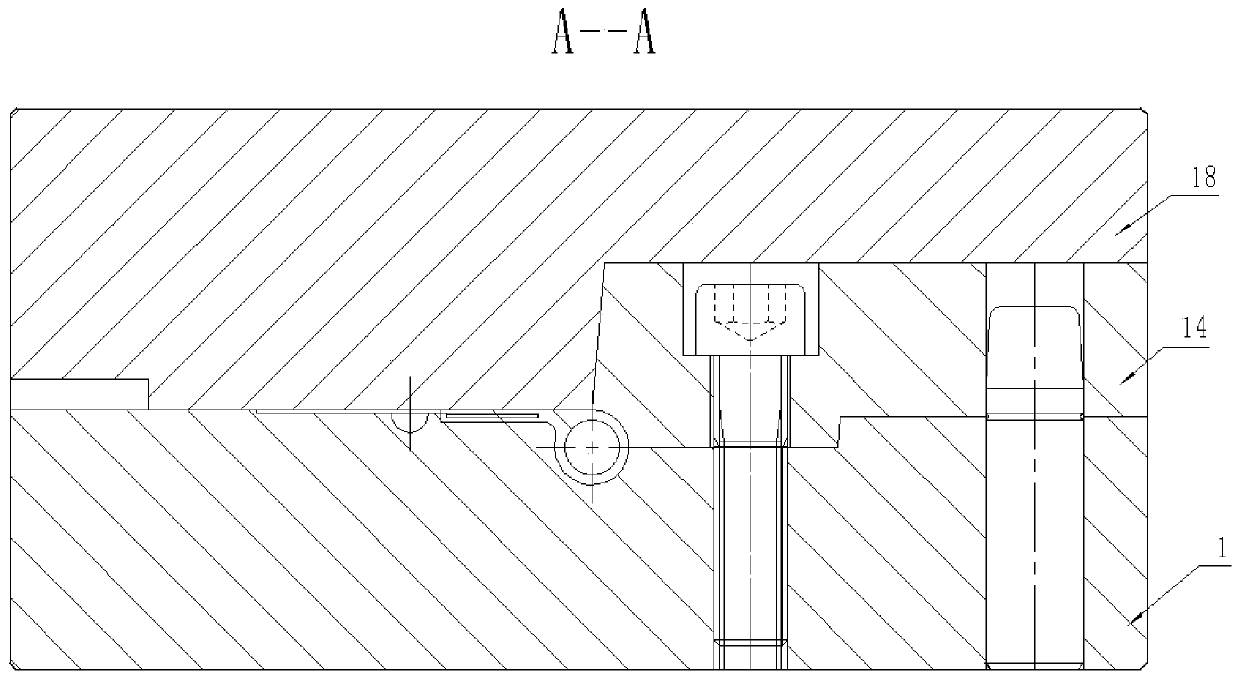

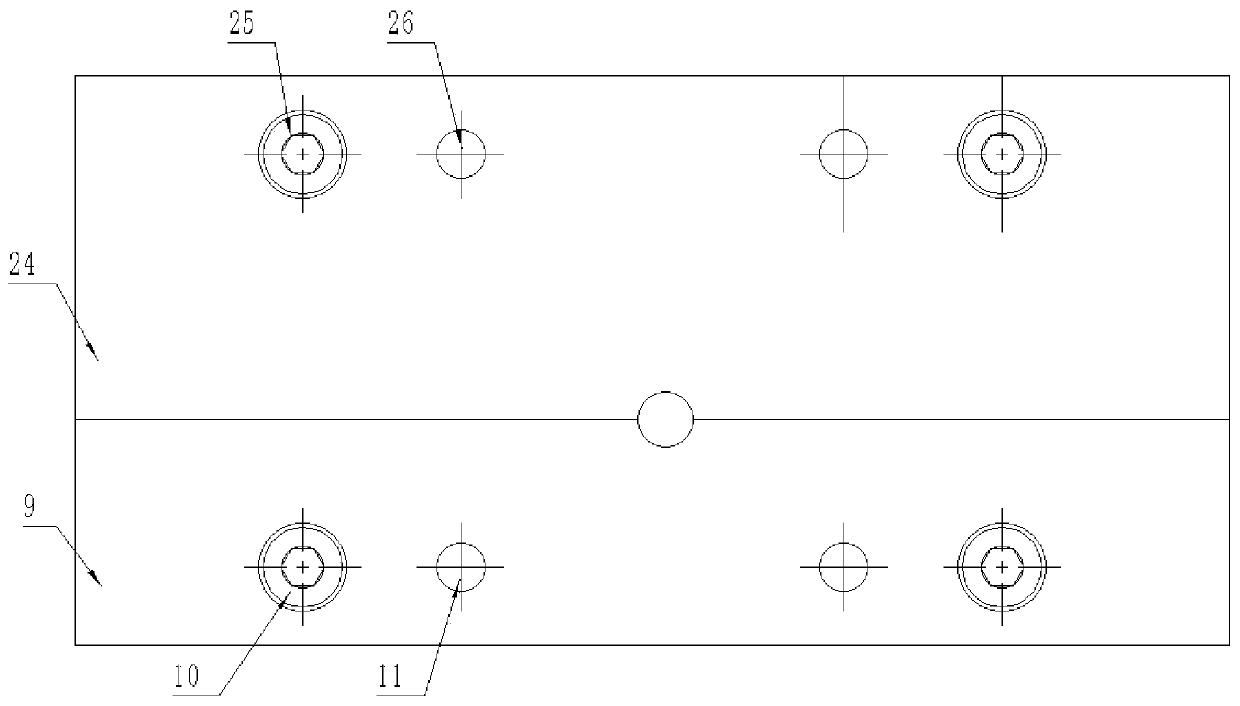

[0050] see Figure 1 to Figure 20 , a mold with a hollow fabric seal, comprising a lower mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com