Preparation process of polypropylene physical foaming composite board

A physical foaming and preparation technology, applied in the field of polypropylene foaming, can solve the problems of low preparation efficiency, uneven mixing of molten liquid and supercritical CO2, low efficiency of composite boards, etc., and achieve the effect of enhancing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

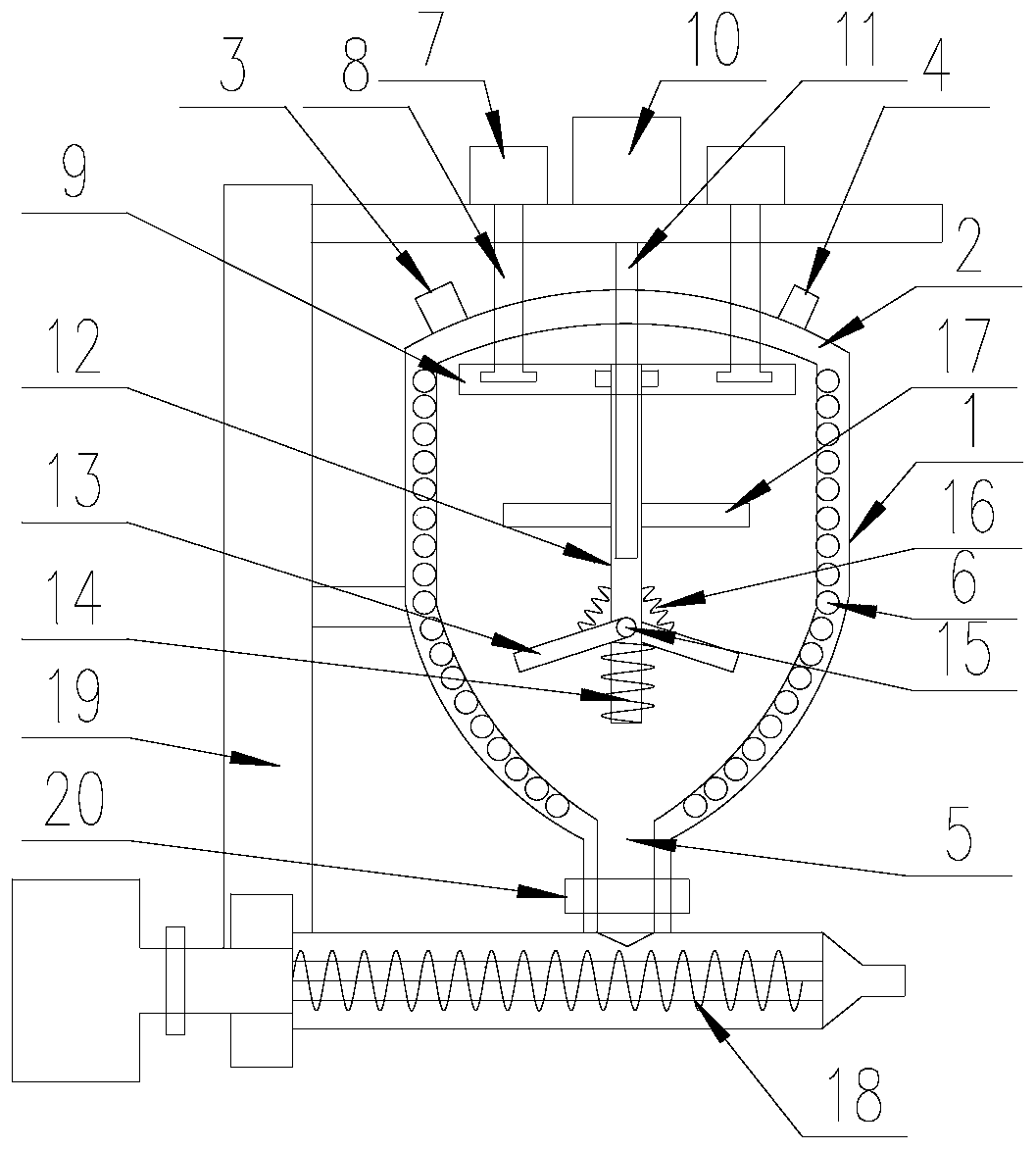

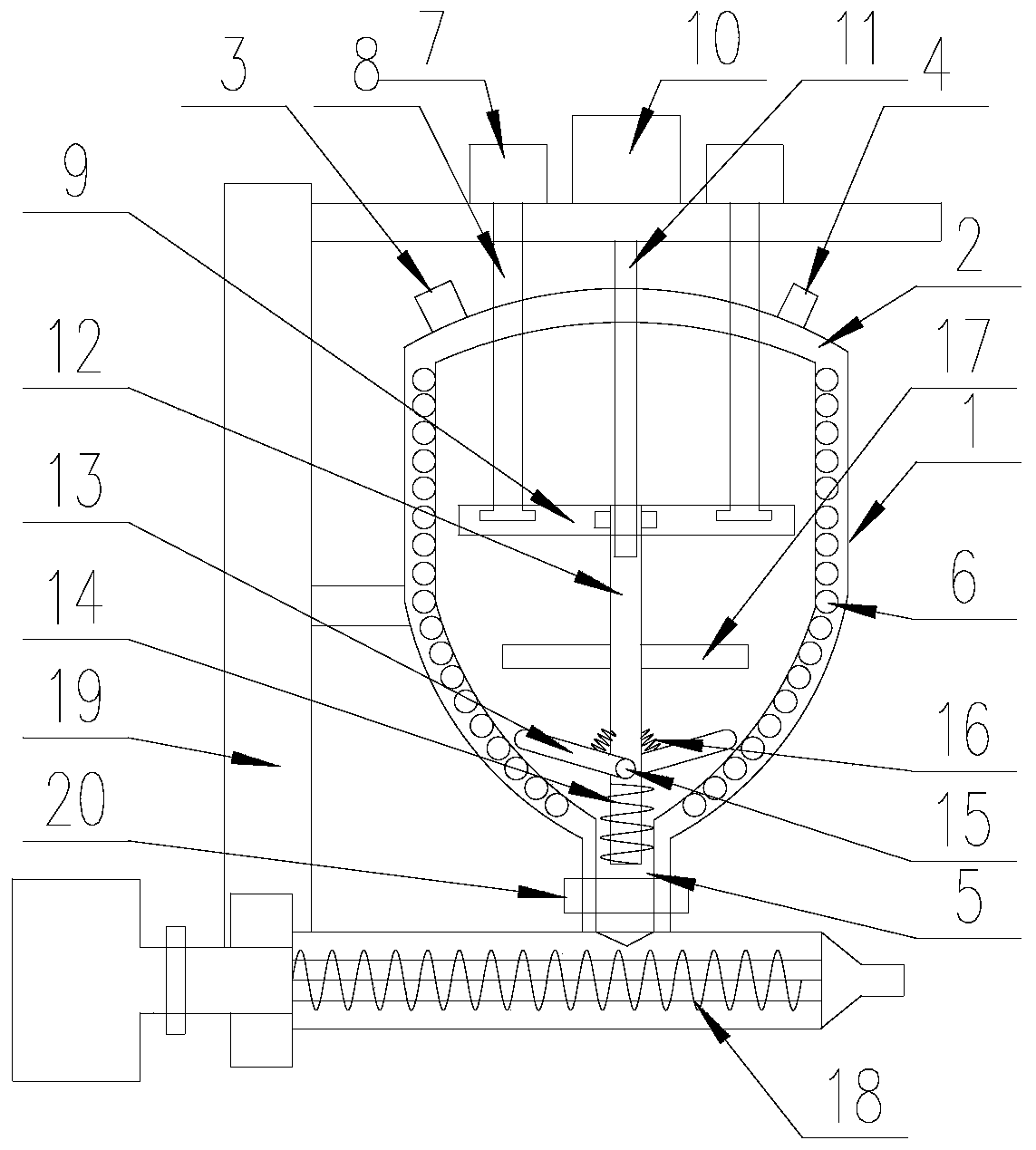

[0041] Such as Figure 1-Figure 3 As shown, the preparation process of polypropylene physical foam composite board includes the following steps:

[0042] Step 1: Add polypropylene granules to the reactor through feed port 3;

[0043] Step 2: feed supercritical CO2 into the reactor through vent 4;

[0044] Step 3: stirring to form a saturated molten liquid;

[0045] Step 4: Open the discharge valve 20, open the cylinder 7 to push the push plate 9 to move downward and inject the saturated molten liquid into the extrusion device 18, and at the same time, the screw 14 under the stirring shaft enters the discharge under the drive of the push plate 9 port 5 and screw extrude the saturated molten liquid at the discharge port 5.

[0046] The semi-continuous extrusion of polypropylene is realized by using the reaction kettle and the extrusion device 18, which not only realizes the sufficient mixing of polypropylene and supercritical CO2 to form a polypropylene-CO2 saturated system, bu...

Embodiment 2

[0055] The difference between this embodiment and Embodiment 1 is that an upper roll and a lower roll are arranged at the die outlet of the extrusion device 18, and the upper roll and the lower roll are coated with decorative surface materials, and the polypropylene foam board comes out of the mold Finally, use the waste heat to directly coat the decorative surface. Because the compatibilizer is added to the polypropylene, the composite of the polypropylene foam board and the decorative surface can be realized without glue, which is highly efficient, non-toxic and safe.

Embodiment 3

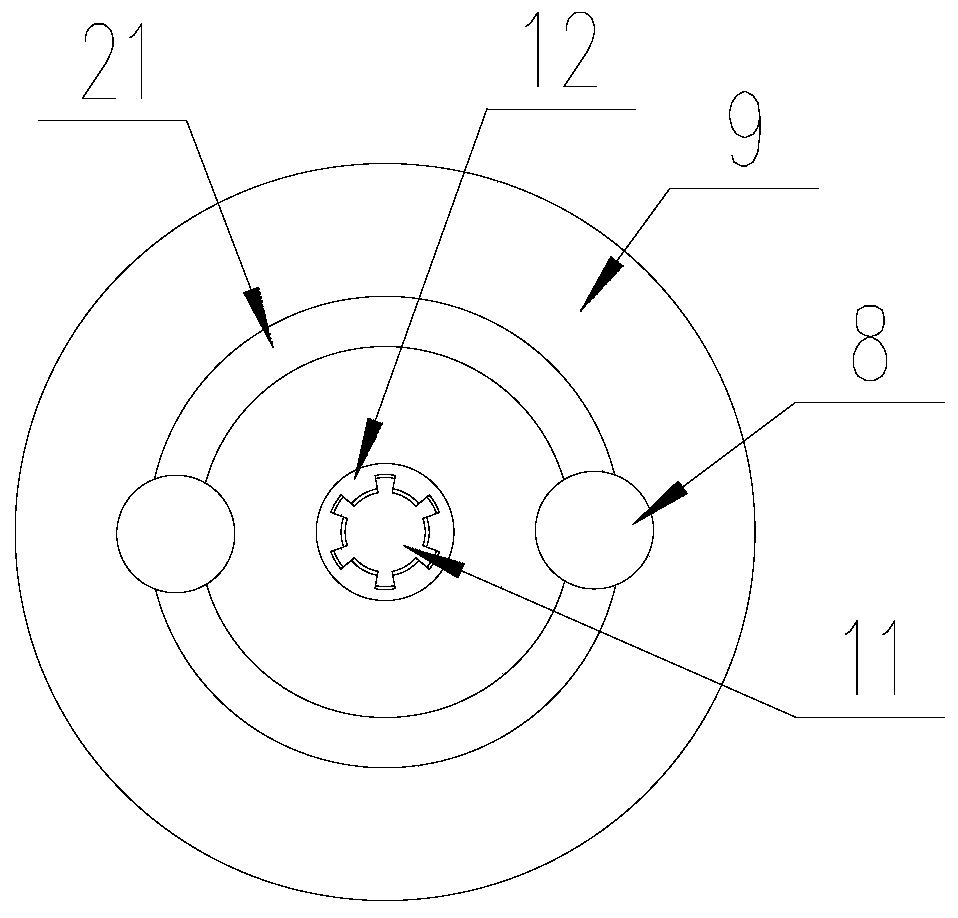

[0057] In the preparation process of polypropylene physical foam composite board, the reaction kettle includes a kettle body 1, a cover body 2, a stirring device, a feed port 3, a vent port 4 and a discharge port 5, and the cover body 2 is provided with The feeding port 3 and the ventilation port 4, the bottom of the kettle body 1 is provided with a discharge port 5, the discharge port 5 is provided with a discharge valve 20, and the interlayer of the kettle body 1 is provided with a heating element 6, The inside of the kettle body 1 is provided with a push plate 9, the diameter of the push plate 9 is smaller than the inner diameter of the kettle body 1, and the push plate 9 is rotatably connected with the push rod 8 and passes through the cover body 2 and the cylinder 7 connected, the stirring device includes a stirring motor 10, a stirring shaft and a stirring paddle 13, the stirring shaft includes an inner shaft 11 and an outer shaft 12, the inner shaft 11 and the outer shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com